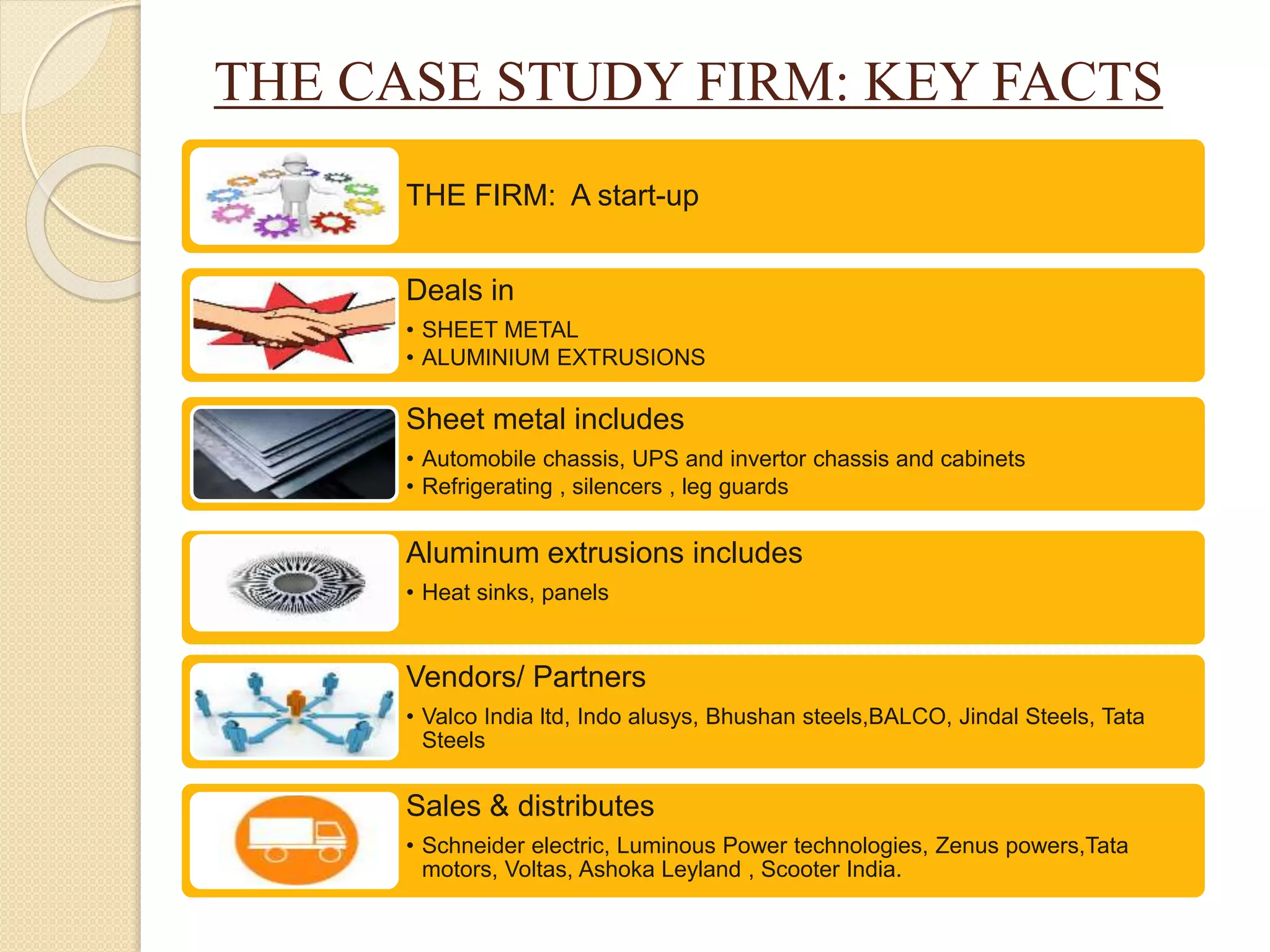

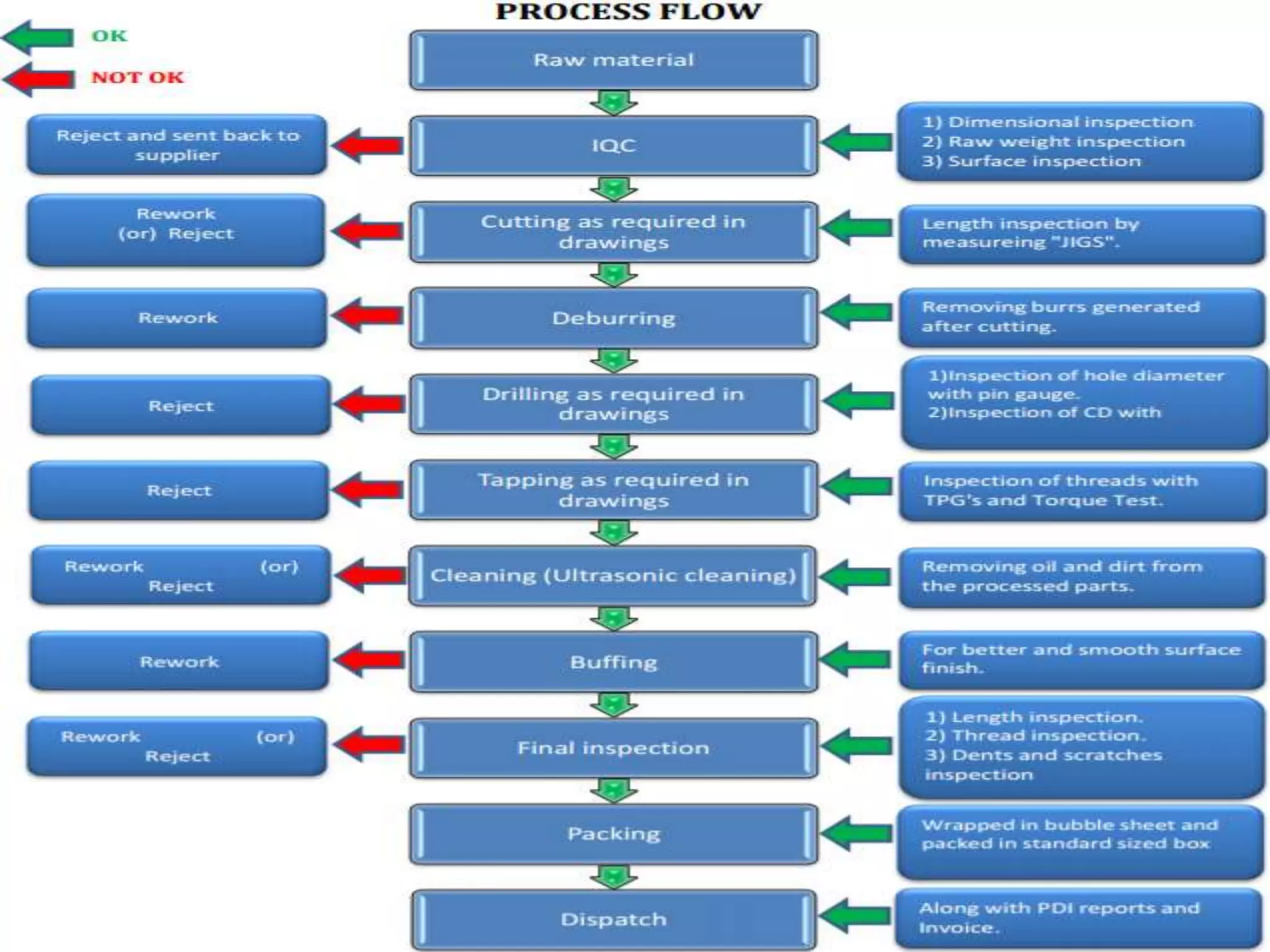

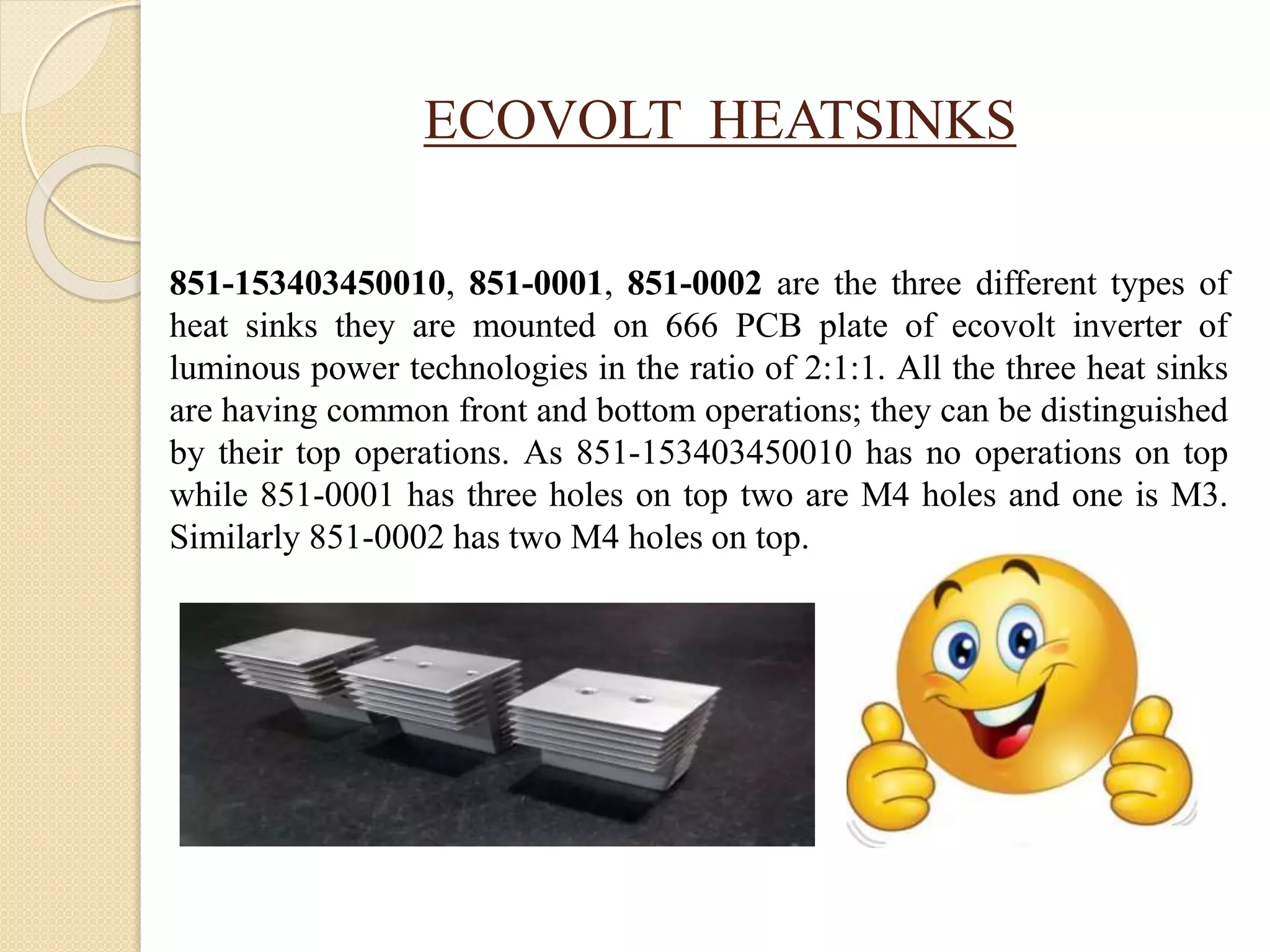

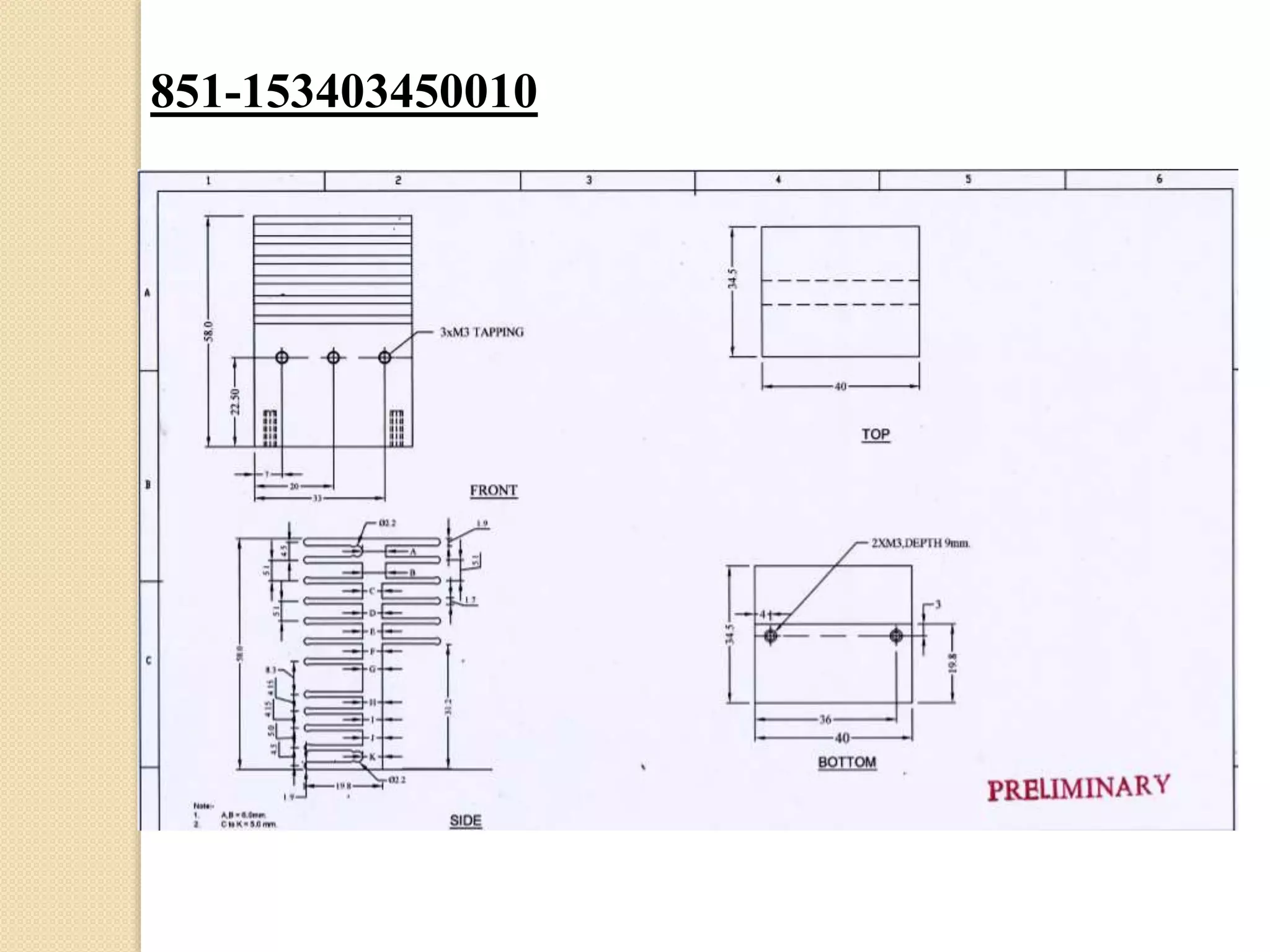

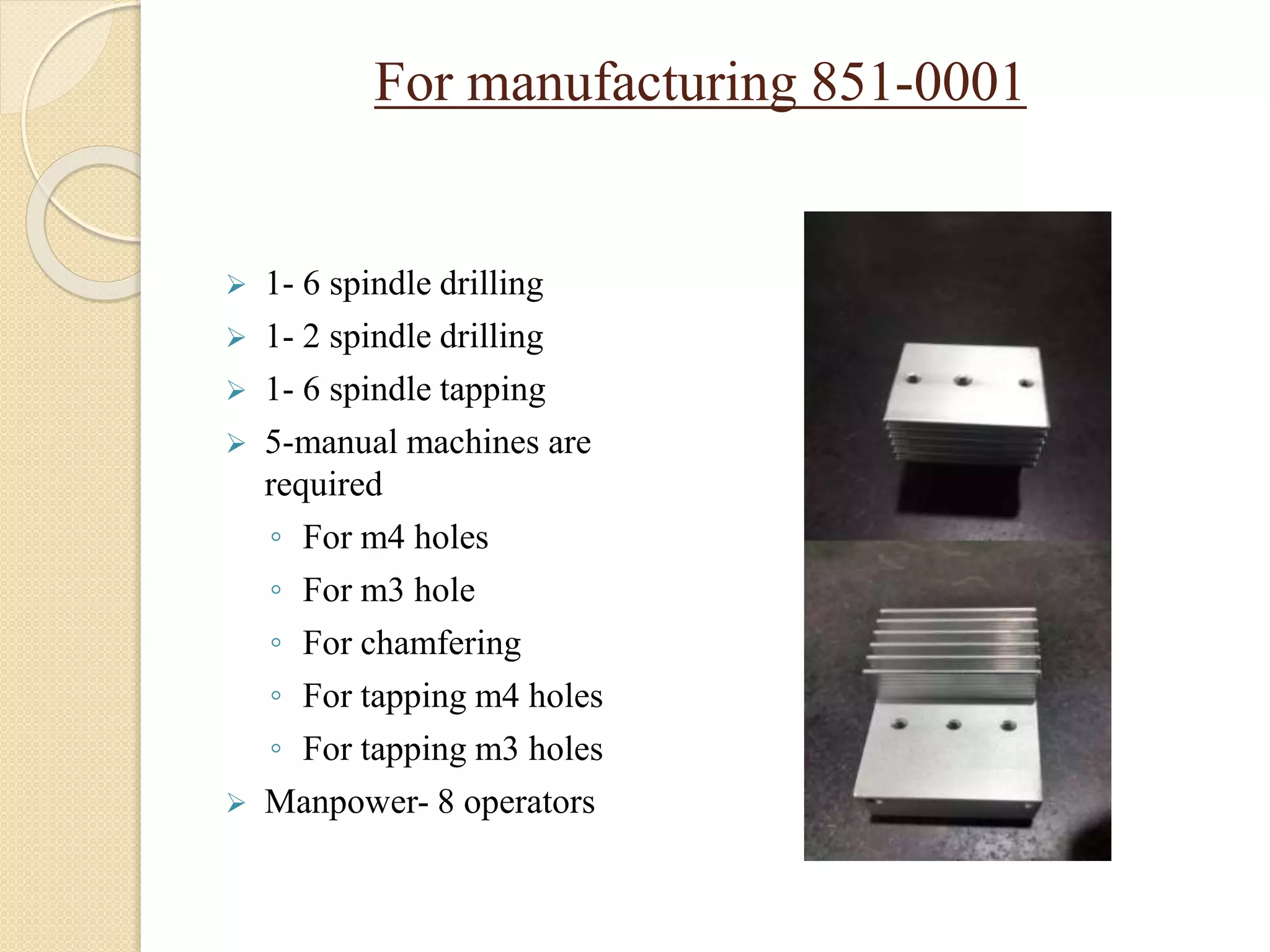

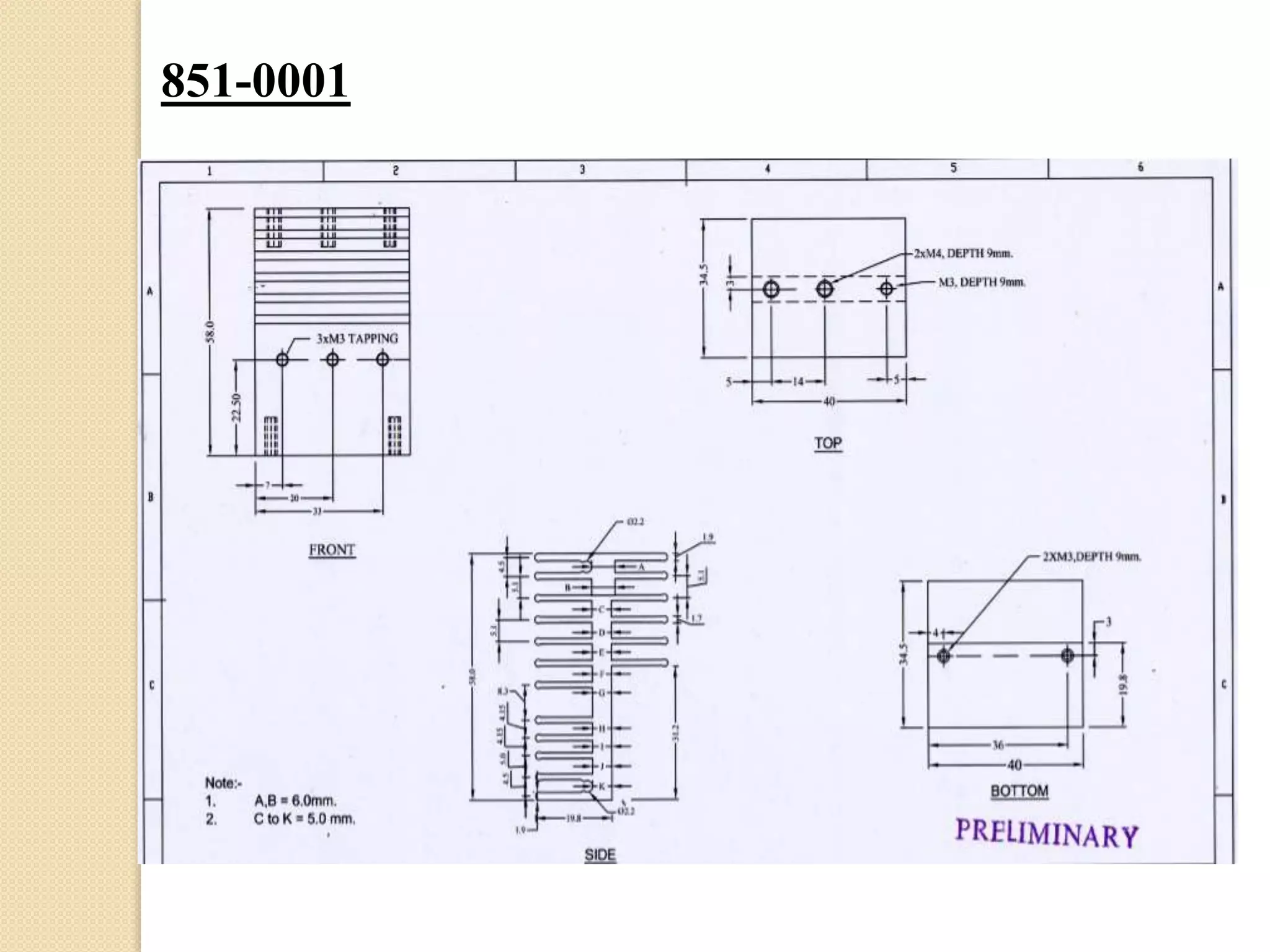

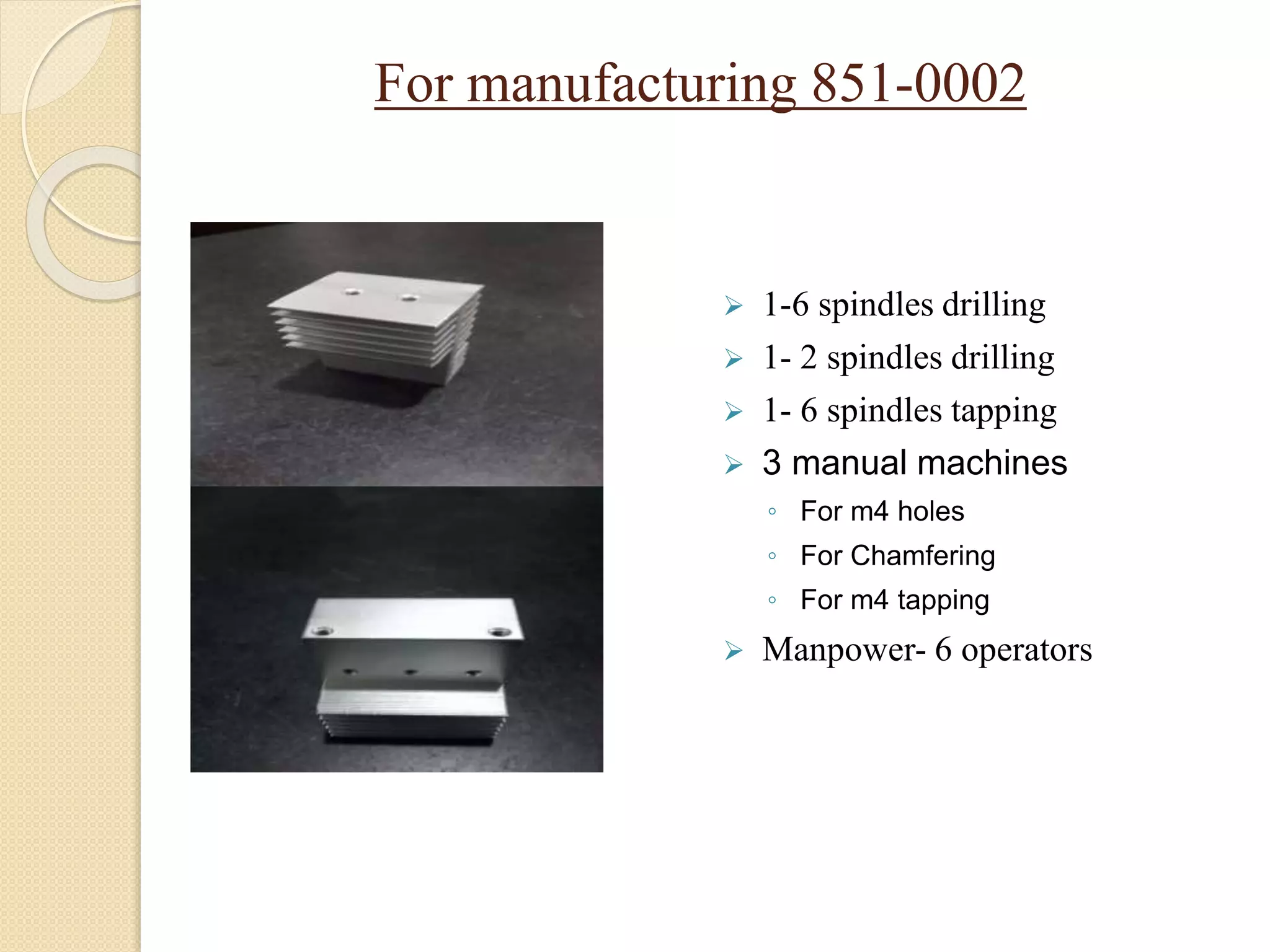

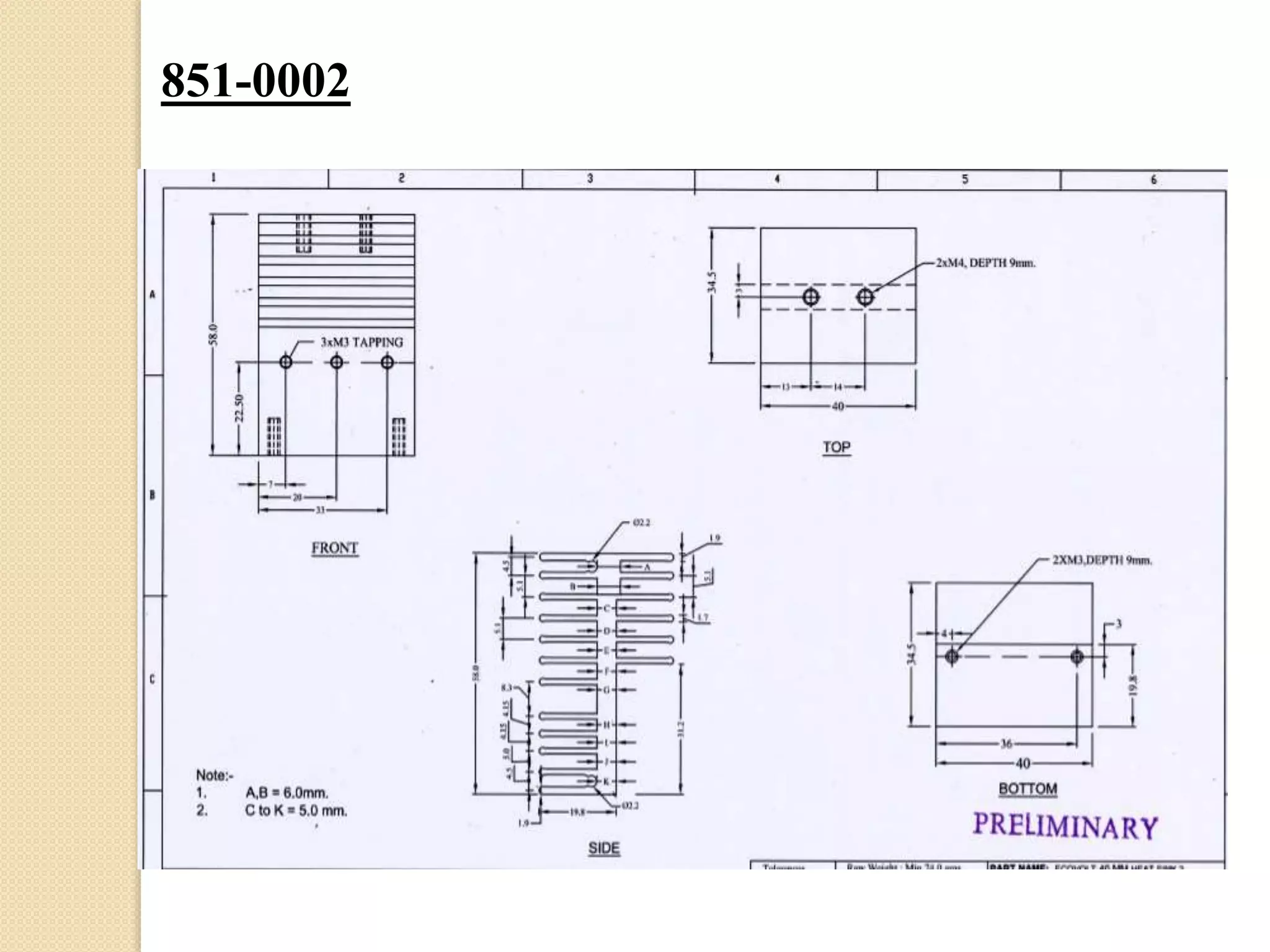

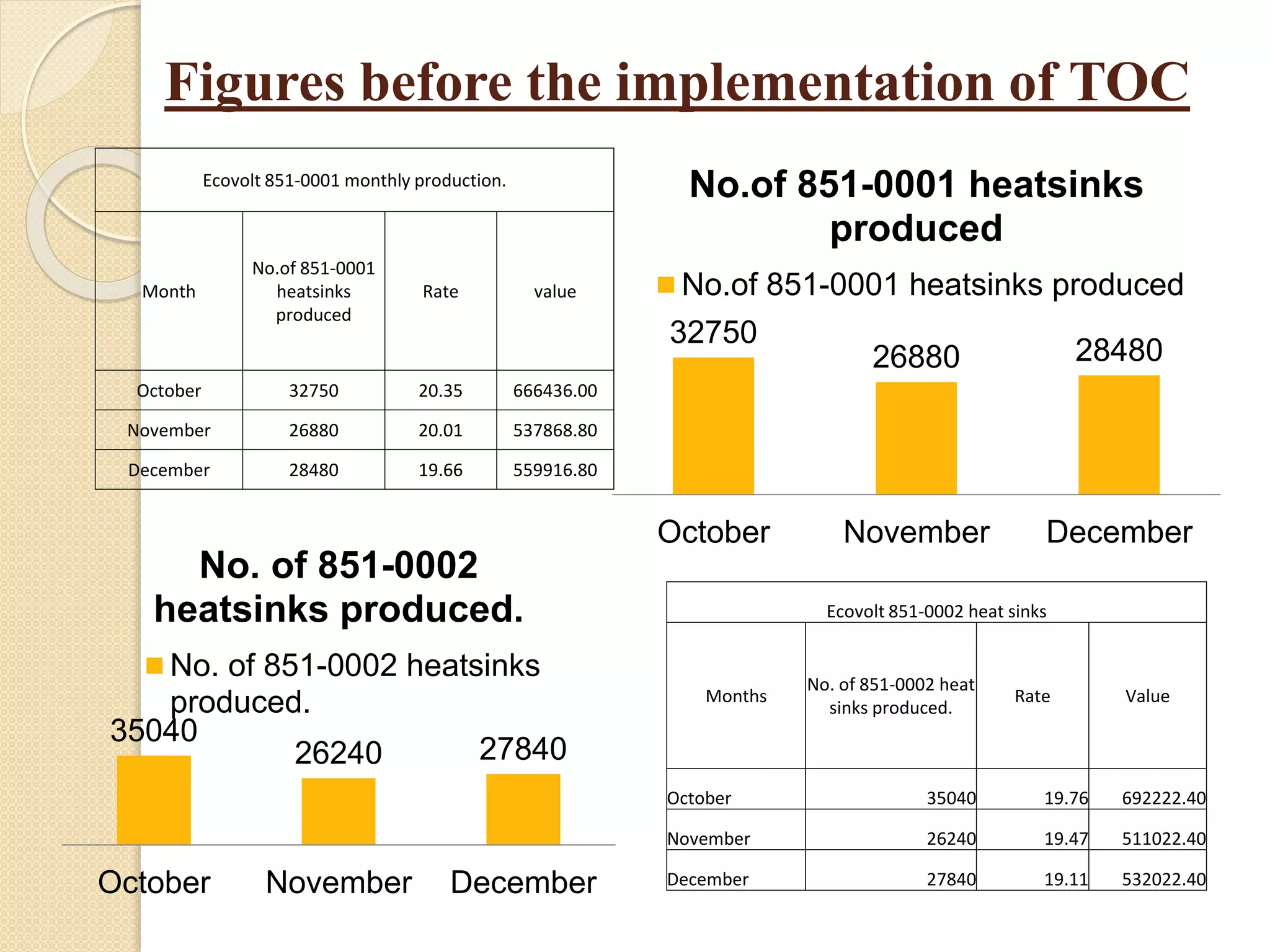

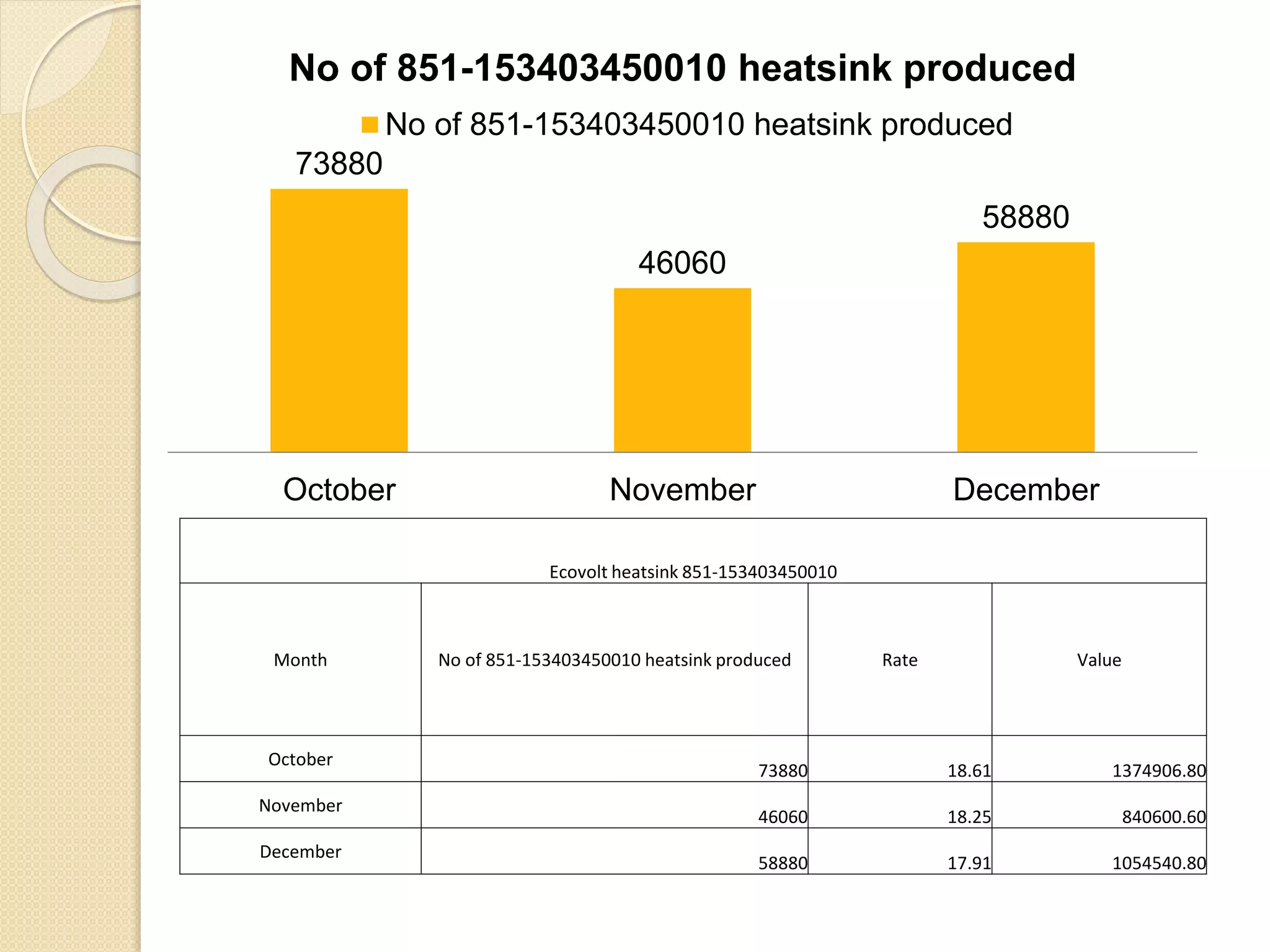

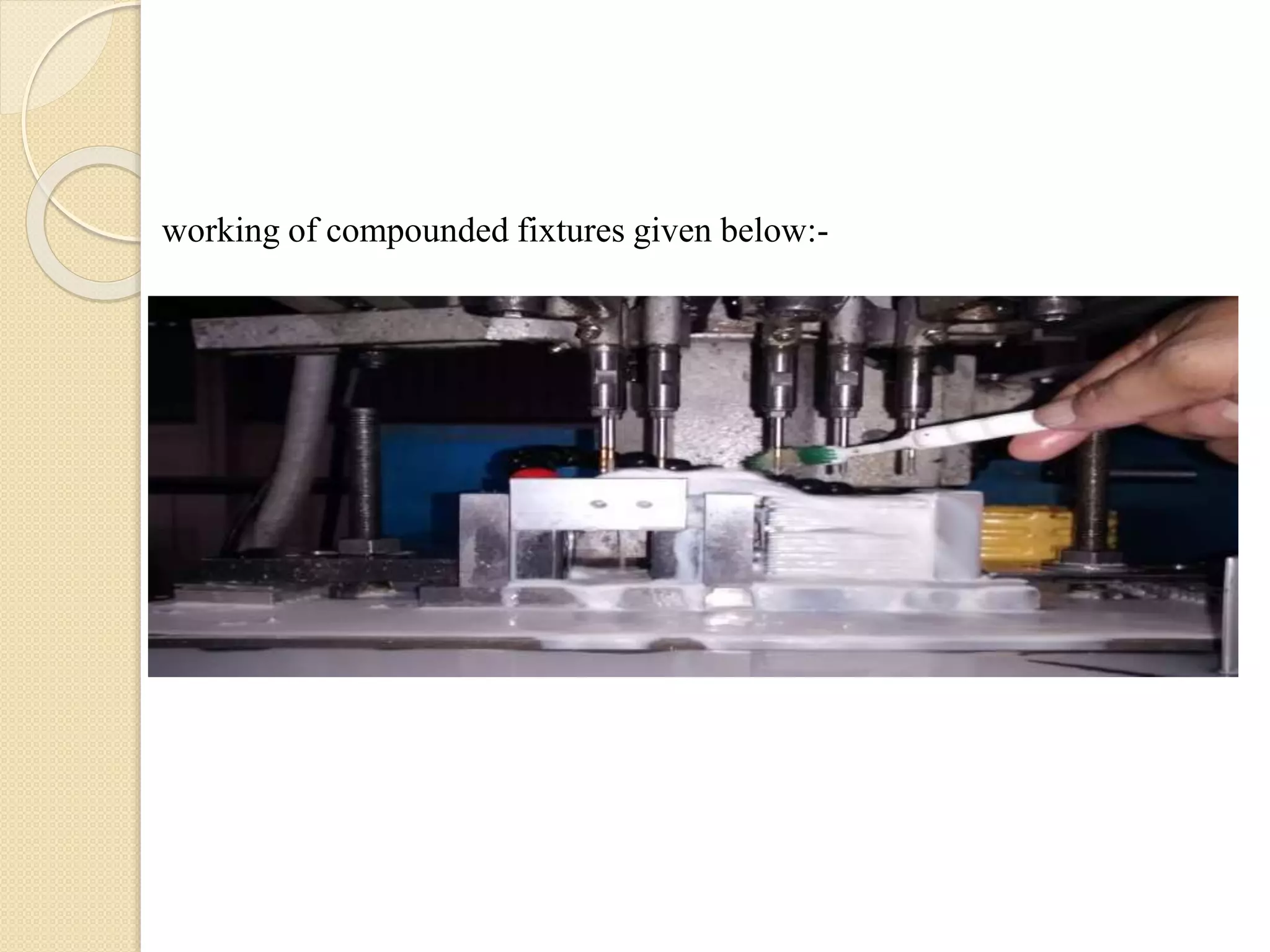

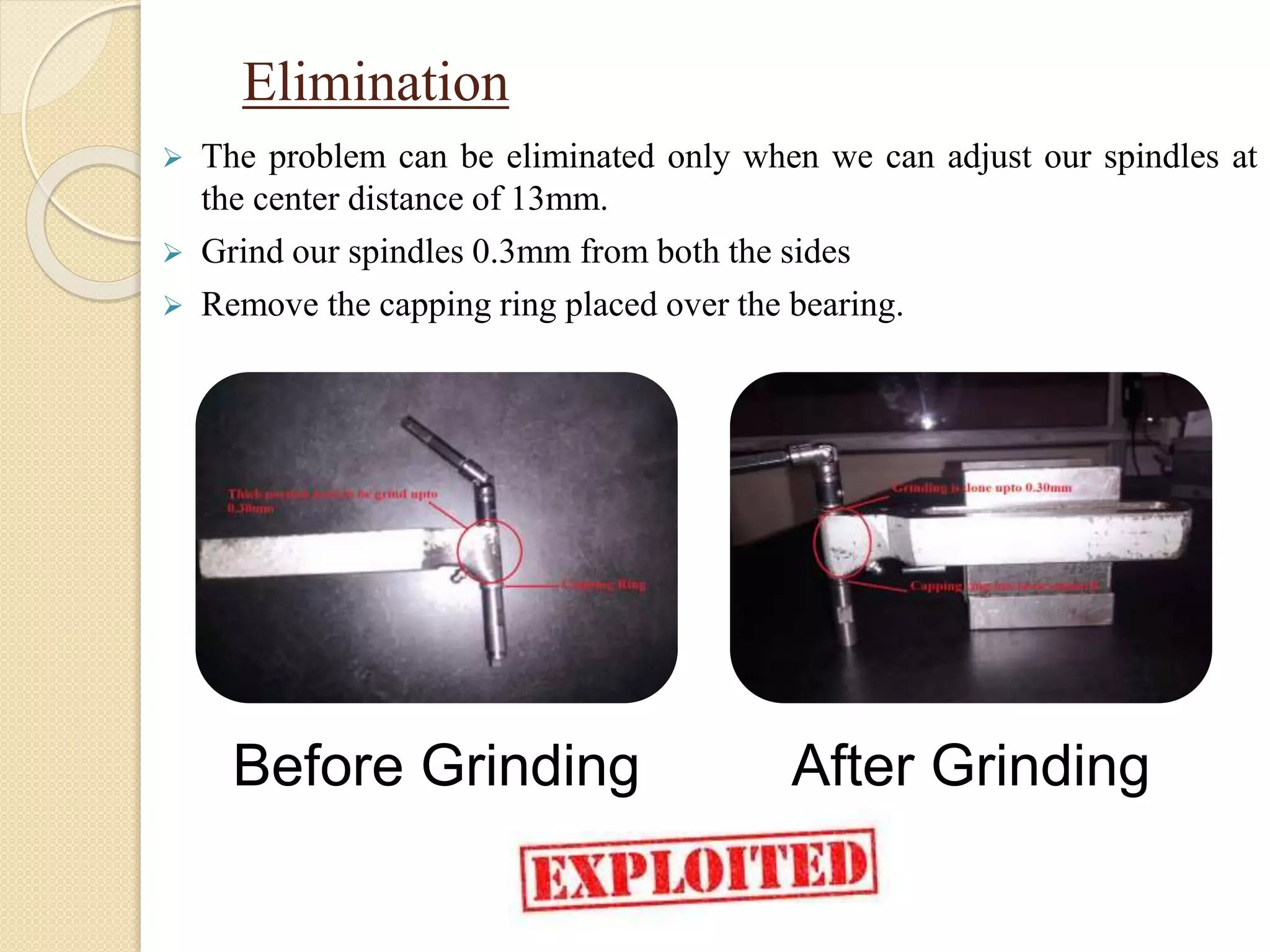

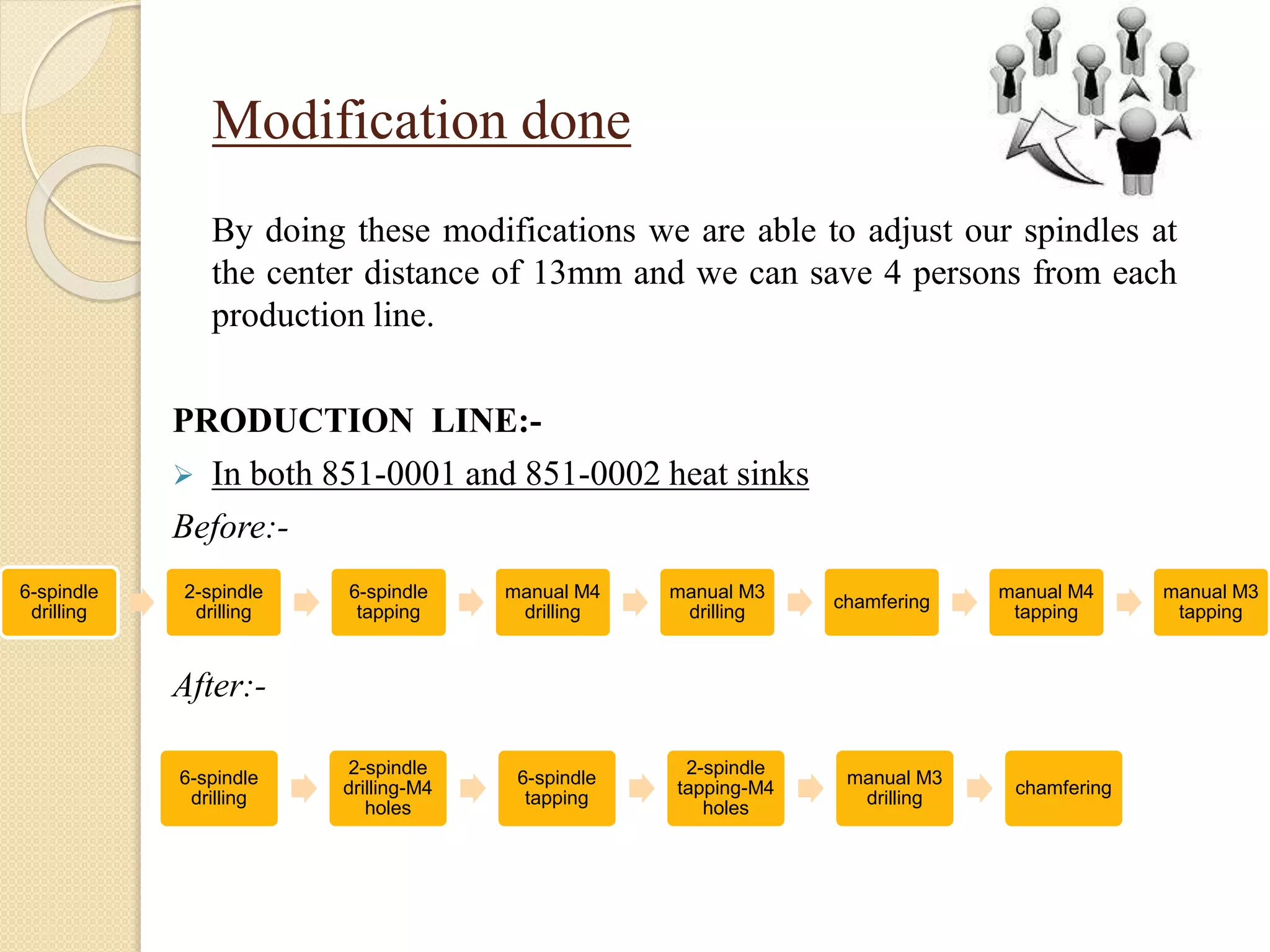

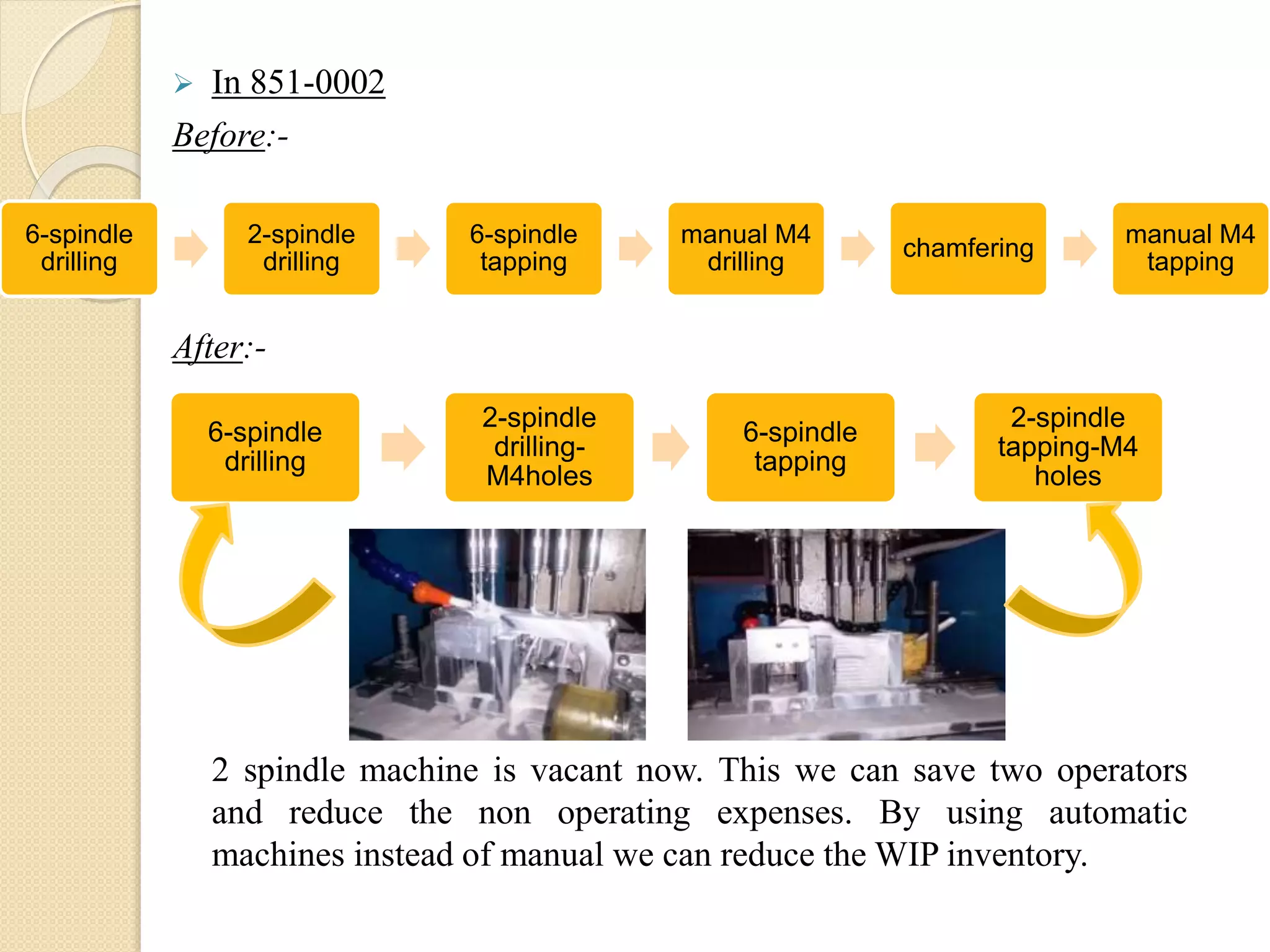

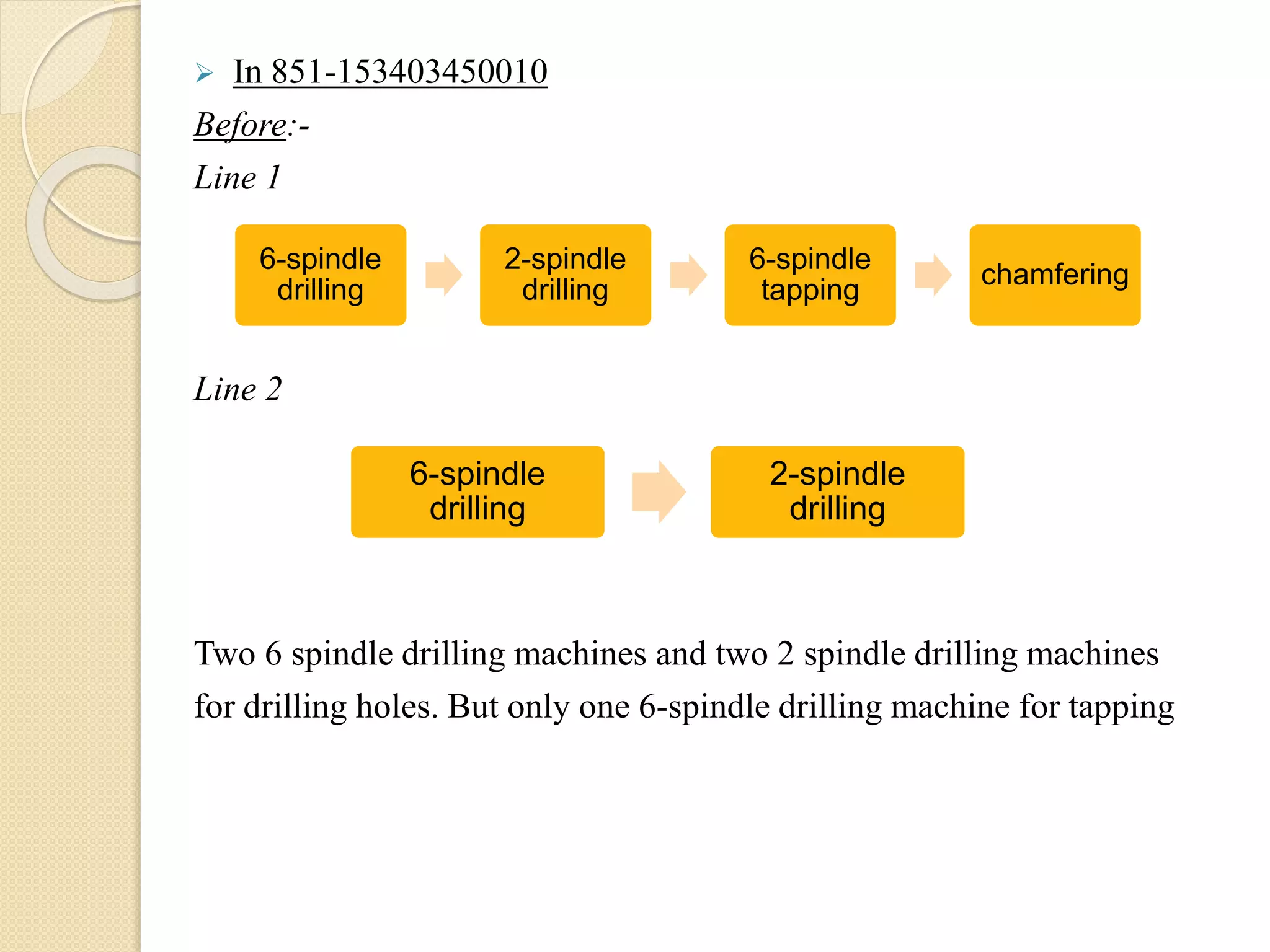

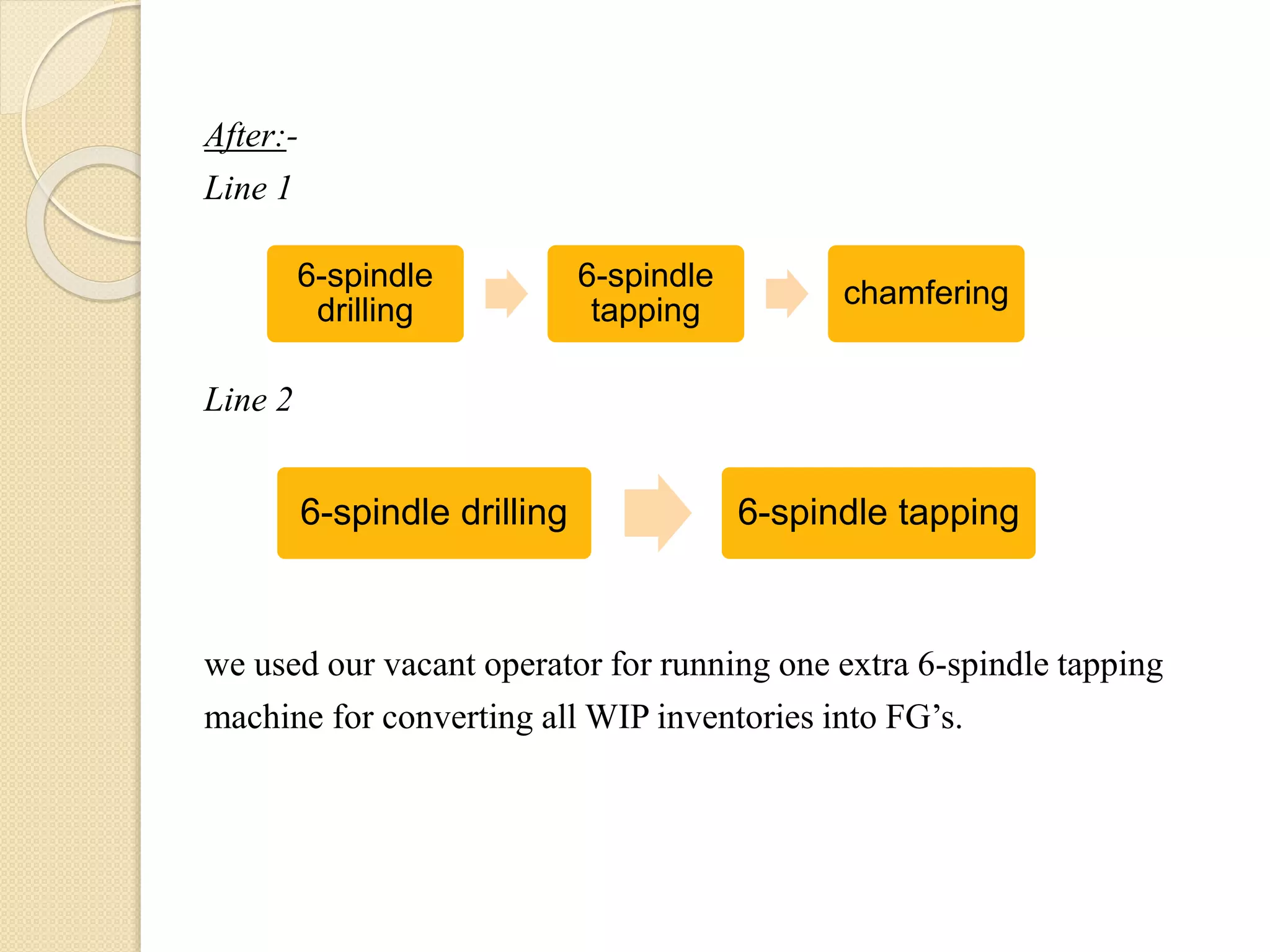

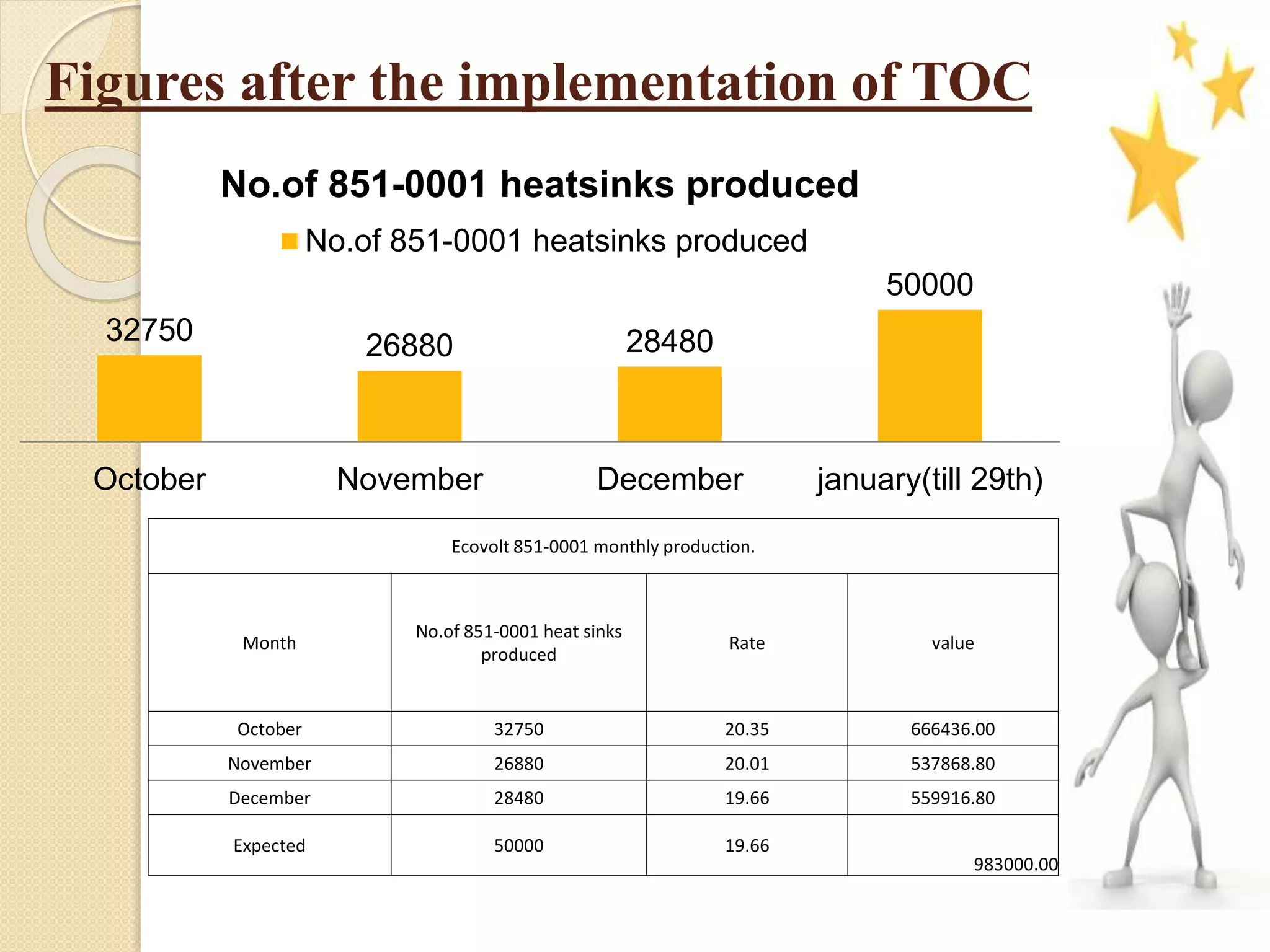

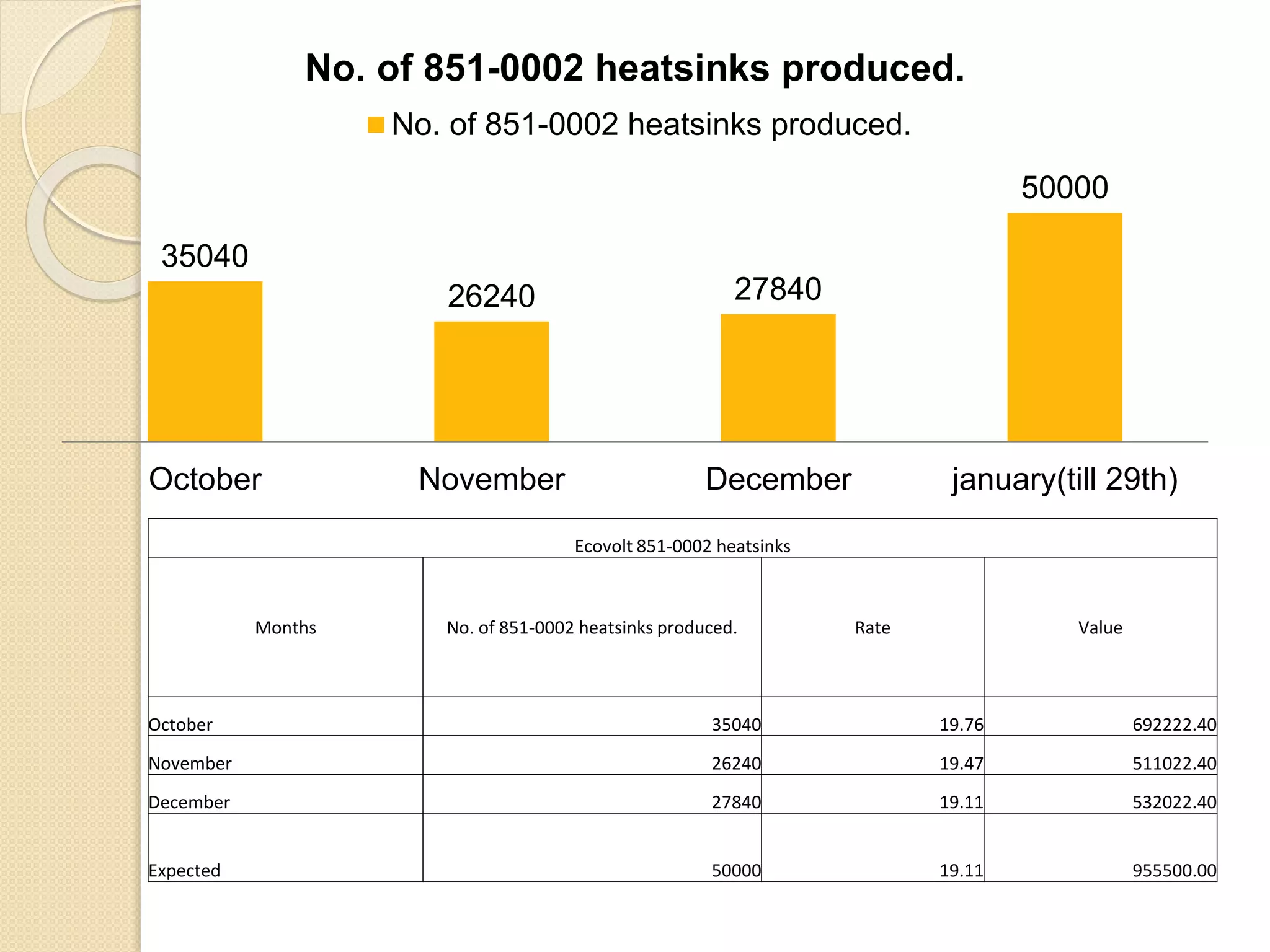

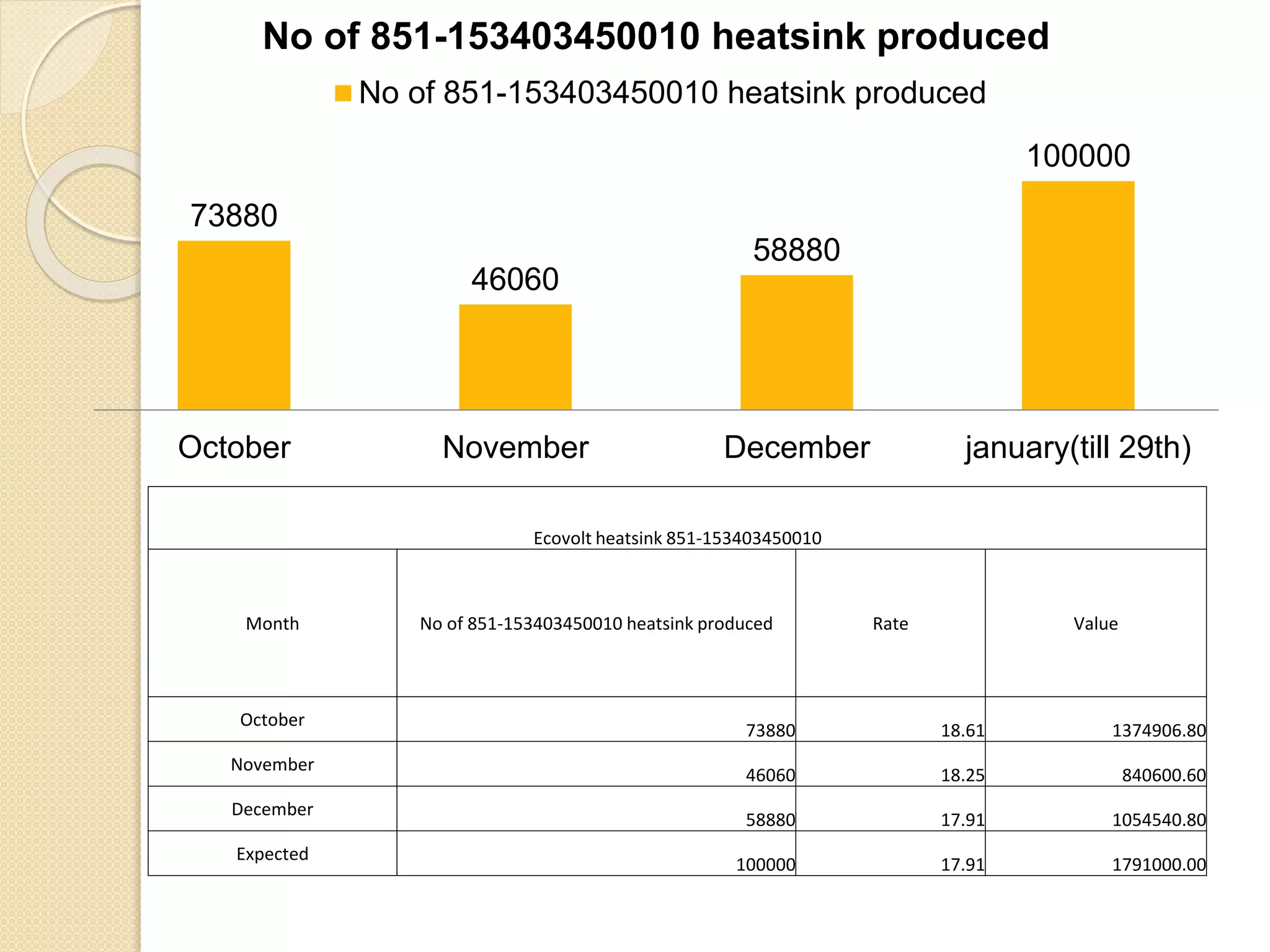

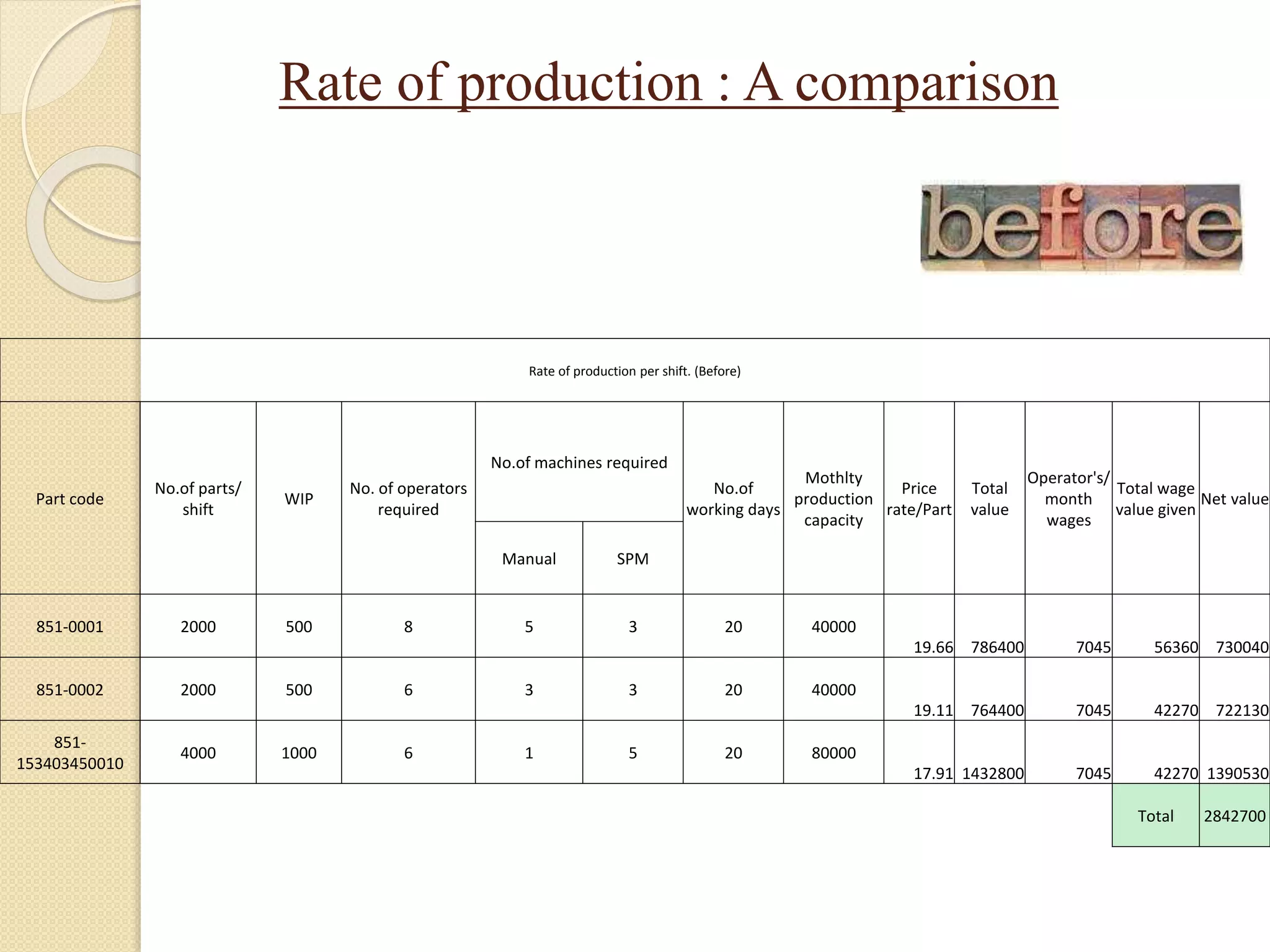

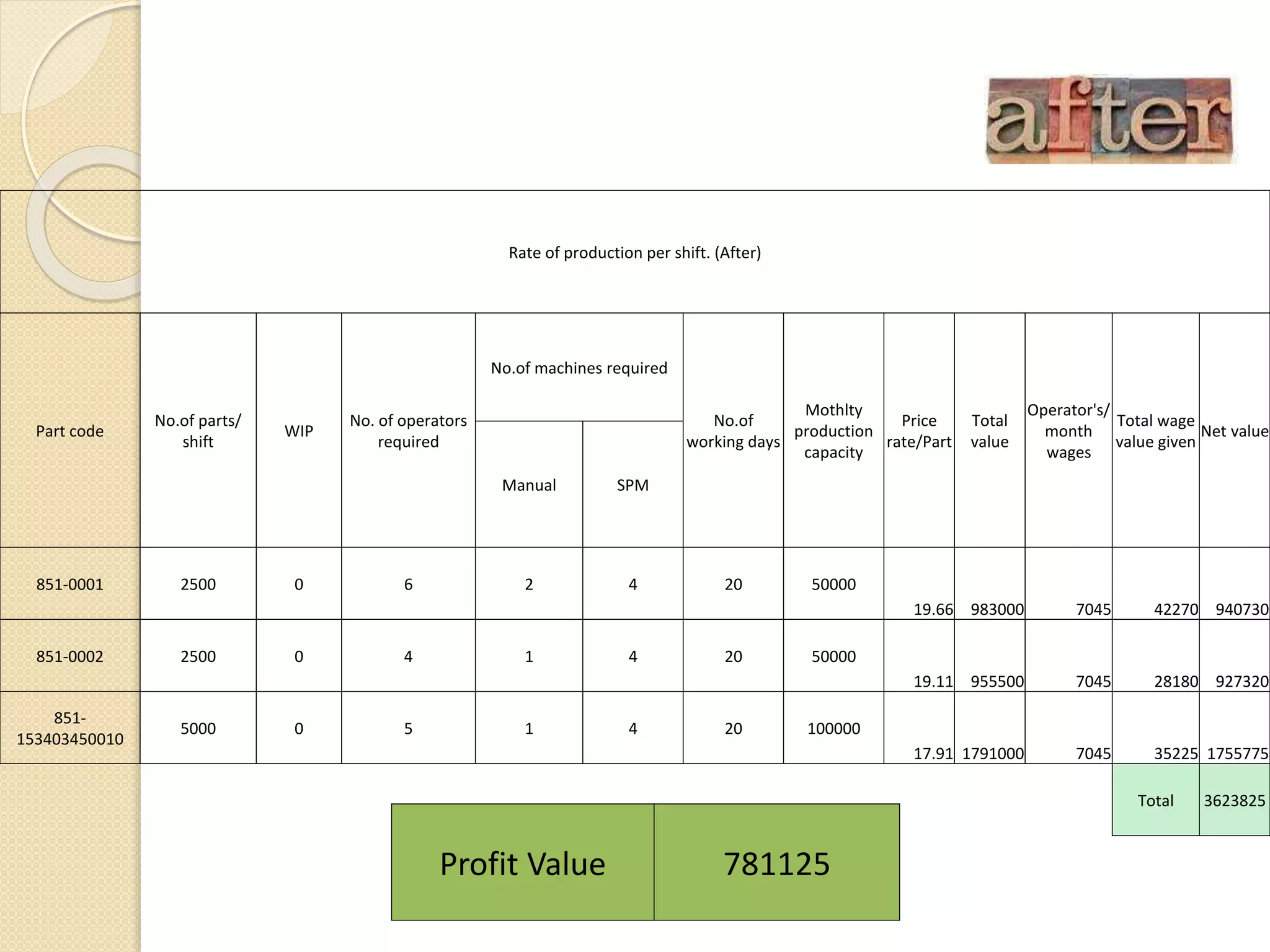

The document presents a case study on the implementation of the Theory of Constraints (TOC) in a start-up firm focusing on the production of anodized aluminum extrusions and sheet metal components. It outlines challenges such as slow throughput and high non-operating expenses, followed by solutions that improved the production rates of various heat sink models while saving on labor costs. Post-implementation, the firm successfully increased its production capacity and profits significantly.