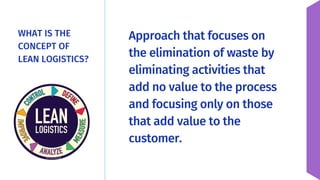

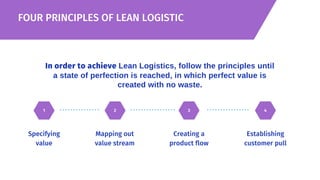

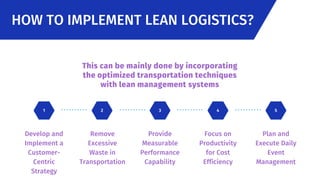

The document discusses lean logistics, which focuses on eliminating waste in business processes to enhance efficiency and quality by defining customer value and minimizing excess inventory and unproductive activities. It outlines the principles of lean logistics, its application across various sectors, and the benefits of adopting these practices, including increased efficiency and responsiveness to consumer demands. Additionally, it highlights the implementation strategies for lean logistics and its positive impact on the entire supply chain.