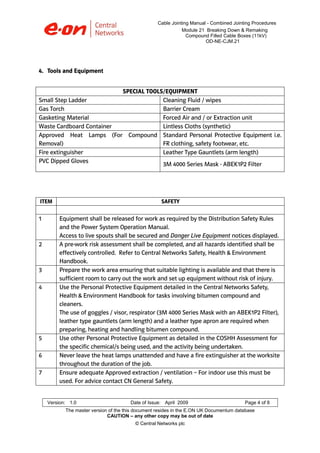

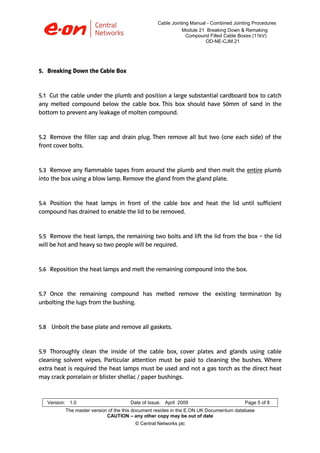

This document is a manual for breaking down and remaking compound filled cable boxes (11kV), outlining procedures, tools, and safety precautions. It emphasizes that this process should only be undertaken if replacing with a new air insulated box is not feasible, and provides detailed steps for dismantling, remaking with XLPE cables, and filling with Guroflex resin. Additionally, it includes information on the necessary safety equipment and the disposal of waste materials.