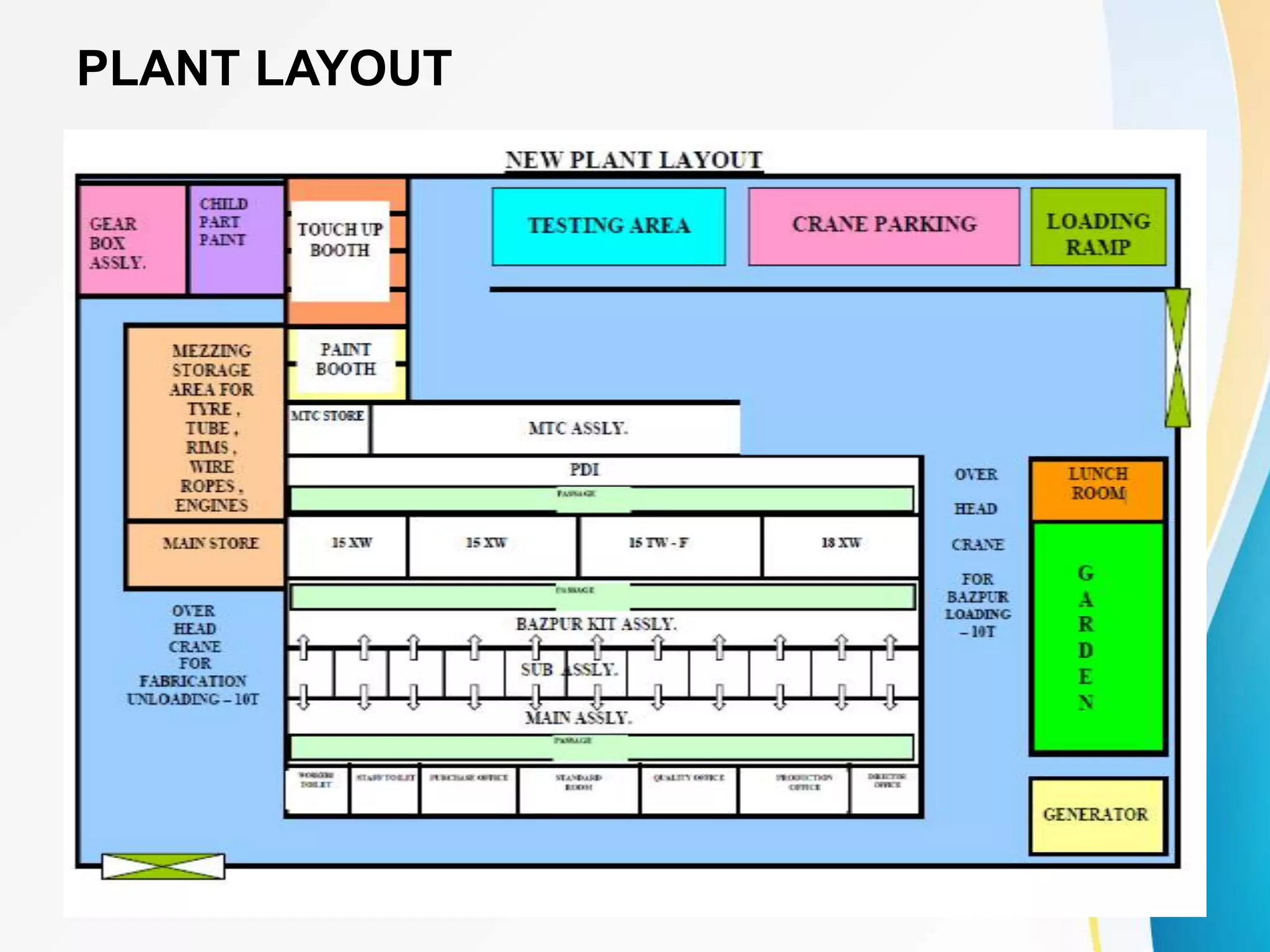

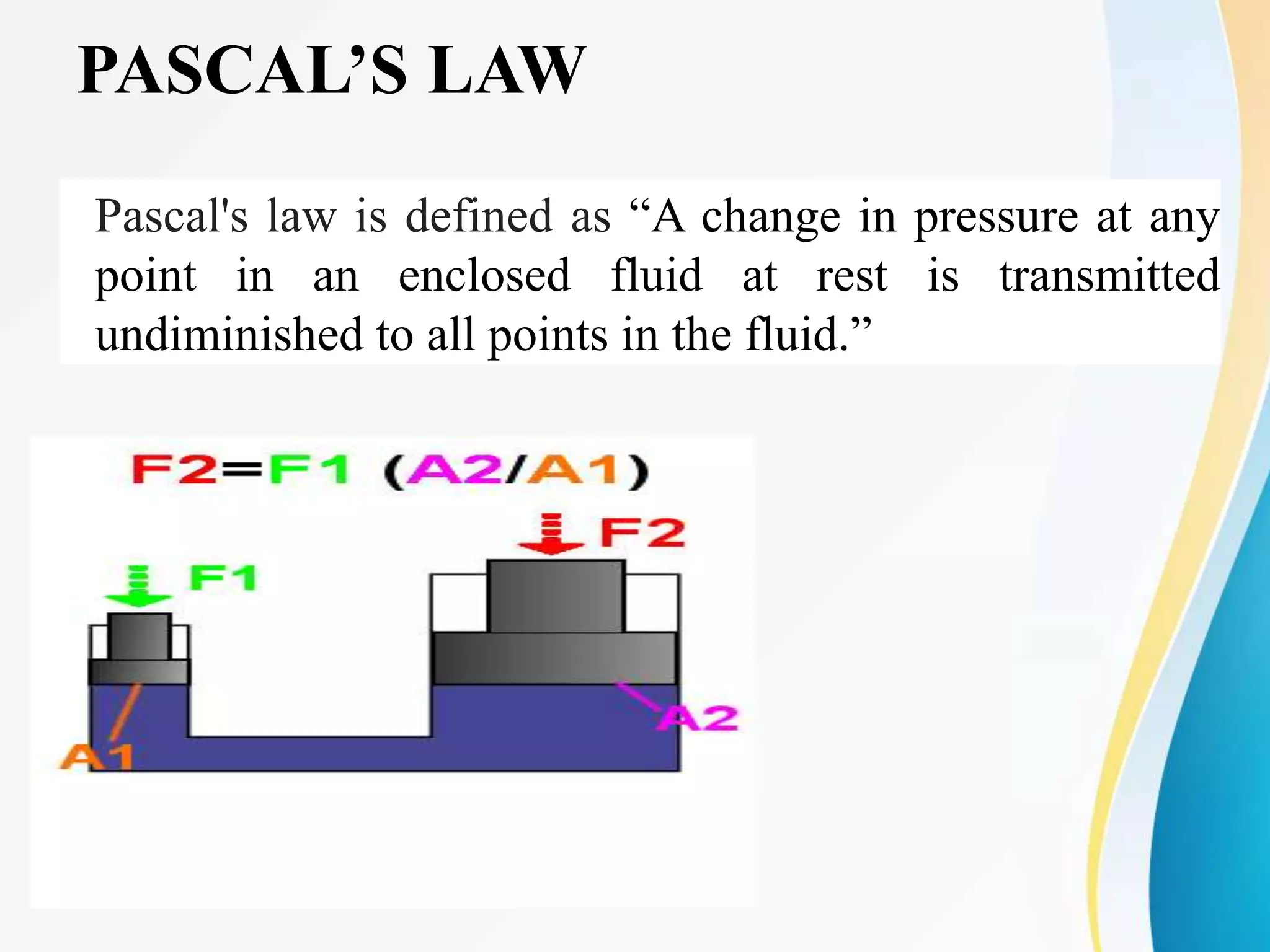

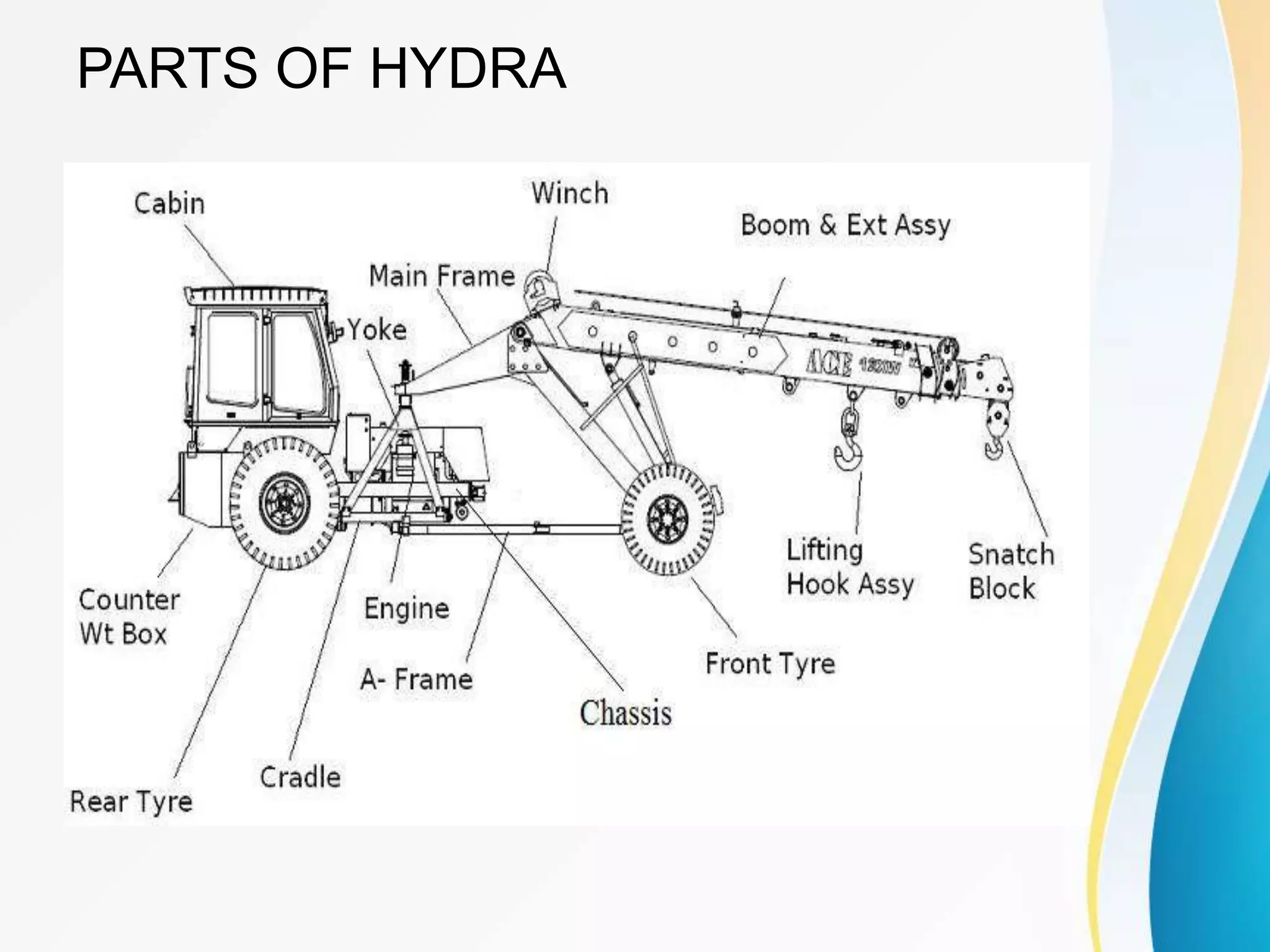

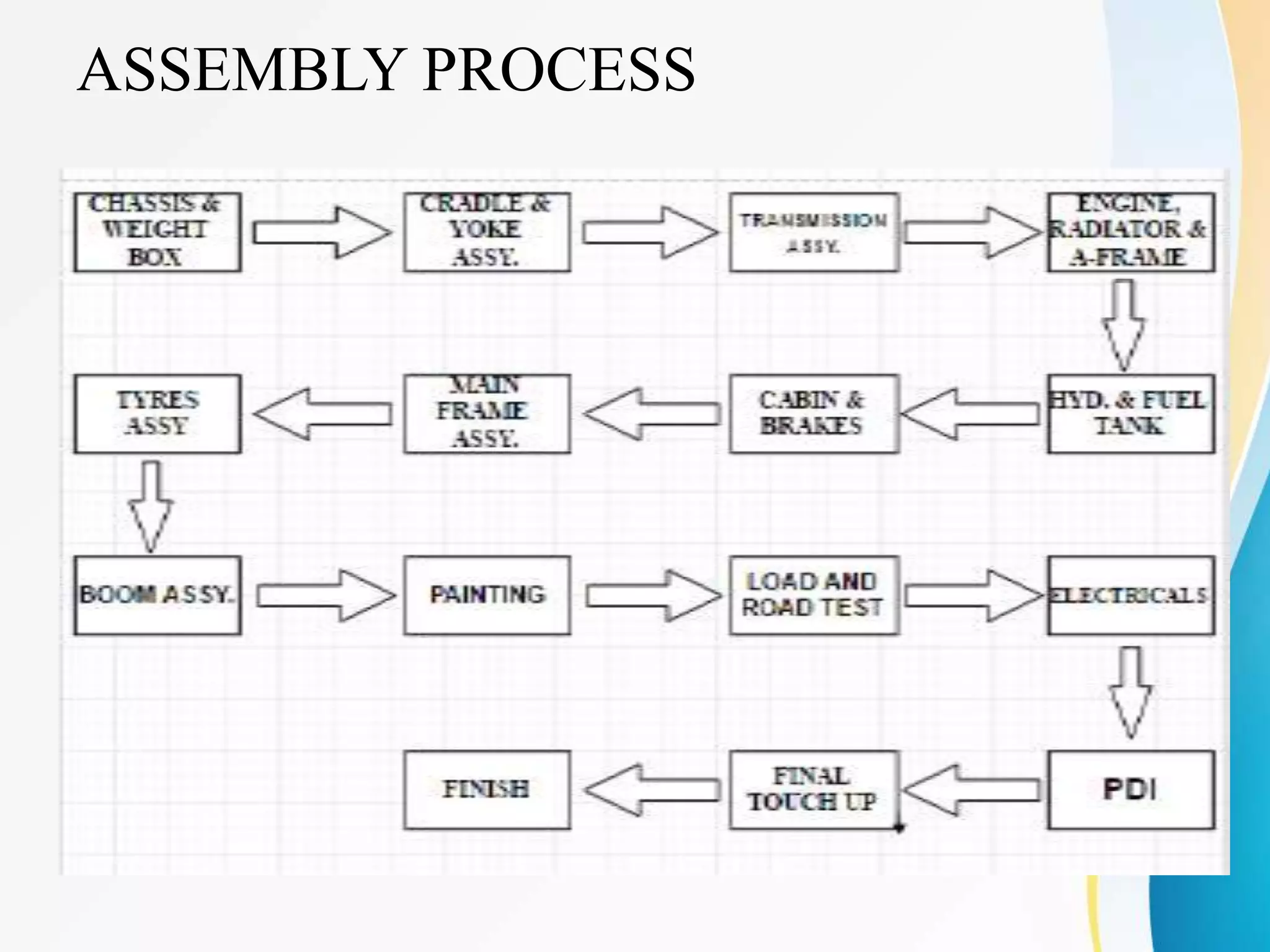

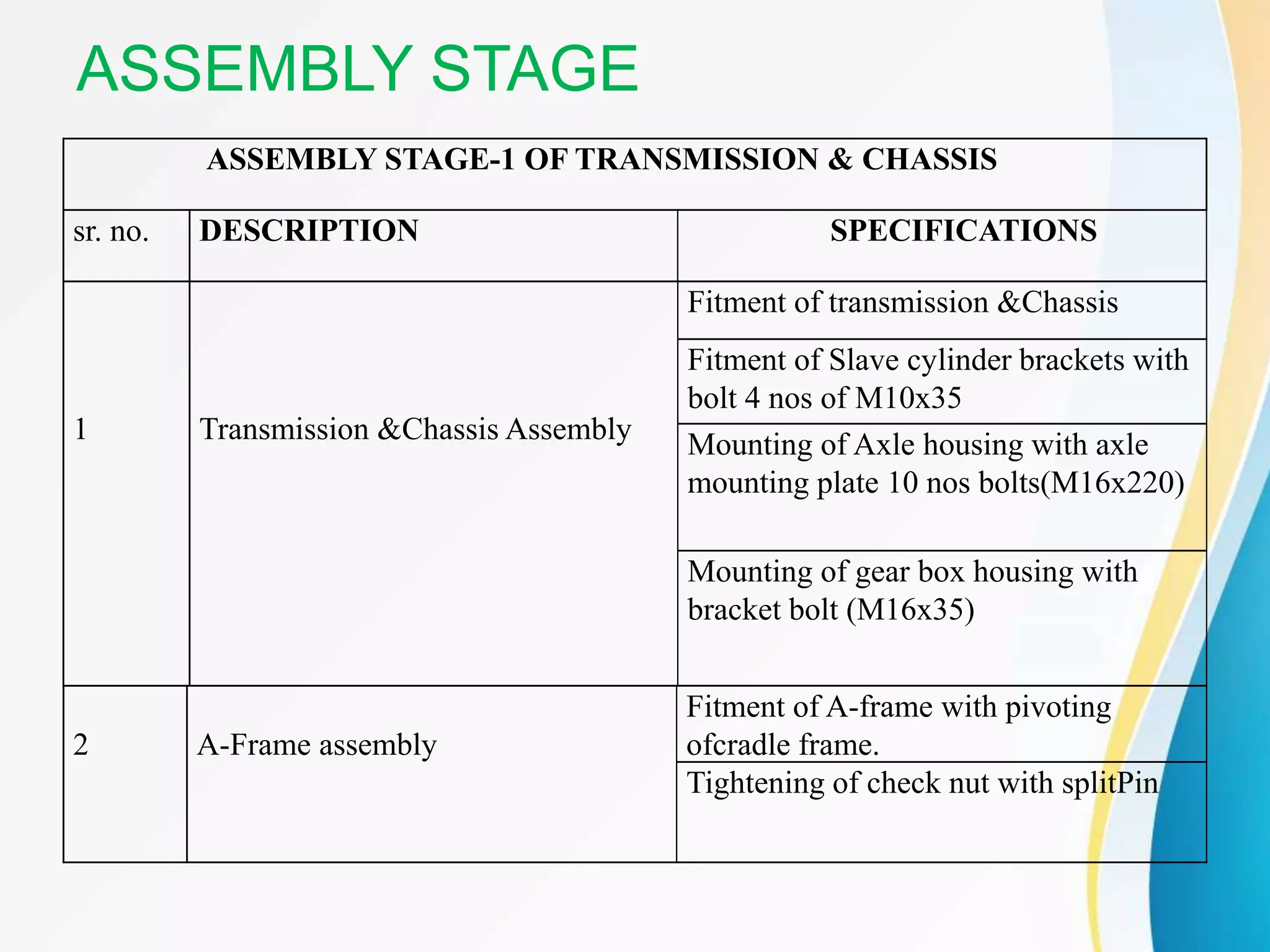

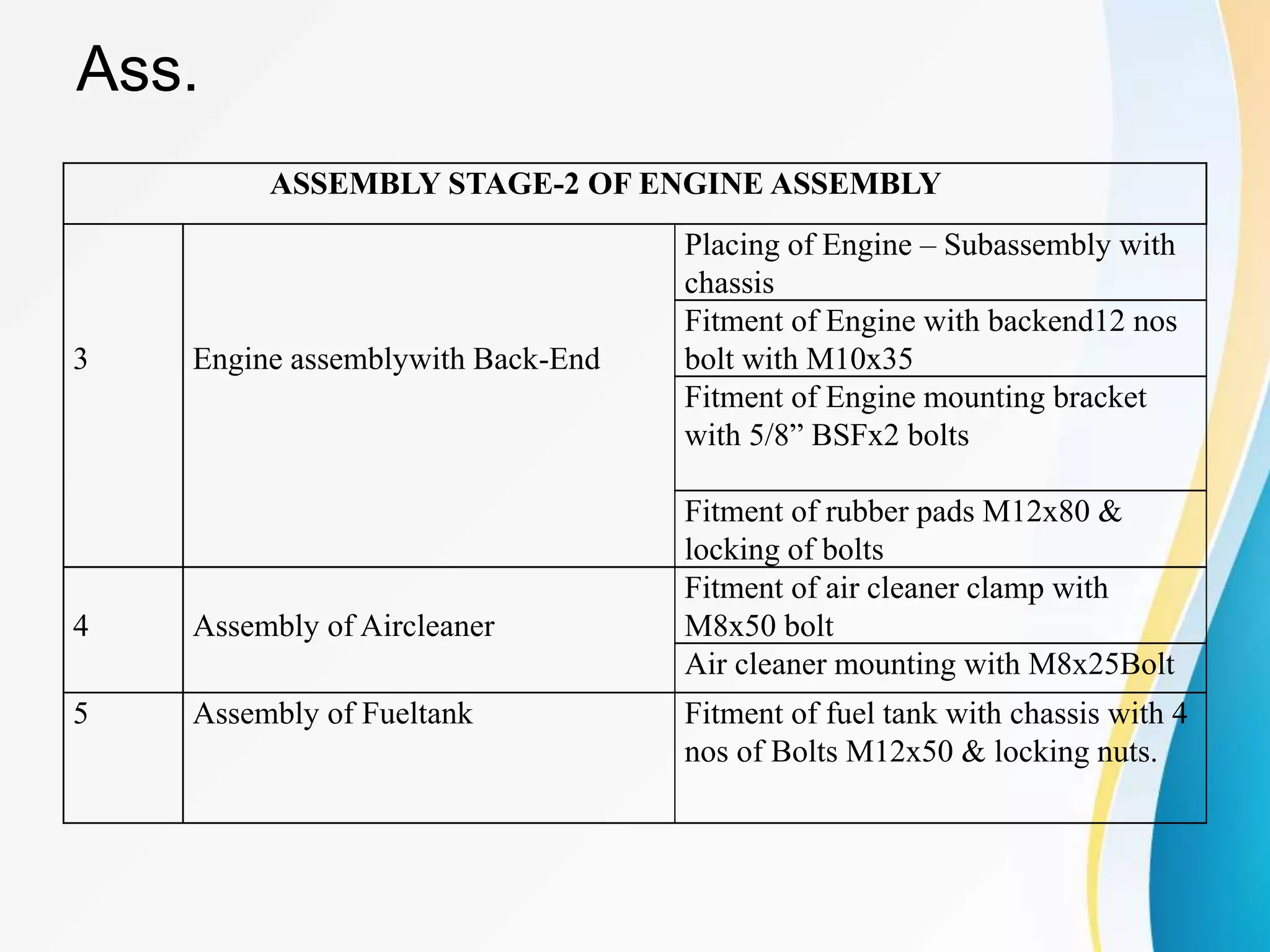

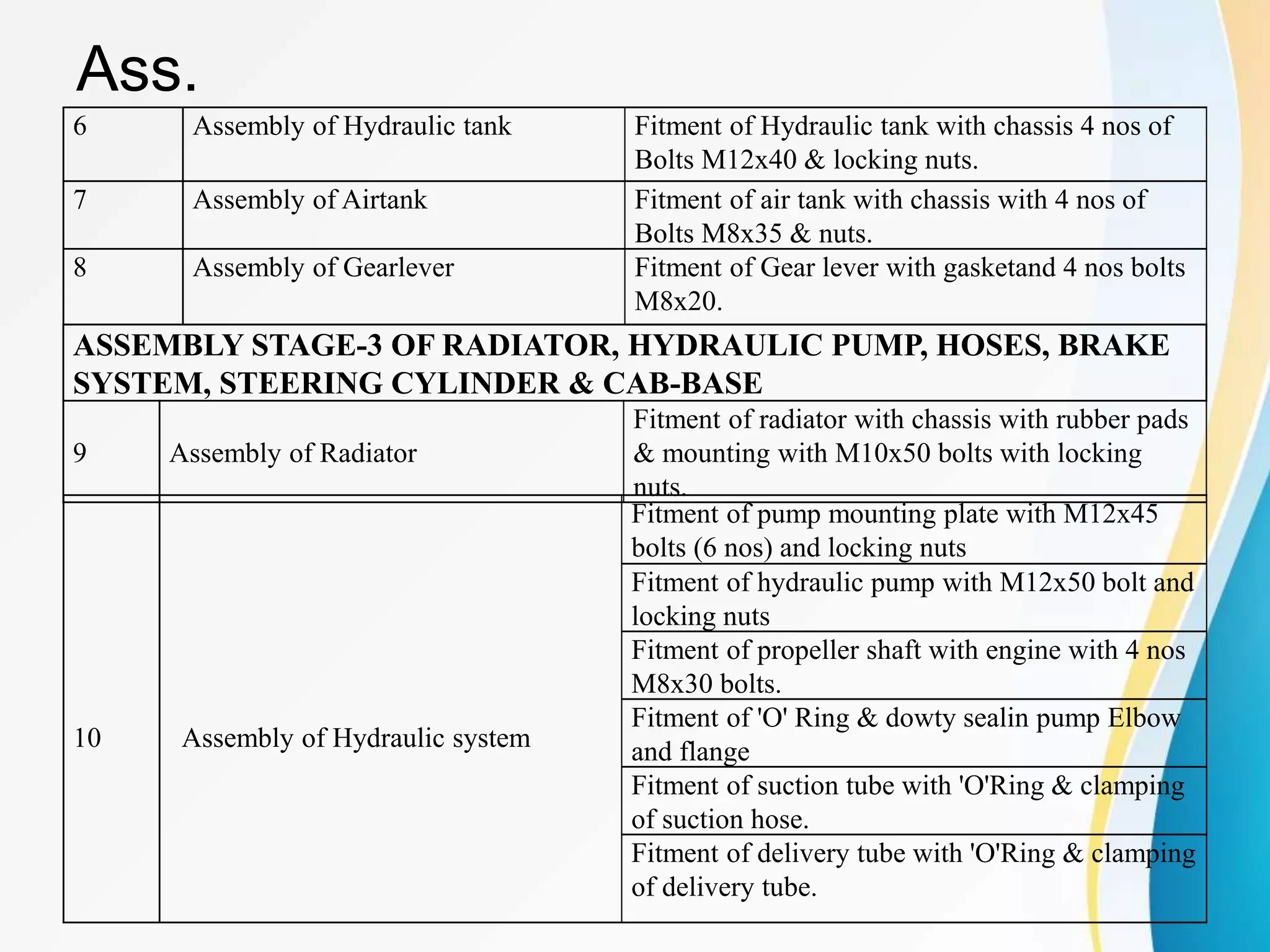

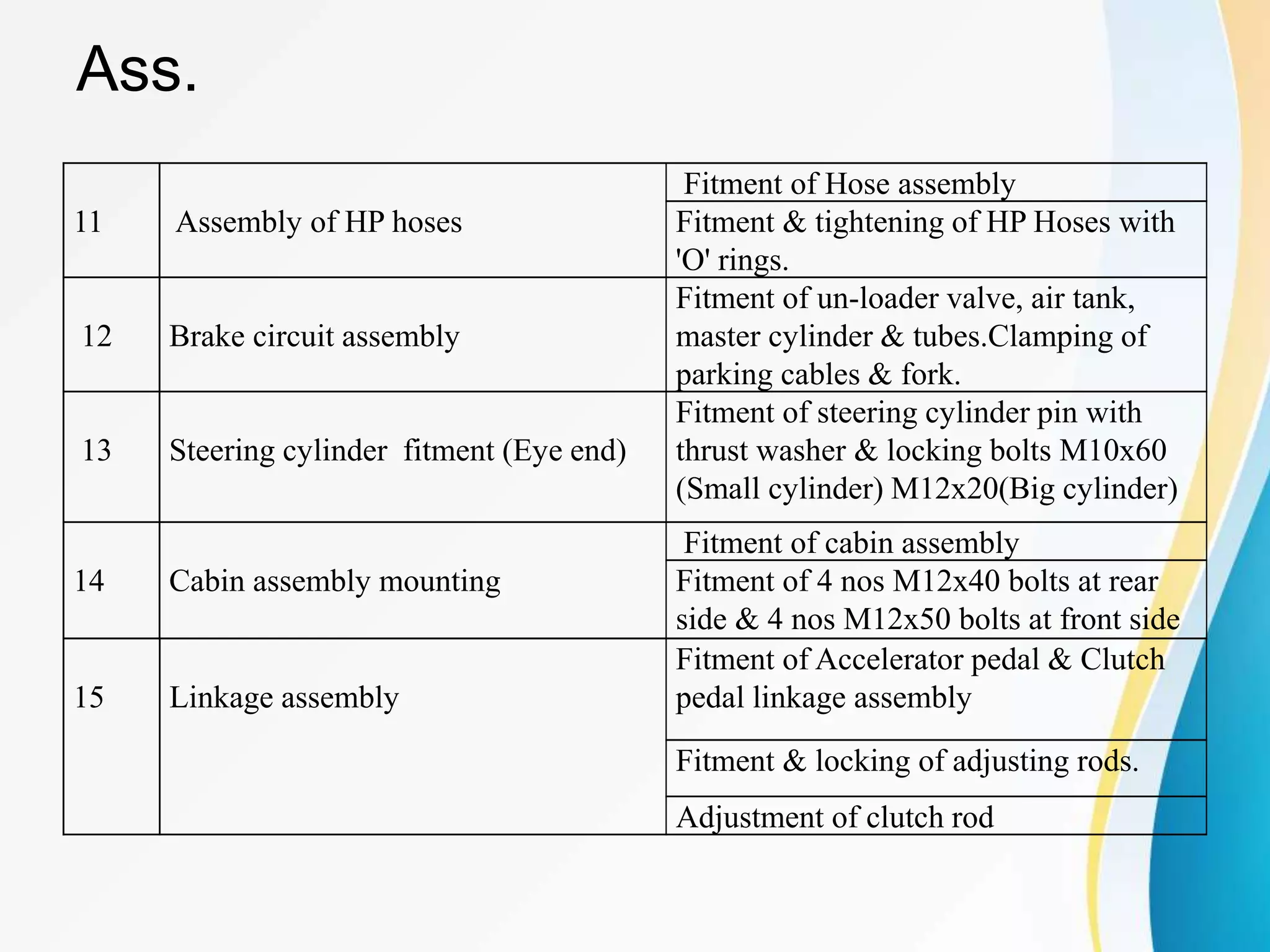

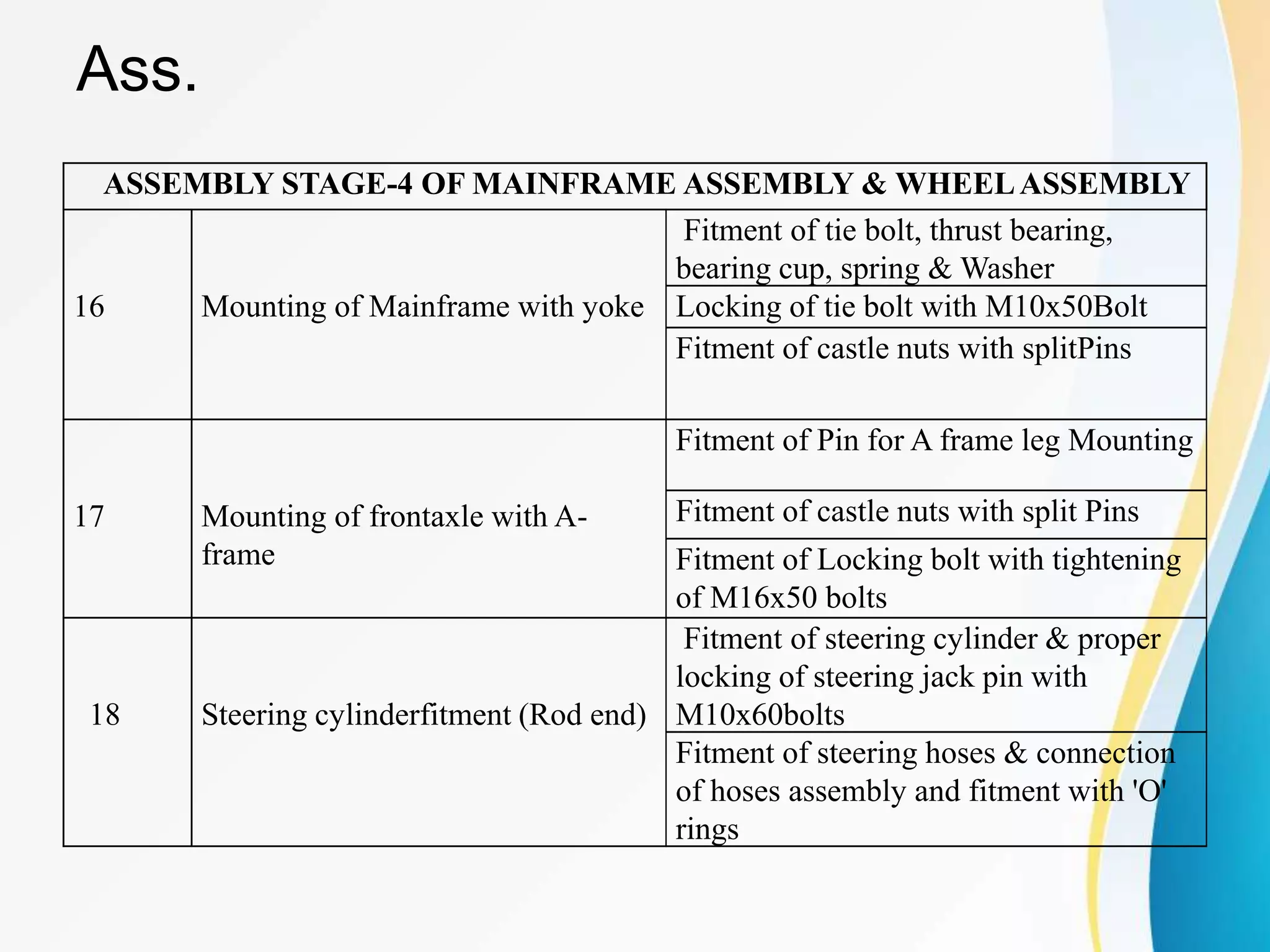

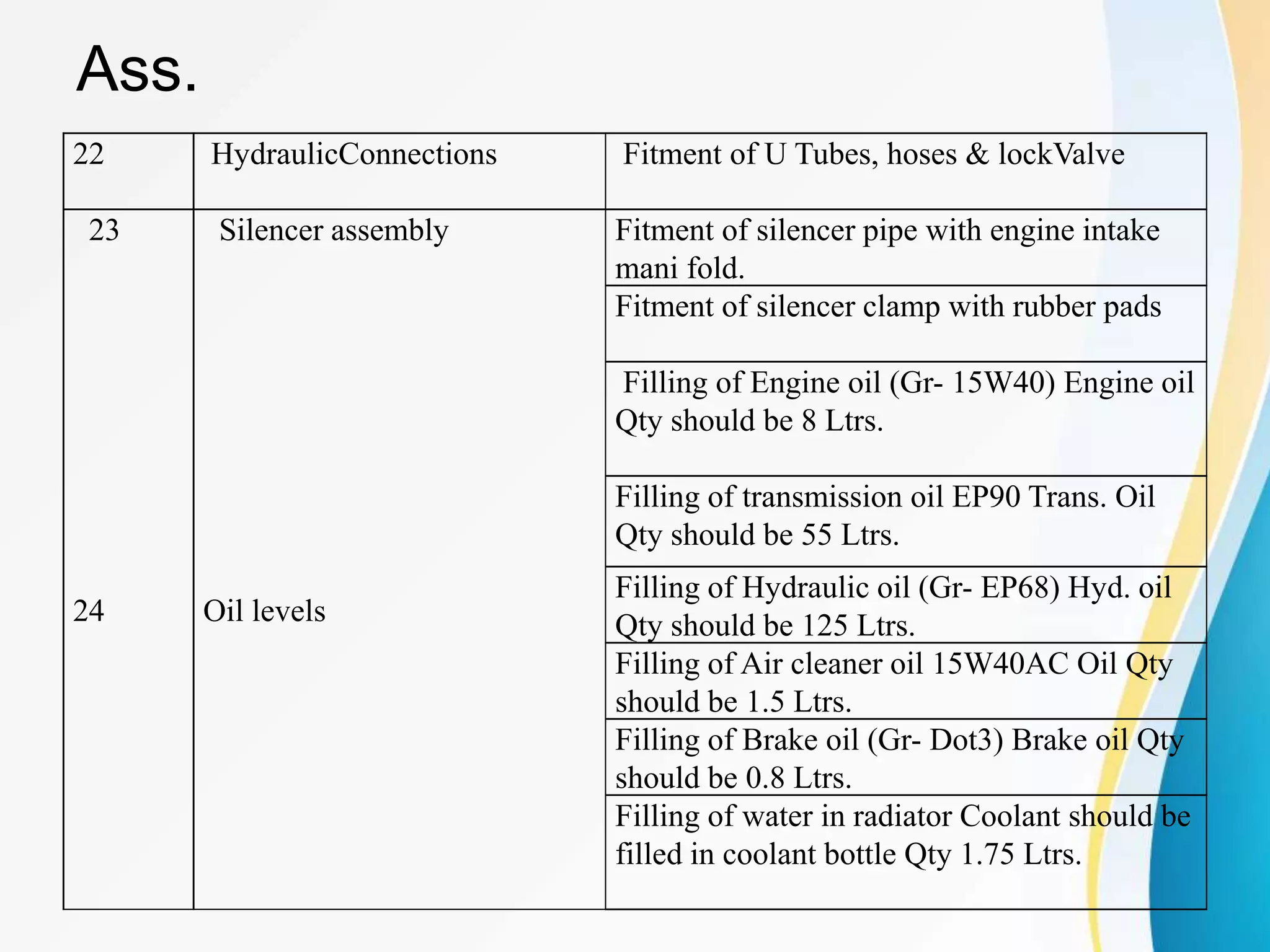

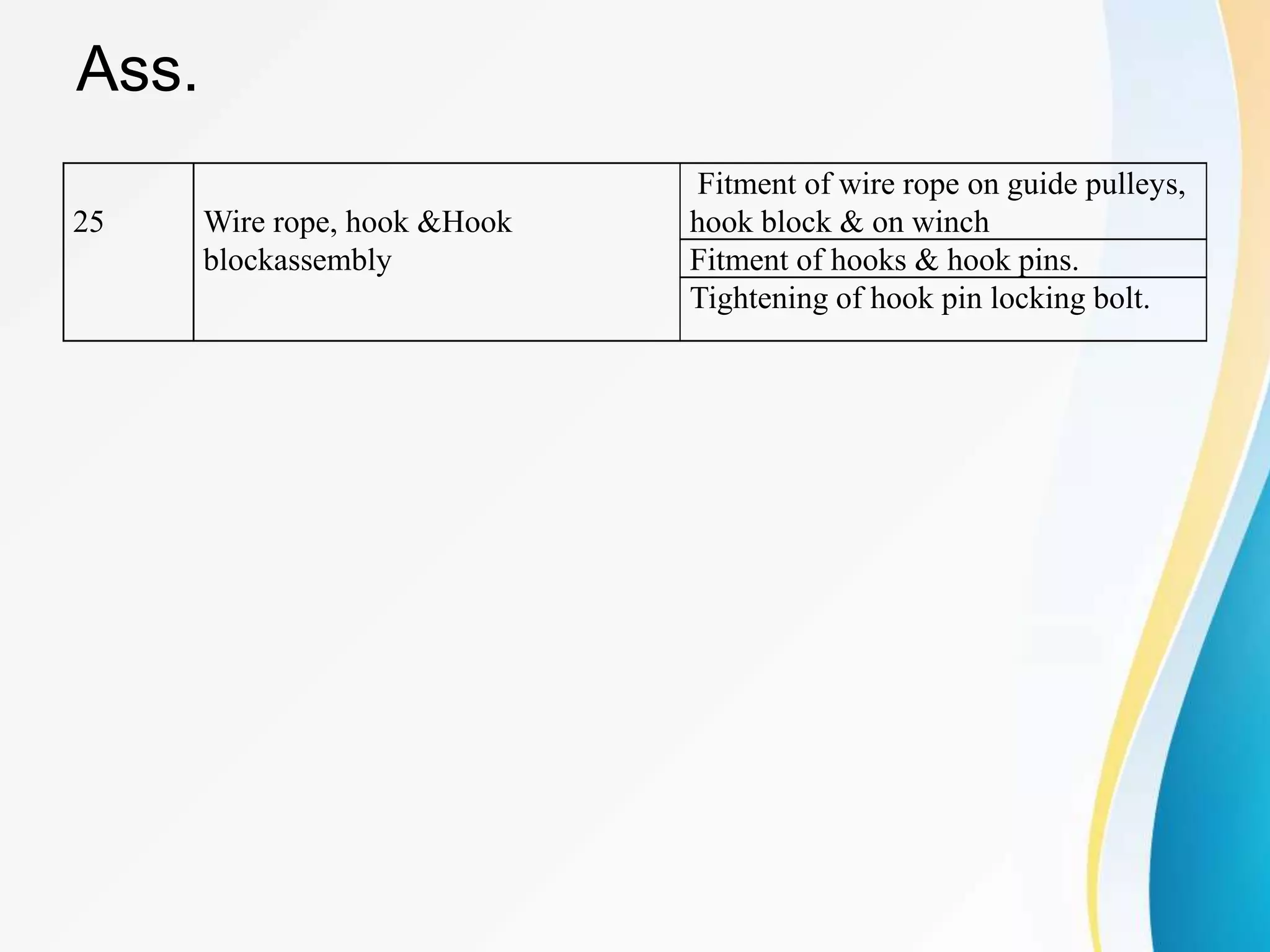

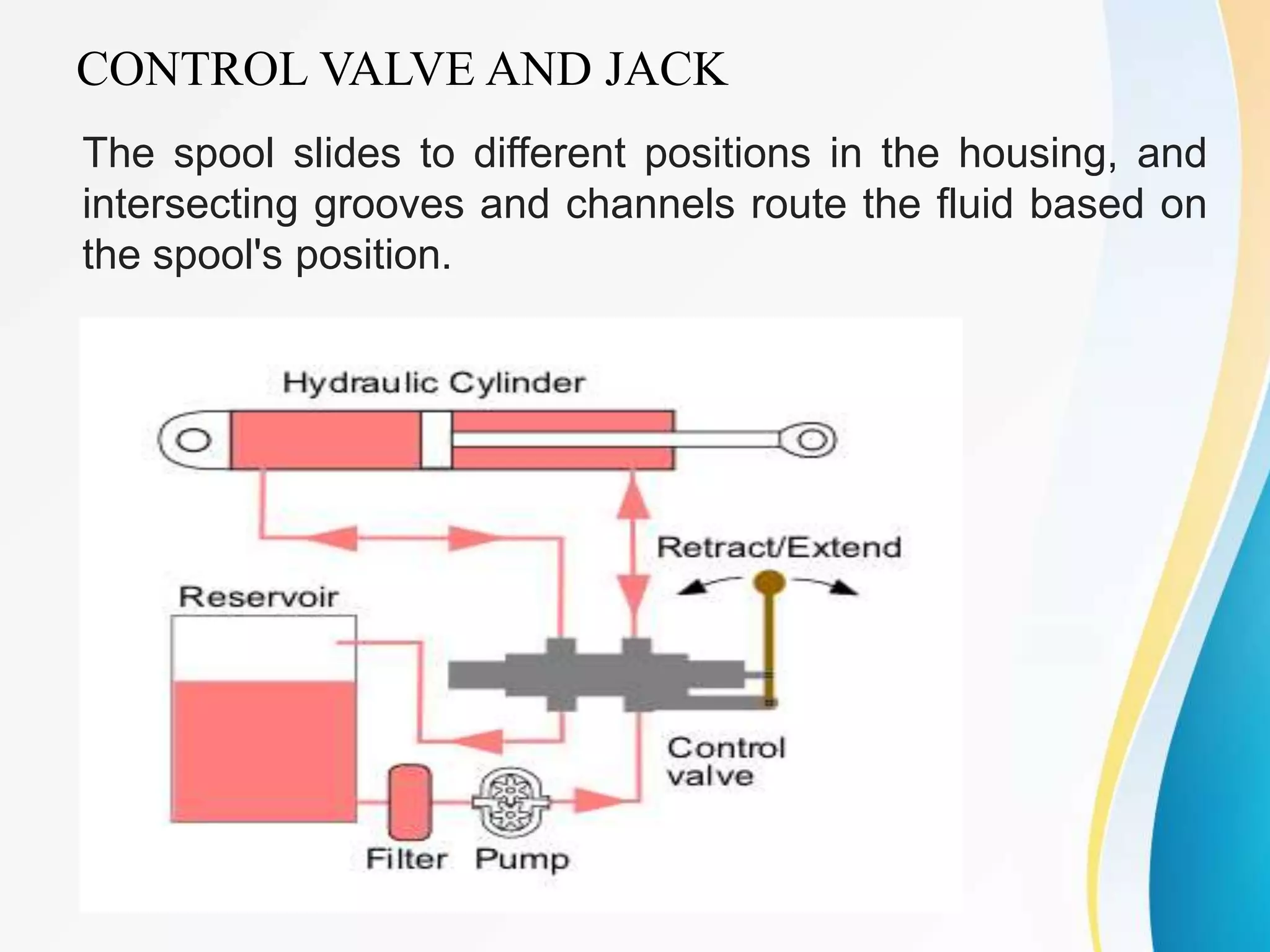

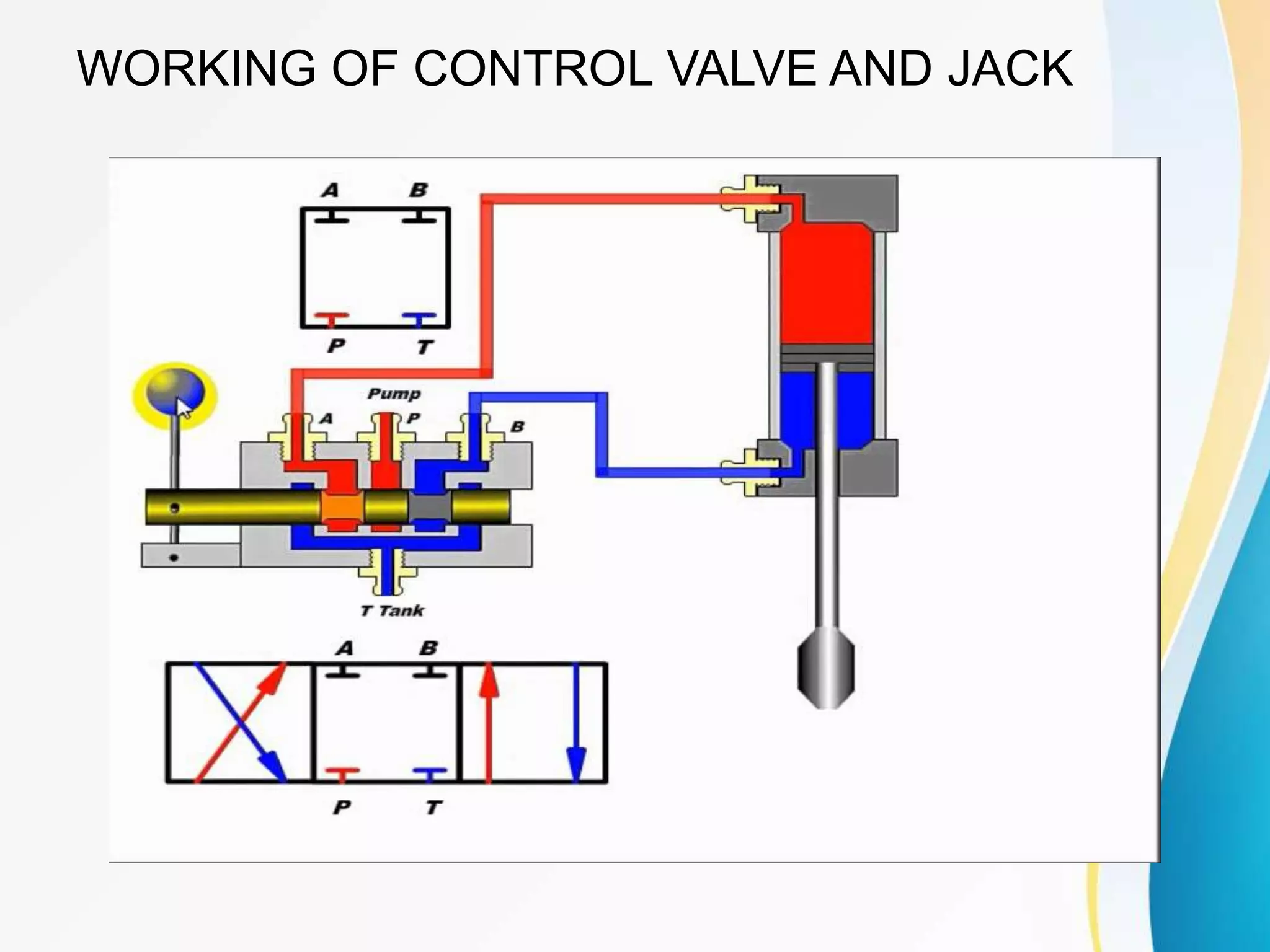

This document summarizes a student's internship project on the layout of an ACE Group plant. It provides background on ACE Group, which is a leading manufacturer of material handling and construction equipment in India. It then describes the assembly process for ACE's hydraulic cranes in 5 stages, covering the assembly of various parts like the transmission, engine, hydraulics, boom, and wheels. It also explains key concepts like Pascal's law that are relevant to hydraulic systems. Finally, it outlines the quality inspection process to check cranes, including incoming, in-line, testing, rework, pre-dispatch, and auditing.