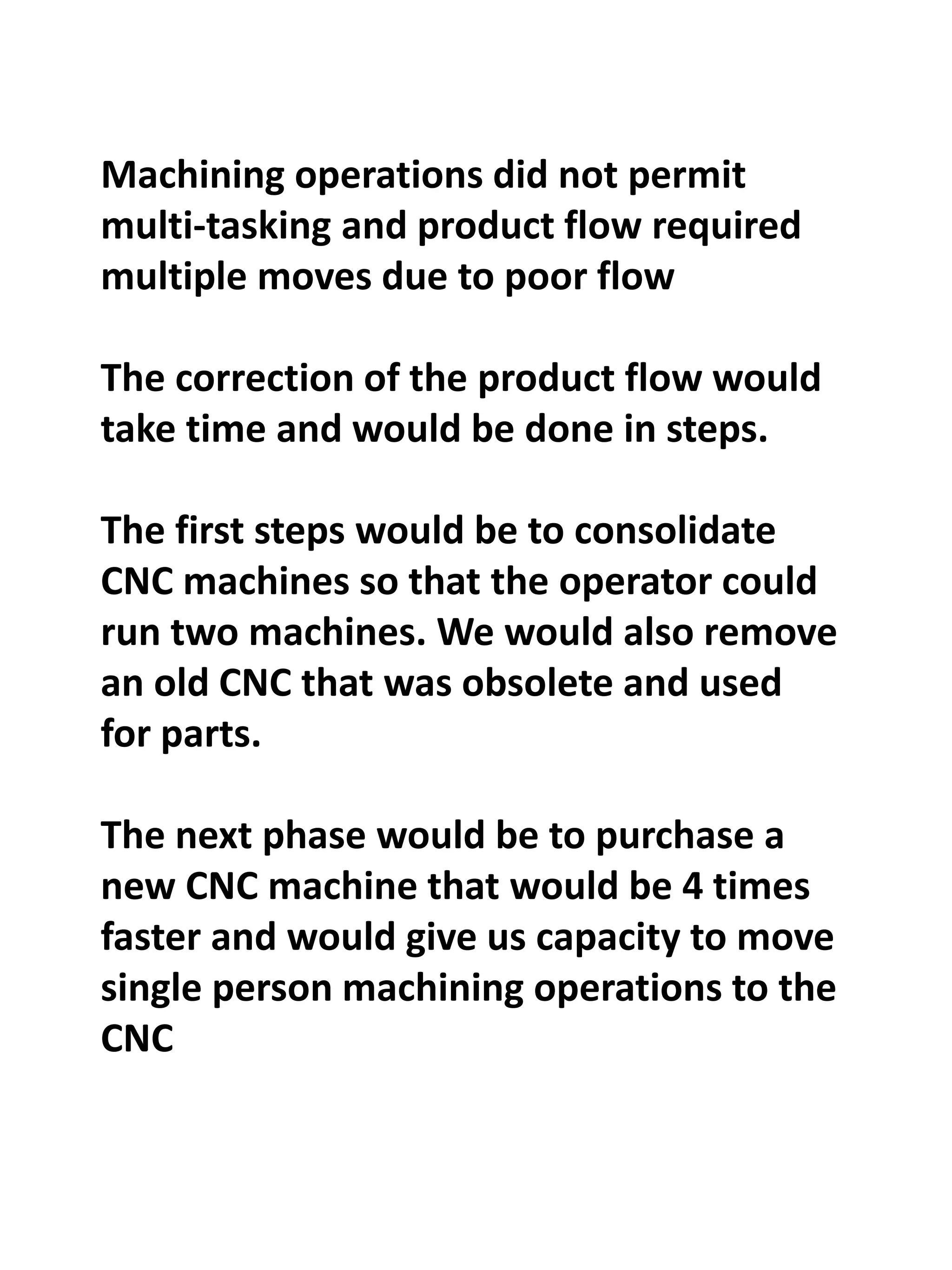

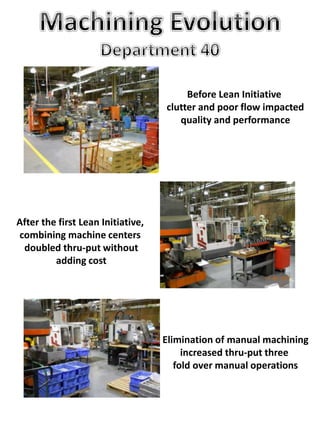

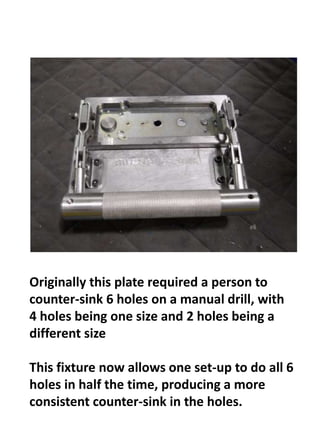

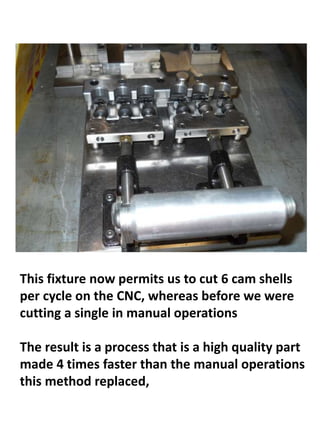

The document discusses improvements made to a company's machining operations through lean initiatives. The first steps consolidated CNC machines so an operator could run two machines and removed an obsolete CNC machine. The next phase was to purchase a faster new CNC machine to increase capacity. Subsequent phases moved machining areas closer to related operations like casting and tooling to improve production flow and reduce material handling. Fixtures were also modified to let CNC machines perform tasks previously done manually but faster and with better quality.