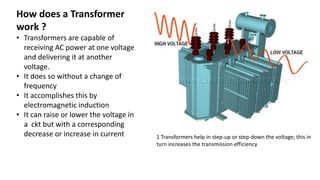

1. Transformers have on-load and off-load tap changers that allow adjusting the transformer's output voltage without interrupting the load current. On-load tap changers can adjust voltage while energized using fast-acting switches, while off-load tap changers require de-energizing the transformer to change taps.

2. On-load tap changers are commonly used in power generation and distribution transformers to control voltage as load and line conditions vary. They monitor voltage and raise or lower taps using an automatic voltage regulator. Off-load tap changers are typically used in solar and wind projects where the generator voltage is low-voltage.

3. The on-load tap changer maintains uninterrupted

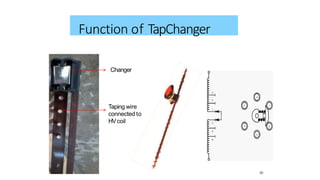

![ON-LOAD & OFF-LOAD TAP CHANGER OF TRANSFORMER ( OLTC Vs OCTC )

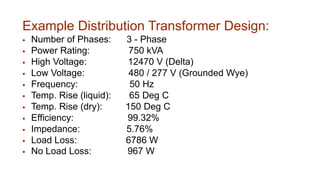

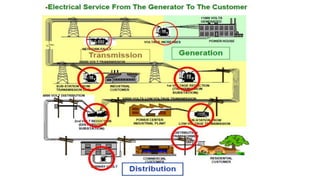

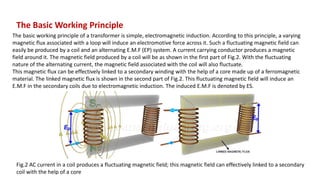

Power Generation, Transmission & Distribution Mainly on AC [Alternating Current]

System, Which is common in the World. So In Alternating Current System having

losses in the Generation as well as in Transmission.

When you are designing a building with high Demand power, then you need

permission to avail power from the Local EB. Meanwhile you have to install

Distribution Transformer to step-down the Voltage level from HT to LT, In Most

Common Voltage Distribution Class is 11 kV / 433 V

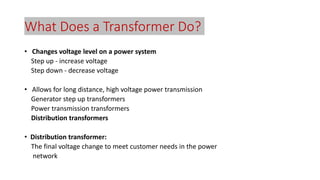

All LT Loads attains full Efficiency when LT System [i.e.433V] gets constant

voltage having Zero Voltage drop. This Scenario is possible only if HT Gets

Uniform Voltage level from the EB End. [i.e 11kV]. We known that

Transmission system having more losses due to the distance and amount of

common losses of AC System.So we difficult to achieve 11kV at HT End. So

the system which is co-ordinate with Grid to support to the Transformer to

achieve proper voltage level for the Distribution Purpose is Called as Tap

Change.](https://image.slidesharecdn.com/meppurchasetransformerppt-190810092720/85/Transformer-Detailed-Presentation-50-slids-17-320.jpg)

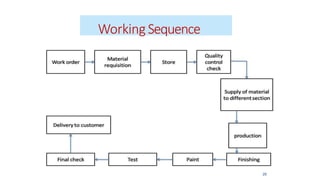

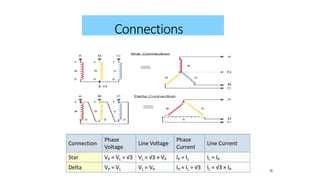

![Tap-changing

Transformers

The change of voltage is

affected by changing the

numbers of turns of the

transformer provided with

taps. For sufficiently close

control of voltage, taps are

usually provided on the high

voltage windings of the

transformer. There are two

types of tap-changing

transformers:

1. Off-load tap changer-

OCTC

2. On-load tap changer

OLTC

OFF-Load Tap Change: Mainly Used in Solar Power Project, Wind

Projects. Here Generating voltage level is LT at Conversion Level.[i.e

Inverter Level]Solar Inverter Duty oil type Transformer & Dry Type

Transformer having OFF-Load Tap Change. Concept.

Concept:

Tap Changing will happen While Transformer is in OFF-Load or No-

Load. In Dry Type Transformer, Cooling Phenomenon mainly Air

Natural. Normally In ON-Load Tap Changer, Arc Quenching will be

limited by medium of Oil When Transformer is ON-Load. But OFF-

Load Tap Changer, Tapping will be done only When Transformer is in

OFF-Switch Condition. In Dry Type Transformer Air is the only cooling

medium which is limited Energy to Arc Quench.

ON-Load Tap Change: Most of the Generating Station, Substation

system having Power Transformer with ON-Load Tap Changer. Not

only in Generating Station Transformer also in Distribution Class

Transformer too.

Concept

Tap Changing will happen While Transformer is in ON-Load. Tap

Changer System Monitors the Voltage level with the help of AVR

[Automatic Voltage Regulator]. AVR is in housed cubicle Called

RTCC Panel. It also houses Push button for Tap Riser & Lower,

Indicator for HT Voltage level, Heat Sensor etc., Most of the Oil

Impregnated Transformer having ON-Load Tap Changer Type.](https://image.slidesharecdn.com/meppurchasetransformerppt-190810092720/85/Transformer-Detailed-Presentation-50-slids-18-320.jpg)