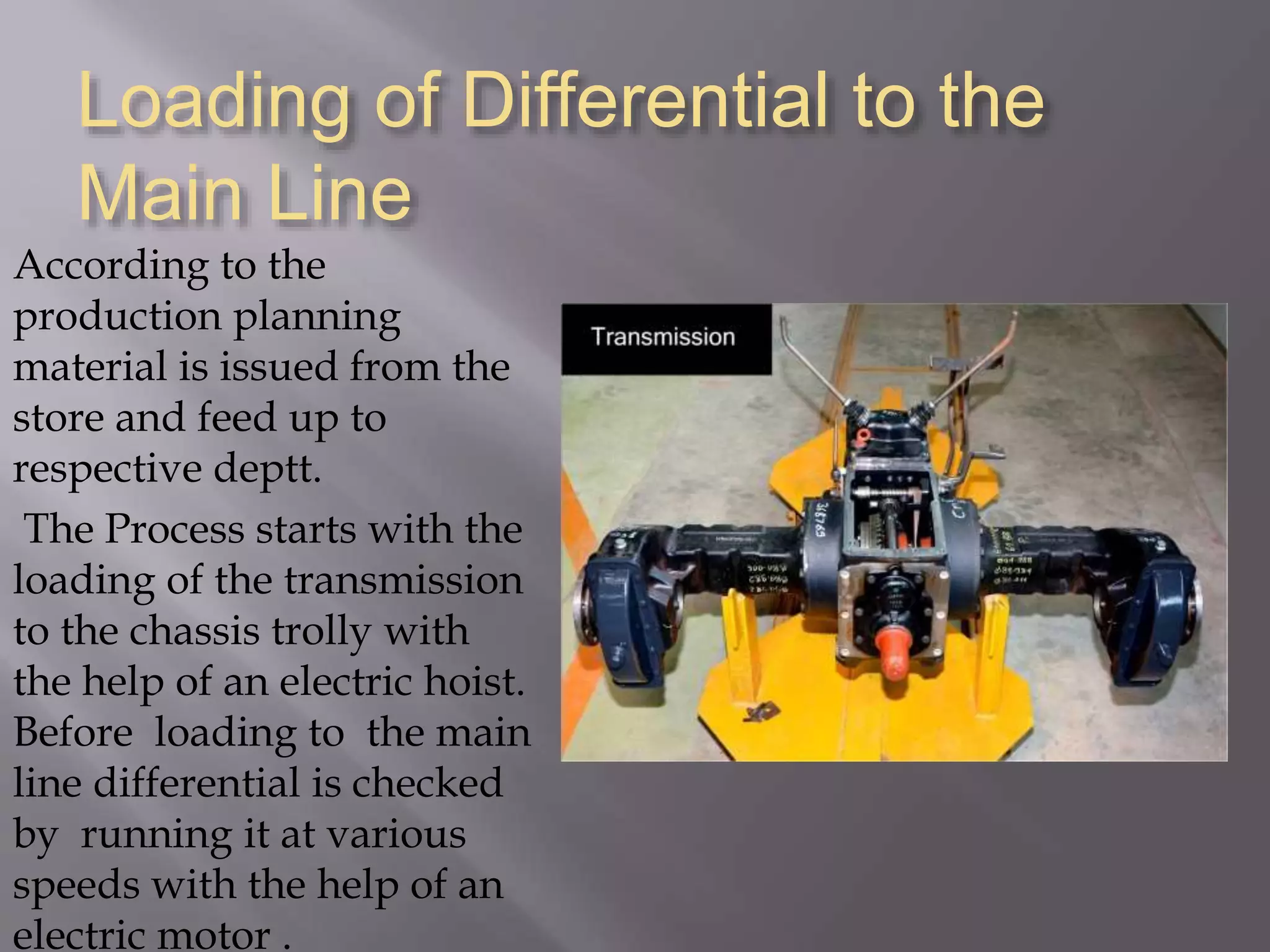

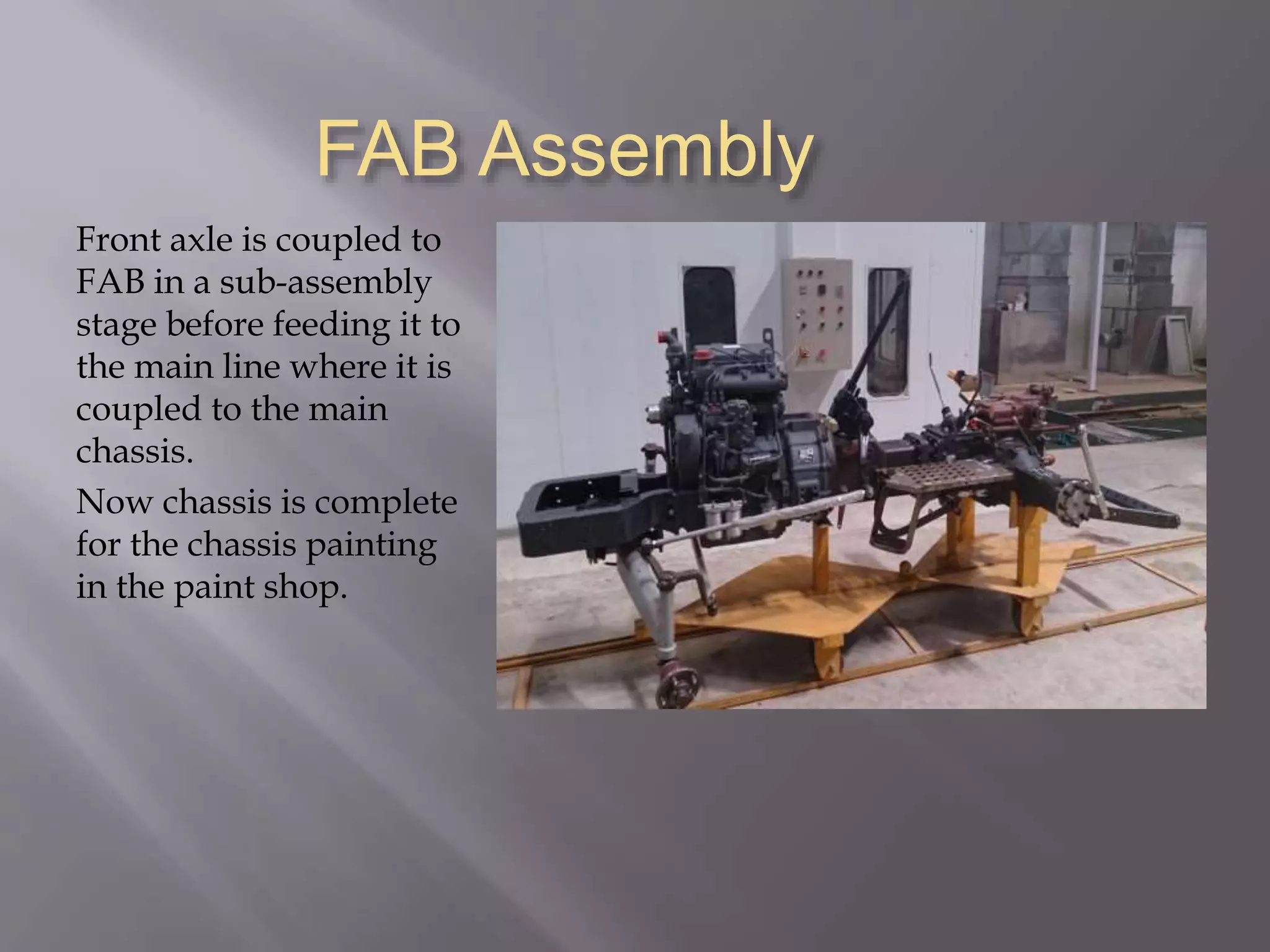

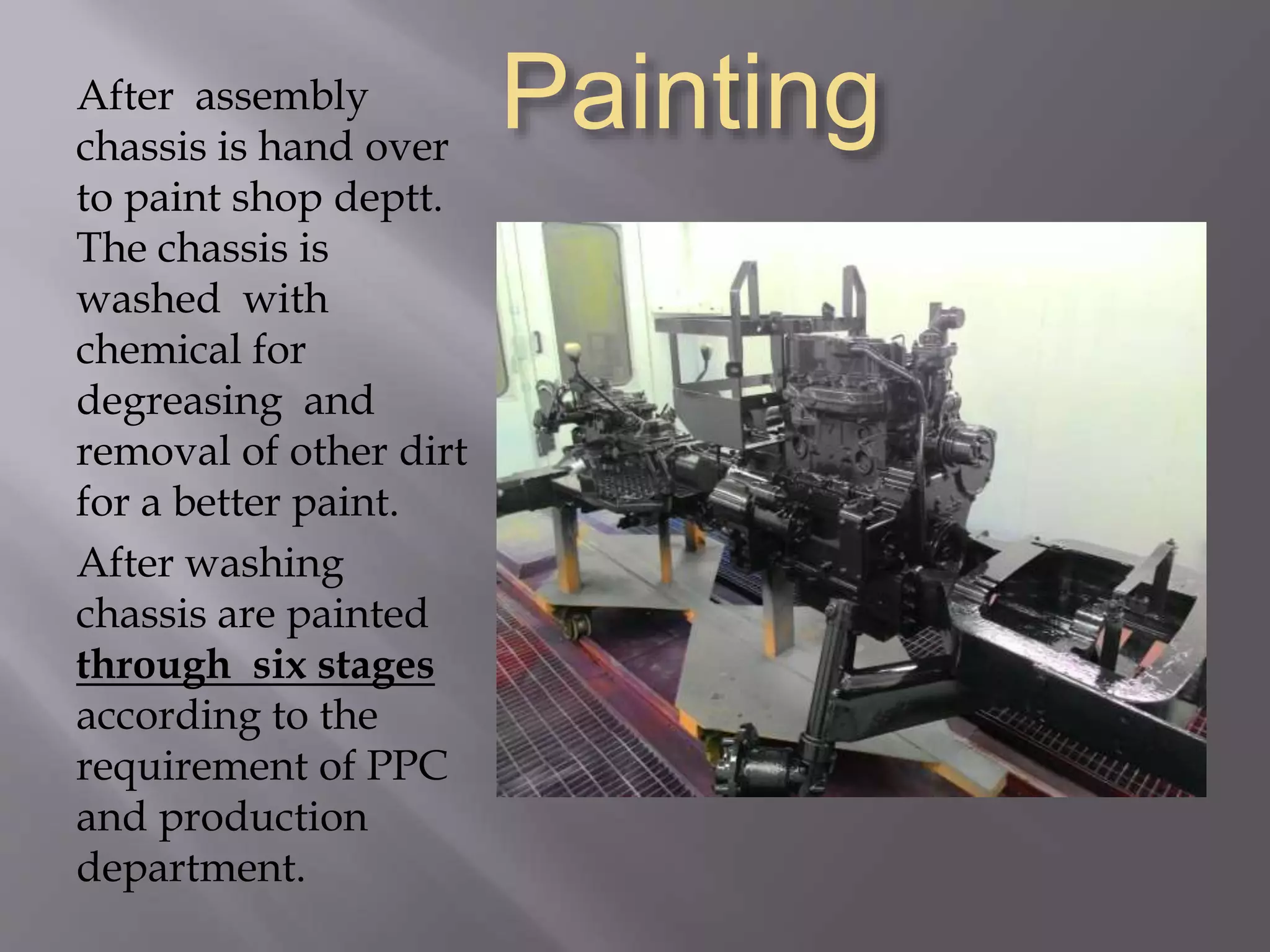

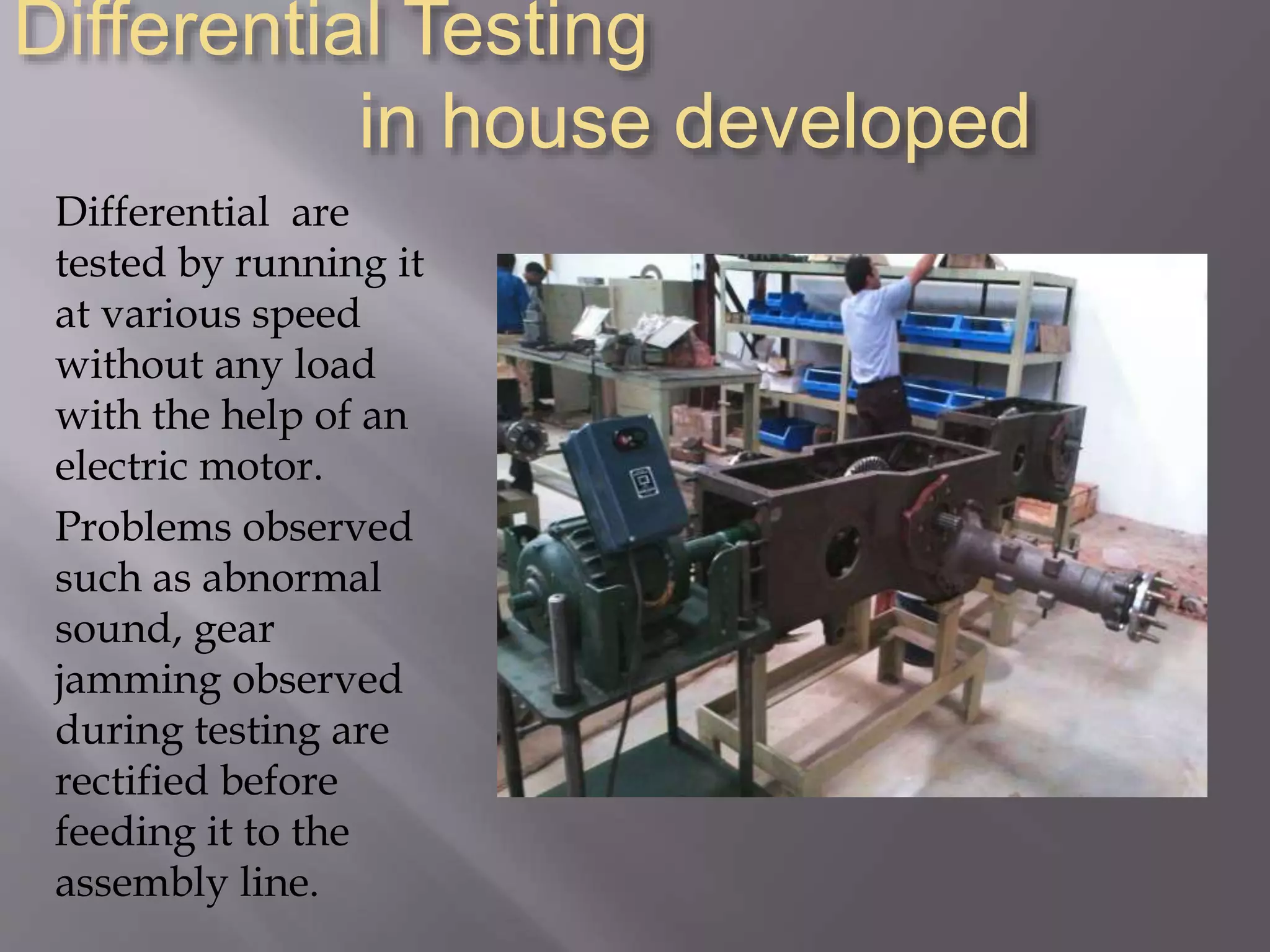

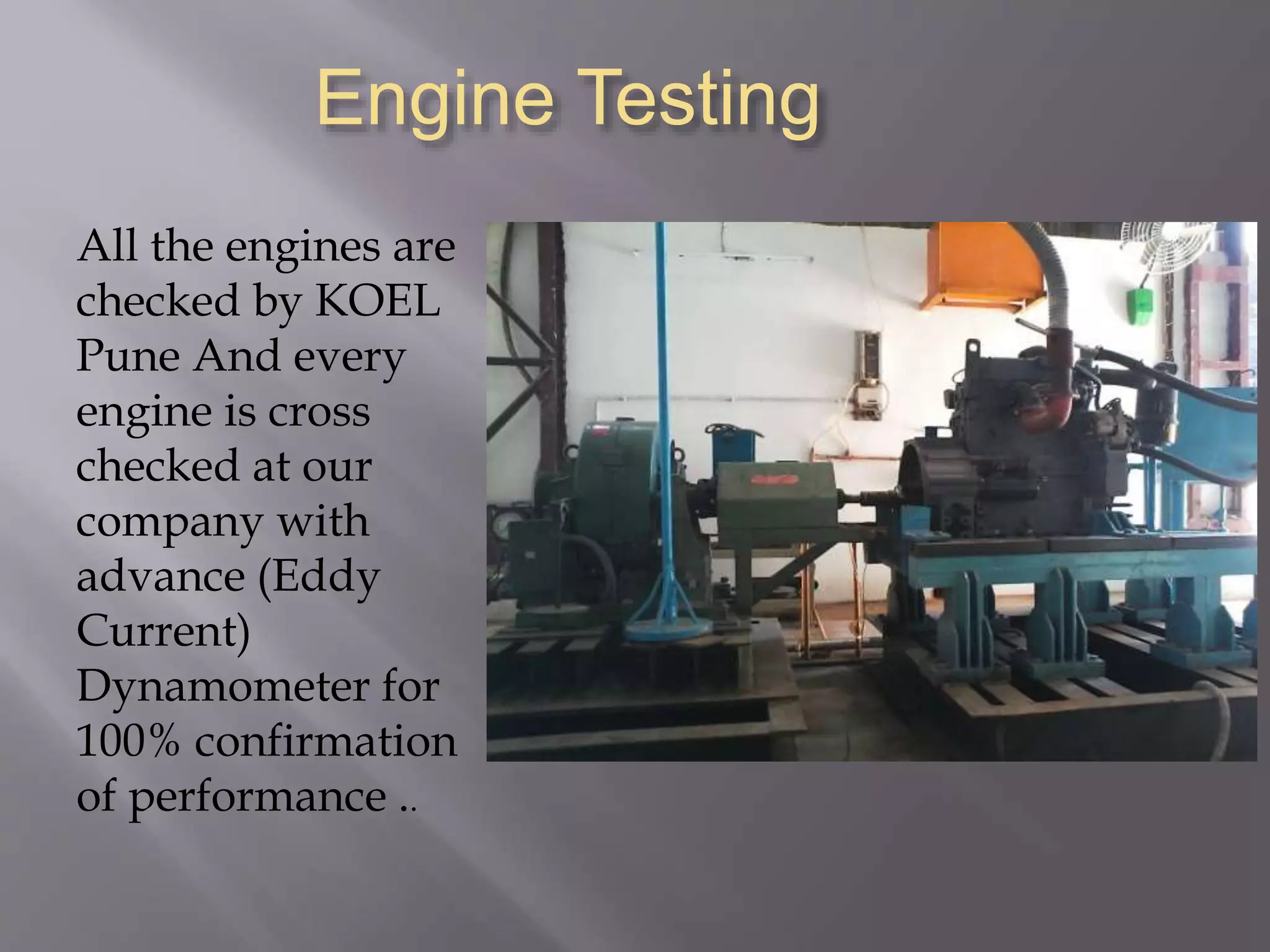

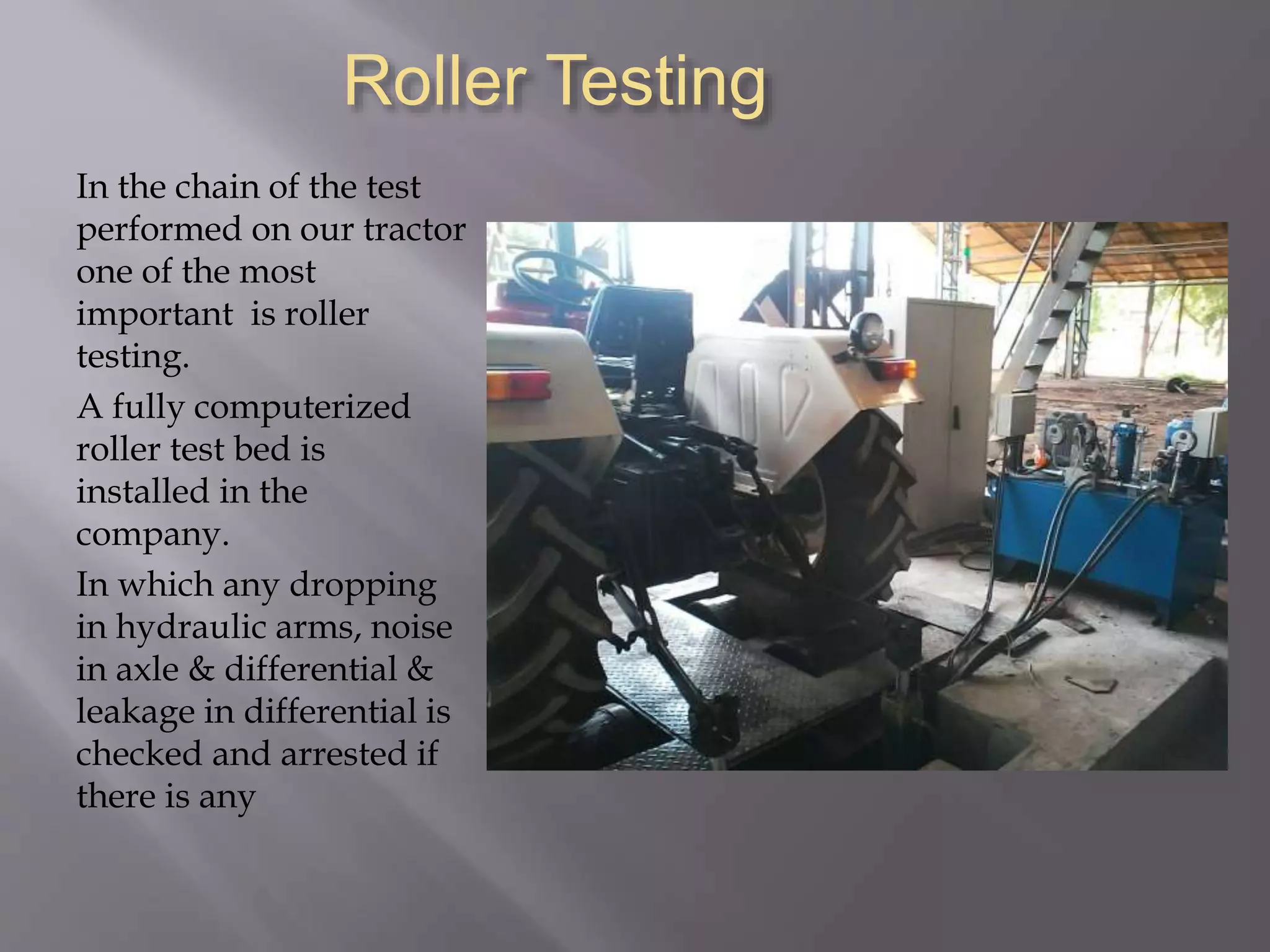

The document describes the manufacturing process for tractors. It involves receiving materials, quality assurance checks, storage, assembly of components like the differential and engine, painting, final assembly, and final quality control testing. Key tests include running the differential at various speeds, testing the hydraulic and PTO systems under load, and roller and "marry go round" durability testing to check for any issues before customer delivery. The goal is to produce high quality tractors through rigorous inspection and testing of components at various stages of production.