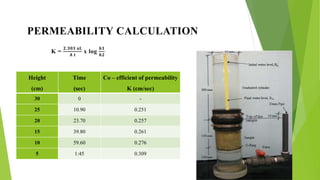

This document investigates the use of permeable concrete for pedestrian pathways. It finds that permeable concrete with a 15% addition of silica fume achieves the highest compressive strength of 20N/mm2. Testing shows that permeable concrete with an aggregate to cement ratio of 2.78:1 and 12.5mm coarse aggregates has a high coefficient of permeability of 0.271cm/sec while maintaining sufficient strength. The document concludes that mixtures using these parameters produce permeable concrete suitable for pavement applications.