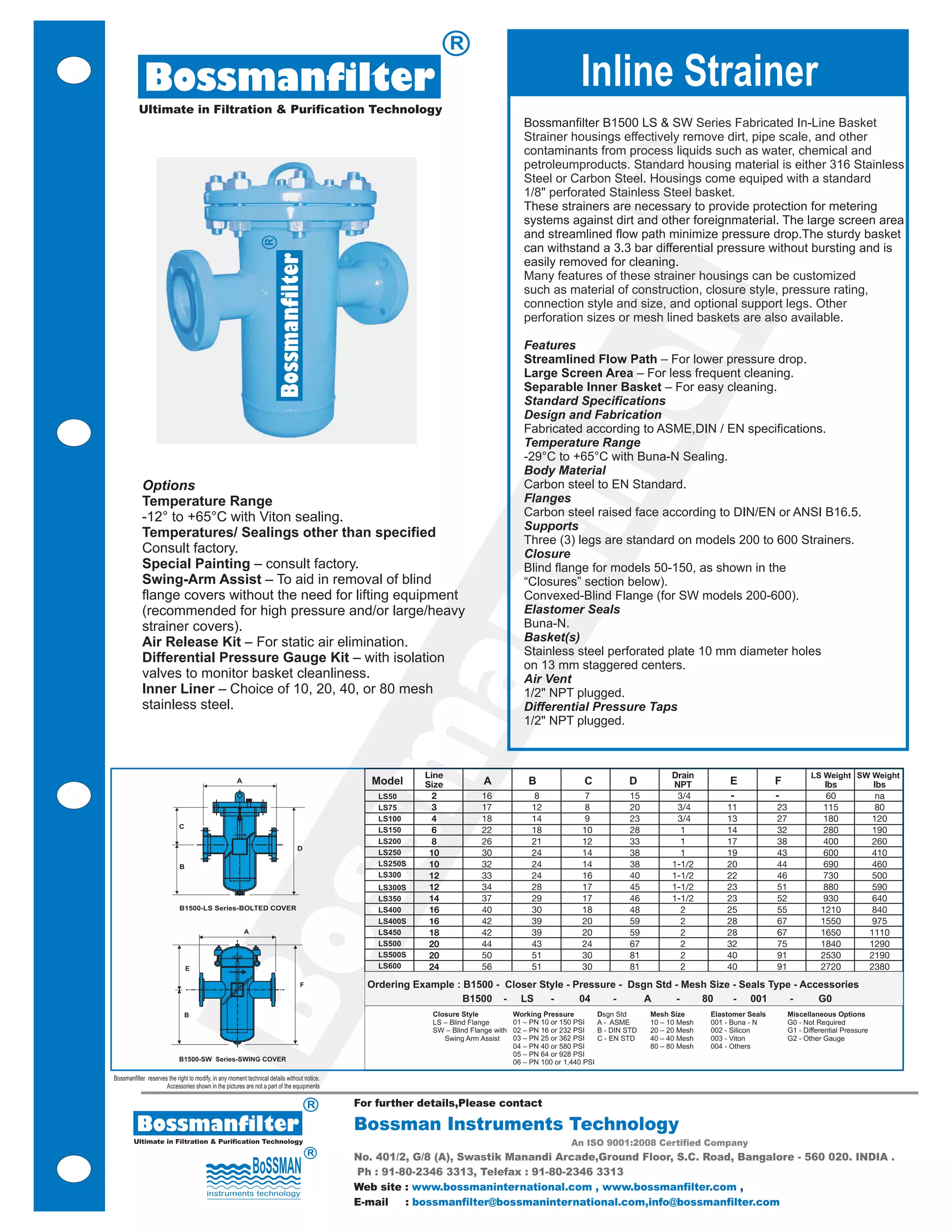

The document describes Bossmanfilter B1500 LS & SW Series in-line basket strainer housings. [1] The strainers remove contaminants like dirt and scale from liquids to protect metering systems. [2] They have a streamlined flow path for low pressure drop and a large screen area requiring less frequent cleaning. [3] The strainers come in carbon steel or stainless steel with standard 1/8" perforated stainless steel baskets.