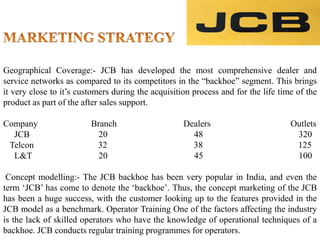

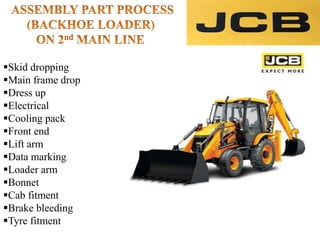

JCB is a leading manufacturer of construction and agriculture equipment founded in 1945 in England with factories worldwide including India, employing over 8,000 people and operating in over 150 countries. JCB produces a wide range of heavy machinery including backhoes, compactors, generators, loaders, excavators and more. The company has the most extensive dealer network of any competitor in the backhoe segment in India.