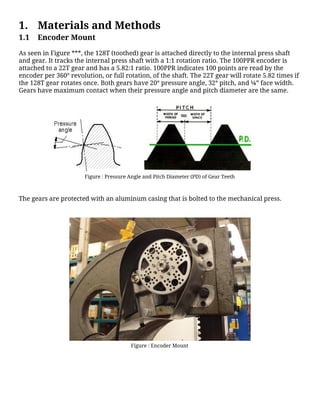

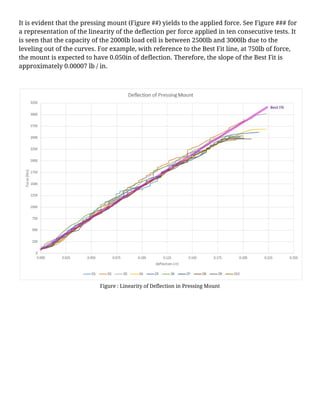

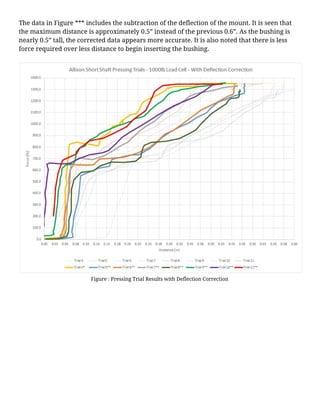

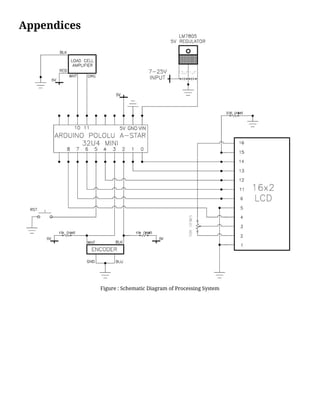

The document describes the design of a stress and strain measuring device for an automotive production company. The device measures the force and stroke distance required to insert bushings into shafts of varying sizes. Key components include an incremental encoder to track press movement, a load cell to measure applied force, and an Arduino microcontroller to process the data. Challenges included ensuring the device's measurements were repeatable under high loads for continuous production use. Testing showed the initial design could accurately measure up to 1350 pounds but deflected under higher loads. Modifications like adding supports and a 2000 pound load cell improved accuracy for the target 3000 pound loads.