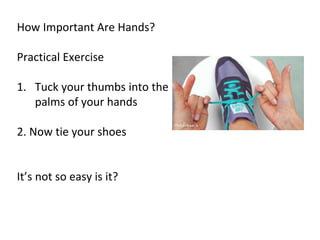

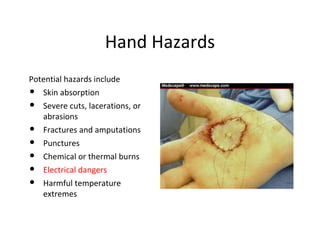

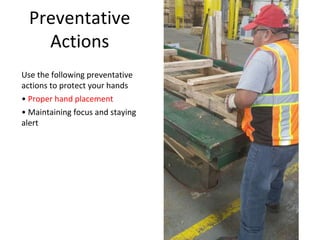

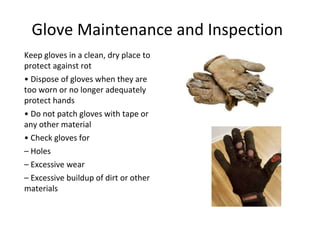

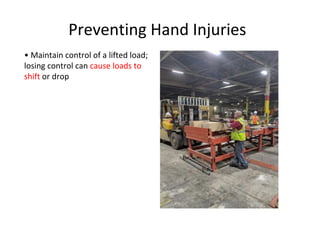

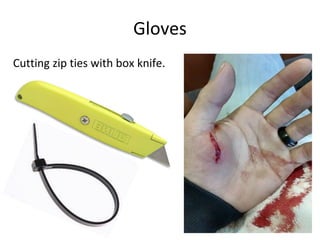

This document discusses hand safety and proper hand protection. It notes that hands are important but vulnerable, as demonstrated by the inability to tie shoes with thumbs tucked inside. The document then outlines common hand injuries like cuts, punctures, sprains and injuries from rotating machinery. It provides examples of past accidents and notes that woodworking and manufacturing jobs commonly involve hand injuries. The document emphasizes choosing the right gloves and PPE for hazards, maintaining focus, and proper preventative actions and precautions to avoid injuries.