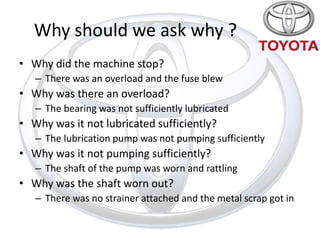

The document summarizes the evolution and key concepts of the Toyota Production System from its origins. It originated from Toyota's textile operations which pioneered the concept of autonomation. The system is centered around just-in-time production and autonomation to eliminate waste. It emphasizes continuous improvement, standard work processes, visual management, and respect for people. In contrast to the American system of mass production and large inventories, Toyota focused on small batch production and the smooth, leveled flow of production.