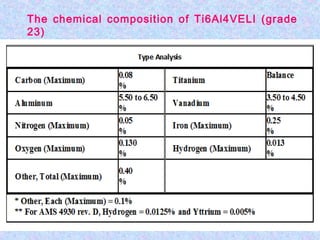

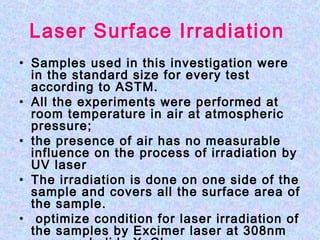

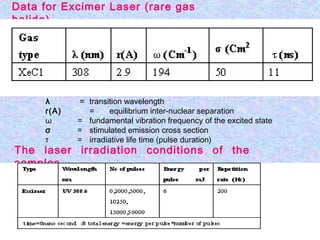

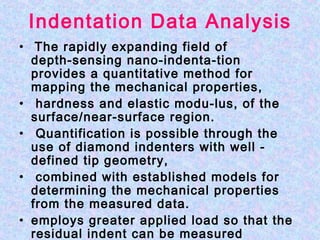

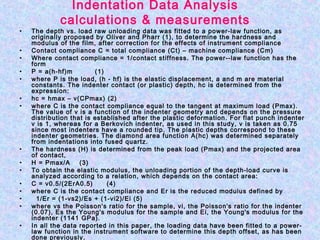

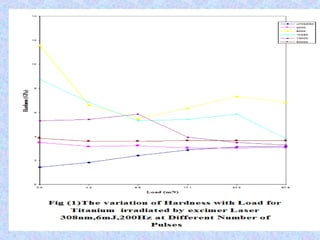

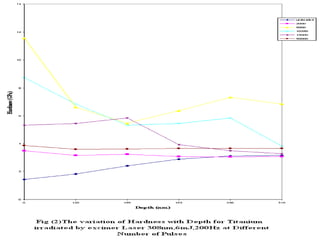

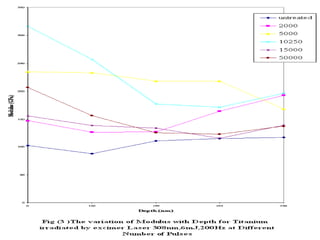

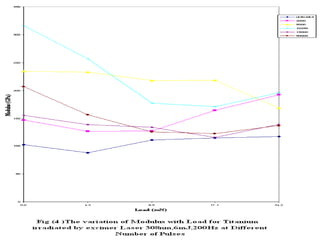

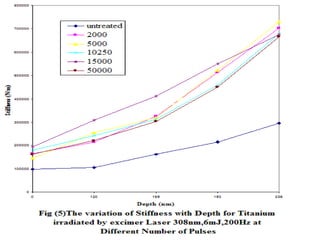

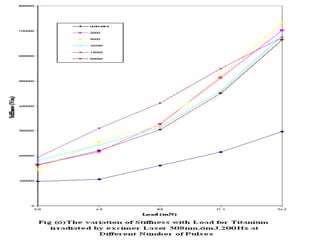

The document investigates the effects of excimer laser irradiation on the properties of the titanium alloy Ti6Al4V, focusing on microstructural changes and mechanical properties such as hardness and modulus. Laser treatment enhanced the alloy's hardness up to 12 GPa and modulus to 330 GPa, with a noted improvement in mechanical properties without thermal damage to the surface. The findings indicate that laser irradiation serves as an effective method for enhancing surface characteristics, providing excellent strength and toughness for various applications.

![INTRODUCTION

• The benefits of titanium to the world are endless. This metal has

completely changed opportunities in medical, chemical processing ,

energy, drilling, aerospace, marine, weaponry, and consumer

industries for ever[1],[2]. Titanium is available in several different

grades. Pure titanium is not as strong as the different titanium

alloys[3].

• The alloy offers the best all-round performance for a variety of weight

reduction applications in aerospace, automotive and marine

equipment. The high strength, low weight ratio and outstanding

corrosion resistance inherent to titanium and its alloys has led to a

wide and diversified range of successful applications which demand

high levels of reliable performance in surgery and medicine as well

as in aerospace, automotive, chemical plant, power generation, oil

and gas extraction, sports, and other major industries. In the majority

of these and other engineering applications, titanium replaces

heavier, less serviceable or less cost-effective materials. Designs

made using the properties provided by titanium often result in

reliable, economic and more durable systems and components[4],

[5].](https://image.slidesharecdn.com/tinano-170416103503/85/Ti-nano-4-320.jpg)

![Qualitative analysis

Metallographic Examinations

The specimens were prepared by:-

• grinding on different grades of silicon carbide "SiC“

• coarse grinding followed by fine grinding at 180,240,320,400,600, and

800

• polishing was conducted with Alumina powder (3µm) size.

• The details of the microstructure were revealed after etching by

standard etching solution of the alloy selected.

• All specimens had to be etched and polished several times to obtain

best results and to produce a uniform level of sample examination.

• The surfaces of the samples before and after laser irradiation were

examined using an Olympus optical microscope Model BHM at selected

magnification[20].](https://image.slidesharecdn.com/tinano-170416103503/85/Ti-nano-11-320.jpg)

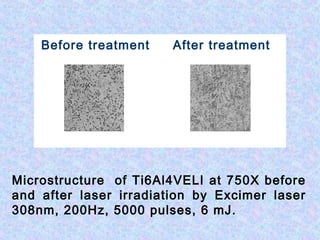

![• This microstructural morphology, consisting of these sets of

parallel plates which have formed with a crystallographic

relationship to the phase from which they formed, is called a

Widmanstatten structure[21]. The laser irradiation of the alloy

is similar action to cooling rapidly , the relatively higher thermal

conductivity of titanium alloy Ti6Al4VELI which is about

0.219W/cmK, β may decompose by a martensite reaction,

similar to that for pure Ti, and form a Widmanstatten pattern.

Different types of martensite may form depending upon the

alloy chemistry and the quenching temperature[29],[30].

• Since in a given β grain there are six sets of nonparallel growth

planes, then a structure of a plates is formed consisting of six

nonparallel sets. The Widmanstatten microstructure developed

So laser treated Ti-6Al-4V has an excellent combination of

strength and toughness along with excellent performance there

is no change in shape and appearance, it has found extended

application of laser irradiation techniques mentioned in this

work because of useful mechanical properties produced by

surface treatments.](https://image.slidesharecdn.com/tinano-170416103503/85/Ti-nano-20-320.jpg)