- The document summarizes a six-week summer training completed by Akhilesh Kumar at Mahindra & Mahindra Ltd. in Jaipur, India.

- During the training, Akhilesh learned about various shops involved in tractor manufacturing like milling, fitting, turning, and the tractor assembly shop.

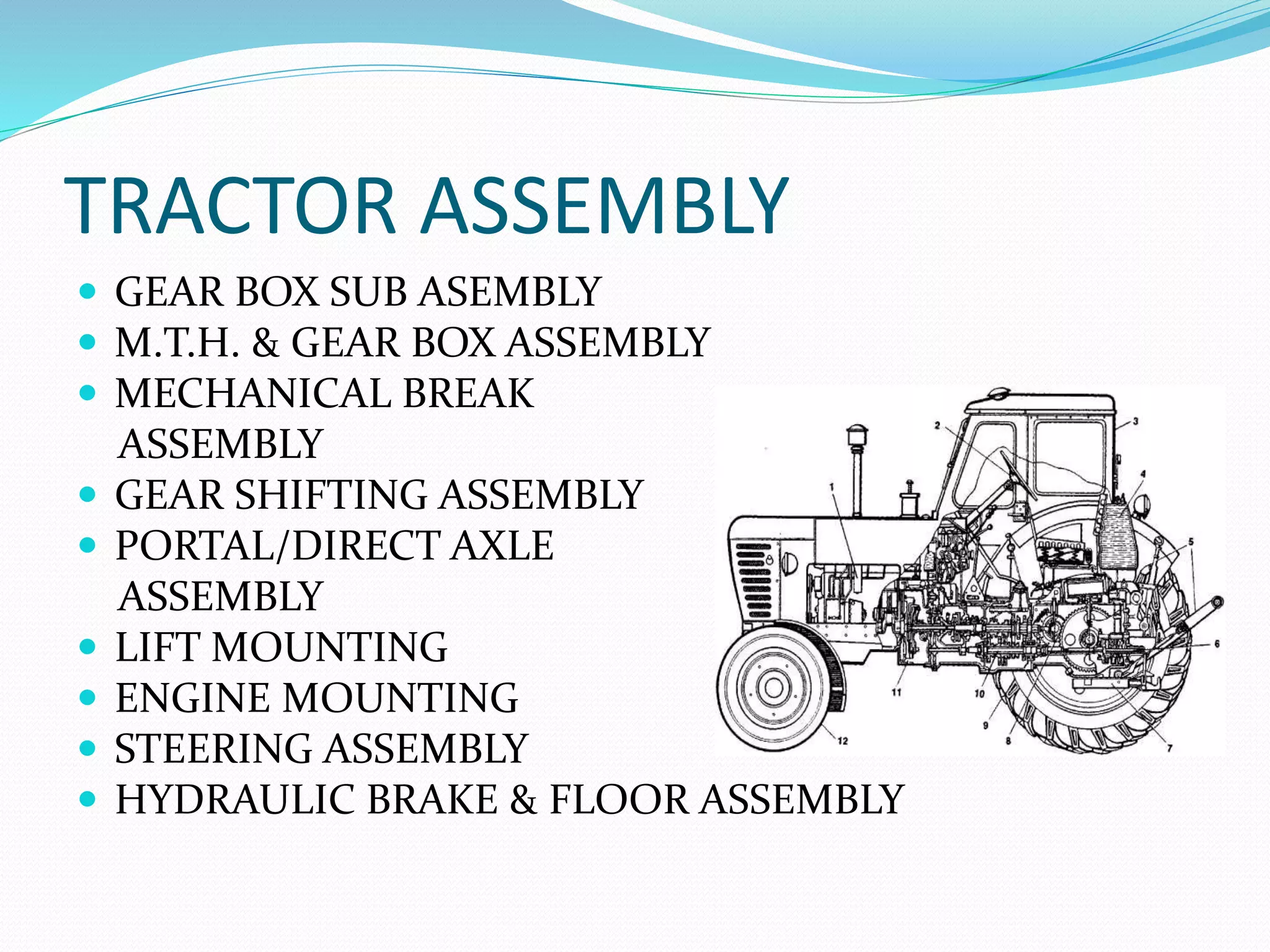

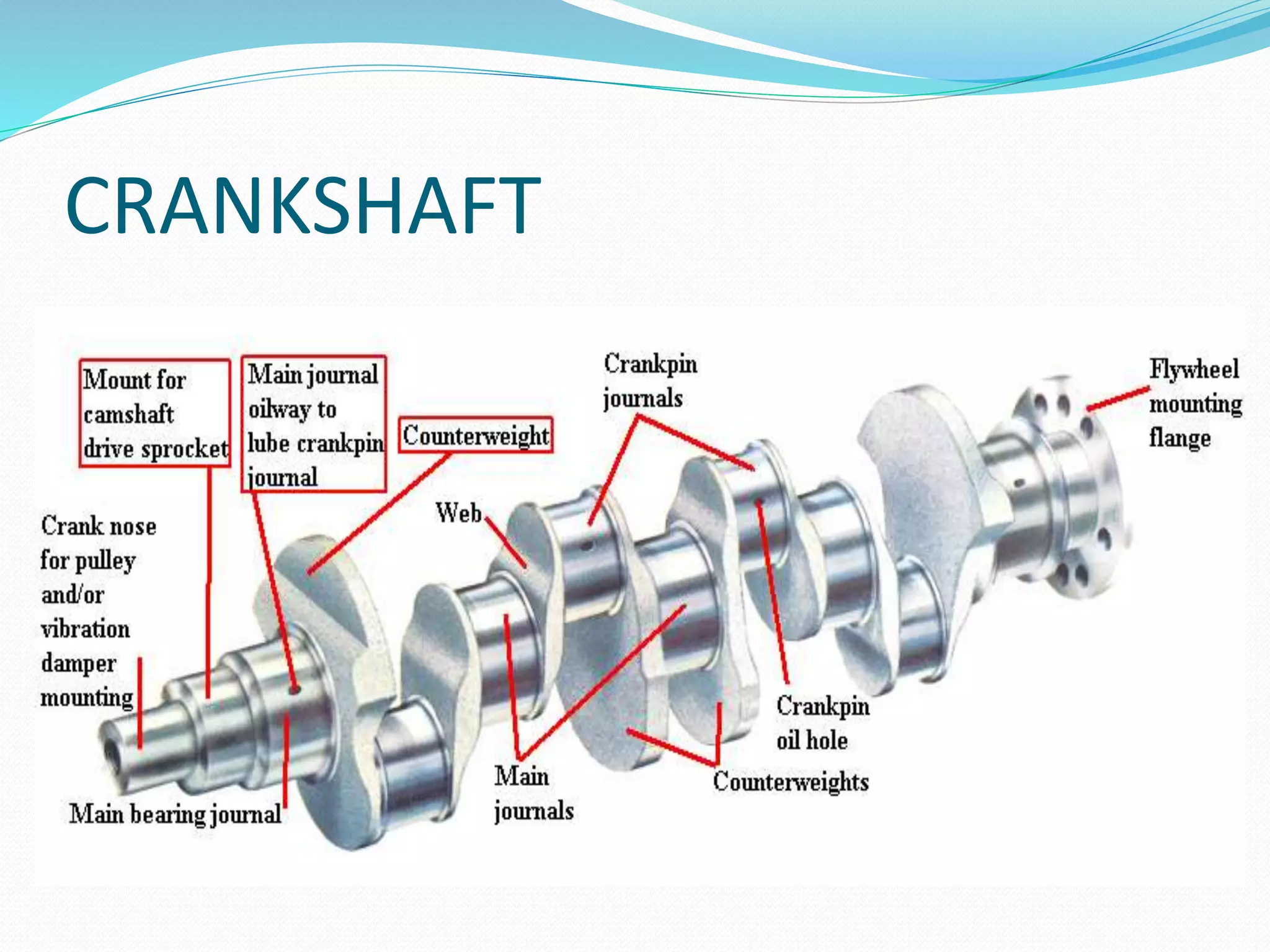

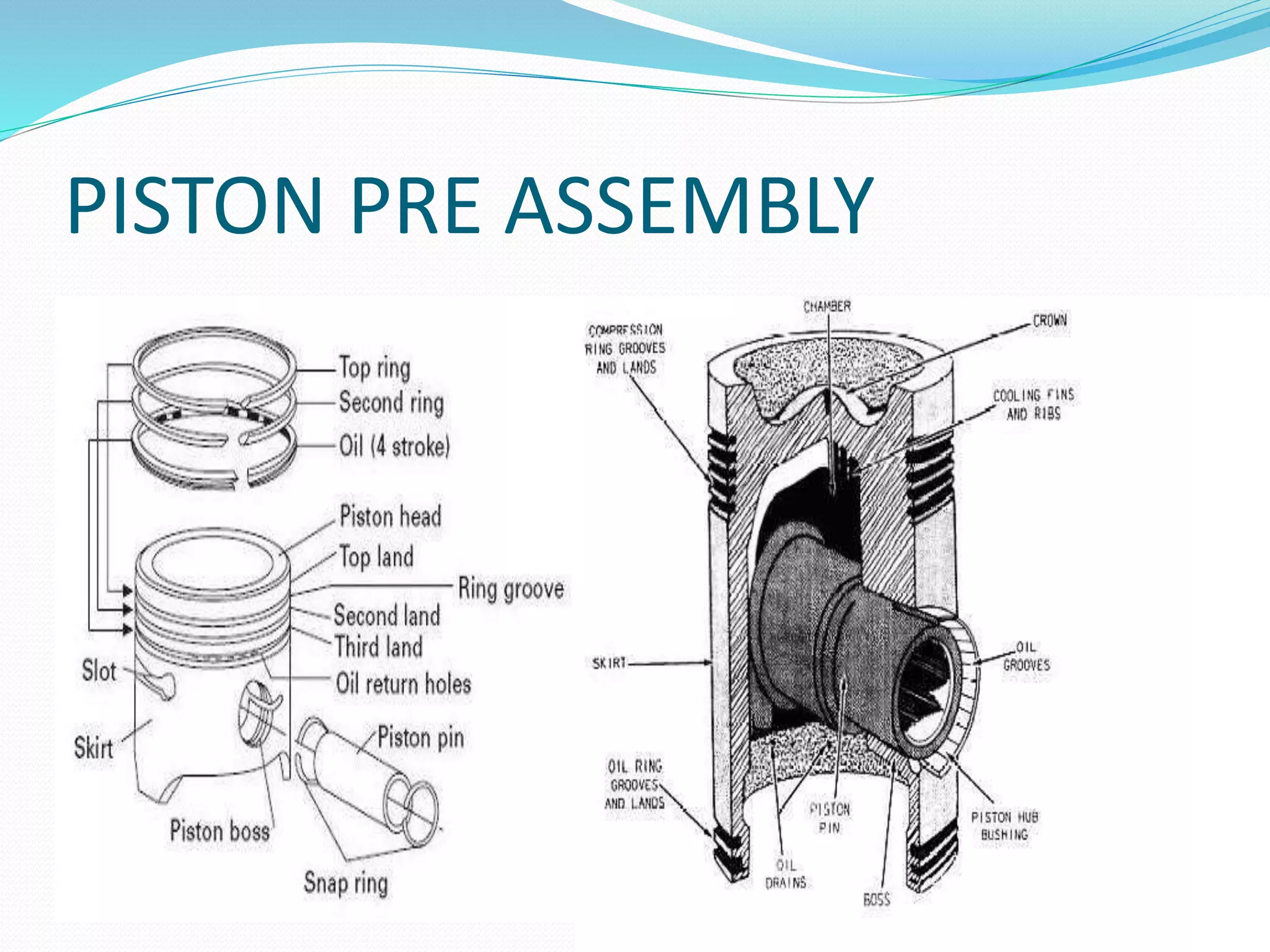

- He observed the assembly process of key tractor components like the engine, gearbox, transmission, hydraulic lift, and final tractor assembly.

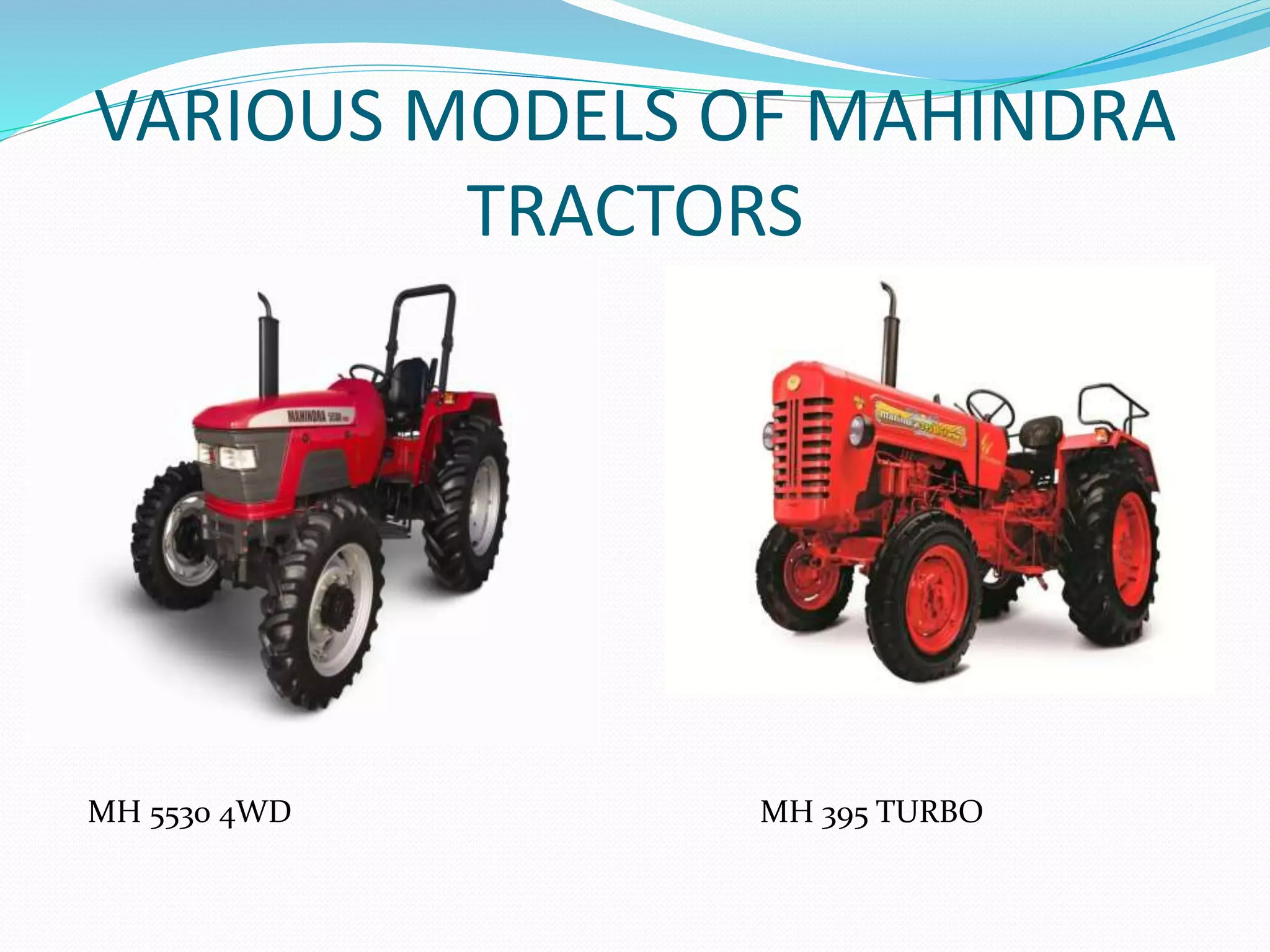

- The training provided insight into Mahindra's tractor models and the manufacturing process at their Jaipur facility.