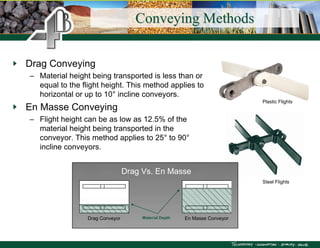

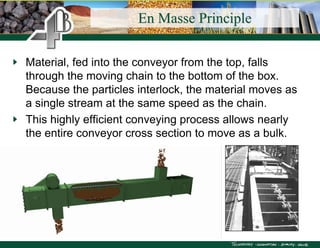

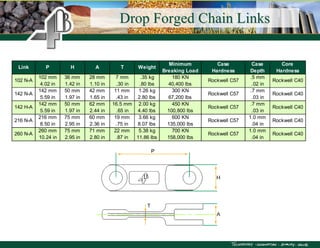

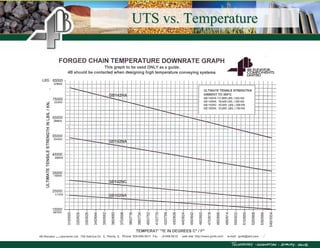

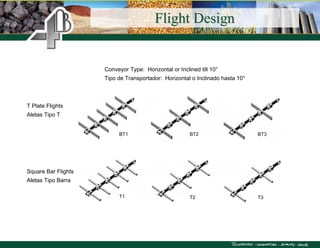

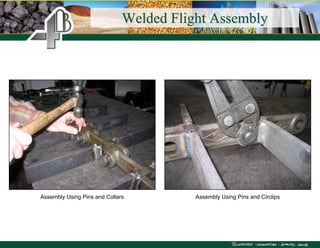

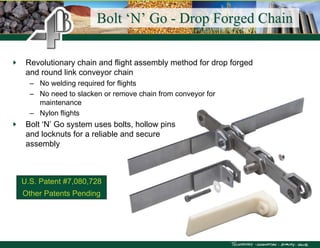

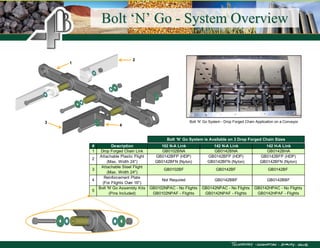

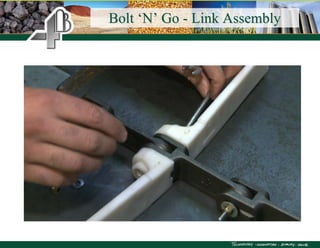

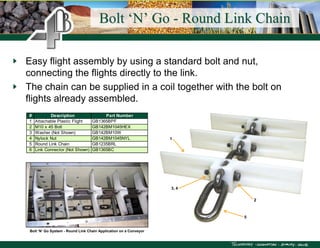

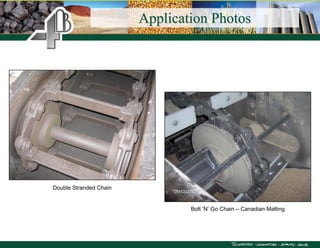

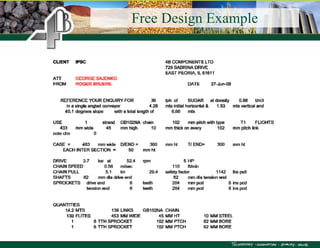

The document provides an overview of drop forged chain options and accessories for various conveying methods, including drag and en masse conveying. It details specifications, applications across multiple industries, and introduces the 'bolt-n-go' assembly method that simplifies maintenance by eliminating the need to remove chains during flight replacement. Additionally, a testimonial highlights the advantages of the bolt-n-go system in real-world applications.