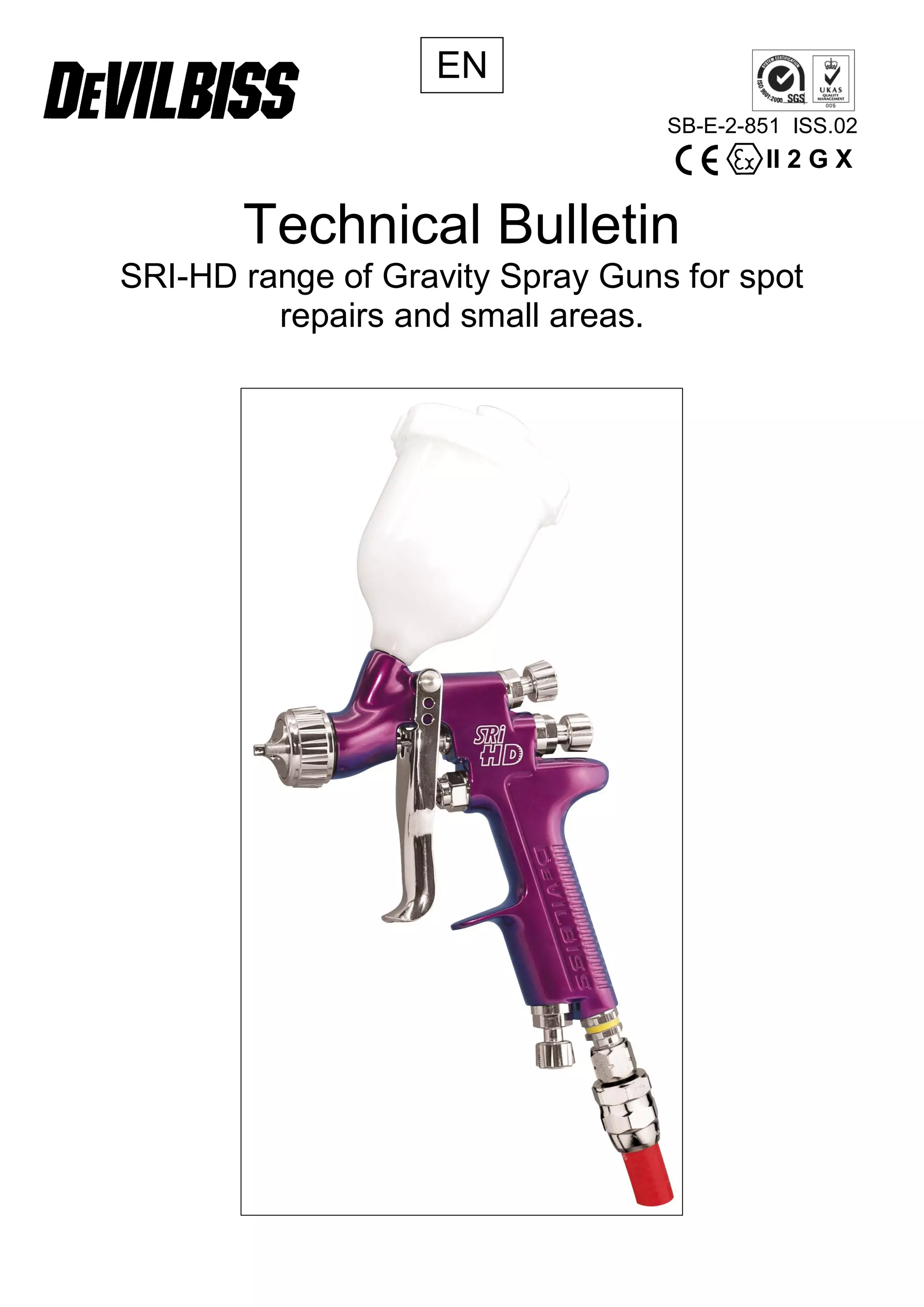

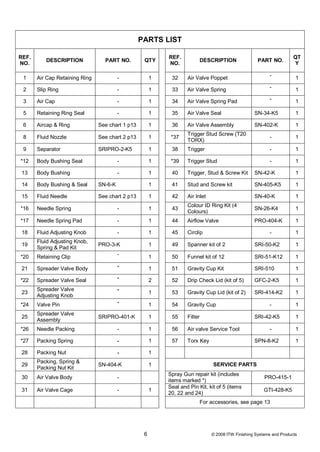

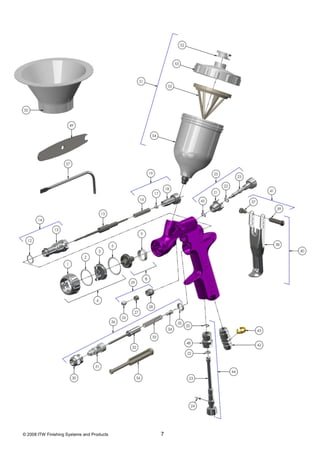

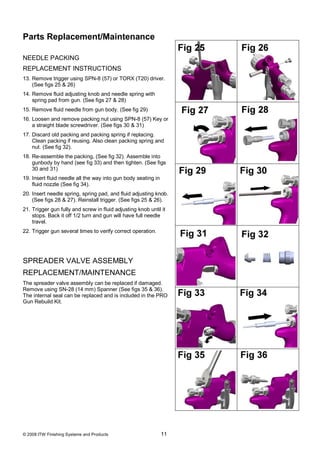

This technical bulletin provides information on the SRI-HD range of gravity spray guns for spot repairs and small areas. It includes details on part numbers, operational description, kit contents, construction features, materials, specifications, safety precautions, parts lists, exploded views, installation, operation, preventative maintenance, cleaning, parts replacement, troubleshooting, accessories, and warranty. Installation and operation instructions emphasize the importance of using the proper air pressure and cleaning procedures. Safety warnings cover fire hazards, personal protective equipment, training, and misuse.