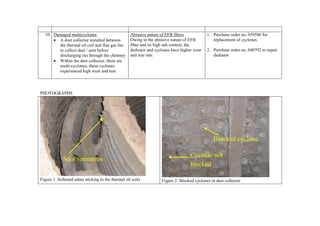

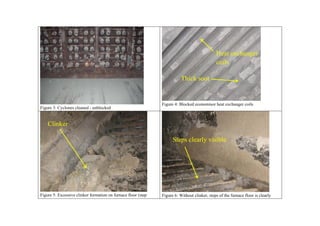

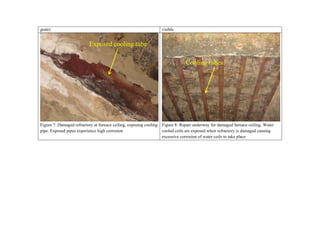

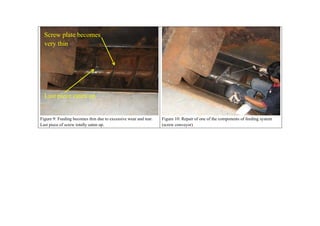

This document outlines several operational challenges faced when using empty fruit bunches (EFB) as a biomass fuel in a furnace. The key challenges included furnace draft issues from ash deposits, clinker formation from ash melting, high furnace temperatures due to low fuel calorific value, overestimation of fuel density leading to conveyor issues, damage to moving floors from abrasive EFB fibers, and overcurrent of screw conveyors also due to abrasive EFB fibers. The root causes of these challenges stemmed from inherent properties of EFB fibers like low ash melting point, low density, abrasiveness, and tendency to entangle.