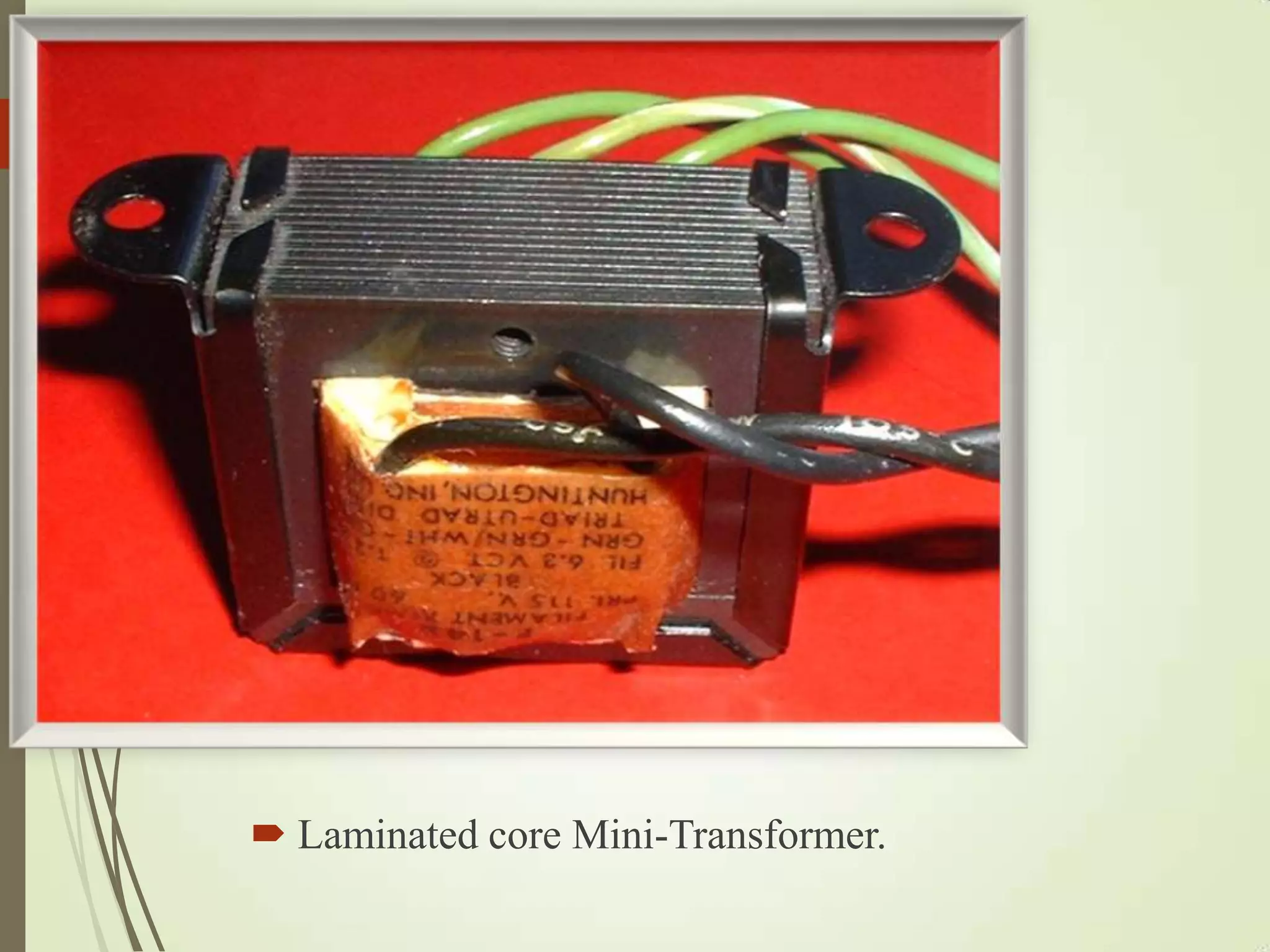

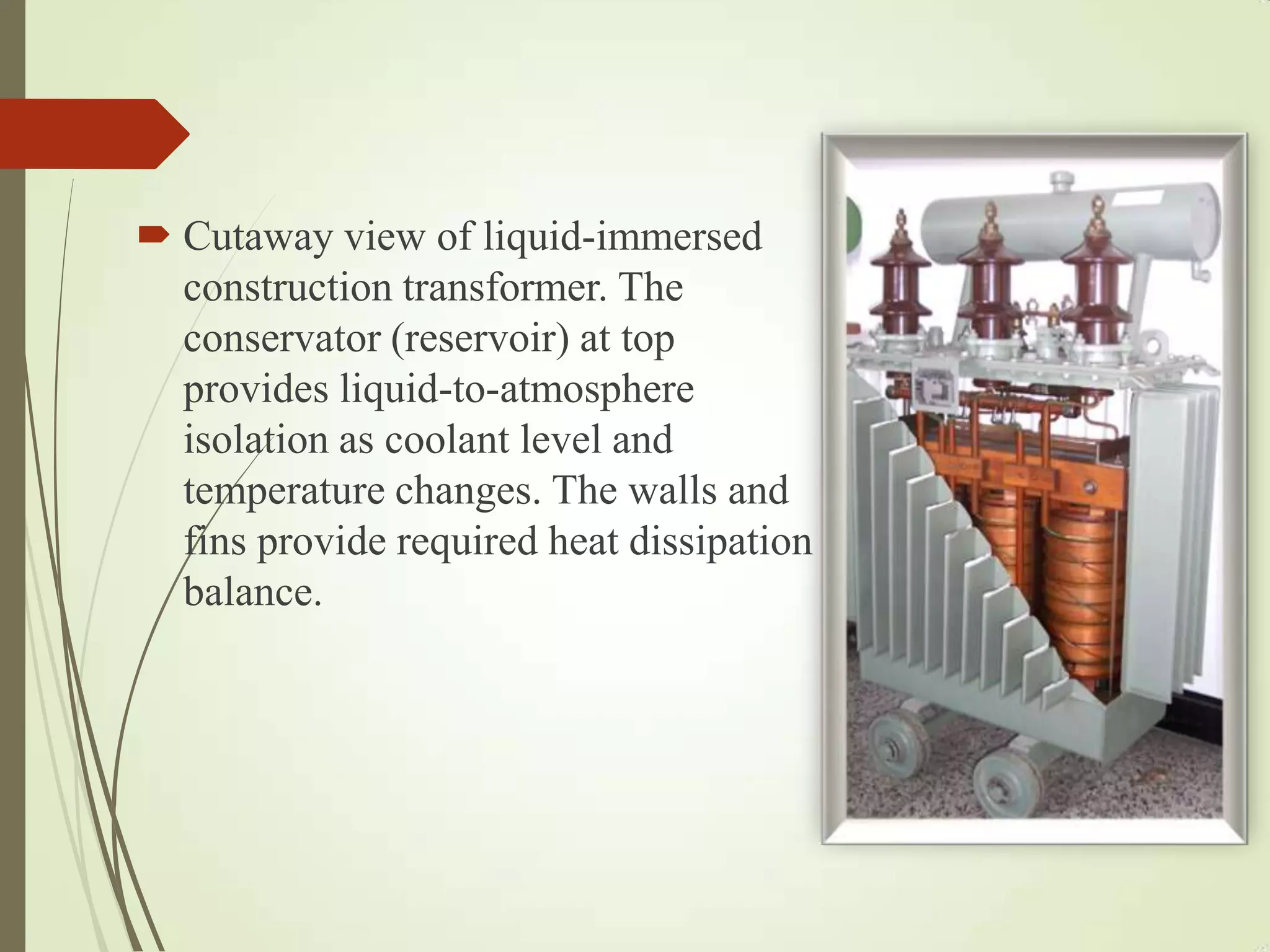

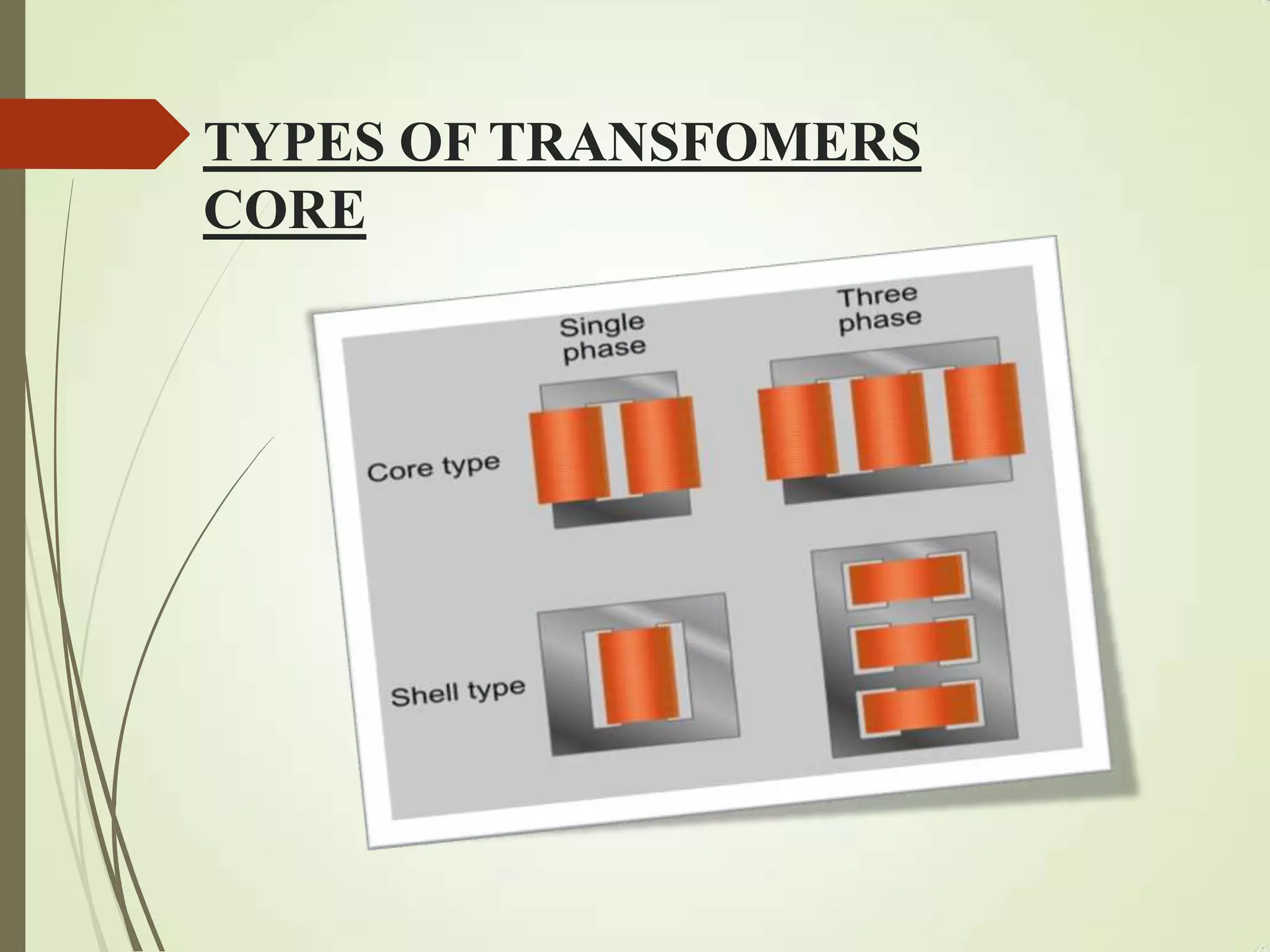

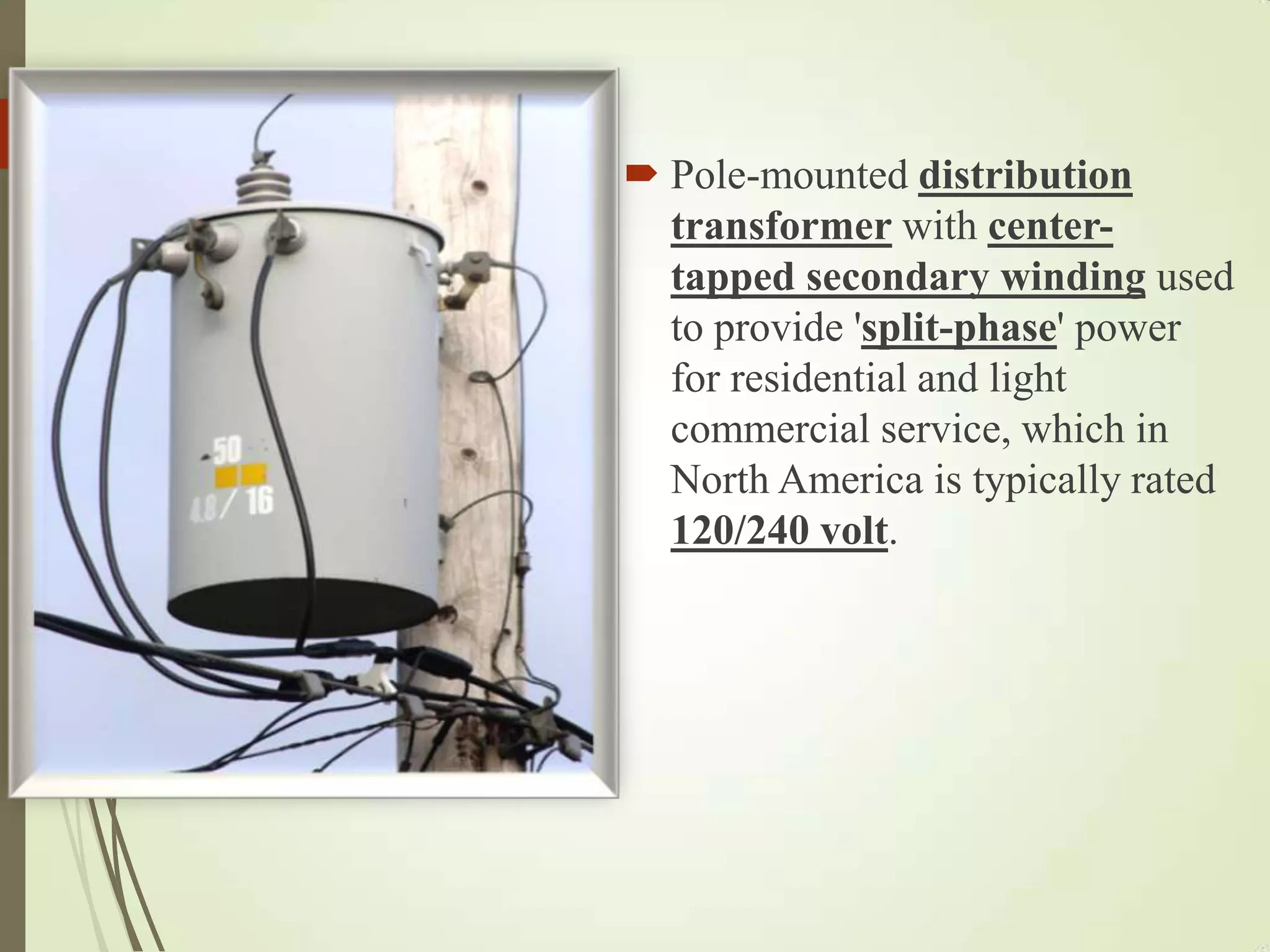

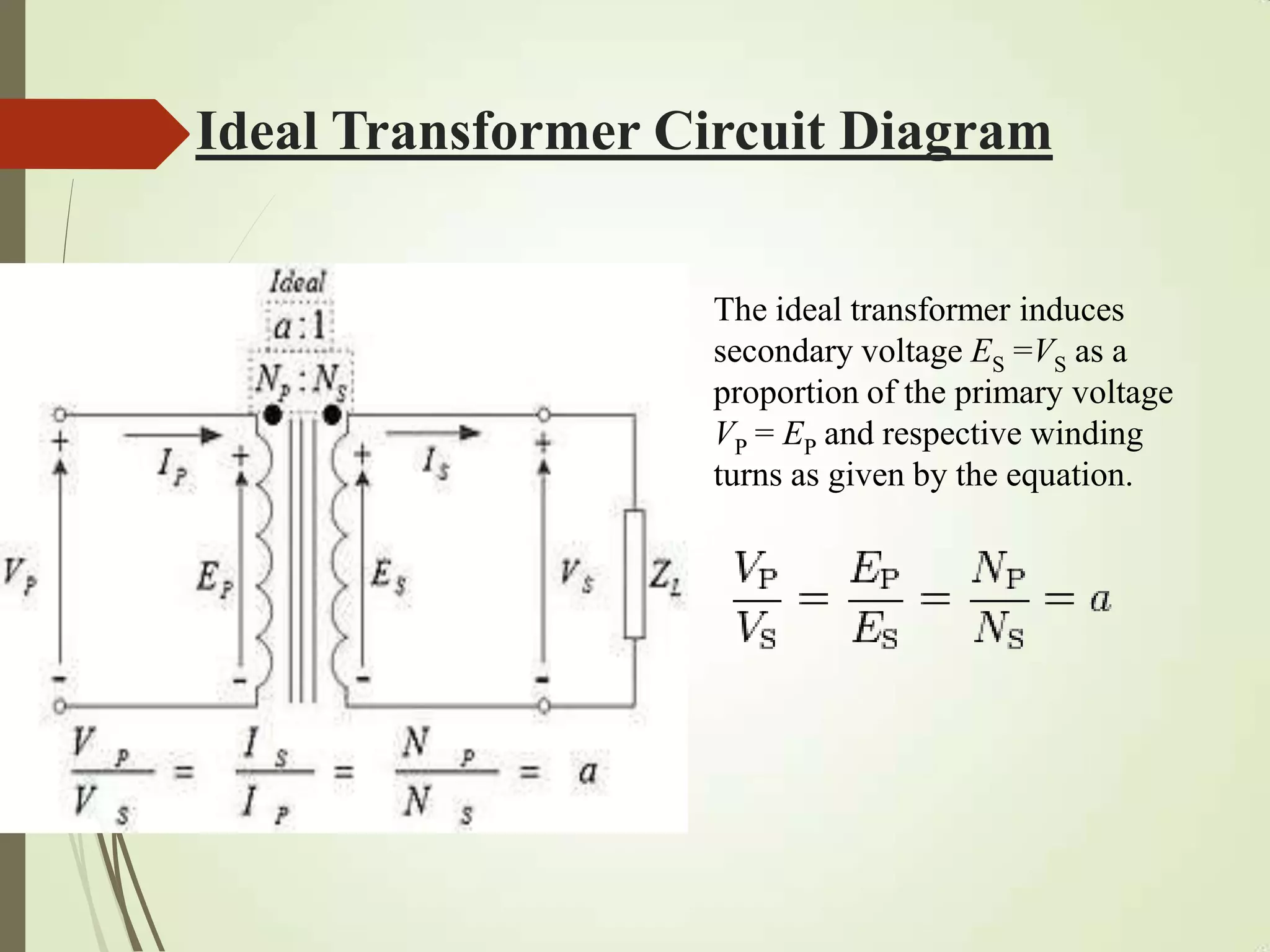

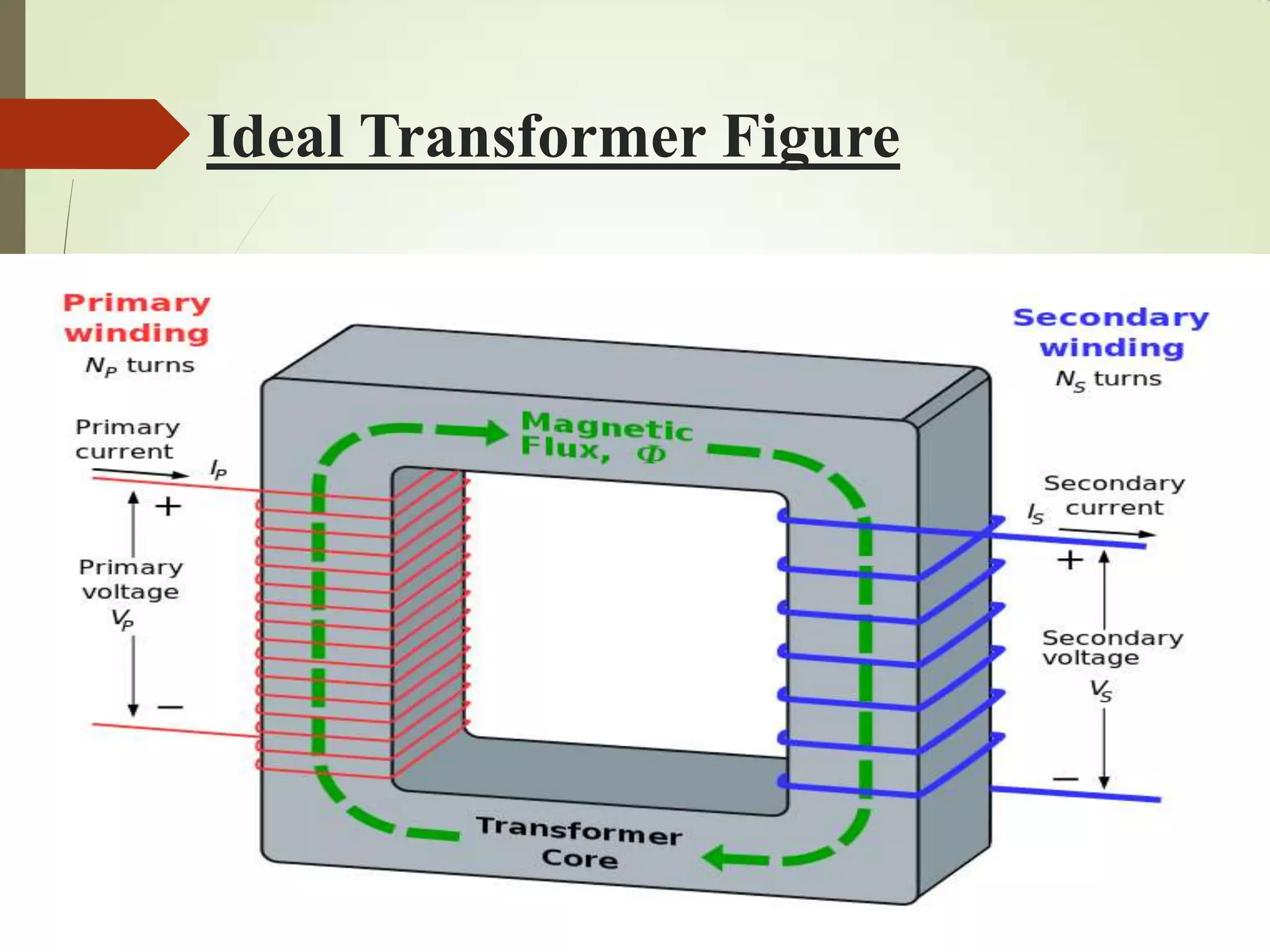

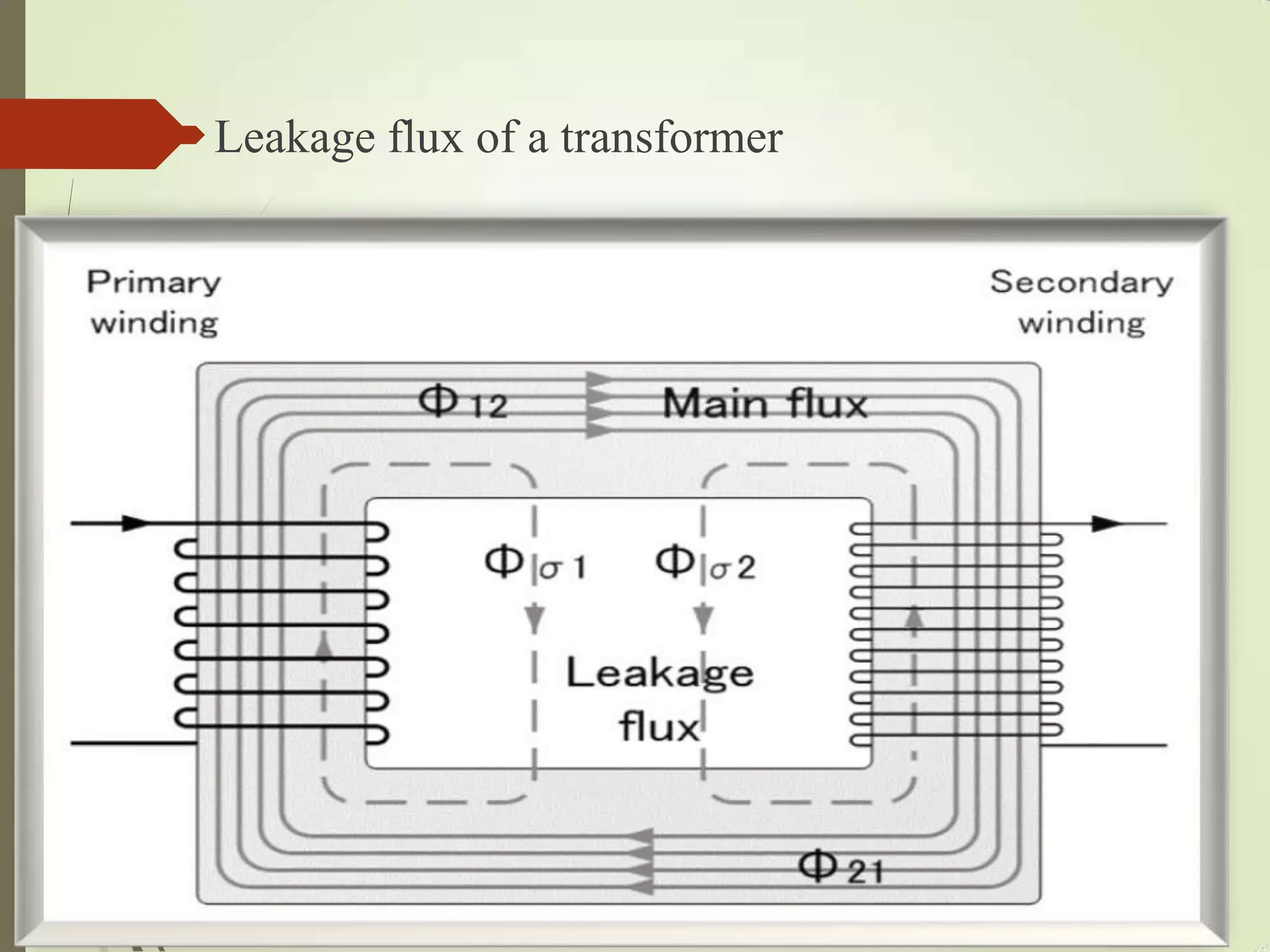

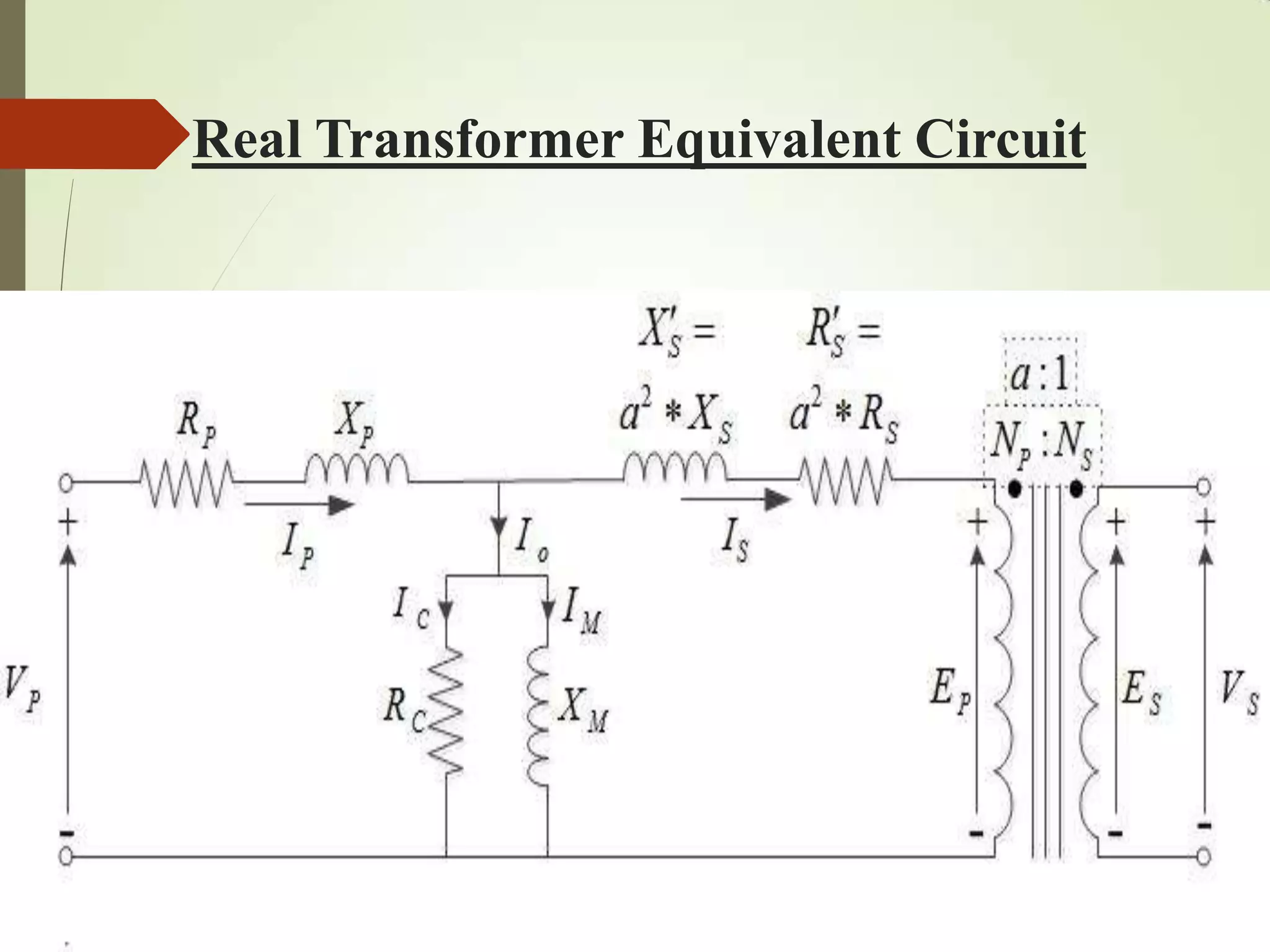

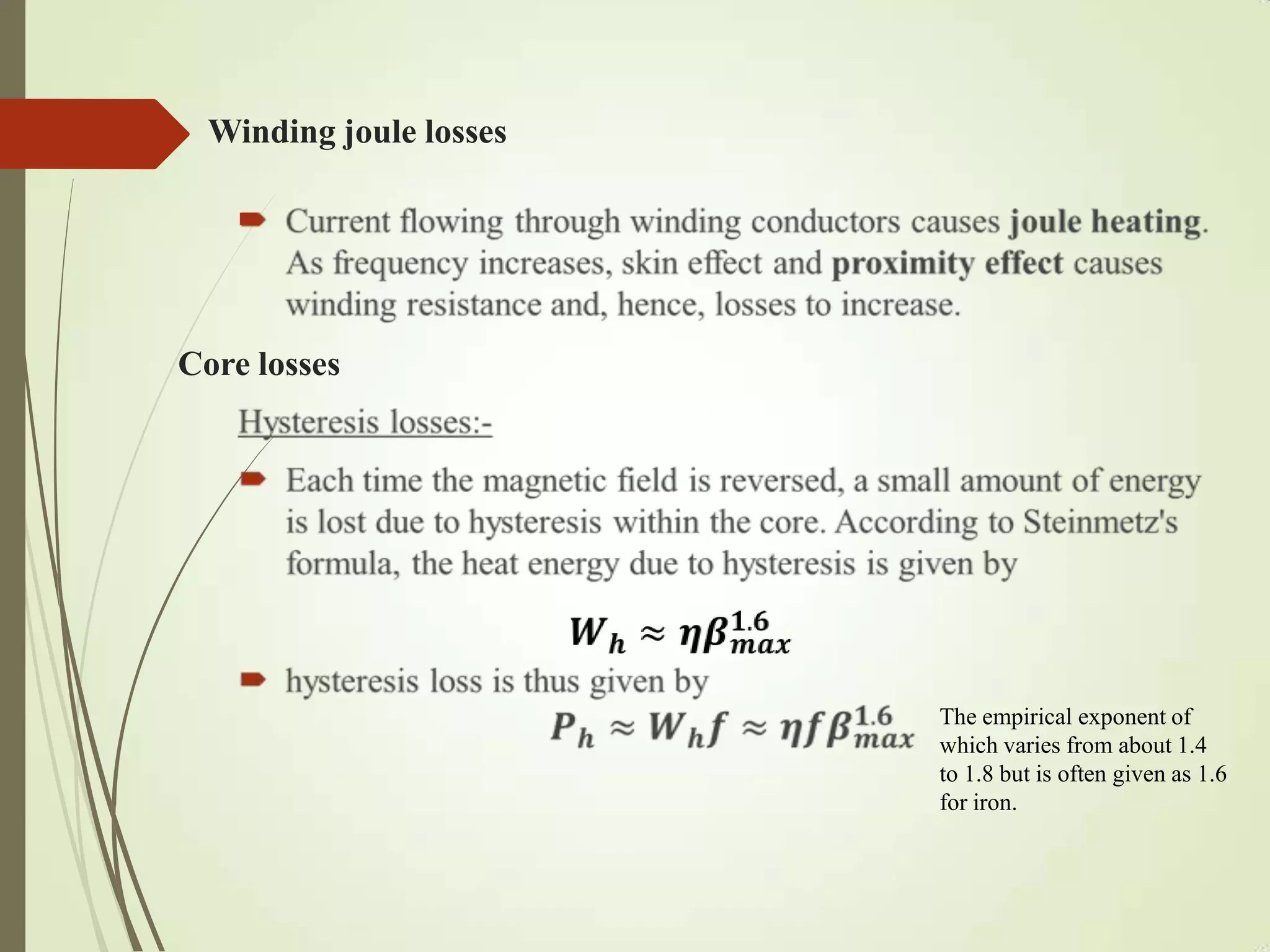

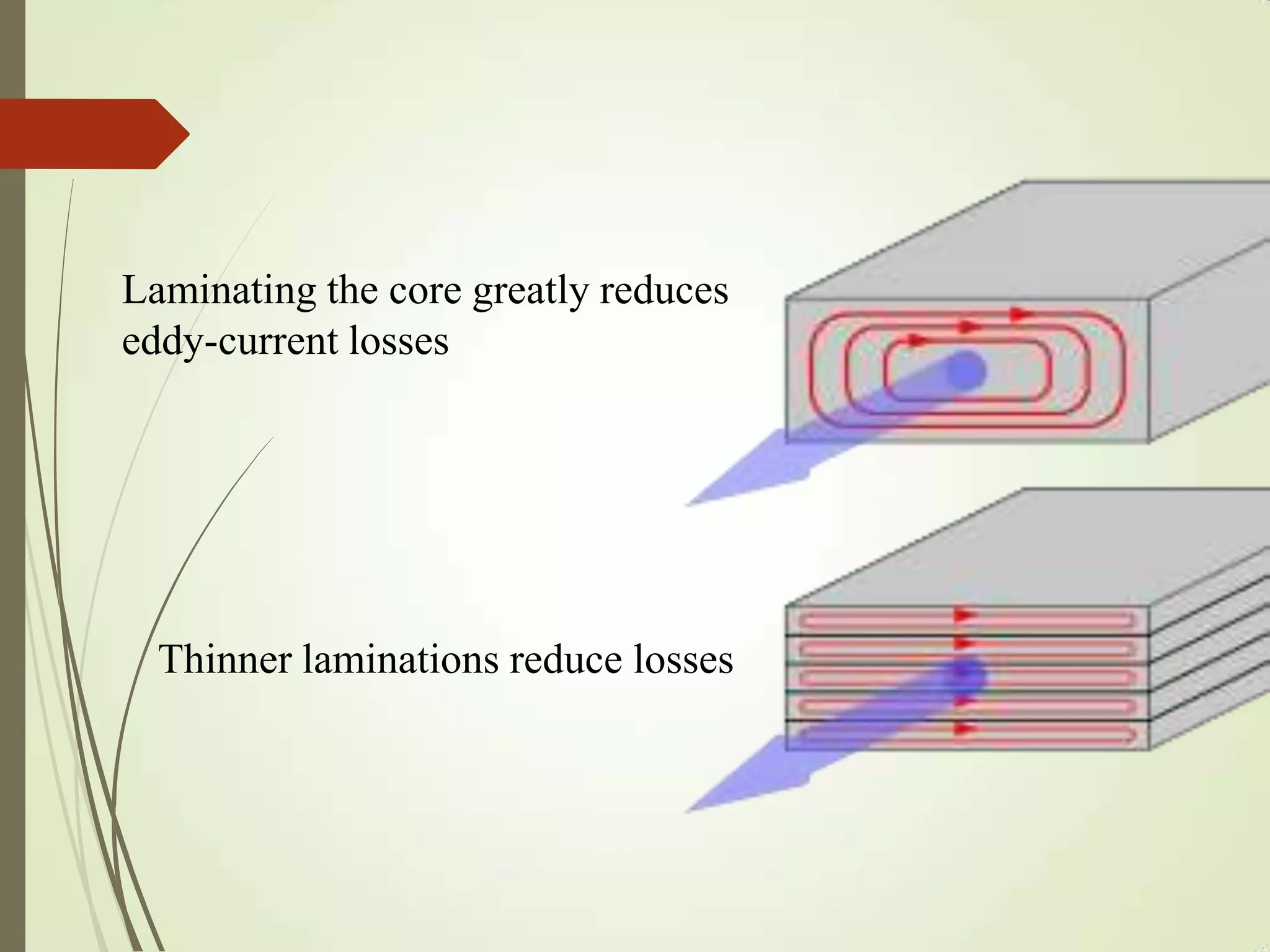

A transformer transfers electrical energy from one circuit to another through electromagnetic induction. It converts an alternating current from one voltage to another without changing frequency. An ideal transformer is 100% efficient, but real transformers have some losses due to winding resistance, leakage flux, hysteresis, and eddy currents. Transformers come in different types for various applications and use laminated cores to reduce eddy current losses.