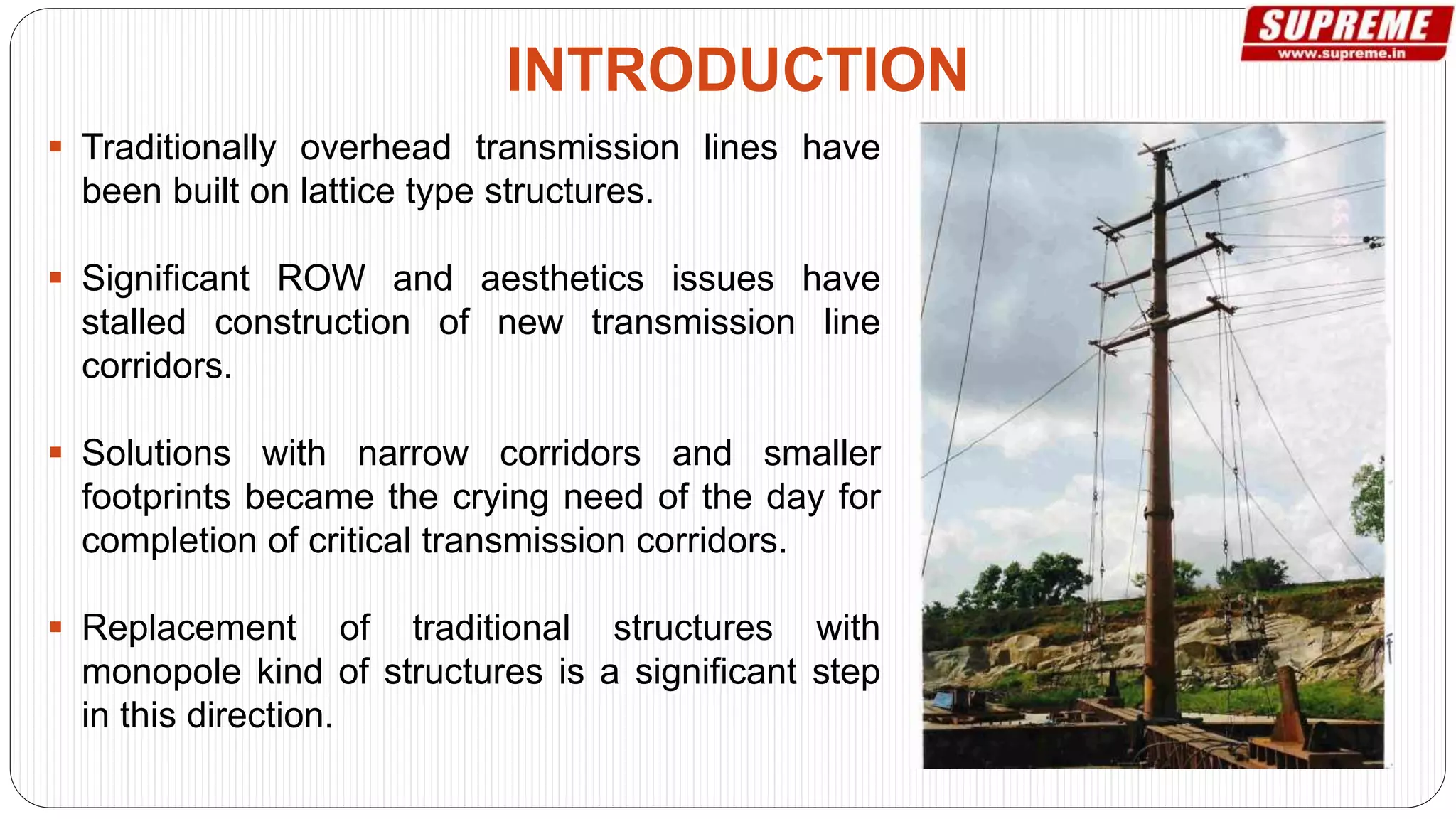

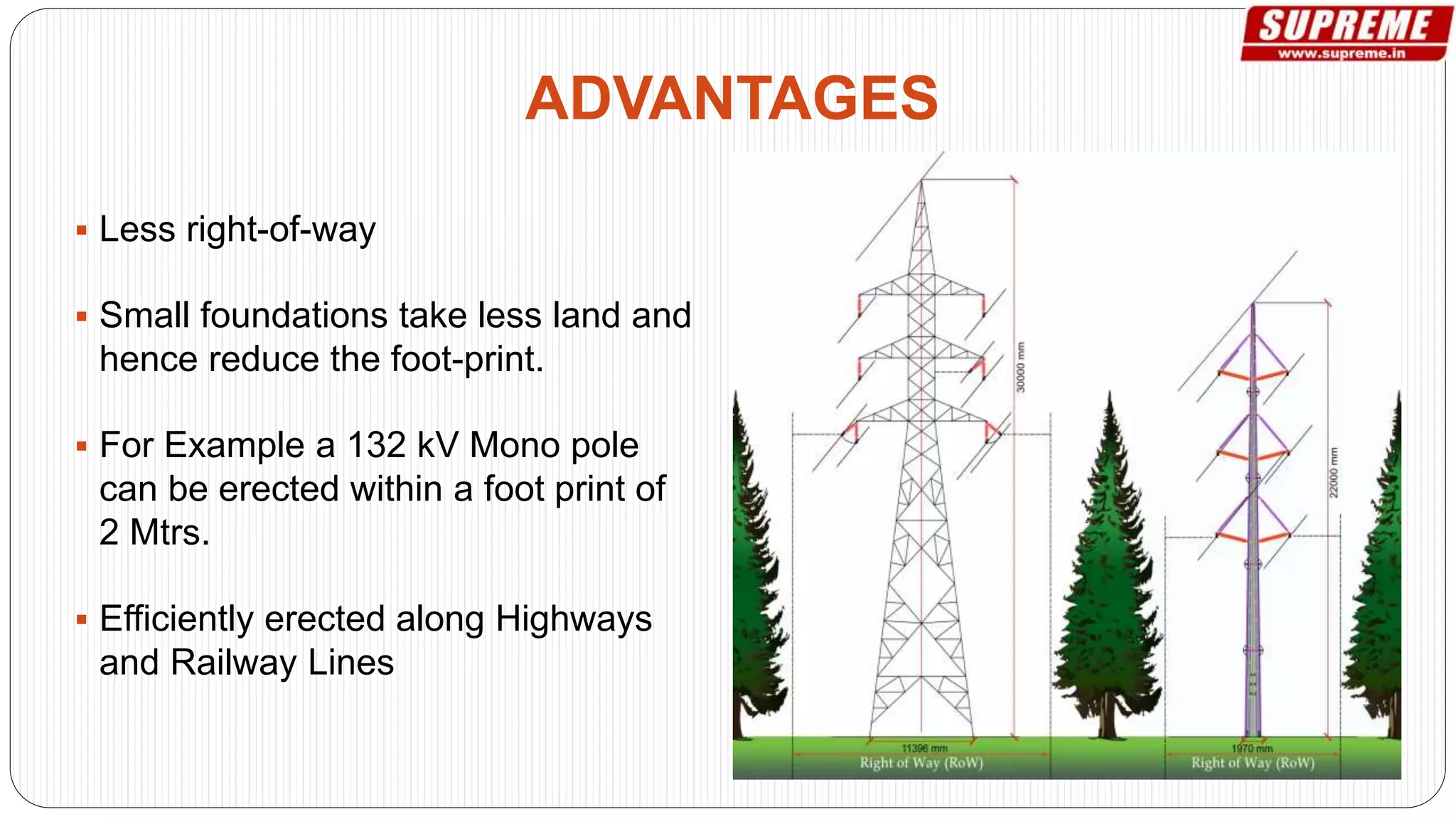

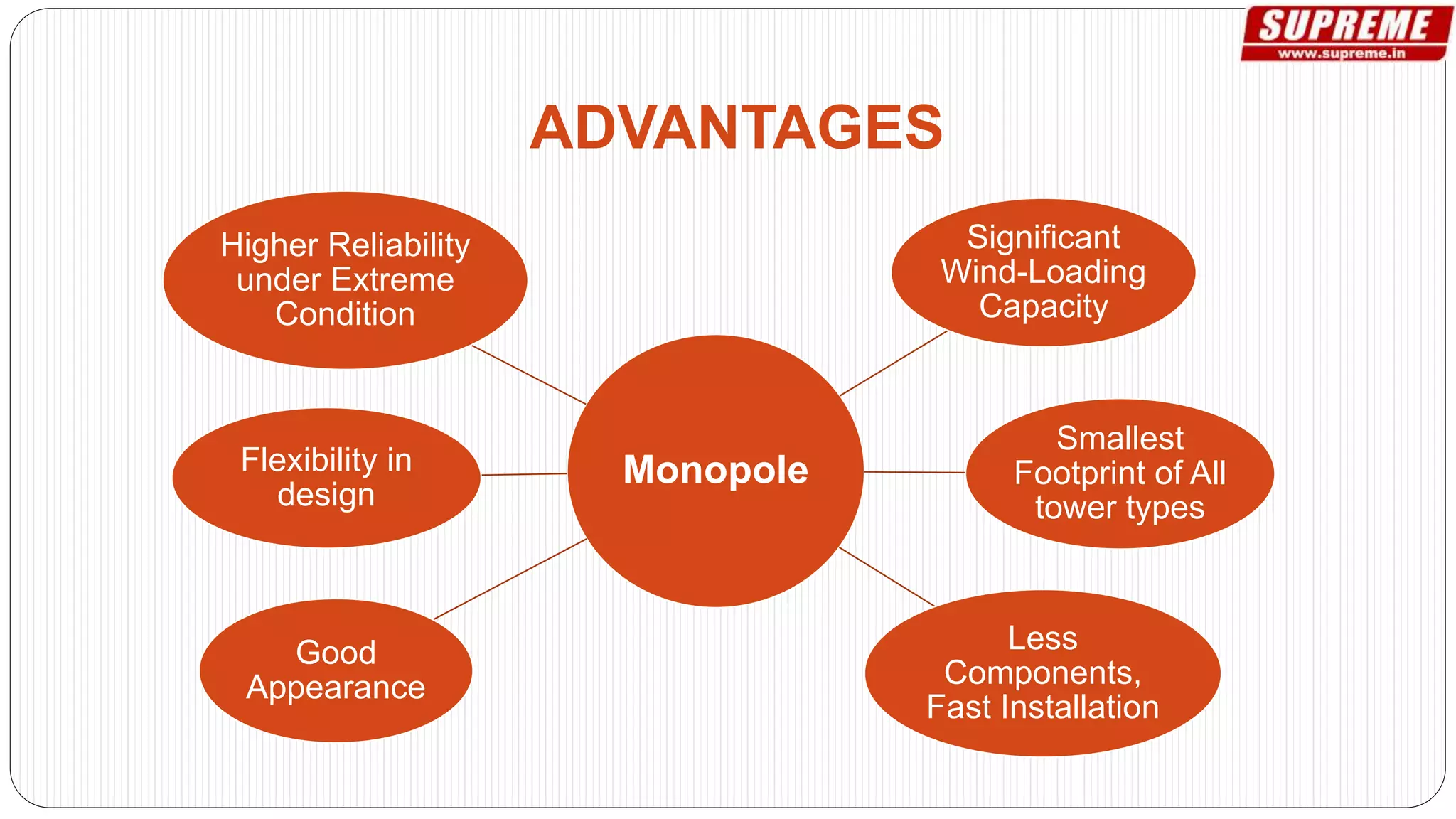

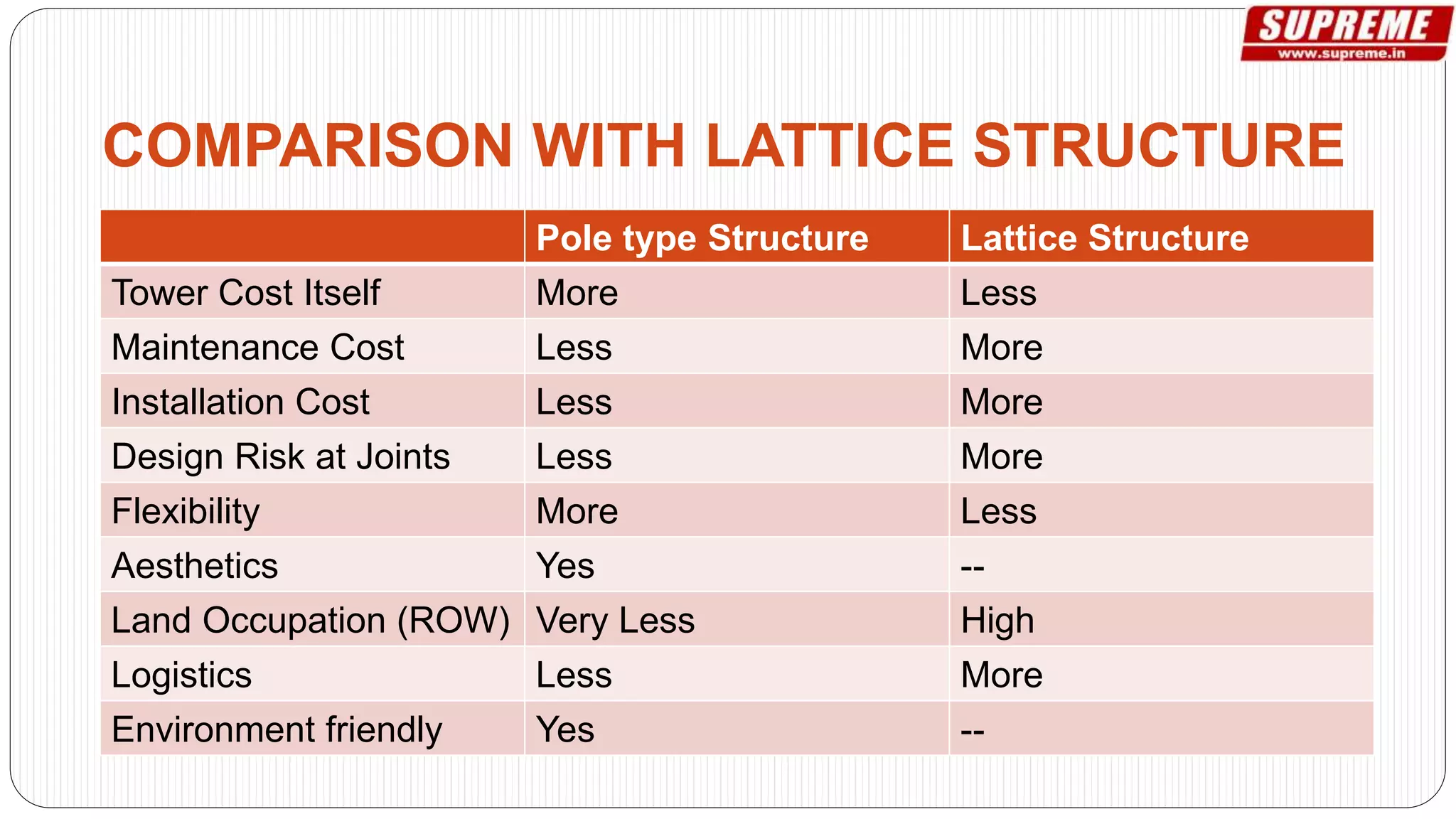

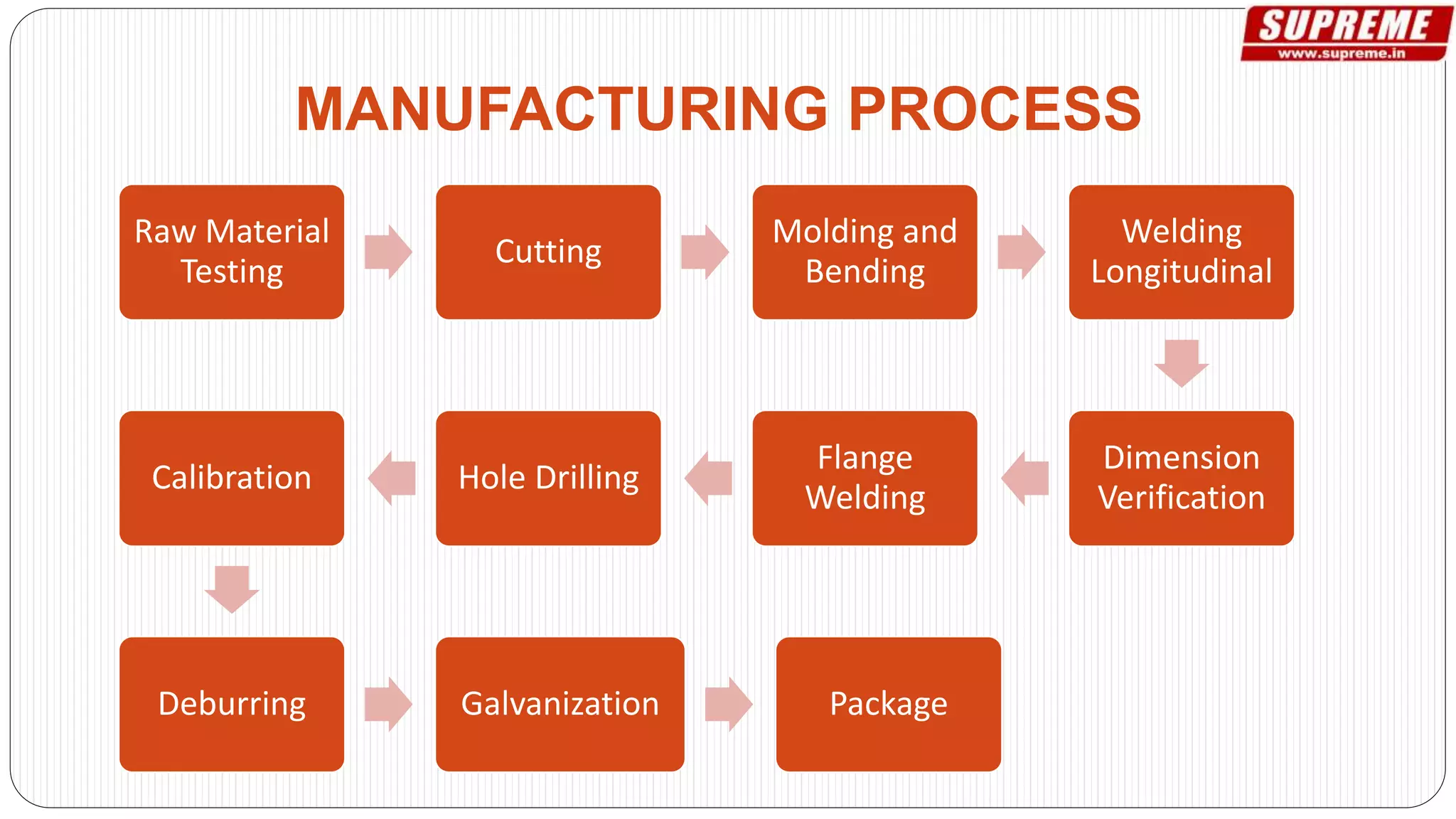

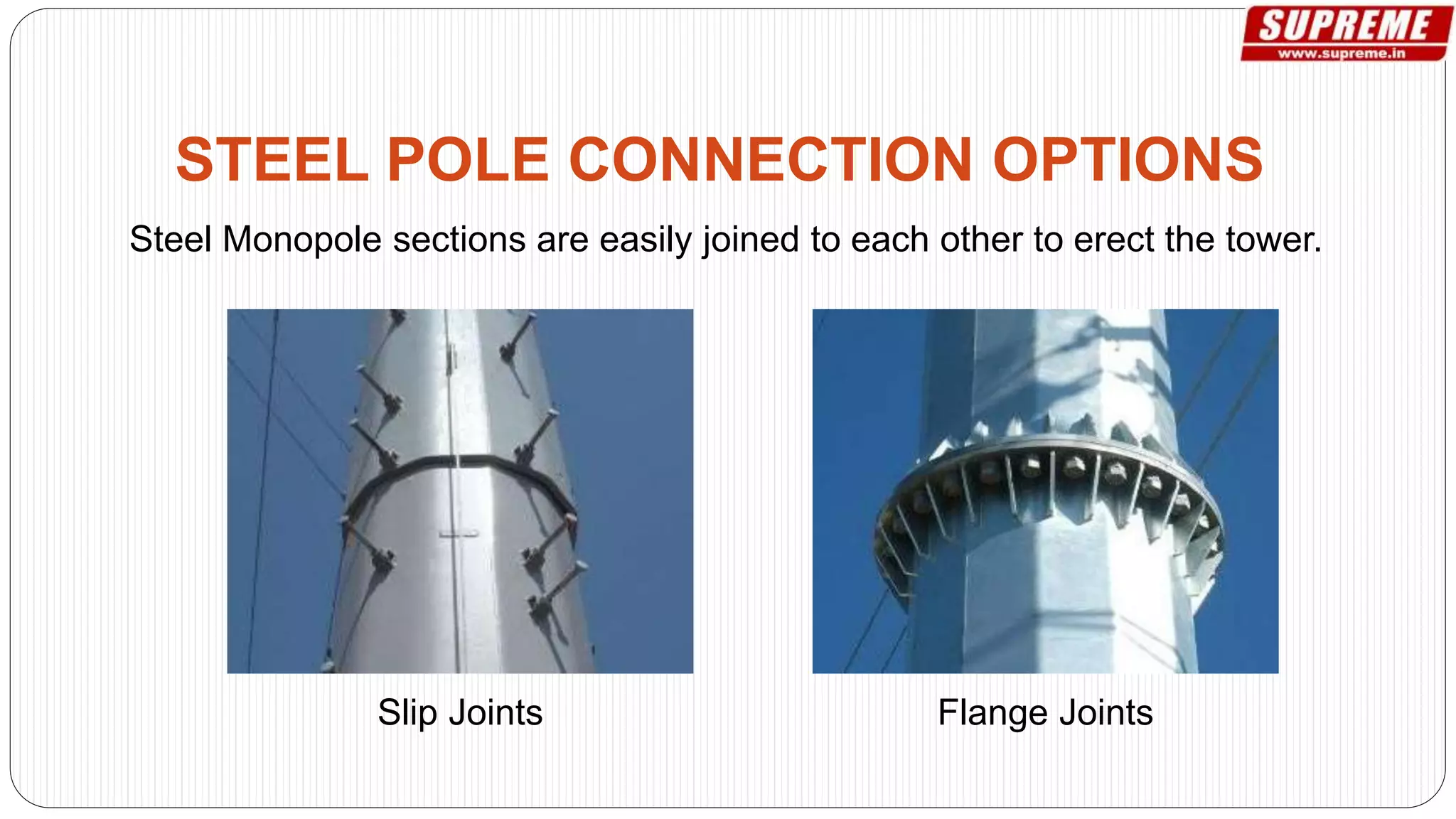

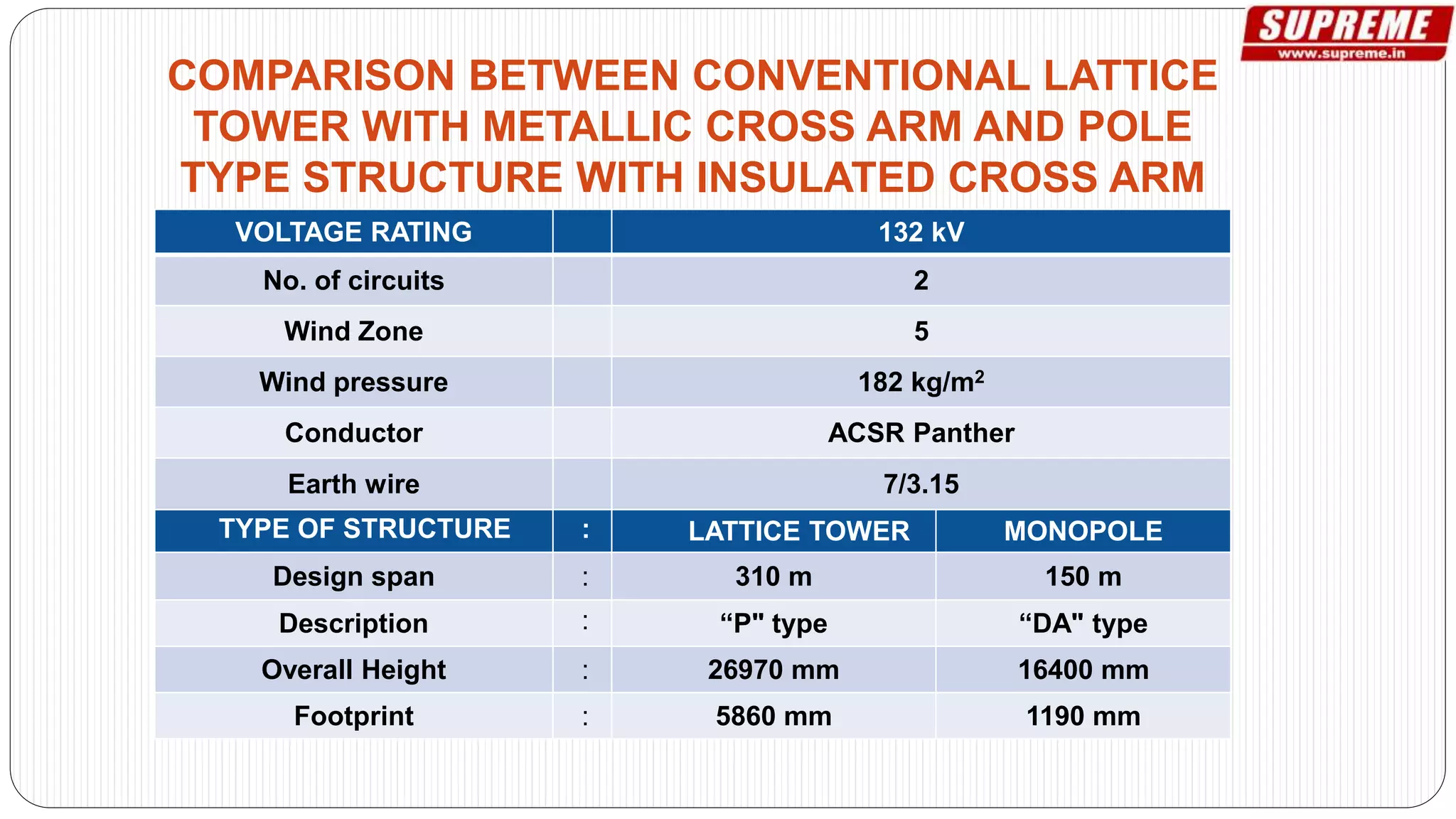

This document discusses the advantages of monopole structures over traditional lattice structures for overhead power transmission lines. Monopoles require less land area since they have smaller foundations. They also have lower installation and maintenance costs than lattice structures. Monopole structures are more flexible, reliable under extreme weather, and have a smaller visual impact. The document provides details on the design, manufacturing, testing and specifications of monopole structures and compares their performance to lattice structures.