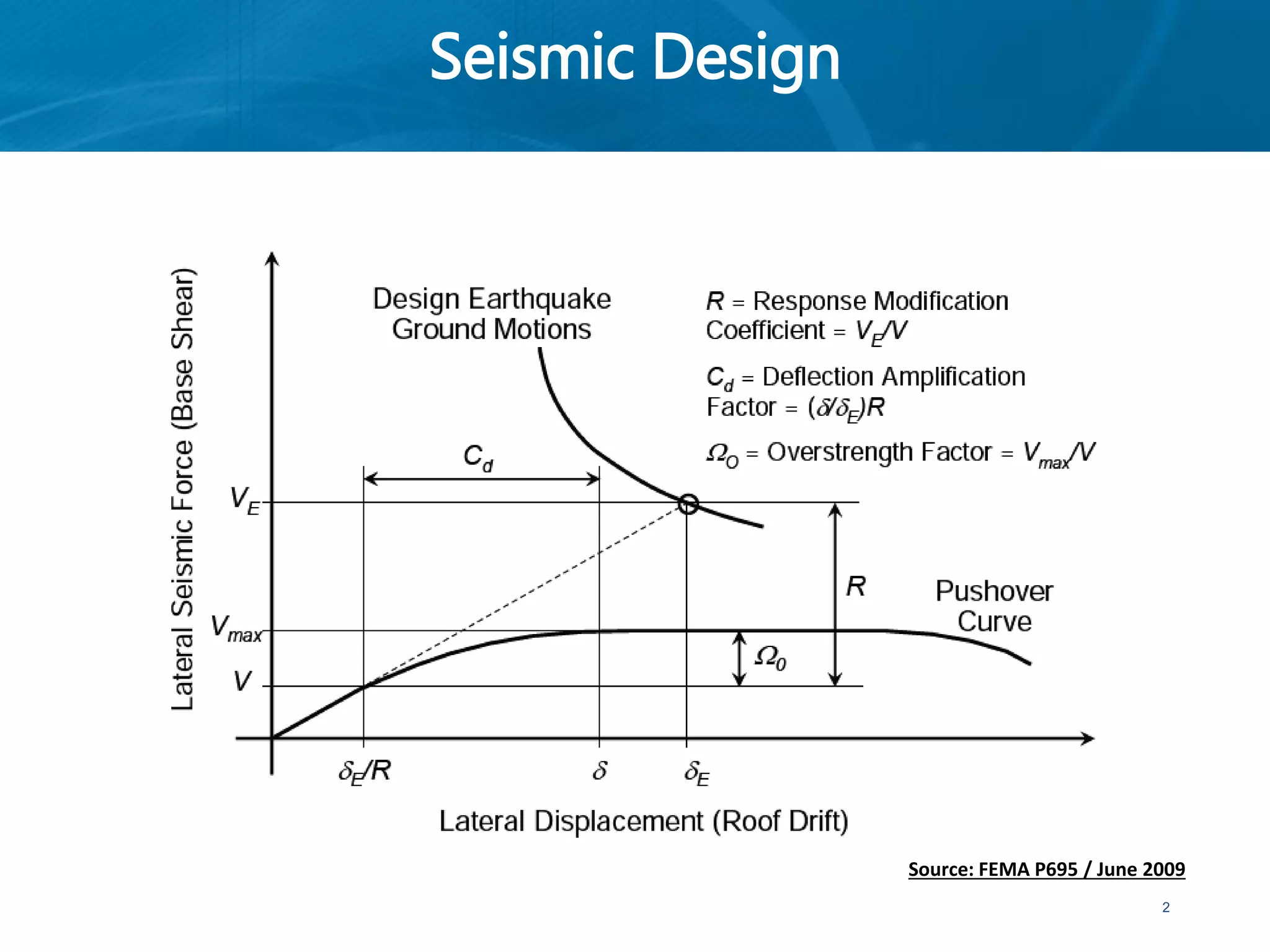

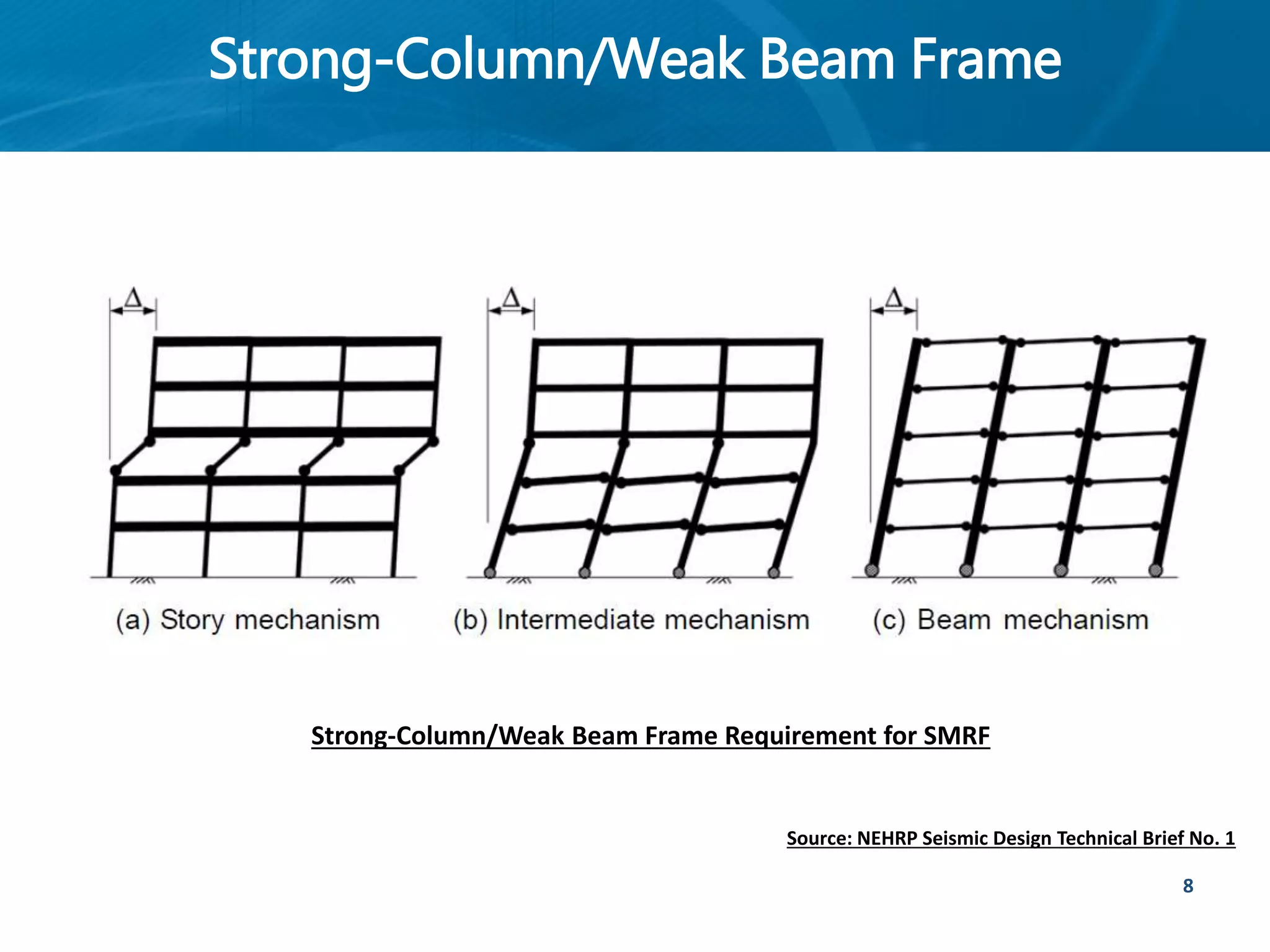

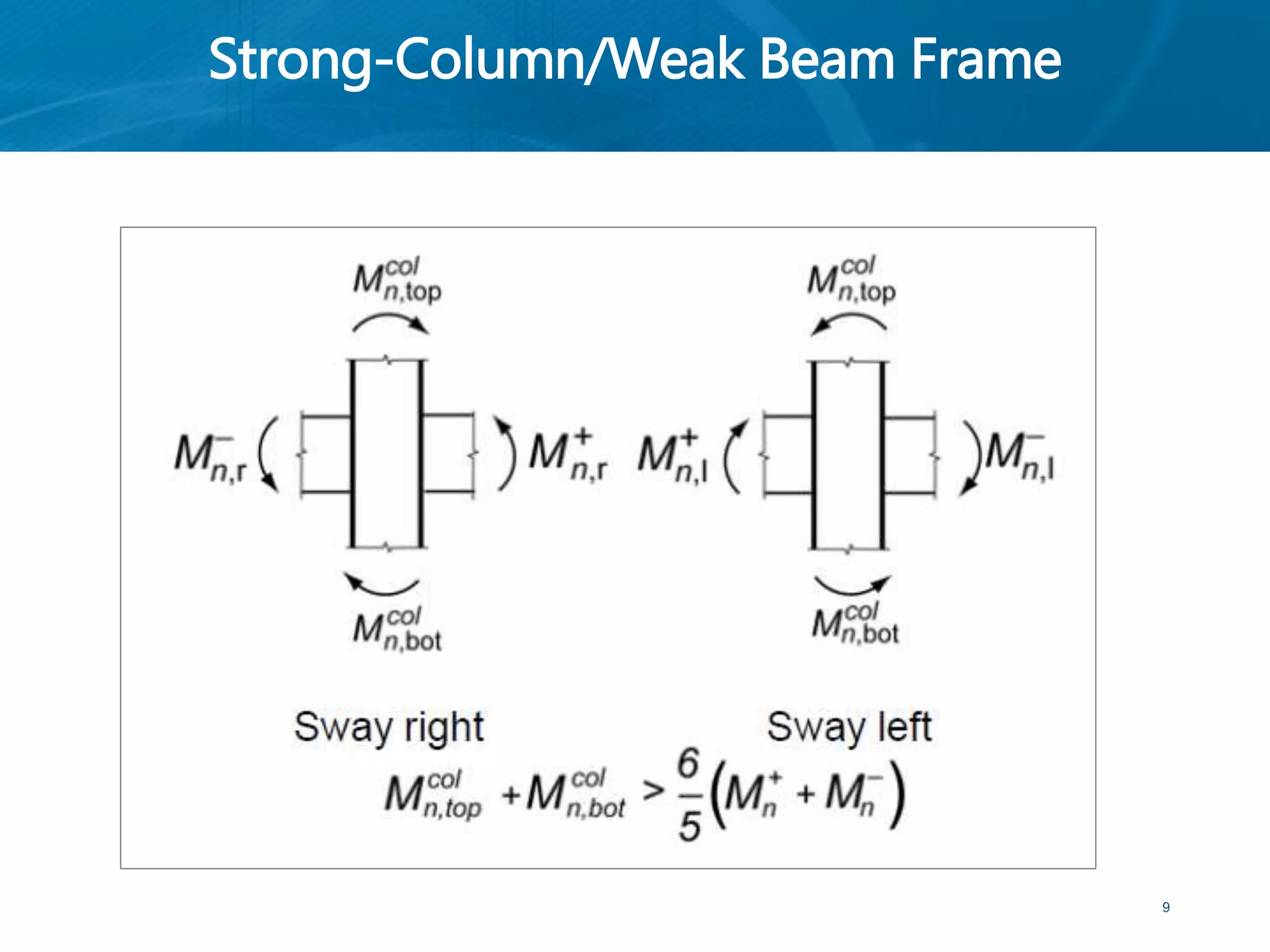

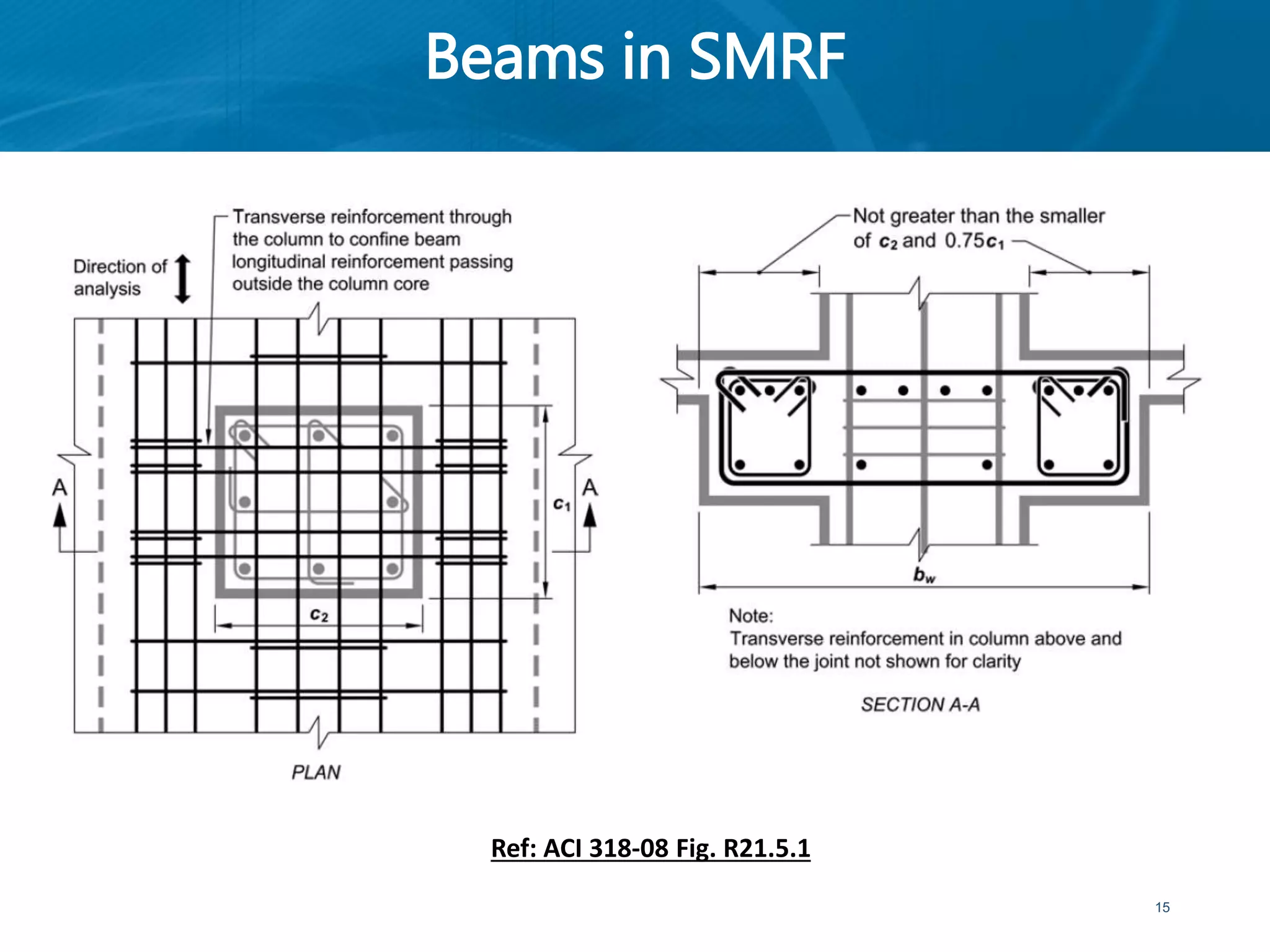

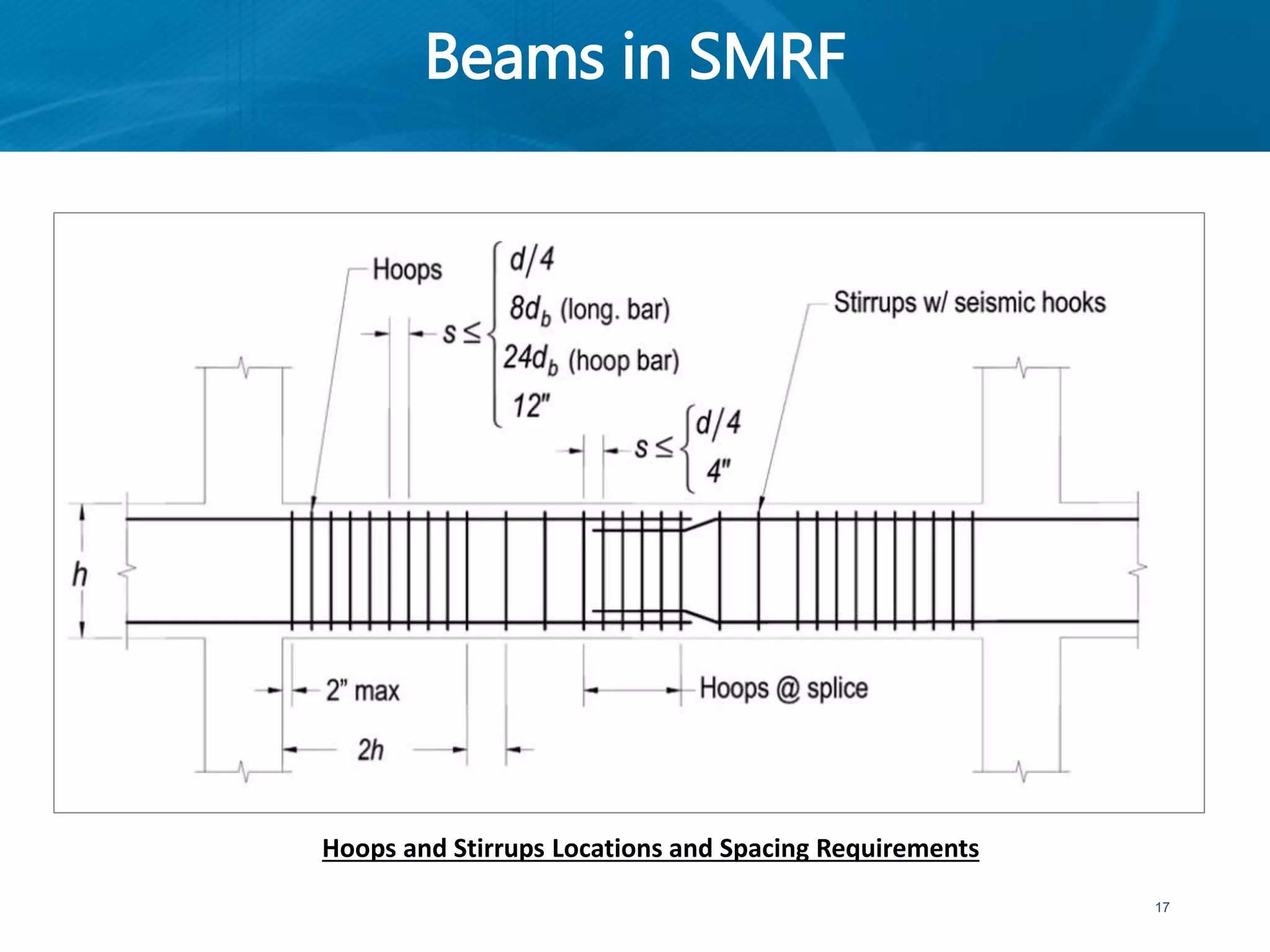

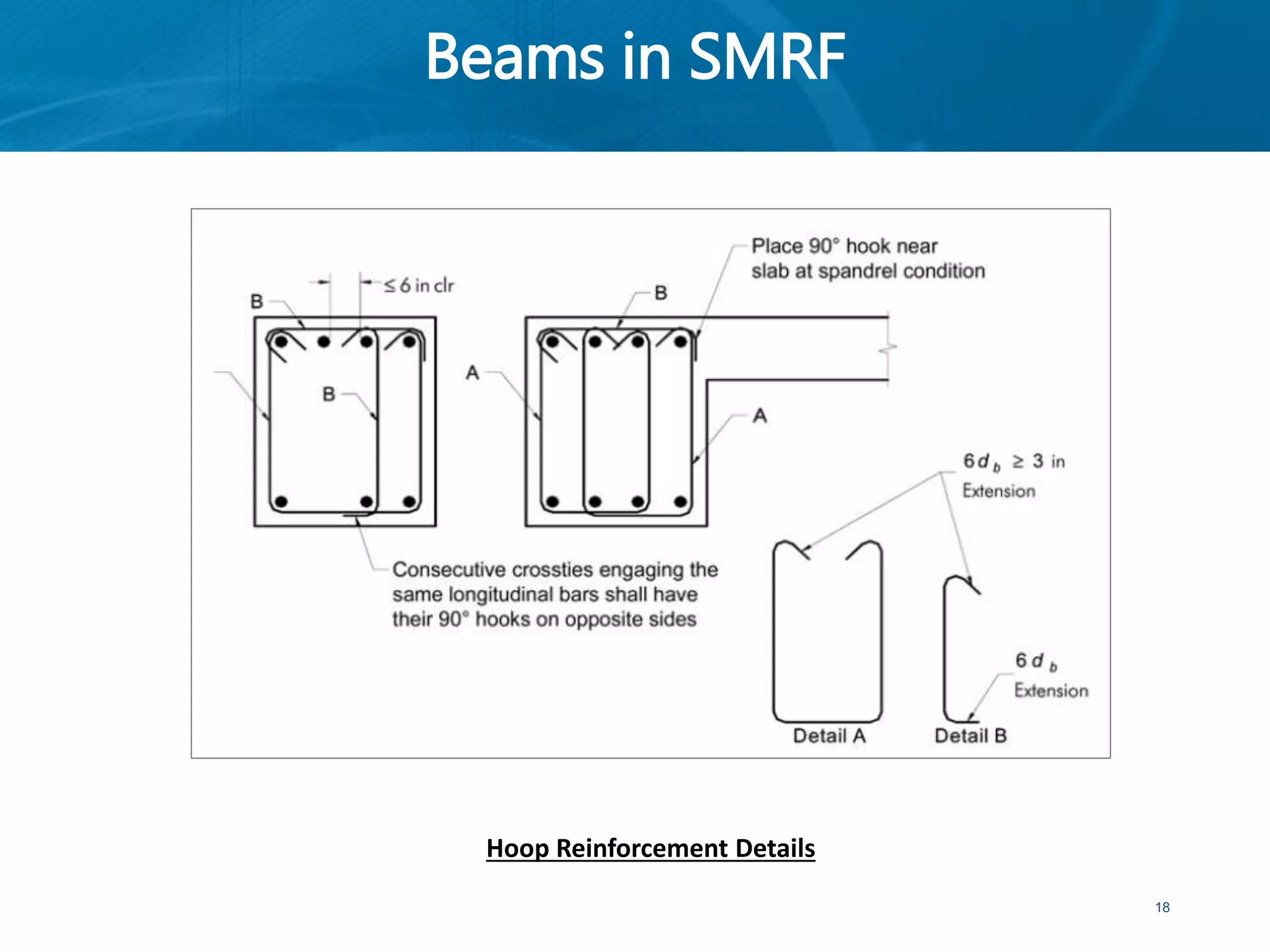

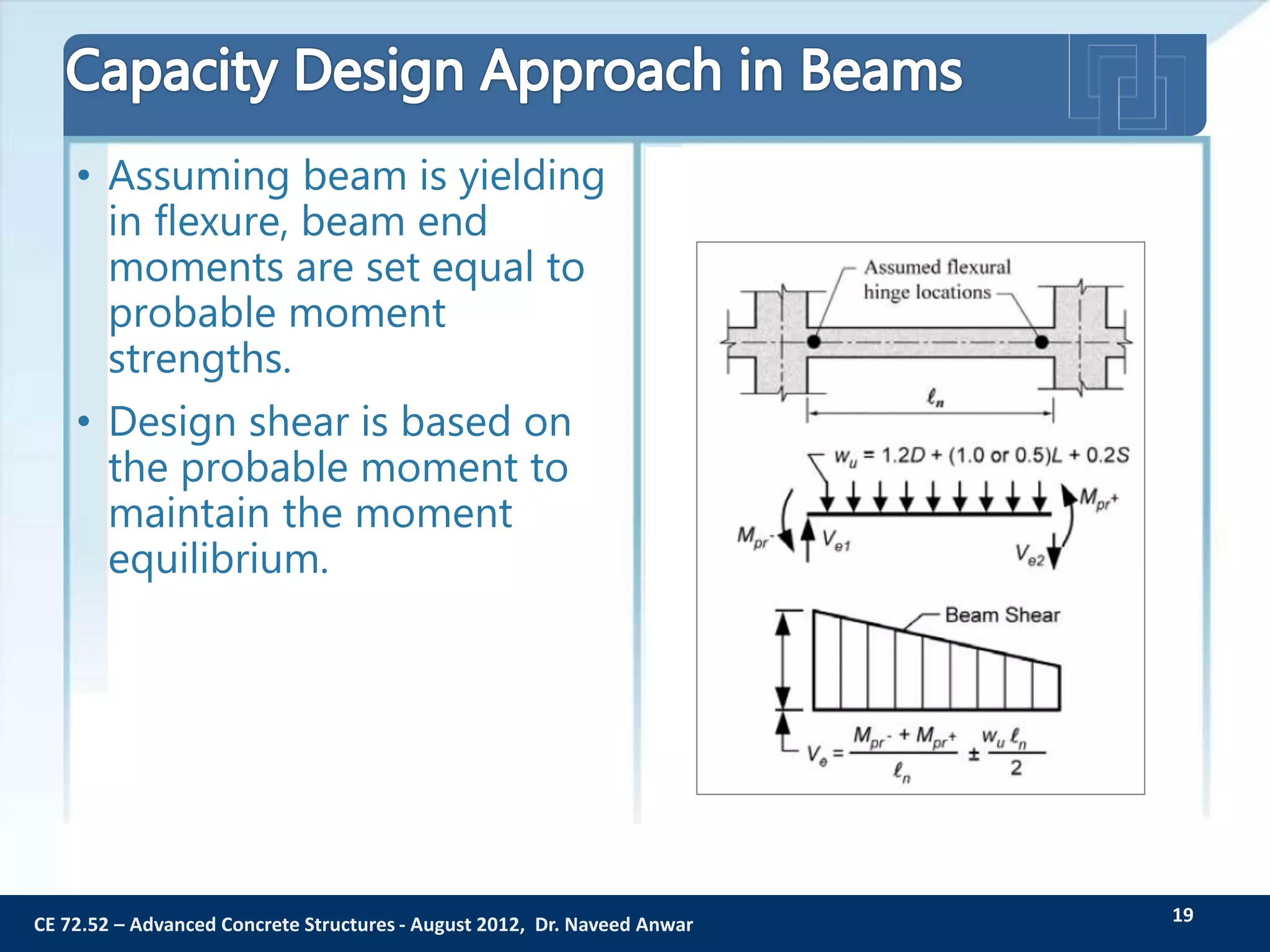

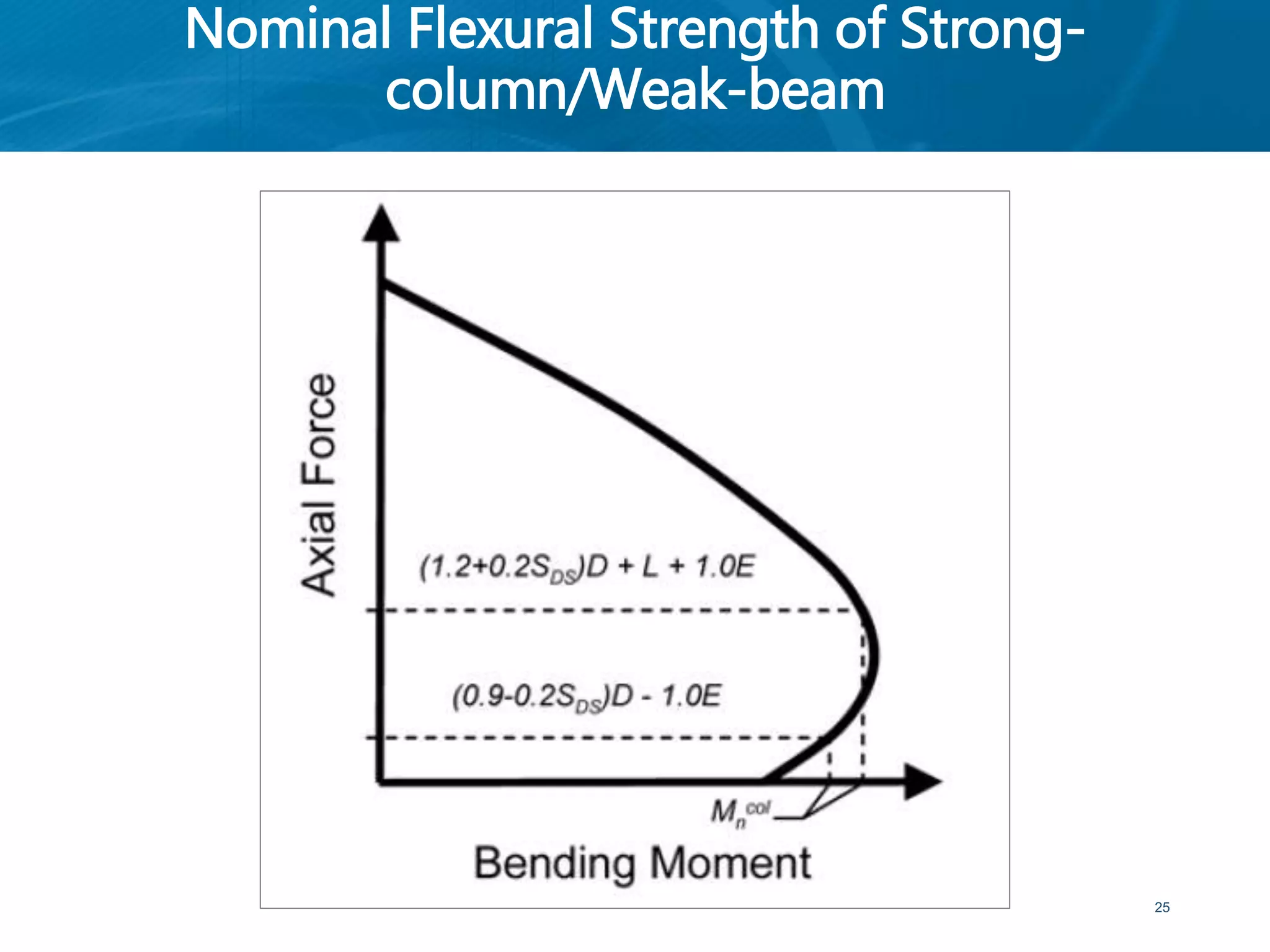

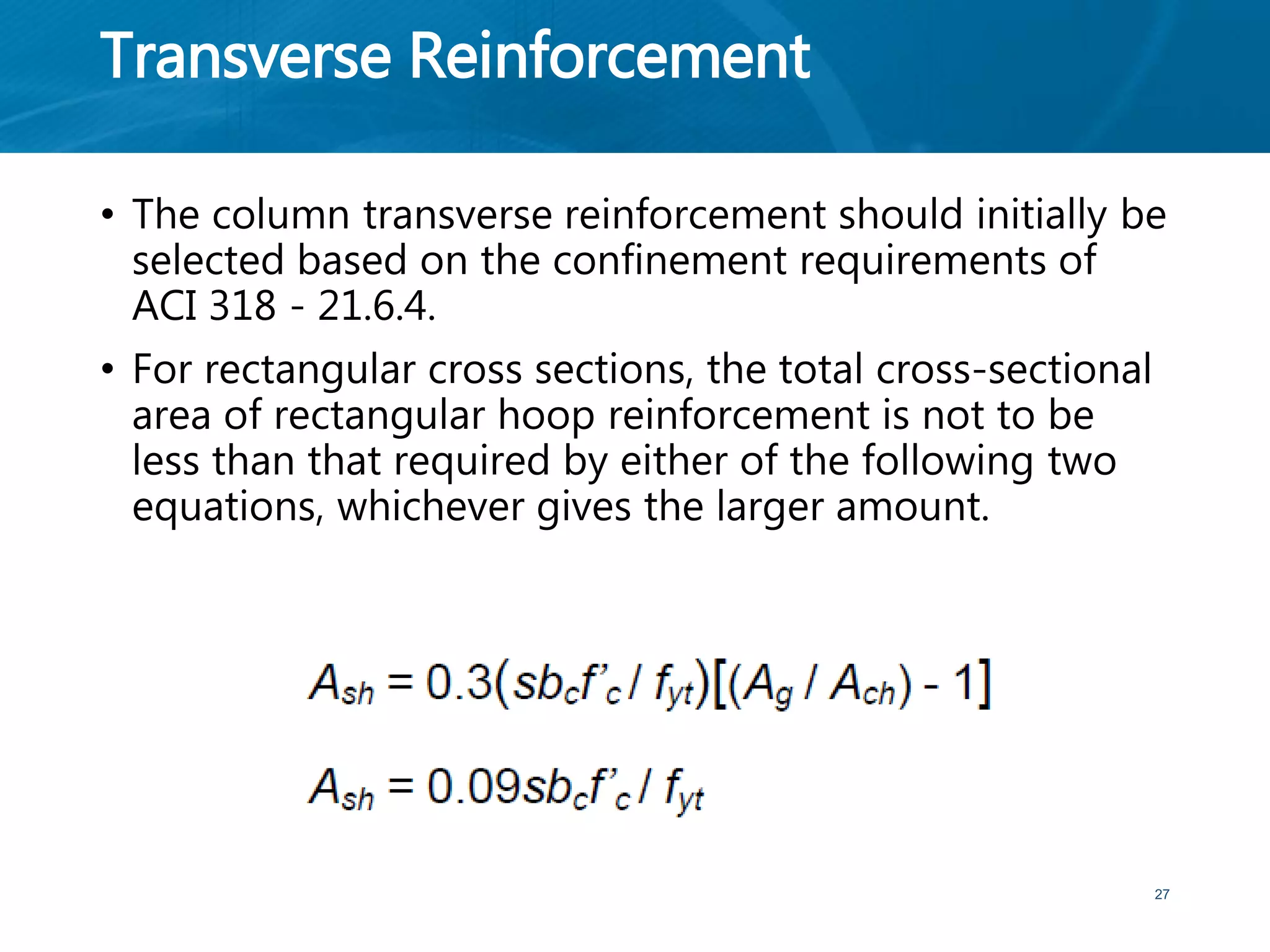

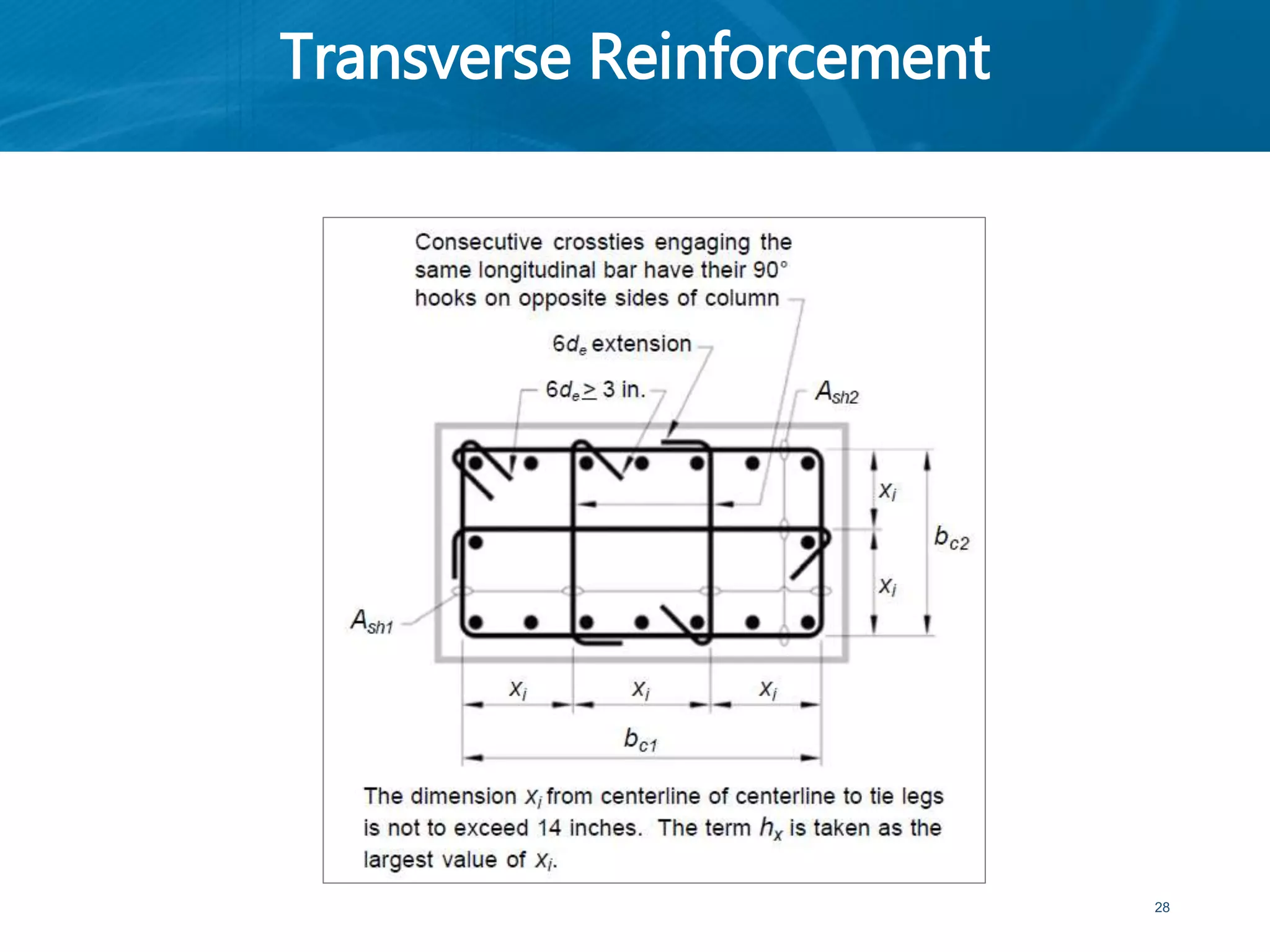

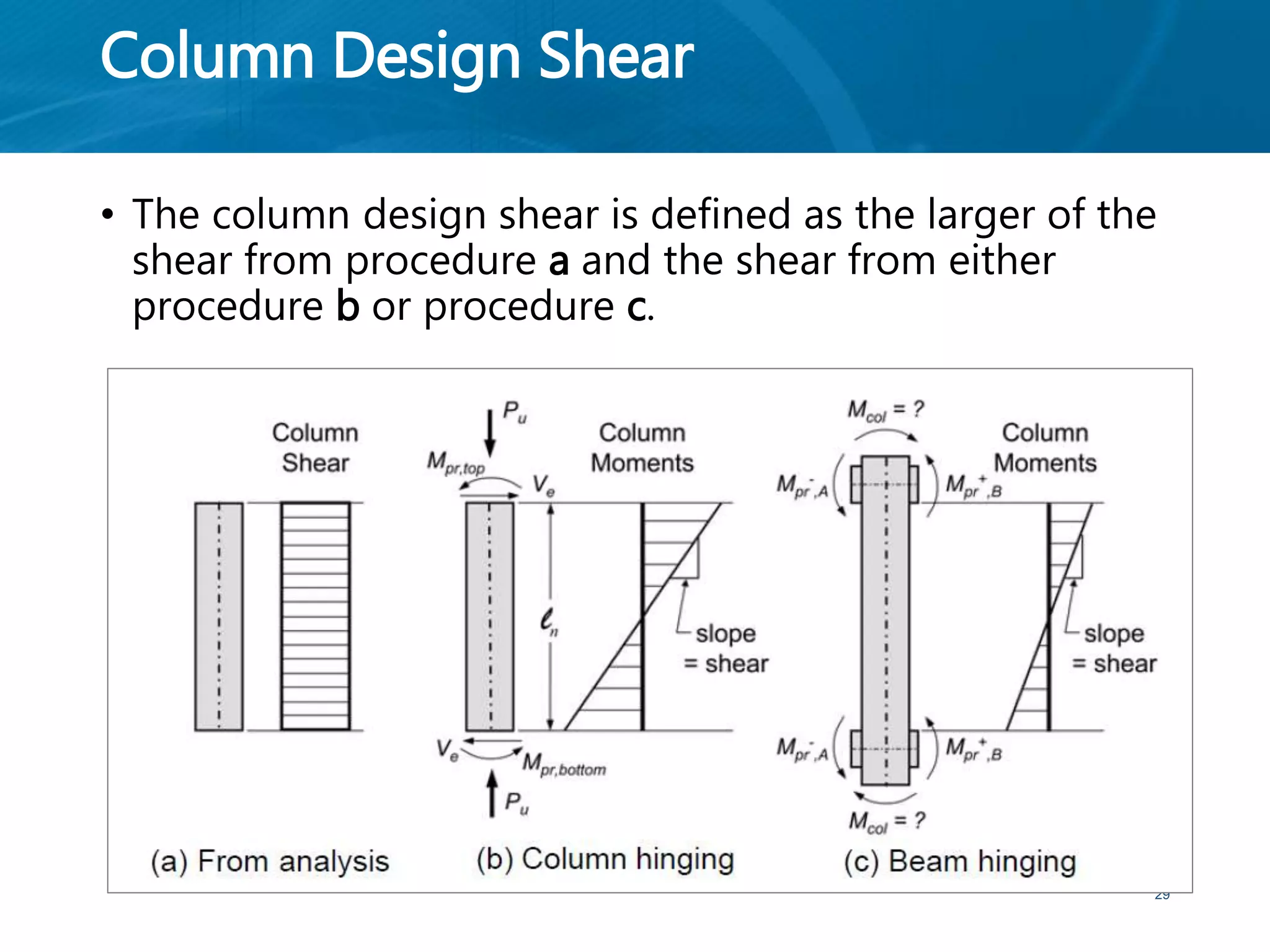

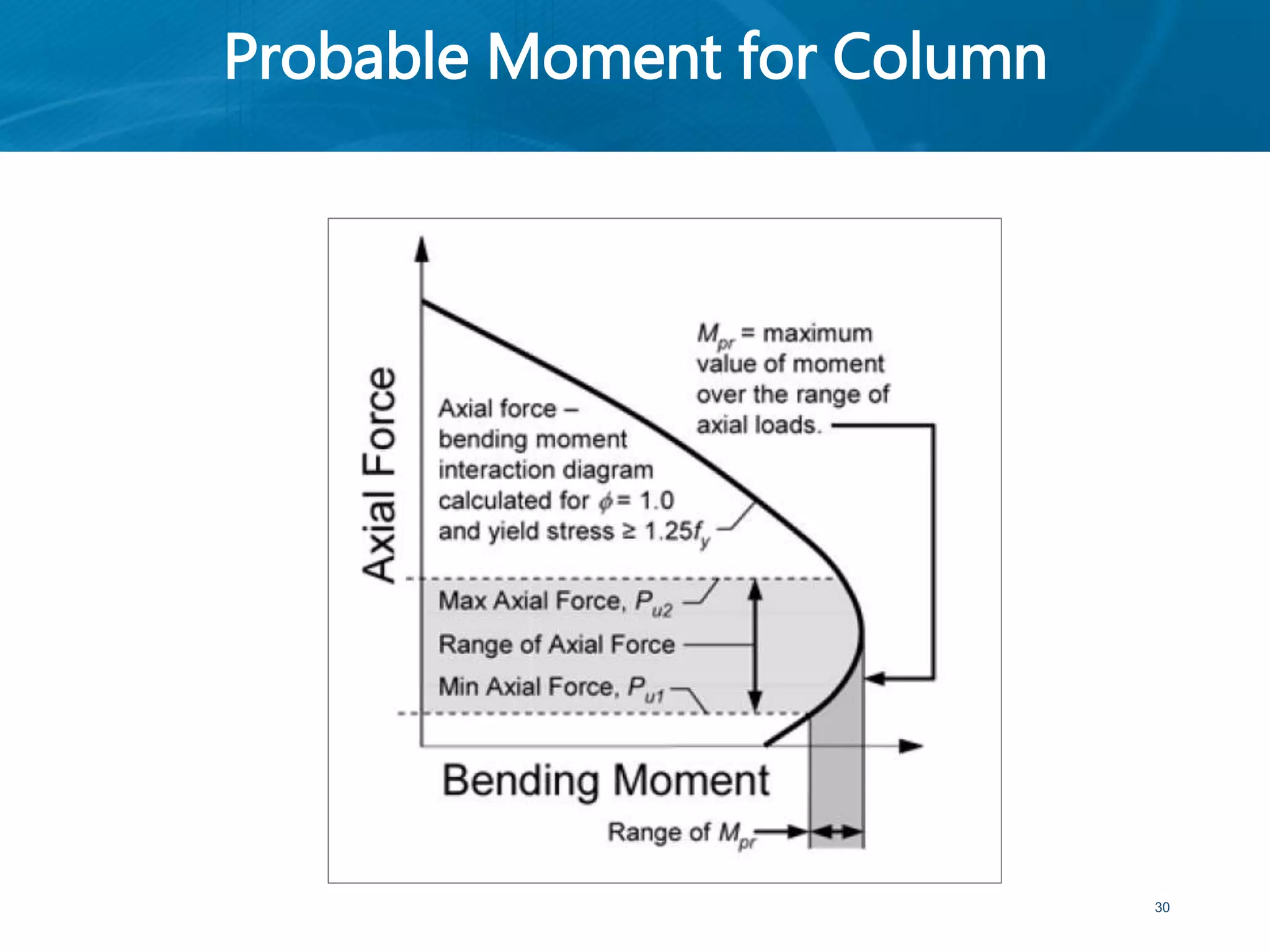

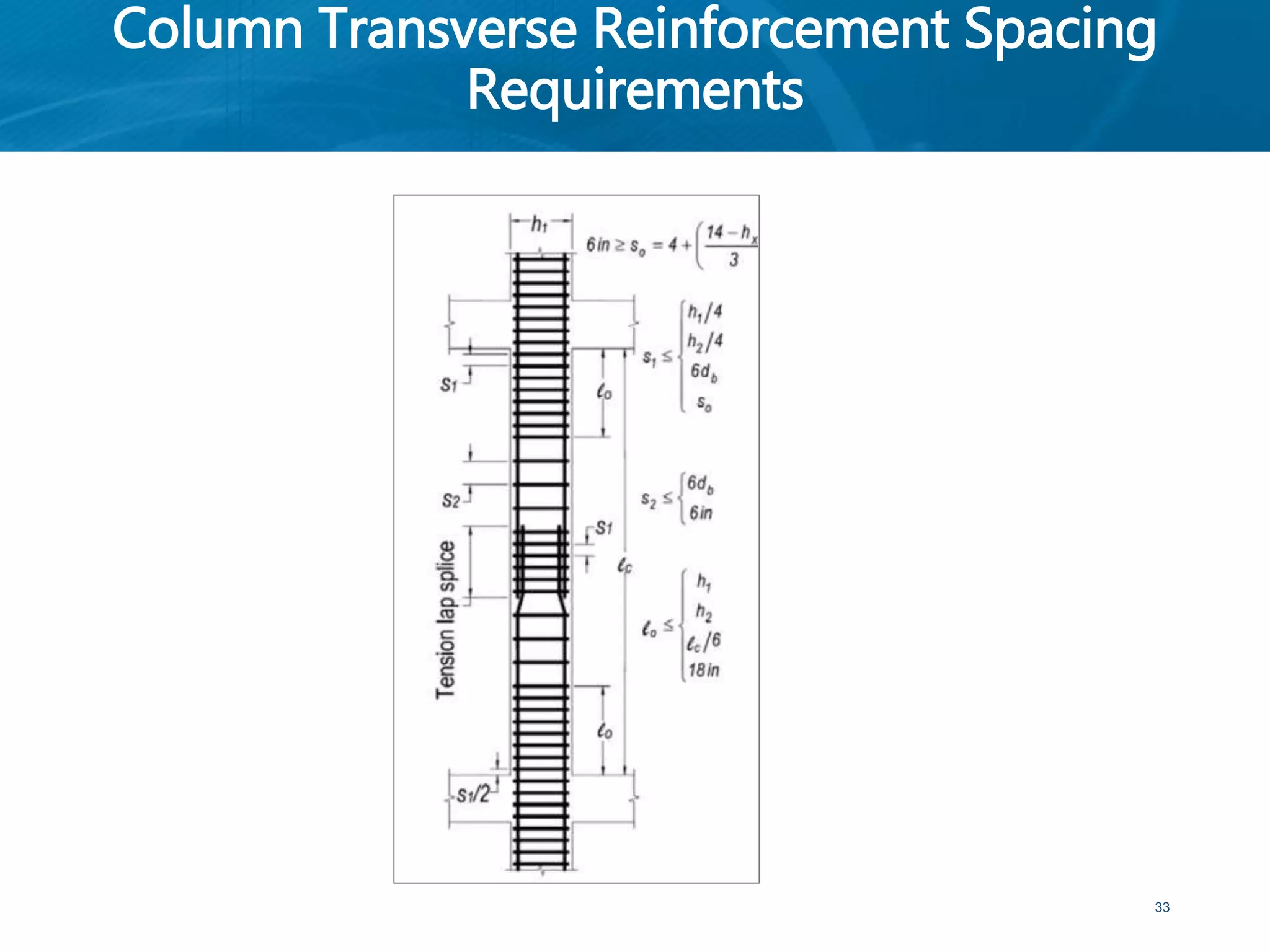

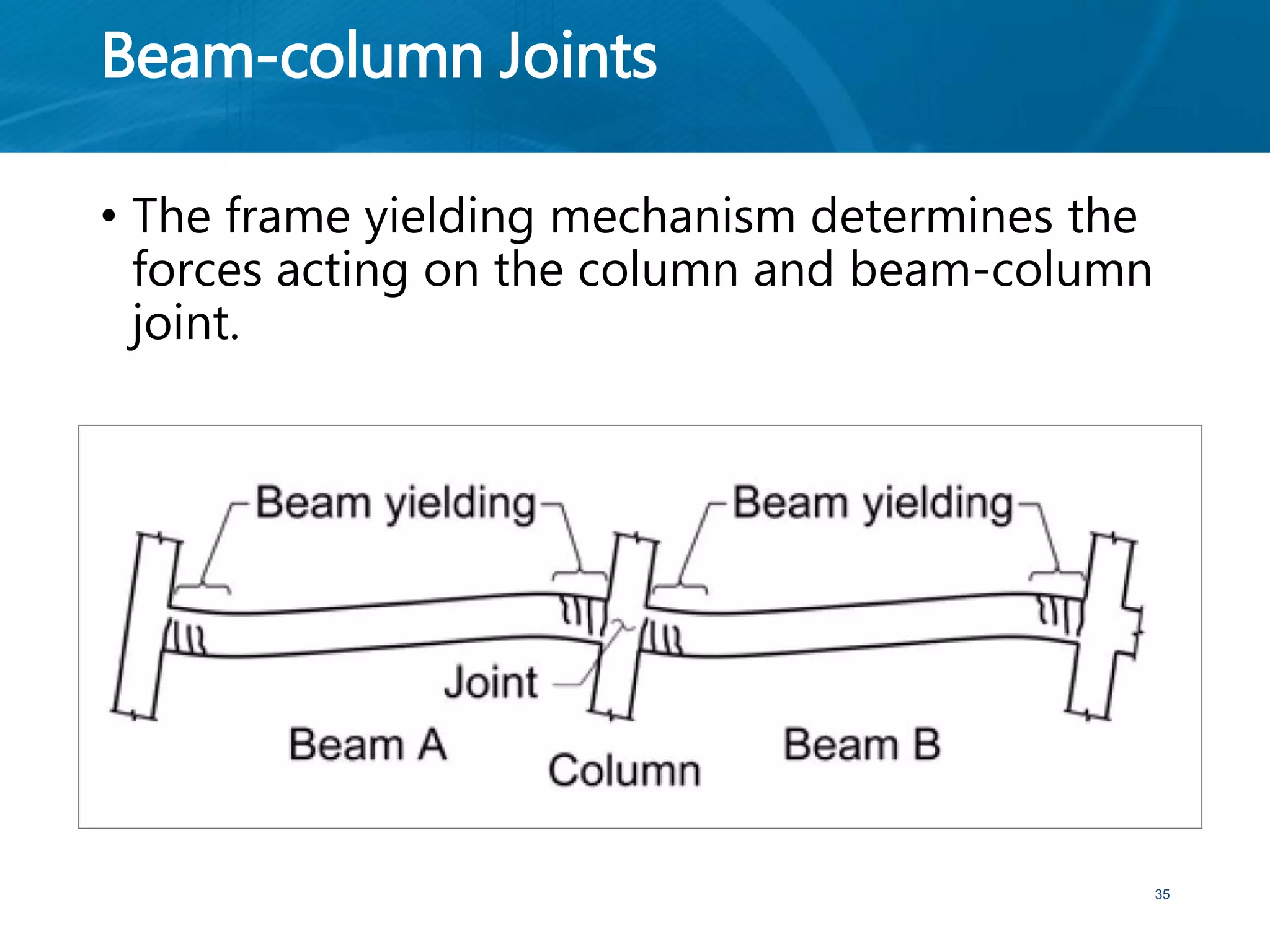

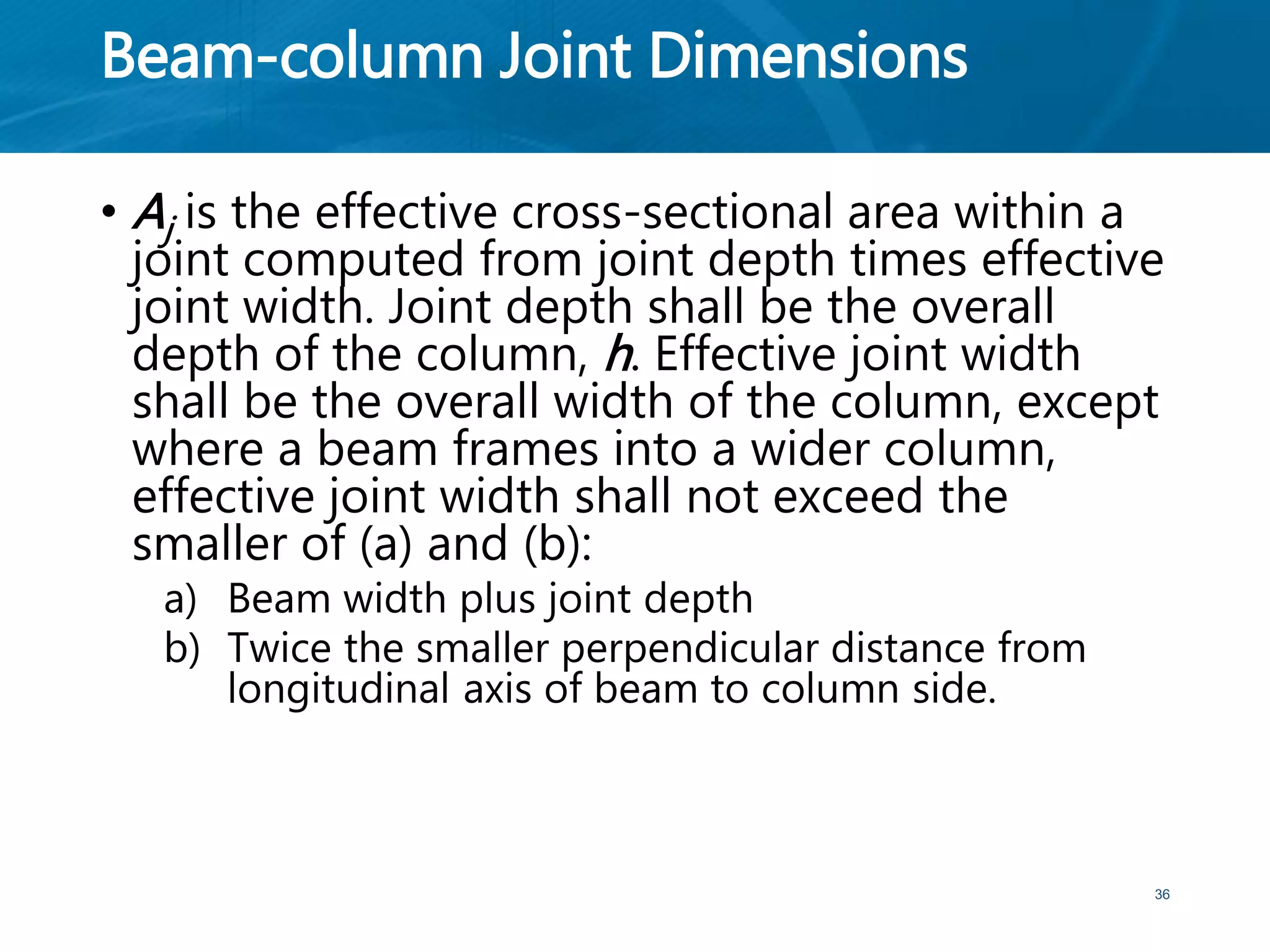

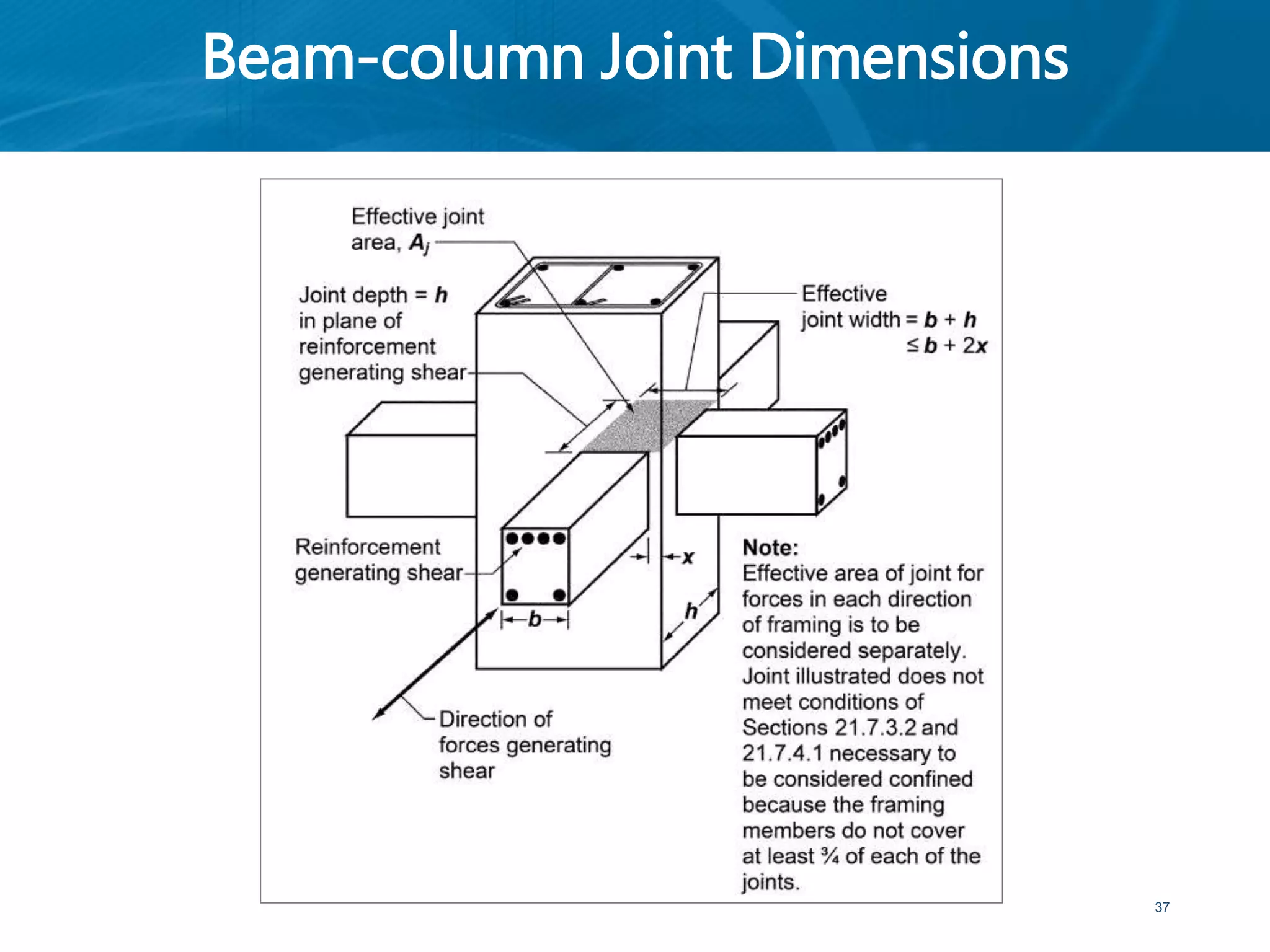

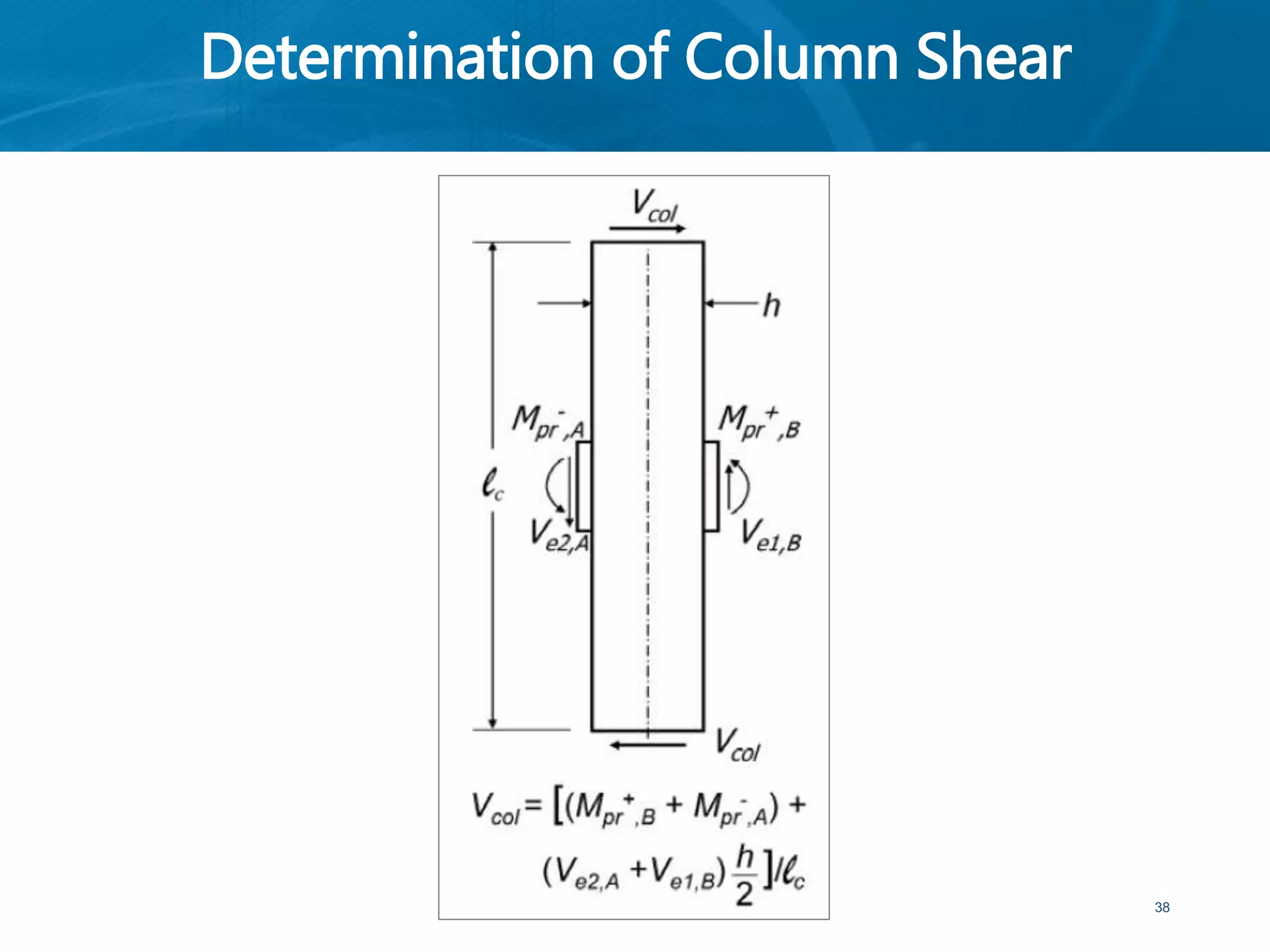

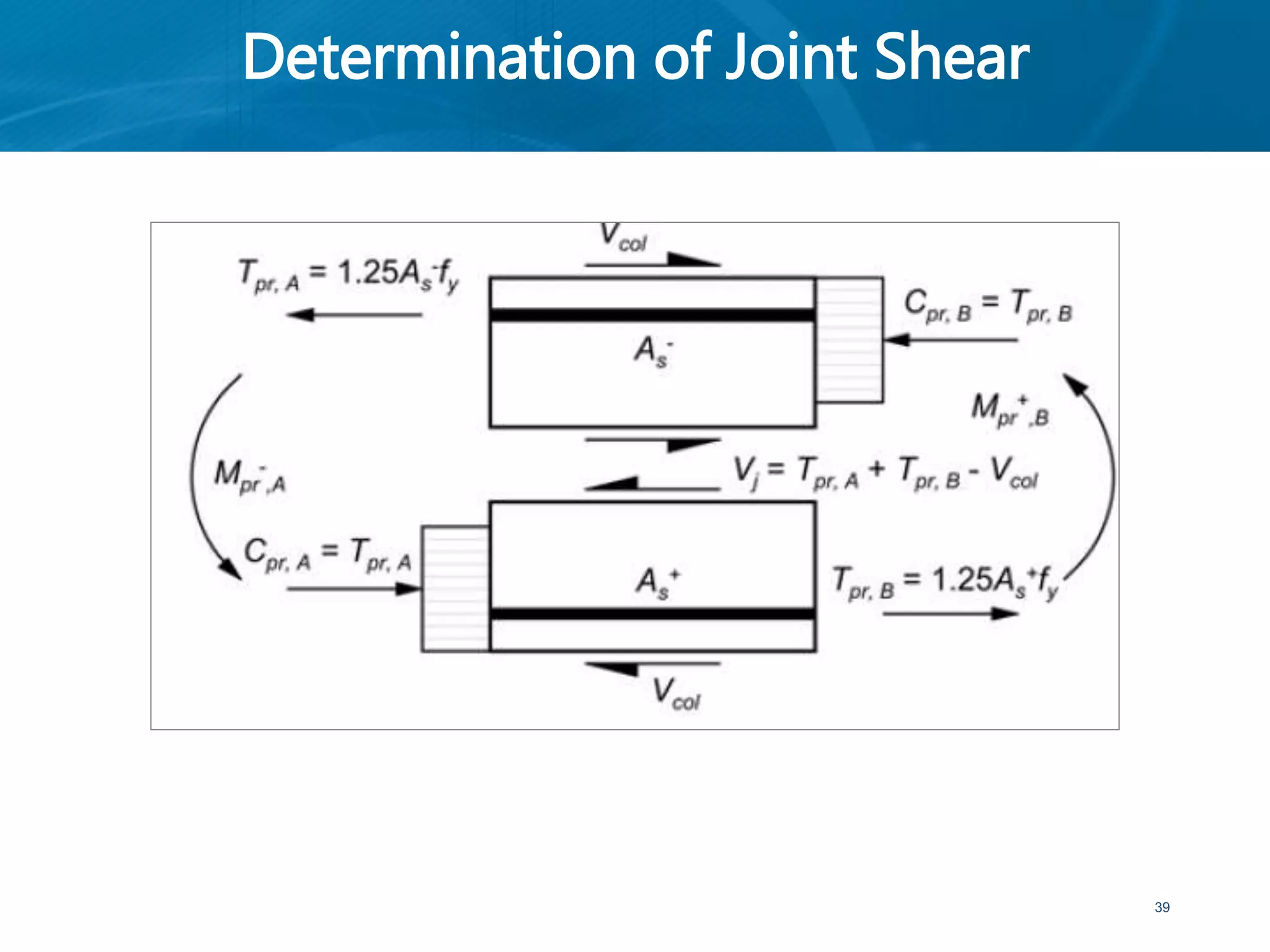

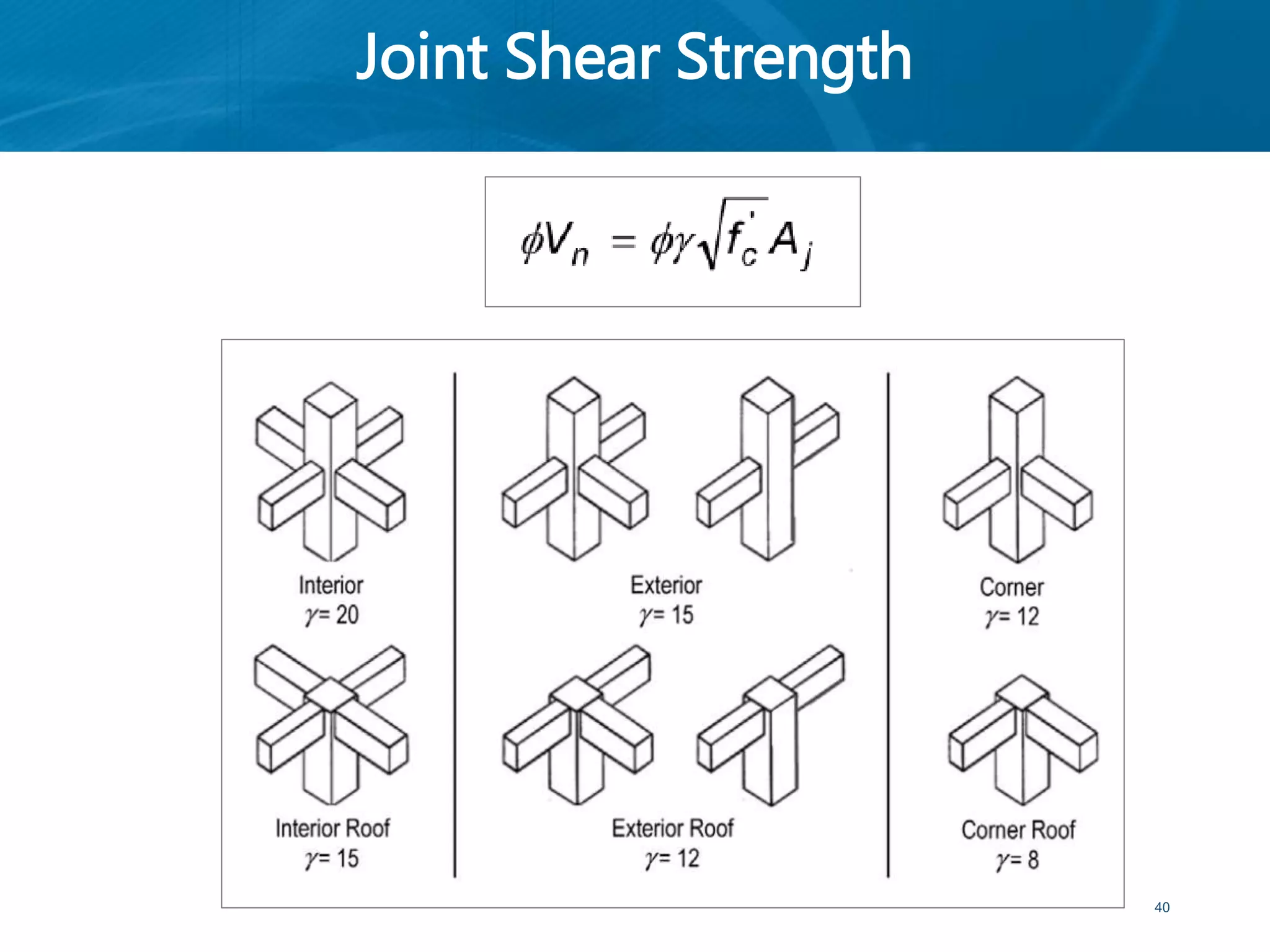

This document provides an overview of member behavior for beams and columns in seismic design. It discusses the types of moment resisting frames and the principles for designing special moment resisting frames, including strong-column/weak-beam design, avoiding shear failure, and providing ductile details. Beam and column design considerations are covered, such as dimensions, reinforcement, and shear capacity. Beam-column joint design is also summarized, including dimensions, shear determination, and strength.