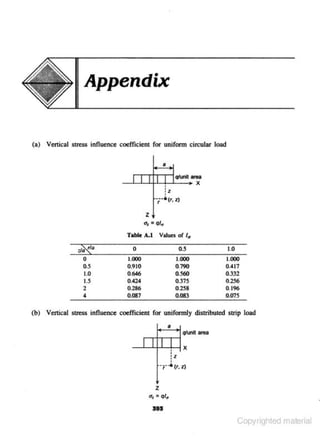

This document provides an overview of the theory and practice of foundation design. It discusses soil as an engineering material, including soil classification, properties, testing, and deposits in India. It also covers site investigation techniques, soil data analysis, types of foundations, stress distribution in soils, bearing capacity of shallow foundations, settlement analysis, design of footings and raft foundations, pile foundations, well foundations, expansive soils, and ground improvement techniques. The book is intended as a reference for civil engineers on the topic of geotechnical engineering and foundation design.

![8 •

Tlu~ory

and Practice of Fouudatio11 Desig11

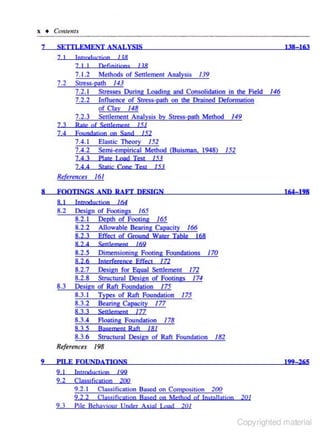

Sand

Gravel

100

.........__

'

['

.: eo

1

];

60

~

~

&

~

~

6

10

0.6

2

-.... k I

j'"'j

0.2

0.06

0.1

1

0.02

.........__

t'

Oispeo>ed

kaolinite

Ctaye~

I'-

0

sandy silt

I

Flocculated

Gra¥elty

sand

20

..... '""--J~montmo1111onlte)

00•um ~ton""'

'

Silty

ne s*nd

Ctay

nne

r---

['

"()

!'I

c

..

Silt

fine coarse meclk.m

ooarse

"'

.......

0.006 0.002

0.01

....

'

0.0006

0.001

0.0001

Particle diameter {mm)

Fig. 1.8

Grai~size

distribution w rve.

whe.re Dro is the diameter of panjcles correspOnding to 60% fi ner and D 10 is the diameter or

the panicle corresponding to 10% finer. The gradation of soil is detennined by the following

criteria:

c11 = l

Uniform soil

Poorly-graded soil

I < c. < 4

c. > 4

Well-graded soil

It must be considered, howeve,r. that the pilrtic1e size alone is not an adequate criterion for

the classification of a soil. as the shape or grains and clay fraction may vory widely depending

upon the constituent minerals. More elaborate soil classification systems. making use of the

Auerberg limits. in addition to che particle size distribution. have since been evolved.

The roost comprehensive of lhese systems are the Unified Soil classification system and

the Indian Standard Classification System. The Unified Soil Class(ficotio" System divides the

soil.into coarse-grai ned soil (having more than 50% retained on number 200 sieve) and 6 ne

grained soil (more than 50%. passing through number 200 sieve). Further subdivisions are made

according to gradation for coarse-grained soils and plasticity for fine-grained soils and each soil

type is given a group symbol (Table 1.3). The Indian Standard Classification System (lS 1498)

is simii3C in some respeccs except that the fine-grained soils are divided into three ranges of

Jjquid limit as opposed to only two in the unified soil classification system.

1.6 RELATIVE DENSITY OF GRANULAR SOIL

The engineering properties of grnnular soil primarily depend upon its relative density, grain0

s ize distribution. and shape of grains. The relative density determines the compactness 1

which the solid grains arc assembled in a soil skeleton and is expressed as

enw;- e x 100

emu - C~nin

(1 .4)

Copyrighted material](https://image.slidesharecdn.com/theoryandpracticeoffoundationdesignreadable-131111103422-phpapp01/85/Theory-and-practice_of_foundation_design_readable-27-320.jpg)

![l6 • Theory and Practice of Foundation Design

•

'

....

•

•

•

•

".

'

]

~

'

.... '

<5 •

"-<

"

/

'

.

~"

/

Undisturbed samples;

Cv in range or >nrgin ccmpres.sion _

c., in range of rec::ompression lies

aboYe this lower limit

/

'

•

•

['..

•

~

I'..

'-..

' ~lely remouldod.L . . . .

f"-~:t'--~

lies below this Uml

•

.......

•

•

., '"'

LIQuid limit I.L

•

'

.

"'

.......

.. ..

..

,

...

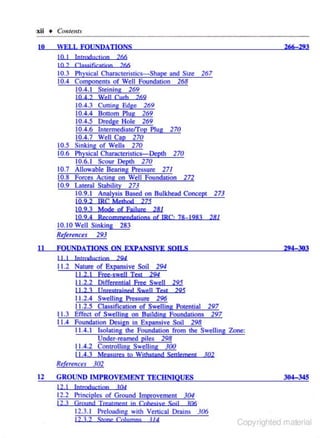

Fig. 1.24 Yal'iation of C., with lquid limit (after U.S. department of Navy (1971)).

1.9.6 Properties of SoU

Coane·p-a.IDecl ooiJa

The relative density of granular soils is measured from in·situ standard penetraticn test. This

test involves counting the number of blows required 10 drive a standard split-spoon sampler to

a depth of 30 em by means of a 65 kg hammer falling from a height of 15 em. An empirical

comlation between standard penetration resistance. N (blows per 30 em), the relative density.

and shear strength of granular soils is shown in Table 1.9 (Terzaghi and Peck 1967).

Table 1.9 Relative density of granular soils

(Tcrzoghi and Peck 1967)

Rtldl1tt

dtnsity (%)

0-15

IS-35

JS-65

65-35

7-85

Nott':

N

(Btows/30 em}

().4

4-10

10-30

30-50

so

~values are tO be increased by

Anglt' of shroring

ruislana (f)

u•

Very Loose

28-30"

Loosc

Medium

Dense

Very Omse

30-36'

3~ ) 0

41.

s• for soils containjng less th.an~~~Ytighted material](https://image.slidesharecdn.com/theoryandpracticeoffoundationdesignreadable-131111103422-phpapp01/85/Theory-and-practice_of_foundation_design_readable-46-320.jpg)

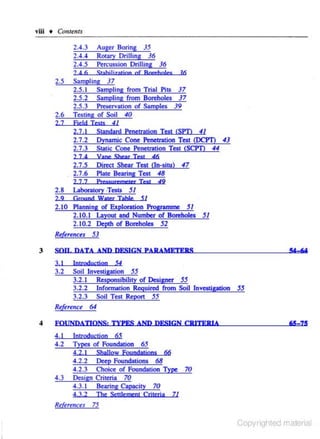

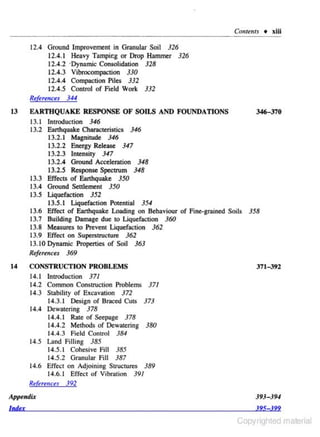

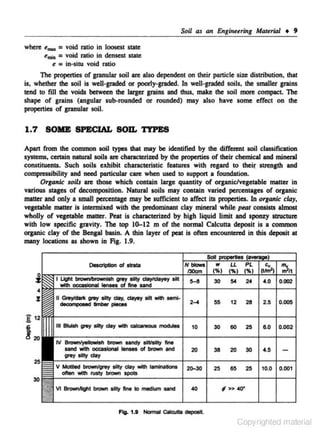

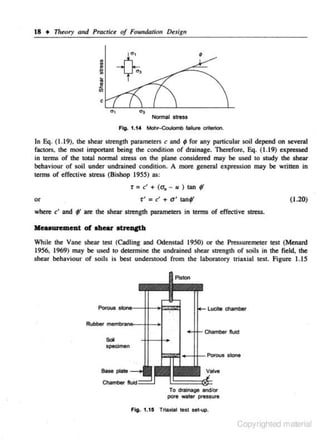

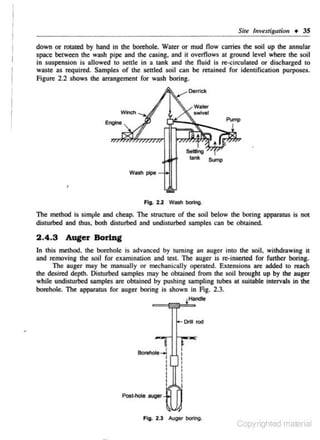

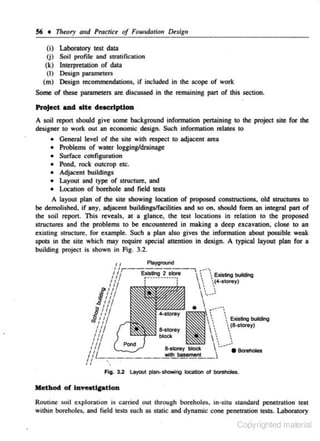

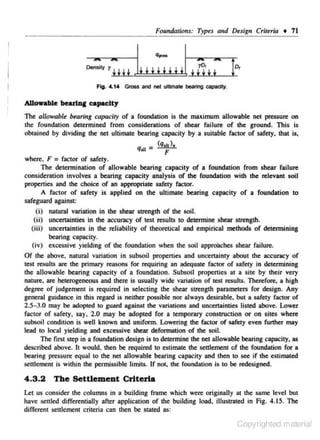

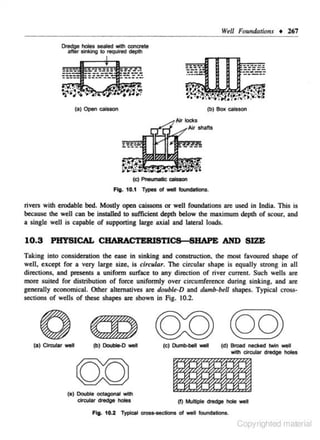

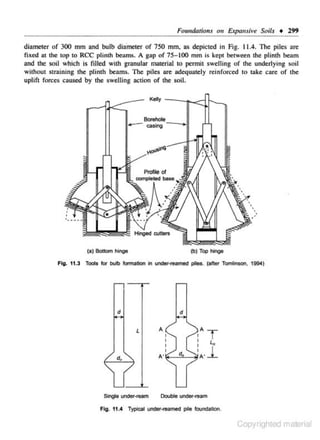

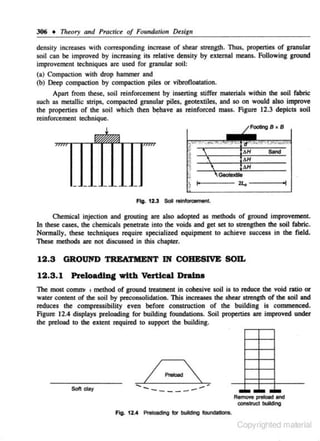

![1. 10 SOJL DEPOSITS OF INDIA

Tile soil deposita of lncha m:~y be classified under most of lhe ~minant aeological

formations (dcscnbed earlier). namely

(b) Marine depositS

(c) Dcsen ooll

(a) Alluvial oolls

(d) Laterite soil

(c) Sleek cotton ooll

(f) Boulder depositS

Figure 1.26 shows the di01ribution of predominant soil deposits in India (Ranjan and Rao

2000).

32°

2$.

z•·

2&·

23.$.

zo•

~AA.MIIt

18"

.-a•ll

mo.-.-

m---

tr

r;m~on~~-

12"

IZ3-~

& ' ! ] - dopoOIII

54·

aa·

1'2"

16·

eo-

54·

aa·

92"

ga·

1ocr

Fig. 1.26 Soil deposits of lndta.

Allu..W aoUa

Large parts o( northern and CIStern India lyina; in the lndo-ao.naetic plains and the

Brahmaputra valley arc covered by the sedimentary deposits of the river> and their

tributaries. Tiley often hove thickness greater than 100 m above lhe bed rock. Tile deposits

..-ly constitute layer> of sand. sdt. and clay depending on lhe pDOJtion of lhe river away

from lhe soun:c.

llarlDe depoe.IU

India has a long coast line extending along lhe Arabian sea. Indian ocean, ond lhe Bay of

Bengal. n.e deposits along the coast are mostly laid down by lhe sea. 11leiC marine c lays of

India are generally soft and often contain organic matter. 'They pOCSC$$ low shear strength

and high compresSibility.

<..opynghted matenal](https://image.slidesharecdn.com/theoryandpracticeoffoundationdesignreadable-131111103422-phpapp01/85/Theory-and-practice_of_foundation_design_readable-49-320.jpg)

![Soil Dai/J and IRs!gn Para,..ttrs • 59

ScnodultoiiHit

+.;- •

• •

•

0

•

0

0

Arm...,

(ml

•

18

•

0

•

0

Soft lilY

cloy

8.~1

•

S..ndy

lilt w(th

el e)l

Bind«

B.H· 2

0

•

0

Arm dly

0

24

v

LL

Pl.

0

0

0

0

0

0

6.0

6.5

11.0

13.5

18.0

19.5

2..25

... 75

0

0

0

0

0

0

0

0

7.50

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

:1.5

0

12

w

I

day

T

-

DenM

10.0

12.5

15.0

11.5

21.0

0

0

GS

.ae uc

0

0

T

tJU)

c

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

-

conlent

uc •

u..

Unc::onlhld

Uquld~

Pl • P1Mic limit

GS • Grein tim

0

0

0

T • Tl1ulol (Wl

c•

Coneolctdon

0

0

0

0

0

0

0

0

0

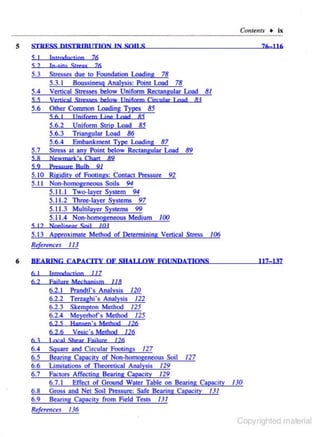

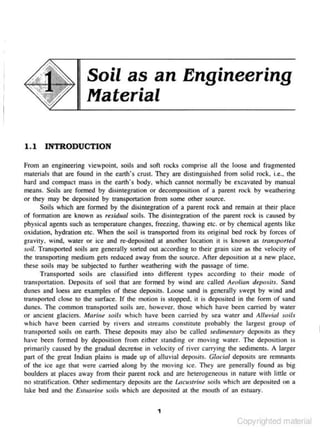

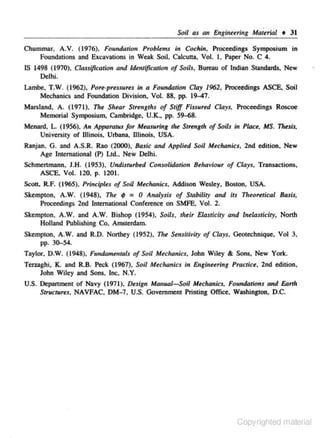

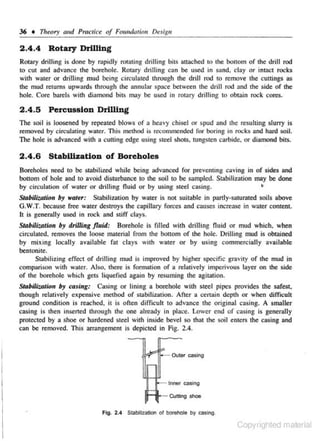

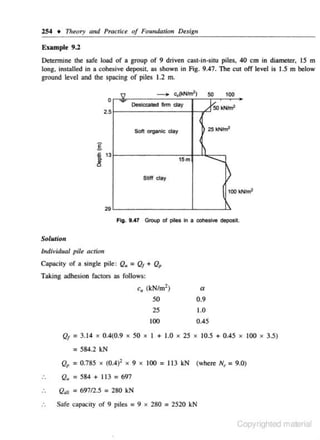

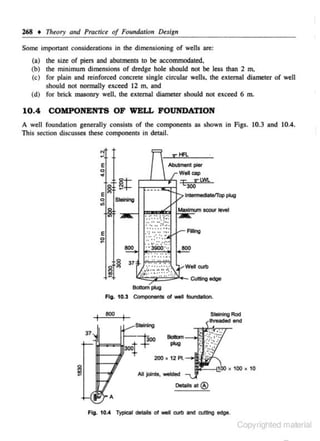

Flg.U -ollobcllobyiMit.

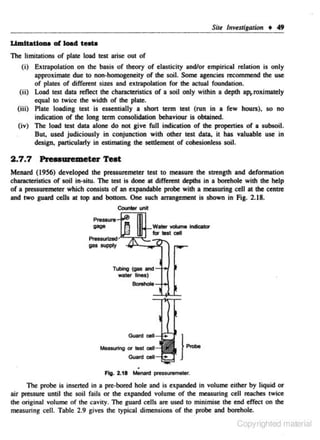

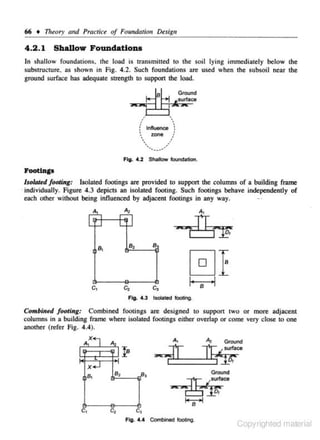

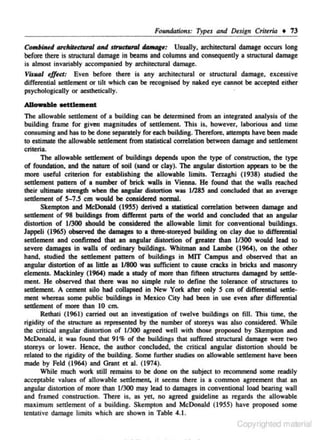

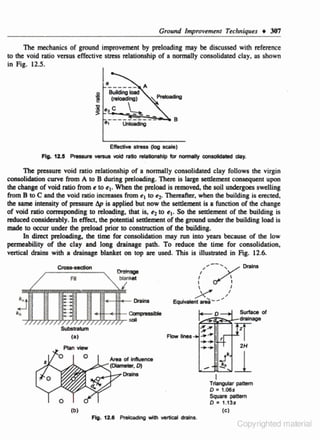

tests should be so chosen ., to give lhe properties of all lhe strata relevant for design. One

should avoid going for unconfined compressioo test in a predomlnandy silty soil.

Similllt'ly. oon.'IOiidation teSt$ are required for cohesive strata only. For sandy strata. one

has to rely more on rield tc5U. such as SPT. Even undisturbed samplu in sand do nor

provide much help.

Soli proftle

Soil profiles should be drawn through a number or boreholes, if not through all of them. to

give the subsoil stratification along a chosen alignment. Such soil profiles dsown for a

number of carefully chosen alignments give a comprehensive picture of the variation of soil

strata, throughout the site. Plotting separately for individual boreholes does 001 cive lhe true •

picture ar a &,lance. Therefore. the best way is to pl01 lhe soil profile on a desired alignment

with nespeet to the vanation of N value with dep<h. The relative consistency of dlffeseot

str.wo emerg<S clearly from sucb a diagram. as depic:tecl throuJb Fla- 3.6.

The position of around water table at lhe time of investiaation should be clearly

indicated in the soil profile. Design or foundations should take appropriate ])OCe of any

seasonal noouation In around water table.

La-.tory tnt data

The lnbor:uory res1 data Qrt given in different fonns in the soil test report. The interpretatjon

t _,,.yrighted ma ,noll](https://image.slidesharecdn.com/theoryandpracticeoffoundationdesignreadable-131111103422-phpapp01/85/Theory-and-practice_of_foundation_design_readable-79-320.jpg)

![Stu.ss Distribution in Soils • 19

Considering soil as a homogeneous, isotropic, and elastic medium, Boossinesq obtained

the expressions for stresses at a poinl (x, y, .t) located at a distance, R from the origin of

coordinates which is also the point of application of the vertical load. Q.

The stress componcnls in Cartesian coordinales are given as:

2

u,

=3Q [y'z

2lr R' -

l-2v{

3

I

~1 =

'

Here,

3Q

2~r

z }]

(2 R +z)x

(R + z)' R3 + R3

- R(R+t) + (R +l)'R' + R'

a~ =

'fx~

+

z}]

(2R+ zll

3Q [ x'z

l-2v{

I

<>x = 2~r R' 3 - R(R + l)

3Q z'

-21< R'

3Q xz1

= -2Jr R'

[.xyz _ 1- 2v {<2R + z).xy}]

3

R'

(5. 10)

(R+ z)'R'

1

R = J<x' + y' + z ) and

v = Poisson's ratio of the soil

h may be observed !hal the vertical slreSs is independent of bolh the stress-strain mndulus

and Poisson's ratio. The lateral stresses and shear stresses. however. depend on Poisson's

ratio but even these are independent of stress-strain mcxlulus. Values of v = 0.5 for saturated

cohesive soils under undrained condition (no volume change) and 0.2-0.3 for cohesionless

soils. are genera11y valid.

In cylindrical coordinateS, !he stress components (refer Fig. 5.3), are:

y

z

"•

Fig. 5.3 Stresses in the aoil due to poin.t load at surface (cylindrical coordinates).

Copyrighted material](https://image.slidesharecdn.com/theoryandpracticeoffoundationdesignreadable-131111103422-phpapp01/85/Theory-and-practice_of_foundation_design_readable-99-320.jpg)

![80 +

111~ory

and Practice of FoundaHon Design

The stress components in cylindrical coordinates arc written as:

3Q •'

(}'. = - 21r R'

u=

[

Q 3tr·

'

21r R'

1-2v

R (R + z)

]

(5. 11 )

I

2]

Q

a, = ii<(l - 2 v) [ R(R+ t) - ?

3Q t 2r

21r R'

The above expressions for stresses are valid only at distances, away from the point of

load application. At the point of load application, the stre:s..~s are theoretically infinite.

For foundation analysis, the venical stresses on horizontal plane (uJ are mostly

required.

Puuing

= J<x' + y' + t 1 )

R

U,=

where Ill

=

=

J<r' + z1 )

-Q I,

,·

,-

(S. I 2)

3

21r[l+(rill'J'"

Ill is the influence coefficient for vertical stress at any point within the soil mass. for the

Boussinesq problem. The vaJues of /8 for different values of rlt are given in Fig. 5.4.

0

'

•

l:'

A

0.5

r

• ·- -~· -

-.......

0.4

0

(u, }" = 2 Is

0.3

z

'•

"' """

0.2

0.1

0

0

0.2

0.4

0.6

0.8

r--1.0

1.2

1.4

rtz

FliJ. 5.4 Str.,. Influence fO<Wr for point load

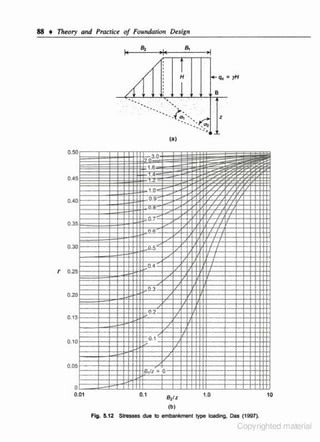

(Boussl~).

Copyrighted material](https://image.slidesharecdn.com/theoryandpracticeoffoundationdesignreadable-131111103422-phpapp01/85/Theory-and-practice_of_foundation_design_readable-100-320.jpg)

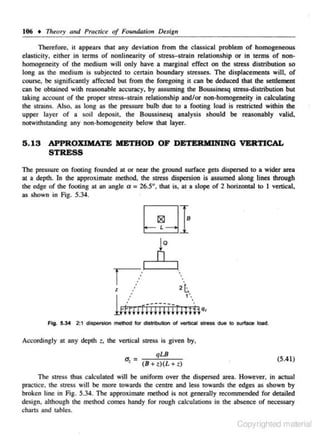

![84 • Tlteory and Proctic• of Found<Jtion Design

!!I.

Ckde

q

!&.

1 dia2b 0.2 0.4 q 0.6 q 0.8 1.0

0

./

---1..

1

q

/

/ ~

2

z

i

q

·/

3

1.2

I

•

5

8

7

8

flO. 5.1 -

·--

~ unilonn -

load.

The load on infinitesimal area rd rt/8 is given by dQ = q rdrd8. Also,

R = (,.l + b 2+

r'- 2br cos9)1n

Integrating over the circular area,

II[r +

J alJr

u, = Jqz

2t

=

1

0 0

rdrd8

b2 + z2 - 2brcos8)512

(5. 19)

{A - 1f~n' +n(I+ t)' [ n' +- (I + r•) E( k) + .!..=..!.llo(k p>

n' I

]}

q

I + t

,

12

(5.20)

where E{k) and n 0(k, p) are complete elliptic integrals of the second and third kind of

modulus k and parameter p.

t = ria

= I

n = <Ia

k' =

A =

4t

n 1 + (1 + 1) 2

I

2

if r<a

if r=a

=0 if r >a

For the special case of the points beneath the centre of me load, r = 0

Copyrighted material](https://image.slidesharecdn.com/theoryandpracticeoffoundationdesignreadable-131111103422-phpapp01/85/Theory-and-practice_of_foundation_design_readable-104-320.jpg)

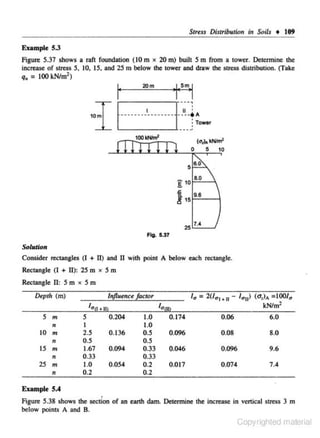

![86 • Theory and Practice of Foundation Design

q

•

tr

•1

t

•

t

- - - tan 1 - - -

()

x+a

[ ( -)

x a

a. = - tan

2?2]

2at(x - t - - a )

.,

,

(xl+ z-- a1)2 + 4a2x.

(S.23)

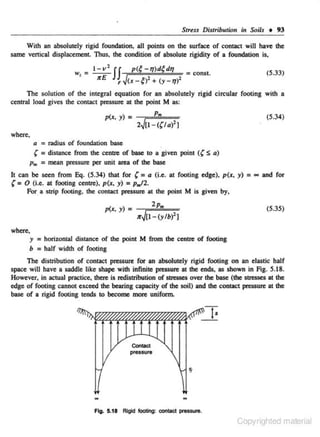

The corresponding stress distribution below the centre. line nnd the edge are shown in

Fig. S.IO. The variation of u,tq with xla and z/a is tabulated in Appendix A.

.

Slllp

width 2b

q

~

q

0.2 M

~

q

0.6

0

1

2

~

I

z

•

I

5

•

/

1.0

1.2

/

lh

3

;;

~

o

.a

I

6

7

8

Fig. $.10 Vertical stress below unlfonn slrlp toad.

5 .6 .3

TrtBDgUJ.ar Load

The venicaJ stresses in the soil due to a triangular load increasing from zero at the origin to

q per unit area at a dislllnce a [refer Fig. 5. 11 (a)) is given by,

(uJA

or

a.

= !!!..[ran·•(_!_) - tan· •(!.)] - [-q ---"-x-~a]

z

Jra

x- a

x

tr (x _ a)2 + z2

1

-·· = 1l

q

x

a

tan·• (

;; ) -

~

a

_

1

tan·•!.!!.

ax

(S.24)

X -I

t _ __,a'-=--~

a(: -I)'+(J

Copyrighted material](https://image.slidesharecdn.com/theoryandpracticeoffoundationdesignreadable-131111103422-phpapp01/85/Theory-and-practice_of_foundation_design_readable-106-320.jpg)

![Stress Distribution in Soils • 87

For x :;:: a, that is, for points below 8,

'(Jt

-·•)

were 1 = - - - tan-.

h

•

1t

2

a

The variation off with va is shown in Fig. S.ll(b). The tabulated values of G/q for

different values of x/a and va are given in Appendix A.

Zl•

00

•

o.•

0.6

0.5

Stress

/'

q/Unit area

X

B

t

1.5

a,=

qr

2

• A(x, Z)

l

0.2

(b)

(a)

Fig. 5.11 (8) Ver1lca1 stre:M due to • triangular load. (b) Variation of f with ria (stress belOw point 8).

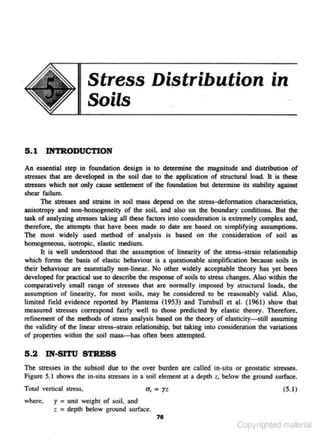

5.6.4 Embankment Type Loading

For an embankment of height H, Fig. 5.12(a), the vertical stress at any poinl below B is

given as, Da.< (1997)

q

l!.p = ; [

81 + 8

B

B, ' (a, + a,) - ~ a., ]

q.

= yH

H

where

(5.25)

= Height of embankment

r = unir weighr of embankment soil

tan·• 81 +

B, - tan·•!!!. rad

l

l

a,=tan -• -B,

-

where I' =

t

l!.p = q.l'

-1'·B.) .

;

(5.26)

f ( a·

The variation of

r

with

~

l

and 82 is shown in Fig. S.J 2.

l

Copyrighted material](https://image.slidesharecdn.com/theoryandpracticeoffoundationdesignreadable-131111103422-phpapp01/85/Theory-and-practice_of_foundation_design_readable-107-320.jpg)

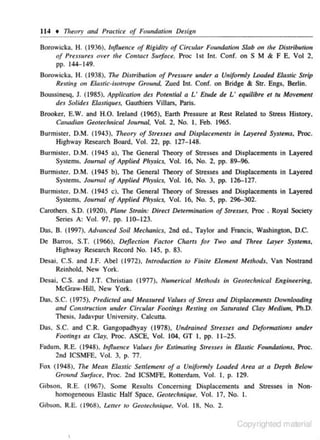

![100 + Thtory and Practice of FoundaJ;o, Dl!sign

Vesic observed that in three-layered systems, the shape of the deHected surface computed by

this approximate technique agrees better with measured deflections of pavements than the more

rigorous analyses.

De Barros ( 1966) proposed an approximate method of reducing a multilayer system to

a three-layer one. keeping the subgrade unaltered, by successively attributing to the two

adjacent layers an 'equivalent mcxlulus' according to the equation

(5.39)

He found that using this technique and reducing a lhree-laycr system to an equivalent

two-layer one, the approximate method is correct to within 10% for lr21b > I and 14% fo~

h, tb > 2 .

An analogous expression was first proposed by Palmer and Barber ( 1940) to reduce a

two-layer system to an equivalent homogeneous medium which yielded deflections very close

to Burmister's two-laye- analysis.

r

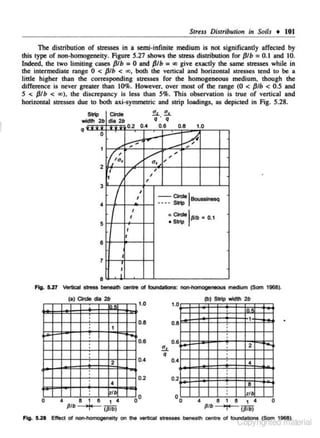

5 .11.4 Non-homogeneous Medlum

The problem of lhe non-homogeneous soil medium whose modulus of elasticity varie.~ as a

continuous function of depth has received only IH:nited attention so far. Korenev (1957).

Sherman (1959), Golecki (1959). Hruban (1959). and Lekhnitskii (1962) have studied

particular problems of non-homogeneity. but no comprehensive

~eory

had been presented

until Gibson developed the theory (Gibson 1967. 196&) of stresse.• and displacements in a

non-homogeneous. isotropic elastic haJf.space subjected to strip or axially symmetric loading

normal to its place boundary, Fig. 5.26.

_jq~·!]·!]f!]·~r~~'!:'!ai..._. •

I

i

I

I

I

A

G{l) = G{O) + mz

~ = G(O)

m

••

'

''

l

..

G{z) • G{O) G{z) • mz

jj•oo

fJ= 0

Fig. 5-26 ~· elastic medium { - Glbooo 1967, 1968).

A semi-infinite incompressible medium whose mcxlulus of e lasticity increases with

depth from zero at the surfa.:e (i.e. p = 0), behaves as a Winkler spring model. In other

words , the surface settlement of a. uniformly loaded area on such a medium is direclly

proportional to the applied pressure and iodependent of the dimensions of the load.

Copyrighted material](https://image.slidesharecdn.com/theoryandpracticeoffoundationdesignreadable-131111103422-phpapp01/85/Theory-and-practice_of_foundation_design_readable-120-320.jpg)

![108 • 11reory and Practice of Foundatiolf Du,.gn

Point C

Qt

=Q, =Q) = Q, = 1000 kN

~r2.--=5,:-+ 2.52

--.,-

r

= -'-----,5: - - - =o.71: 1, = 0.11

1000

(<>,lc = __,- [4 x 0.17)

:.

s

= 27.2 kNim'

Example 5.2

Figure 5.36 shows the plan or a nexible rafl fou nded on lhe ground surface. The area

suppOrts a uniform vertical load or 200 kN/m 2. Estimate the increase in vertical stress 15 m

below point A.

,.

30m

15m

"!"

T

.,

15m

l__

A

Fig. 5.31

Sol uJion

Consider <WO rectangles (I + II) and II wilh lhe point A at lhe comer of each rectangle.

(UJA

=q l -; lau)

(lat•l

Rectangle (I + II): 15 m x 45 m

nr

=

45

"i5

15

= 3.0; n = 15

= 1.0,

= 0.201

/•t•n

Rectangle II: 15m x 15m

m=n=

(u,}A

IS

15

= 1.0; /

0

u

= 200 [0.20 1

= 0.174

I

2

X

0.174]

= 22.8 kN/m2

Copyrighted material](https://image.slidesharecdn.com/theoryandpracticeoffoundationdesignreadable-131111103422-phpapp01/85/Theory-and-practice_of_foundation_design_readable-128-320.jpg)

![110

Theory and Practice of Foundation Design

t

6m

6m

6m

q

- ,_

3m

'''

'''

'

/('((~

3m

r

p

__

I

3m ._

- '-· B ·-

''

''

''

'

'~

u

s

,.,

Fig. 5.38

$elution

Point A

Stress due to s

trip load qmt:

2a = 6m

z=3 m

q = 50 k.N/ m 2

a,

= q(l.,) where Ia =I ( ~ , ; ) . from

X

l

Here. -

= 0; -

a

a

3

= -

3

Eq. (5.23)

= 1.0: Ia = 0.96

Stress due lo triangular load, pqr

= 6m

a

z=3 m

q = 50kN/m2

<1.

•

=qUa> where Ia

Here,

X

9

=I(!.~).

a a

l

from Eq. (5.24)

3

- - - - 1.• - - - - 0 5· I q -0 06

5·

- ·

-· ·

a

6

a

6

(a.). = 50[0.96 + 2(0.06)]

=54 kN/m2

Point B

Stress due to strip load: qurt

X

-;; =

9

3

= 3.0;

l

0

= 1.0; Ia = 0.003

StreSS due to trinngulnr load: pqt

X

a

= 0;

l

a =

3

6

= 0 .5: 10 = 0. 13

Copyrighted material](https://image.slidesharecdn.com/theoryandpracticeoffoundationdesignreadable-131111103422-phpapp01/85/Theory-and-practice_of_foundation_design_readable-130-320.jpg)

![128 • 17reory and Practice of Foundation

D~sign

(6. 19)

2.2

2.0

...

1.8

~

1.8

c

~

Smooth, Fs

1.2

1.0

0

•

8

12

16

20

0.05

0.03

!,.h'8

0.01 0

Fig. 8.10 Bearing capaelly of non-hOmogeneous toll {aflor Oavls and Brcol<or 1973).

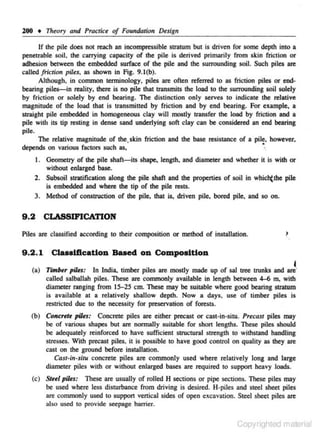

where A is a parameter which depends on the roughness of the footing and ~ is the rate of

increase of c., with depth.

Davis and Christian (1971) analyzed the case of cross-anisocropic soil and found that

the value of c. may be talcen with sufficient accuracy. as

c, = o.{··; c,.)

(6.20)

where ''"' and c..,. are the undrained strength of the soil in the vertical and horizontal

direction respectively. Good prediction of bearing capacity of model footings in Boston blue

clay was obtained by using Eq. (6.20).

Vesic (197S) made detailed theoretical analysis of two-layer soil system, shown

in Fig. 6.11. with the bearing stratum either softer or stiffer than the underlying stratum.

In the first case. failure is partly by lateral plasLic now whereas in the second situation.

failure is caused by punching shear. The net ultimate bearing capacity of the footing is given

by.

(6.21)

where Nm is a modified bearing capacity factor which depends on the ratio of shear strength

of the two strata and the thlckness of the bearing stratum and is given as

Nm = {k(k + l)N; + k + {J - l][(N; + {J)N; + {J - I] - (kN; + {J - I)(N; +I)

(6.22)

Copyrighted material](https://image.slidesharecdn.com/theoryandpracticeoffoundationdesignreadable-131111103422-phpapp01/85/Theory-and-practice_of_foundation_design_readable-148-320.jpg)

![134 + Theory and Practice of Foundation Design

According co Skempton's fonnula

(q,.),.. = c.N,

N, = 6( 1 + 0.2D 1B)

1

Here,

= 30 x 6.6 kN/m2

= 6.6

(q .,,,),..

=

30 X 6.6

2.5

= 2.5)

(Fs

= 80kN/m2

Net safe canying copocity of the footing = 80 x 2 x 2

= 320 kN

Since this is a total stress analysis, there will be no change in the safe load if the water table

rises to the ground surfoce, unless there is a change in strength of the clay.

Example 6.2

The subsoil at a building site consists of medium sand with y = 18 kN/ml. c' = 0, ~· = 32°

and water wble at the ground surface. A 2.5 m square footi ng is to be placed at 1.5 m below

ground surface. Compute the safe bearing capacity of the footing. What wouJd be safe

bearing pressure if the water wble goes down to 3 m below G.L?

Solunon

Since ,. lies between 28° and

35~

the bearing capacity factors are obtained by interpolation

between local and general shear failure conditions.

Refening to Fig. 6.7, for 9' = 32°, Nq = 28. N', = 10, N1 = 30. Ni= 6

= 10 + [

18

;~ 2-- 2 ; 8)] = 20.3

we get.

N,

and

Nr = 6 + [24i;2

-2~8)) = 19.7

Cas. I (water lJible at G.L.)

Using Eq. (6.27) modified for square footing, ultimote gross bearing capac ity

(q,,.)1..,, = y'D1N, + 0.4y'BN1

: 8.0 X 1.5 X 20.3 + 0 .4

X

8.0

X

2,5

X

19.7

= 243.6 + 157.6 =401.2 kN/m2•

and ultimate net bearing capaciry.

(q,"),,.. = (q,,.>...,.

-

= 40 1.2 - 18

rDt

X

1.5 = 384.2 kN/m2

Copyrighted material](https://image.slidesharecdn.com/theoryandpracticeoffoundationdesignreadable-131111103422-phpapp01/85/Theory-and-practice_of_foundation_design_readable-154-320.jpg)

![S~ttl~m~nl

Analysis • 147

So. the changes in effective stress during consolidation an: given as

[6u,l, =

Horizontal:

11.u-

6

(7 .11 )

Vertkal:

where

6 = 6u, 1 - 6a.,.

The ratiO of the effective stress changes during consolidation, K' is then given by

K'

=

[Au,J.: • I - .!.._

[Aa,l,

(7.12)

6u

Now. for the Boussinesq problem, the general expressions for stresses beneath the centre of a

uniform circular load (dlameter 2b and load intensity. q) are (Wu 1966),

u _

' - q

[I _

(tlb)

3

]

(I + t 2/b2 ) 311

(7.13)

3

a = !l.[(l + 2v) _ 2(1 + v)(tlb) +

(t/1>)

]

'

2

(I+ z2 /l?)

(I + z3/b3 ) 311

which can be more conveniently written as,

u, = q(l - '1')

u, = ~((I + 2v)- 2(1 +

V)'l

+ '1'1

(7. 14)

where.

(7.15)

Using these expressions,

Aa, = (u, ),. 111 = q(l - 11'>

6a,, = (u,),. 112 = ~ [2- 3'1 + 11'1

(7.16)

6u., = (u,), . .. = ~[(I+ 2v') ~ 2(1 + v') '1 + 11'1

Combining Eqs. (7.13) to (7. 16). we have

K' _ I _ [

I - 2v

]

I + IJ{l + 1J)(3A - I)

(7 .17)

Eq. (7 .17) can then be used co determine the mt.io of the s

tress increase during consolidation

at any depth beneath the centre or a uniform circular load.

Copyrighted material](https://image.slidesharecdn.com/theoryandpracticeoffoundationdesignreadable-131111103422-phpapp01/85/Theory-and-practice_of_foundation_design_readable-167-320.jpg)

![Seltlement Analysis + 151

pore pressure parameter A. stress-strain relationshjp of the soil. and so on. As an

approximation, however, its value can be determined from Eq. (7.17), for a footing of

diameter 2a. According to Eq. (7. 17),

K _ I _[

I - 2v

]

I + IJ(l + q)(JA - I)

where,

)-t/2

•'

1]= -< ( 1 + Q

a'

v = Poisson's ratio

A = Skempton's pore-pressure parameter

Knowing the value of K', A. can be obtained from experimental relationships as shown in

Fig. 7.7. The value of (m,):, should, of cour>e, be obtained from appropriate stress-path test,

bu~ for practieal purposes, can be determined from properly conducted oedometer test. Then,

(m.)) may be taken as approximately equal to (m,) 1, the oedometer compressibility in terms

of venical effective stress.

It may be noted here that evaluation of the K versus A relationship for any problem

requires determination of Poisson's ratio and pore-pressure parameter, A of the soil. But for

most soils, Poisson's ratio varies between 0.1 and 0.3 and pore-pressure parameter, A

between 0 and I. Accordingly, K varies within a narrow range of 0.6-0.9 and A in the range

0 ..5-0.8. It would, therefore, be convenient to select a value of l within this range for most

practical problems (Som, 1968).

7 .S

RATE OF SETTLEMENT

The rate of settlement of foundations on clay is generally determined from Tenaghi's theory

of one-dimensional consolidation although tield..:onsolidation is often three-dimensional (See

O!apter I. Section 1.9.5).

According to this, the excess pore-pressure at any point at depth t within a soil mass

after a time from load application, is governed by the equation

C lflu = 8u

'8:'

where~

8t

(7.24)

u is the excess pore·pressure and

C" coefficient of consolidation.

The degree of consolidation at any time, 1 (defined as the percentage dissipation of

pore-pressure) may be obraincd by solving Eq. (7.24) for appropriate boundary conditions.

Table 7.2 gives the relationship between time· factor, T, = C,JIH 2 and degree of

consoHdation, U for different boundary conditions.

Copyrighted material](https://image.slidesharecdn.com/theoryandpracticeoffoundationdesignreadable-131111103422-phpapp01/85/Theory-and-practice_of_foundation_design_readable-171-320.jpg)

![156 +

Tlr~ory

and Practice of Foundation DeJign

Pore· pressure corrcc.tion factor. J1 = 0. 7

(refer Fig. 7.4)

p, = 0.7 x 62 = 43.4 mm

Final

se t~ emen t

= 4.8 + 43.4

= 48.2 mm

From Eq. (7 .17),

I - 2v

K' = I [ I + !J(l + !J)(3A

Substituting v = 0.3 and A = 0.7,

K' _ I _ [

I - 2 x 0.3

]

I + 0.3(1.3)(3 x 0. 7 - I)

= 0 .84

From Fig. 7.7, for undisturbed Calcutta soil

.l. = 0.6

{f, = 0.6 x 43.4 = 26 mm

PJ = 4.8 + 26 = 30.8 mm

Example 7.2

A raft foundation. 8 m x 12m in plan is to be placed 2 m below G. L. in the subsoil shown in

Fig. 7 . 10. The net foundation pressure is 50 kNfm2• Calculate the total settlement of the

foundation

Raft foundation

8 m x 12 m

0

50 kNtm'

II I II II

--

-2m

~~5Am

m

/

/

- Sm

f

f

I

I

I

f

'

/

E

:

Fig. 7.10

I Fwm desiccated silty clay

y • 18 kNtm3

' C11 • 40 kN!h'Y

c,11 + eo= o.06

'-

+a

I

I

I

I

II Soft ()(ganlc silty clay

r = 11 kNim'

~ = 25 kNii

c,J1 . .. = 0 .12

m

'

Raft foundation on day.

Copyrighted material](https://image.slidesharecdn.com/theoryandpracticeoffoundationdesignreadable-131111103422-phpapp01/85/Theory-and-practice_of_foundation_design_readable-176-320.jpg)

]

](' =

Substituting v = 0.3 and A = 0.8

K' _ I [

I - 2 x 0.3

]

- I + 0.3(1.3)(3 X 0.8 - I)

= 0.84

From Fig. 7.7,

). = 0.6

.. Jf,=0.6x97=58mm

Pt = 19 + 58 = 77 mm

Eumple 7.3

A S m x S m foundation is placed I m below G. L. in the stratified sandy deposit as

depicted in Fig. 7.11. Calculate the settlement of the foundation.

1600kN

1m

5m

i

'I'

I

I,

•m

--

Medii.ITI sane~

r• 18~

N = 20

= 8000 kNim'

'

+

' c..

I

1

5m

I

+.

/

,,

I

' Medium sand

I

I

r=

19 kNim~

N • '2!5

clll:f = 1

o.ooo kNfml

Medium sand

r• 20 kNim3

N • 30

c.,= 12.ooo kNim'

Flg. 1.11 FCIUI'Iaation on sand.

Copyrighted material](https://image.slidesharecdn.com/theoryandpracticeoffoundationdesignreadable-131111103422-phpapp01/85/Theory-and-practice_of_foundation_design_readable-178-320.jpg)

![iC!J8iCW P'Jilj6pAdO:::J

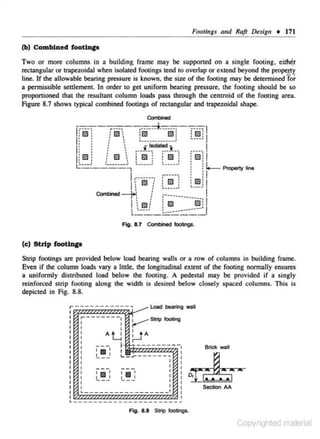

Footings curd Raft Design • 173

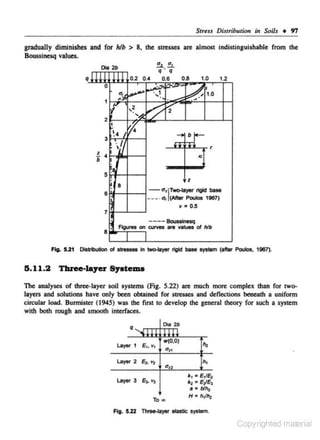

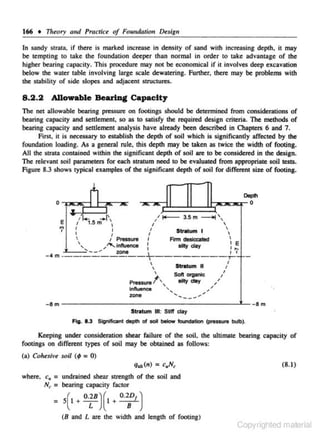

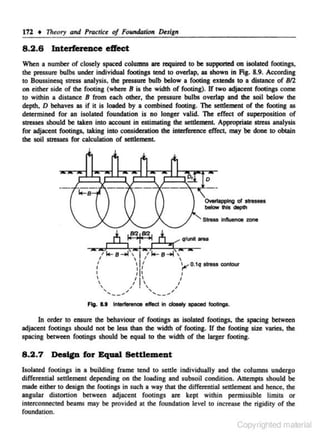

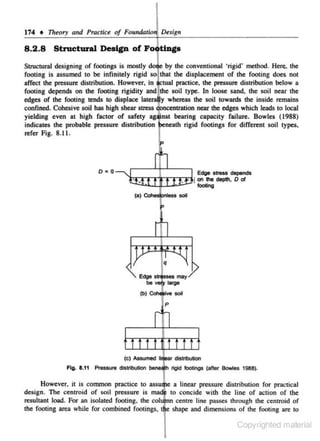

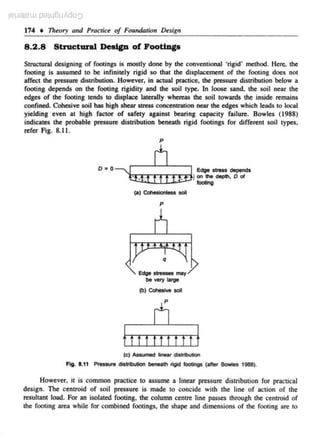

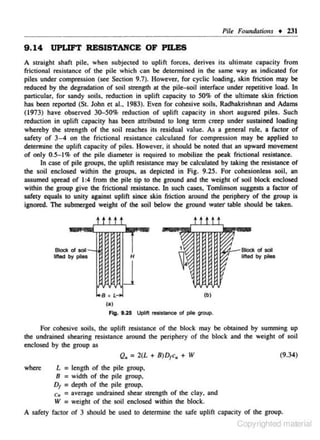

The basic factors which affect the settlement of footings on a give.n soil arc the

intensi<y of loading and 1he size of the loaded area. The senlement increases in almost direct

proportion to these parameters. It is a common experie.nce lhat even though the foundation

pressure is the same under all footings, a bowl shaped defonnation 1rough is obtained with

greater settleme- t at the centre than along the edges of the building mainly due to greater

n

load in the central columns and the overlapping of stresses from adjacent footings. Hence, to

produce uniform settlement. it may be necessary to adjust the pressure with size of footing,

that is. to impose greater pressure under smaller footings than under larger ones and also to

use larger pressure under the footings along the edge of the building. The principle was

u1ilized in the CB I Esplanada Building, Sao Paulo which was founded on moderately

compact fine to medium sand. A pressure of 550 kN/m2 was used under the OUler f()()(ings

and 400 k.N/m2 under the inner footings, with the result that the maximum differential

settlement did no< exceed 8 mm ($kempton, 1955). So, lhe bearing pressure of footings in a

bu.ilding frame may be varied though it is always kept within the safe bearing capacity so as

to have the maxjmum and differential settlement within permissible limits. This may require

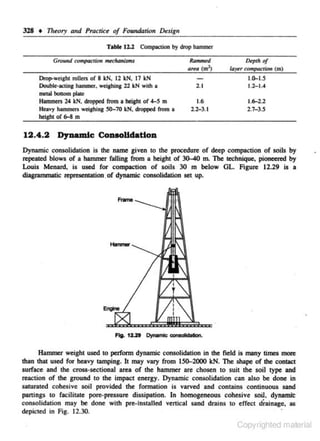

a number of Dials before the finaJ design is arrived at. A simple caJculation for achieving

unifonn settlement of adjacent footings is shown in Example 8.4.

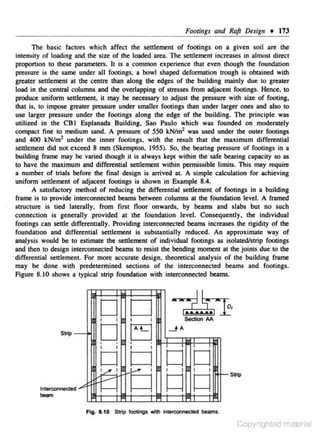

A satisfactory method of reducing the differential settlement of footings in a building

frame is to provide interconnected beams between columns at the foundation level. A framed

slructure is tied laterally, from firs! floor onwards, by beams and slabs but no such

connection is generally provided at the foundaHon level. Consequently. the individual

footings can settle differentially. Providing inten:onnec<ed beams increases the rigidity of the

foundation and differential settlement is subscantially reduc-ed. An approximate way of

analysis would be 10 estimate the settlement of individual footings as isolated/strip footings

and then to design interconnected beams to resist tbe bending moment at the joints due to lhe

differential settlement. For more accurate design. theoretical analysis of the building frame

may be done with predetermined sections of the interconnected beams and footings.

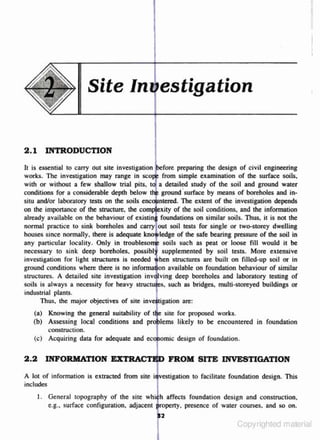

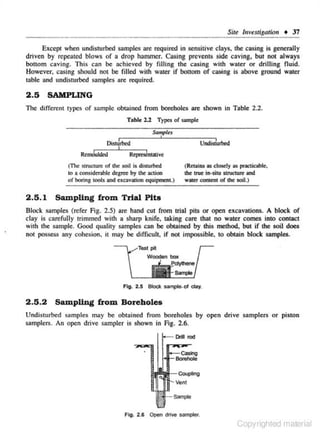

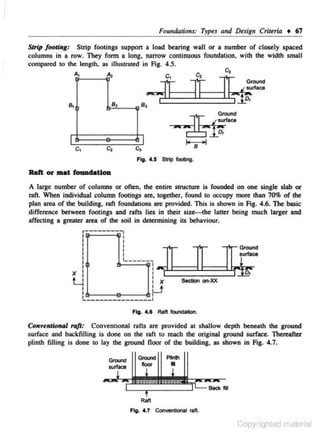

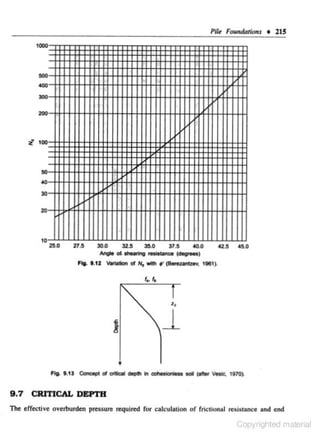

Figure 8.10 shows a 1ypical s:aip foundation with interconnected beams.

~

D D -~;dk,]~

D EJ

0 L! D D

I

I

Section AA

I

_JA

Strip

•

•

I

,.....

I

1/

lnterooonec::te'

I

I

1---

beam

F~. 8.10

•

•

I

I

I

I

I

I

I

I

I

I

~ ~ ~

Strip footings with interconnected beams.

f-

Strip](https://image.slidesharecdn.com/theoryandpracticeoffoundationdesignreadable-131111103422-phpapp01/85/Theory-and-practice_of_foundation_design_readable-200-320.jpg)

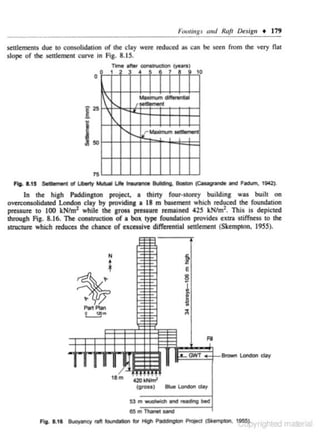

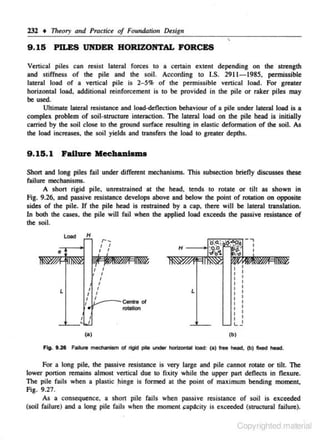

![Footi11gs and Ruft Desigu •

187

Depth correction:

- =L

8

17

= 6.8

2.5

D

=

JL8

1.5

,)2,5

X

J.7

= 0.23

Correction fac tor = 0.95

(p;},0 rr

= 0.95 x 0,018 = 0.017 m = 17 mm

(c) Collsolidation seltlemetll

""

C,

L...1

+ t>.o

H log p., + flp

Po

Two layers (I and If) are involved in the pressure influence zone.

At

A: Po = 19 x 1.0 + 9 x 1.0 = 28 kN/m•

'

flp [for Z/8 = 1.6/2.5

At

B: Po

= 19 x

1.0 + 9 x 2.0 + 8 x 1.5

flp (for Z18

...

~

= 0.4] = 0.85 x 65 = 55.2 kN/m·

'

= 004

.

=49 kN/m2

= 3.512.5 = 1.4) = 0.42 x 65 = 27.3 kN/m 2

x

21

og

28 + SS.2

D

0 IS

+ .

x

21

•

49 + 27.3

49

= O.Q38 + 0.058 m

= 0.096 m

Depth correction

= 0. 95

Rigidity correction = 0.8 (lnrerconnected strip provides rigidity to the foundation)

Pore-pressure correction. J1 = 0.75

(Major contribution to settlement comes from strata I and II. Hence. J1 correction for N.C.

clay is considered.)

..

(p,)""' = 0.95 x 0.8 x 0.75 x 0.096 = 0.055 m = 55 mm

..

Total setdement. p1

= 17 + SS = 72

mm < 75 mm

Example 8.3

A column carrying a superimposed load of 1500 kN is to be founded in a medium sand as

shown in Fig. 8.22. Design a suitable isolated footing.

Copyrighted material](https://image.slidesharecdn.com/theoryandpracticeoffoundationdesignreadable-131111103422-phpapp01/85/Theory-and-practice_of_foundation_design_readable-209-320.jpg)

![222 • T11eory and Practice of Foundation Design

where

Q,. = ultimate load in tons.

L = embedded length· of pile in fl.,

W = weight of hammer in tons.

N = total number of blows,

S = penetration for last blow in inches. and

H = drop of hammer in ft.

9.11.4 Janbu's Formula (Janbu, 1953)

EH

(9.27)

Q. = K S

•

where

K, =

c"

cd(1 + J~ + ~}

=. o.1s +

o.l4(~}

and

EHL

The ultimate pile capacity as detennined from tbe pile driving formulae may be used to

determine the safe load capacity of a pile by using a fac tor of safety. ln view of the

uncertainties involved in tbe calculation, a high factor of safety, not less !ban 3, should be

used. The early ENR formula even recommended a factor of safety equal to 6.

Sorensen and Hansen (1957), Housel (1966), and Olsen and Flaate (1967} made

comprehensive studies on the use of different pile driving formulae in predicting the pile

capacity. It appears from tbeir studies, "if driving formu lae are to be used, those which

involve the least uncertainty arc the Hiley and Janbu formulae while the most uncertain is the

ENR formula",'' (Poulos and Davis. 1980).

9 . 11.5 Wave Equation

It has been long recognized that the phenomenon of pile driving involves ltansmiss.ion of

compression waves down the pile. Smith (1960) gave a practical method of solving the wave

equation using a dig.itaJ computer for studying the dynamic behaviour of a pile during

driving. The analysis involves dividing 1he pile into a number of segments, each beam

represented by a weight joined to the adjacent weights by springs. The hammer, pile cap, cap

block, and cushion block are also represented by weights and springs. The soil resistance is

represe nted by a Kelvin rheological model consisting of s pring and dash pot. A set of

ec1ua.t.ions can be set up considering dynamic equilibrium of each e]ement. The pile resistance

corresponding to a given set observed in the field can be obtained by solving the set of

simultaneous equations. The procedure has been described by Bowles (1968. 1974).

The s uccess of this metbod is handicapped by the lac k of knowledge of essential

parnme1ers involved in the equation. Nowadays. with the advent of sophisticated equipment

such as Pile Driving Analyzer (PDA) and suitable transducers whic8cr~'}~l~t~hFdd<t!';ii.~](https://image.slidesharecdn.com/theoryandpracticeoffoundationdesignreadable-131111103422-phpapp01/85/Theory-and-practice_of_foundation_design_readable-244-320.jpg)

![Pile Foundar;ons • 253

(i) N value.

(ii) Overturden pressure considering c ritical depth.

Take effective unit, t' =- 1.73 tlm3 above water table. and 0.73 rJmJ below water table.

So/uJion

(i) Using N value

Average N along pile shaft. N., = [(5 • 2) + (16 • 15) + (22 • 3.6)Y20.6 = 15.98

= 16 (upco 20 below tip)

N value below tip = 22

Using Eq. (9.19)

Q• = 4NAp + N., A1

6

= 4 X 22 X 0 .785 X (0.3)2 + (16/6) 3.14 X 0.3

=62.22 + 50.24 = 112.41 = 112 I = 1120 kN

(ii) Considering critical depth for overburden

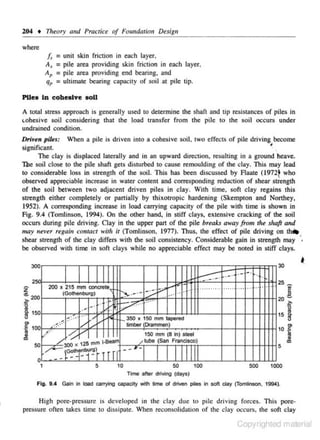

For medium sand, ~ID :: 20, z~ = 6 m, N,

Fig. 9. 12.

For driven steel pile, lAke K, = 1.5, ;.. =

0 -3 m: '-•

3- 20 m :

Also,

Q.

~

..

= 45,

X

20

using Berez.antzev's curve.

0. 7~'

= 0.7;'

X

=0.74>' •

28° = !9.50°

32°

=22.5°

= f. + A ,

LA, ,q

f., = K,yD 1An 19.5° = 1.5 x 17.3 x 3 x can 19.50° = 27.6 kN/m2

1

/,, = K,y•o1 can 22.5°

= 1.5(17.3 x 3 + 7.3 x 1.5) tan 22.5°

= 39.0 t/m2

.

_LA,f. =

1f X

0.3[ 3 X

~7.6 + Je7.6/ 39) + (14

X

39)]

= 1f X 0.3(41.4 + 99.9 + 546)

= 647 kN

and

A9 q,

= " •

°·

,

3

• ( y' D1Nq)

4

2

1f • 0 .3

:

{17.3

4

= 559 kN

X

3 + 7.3

X

J7)

X

45

Q. = 647 + 559 = 1206 kN

Copyrighted material](https://image.slidesharecdn.com/theoryandpracticeoffoundationdesignreadable-131111103422-phpapp01/85/Theory-and-practice_of_foundation_design_readable-277-320.jpg)

![258 • Theory nnd Practice of Foundaticll Design

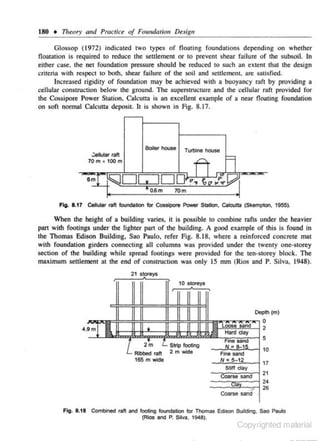

Example 9.5

Compute the long tenn ~ulement of the pile group considered in Example 9.2.

The load on the pile c-ap is assumed to spread at a slope of 4 horizontal to I vertical

upto the level of 213 pile length from the top. and then at slope of 2 vertical to 1 horizontal

to a depth of 12 m below that level, which is about 1.5 times the width of equivalent

imaginary footing.

Solution

Two points A and 8 arc considered at the mid point of the relevant strata beneath the

imaginary footing. Water table is assumed to be at G.L.

At A.

Po = 12.25 x 9 = 110 kNim1

fl.p

At B,

= 25201(8.2)2 = 37.4 kN/m2

6, = 0.10 x 150 x logto [(110 + 37.4)1110)] = 1.9 em

Po = 19 x 9 = 171 kNim2

tJ.p =' 25201(12.2

62 =

X

12.2)2 = 10.2 kN/m2

x 1200 x lo&to [(171 + 10.4)1171)] = 2.46 em

:. Total settlement = 1.9 + 2.46 = 4.36 em

0.08

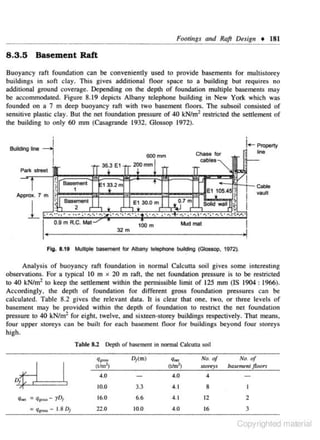

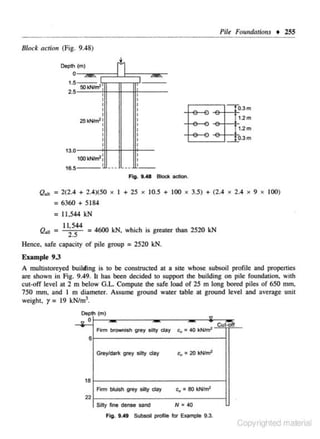

Example 9.6

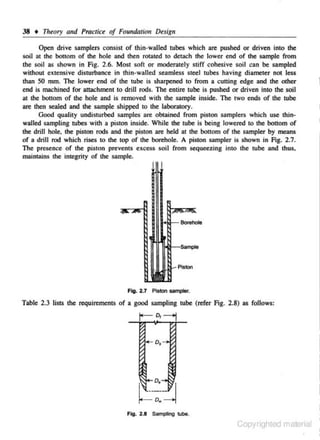

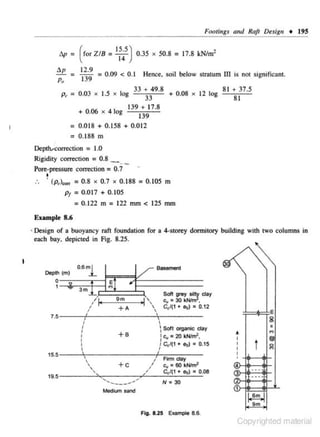

RCC bored piles, 1000 mm diameter x 20 m long are proposed to be used for a flyover

passing over a canal bed with predominantly river channel deposits, as depicted in Fig. 9.50.

OMC method of boring is adopted and steel liners would be u~d to a depth of at least 15 m

below G.L. Design the safe pile capacity.

N (BiowS/30 em)

0

0

3

•

-

10

--

20

30

40

- :'off-- -,

~

Cut

~N

= 20

10

Brownl$h

medium 10

sand

£

2'

20

0

30

Greyish brown

stiff clay

c., • 100 k.Nim2

40

I

Fig. 9.50 RCC bored plies for Example 9.6.

Copyrighted material](https://image.slidesharecdn.com/theoryandpracticeoffoundationdesignreadable-131111103422-phpapp01/85/Theory-and-practice_of_foundation_design_readable-282-320.jpg)

![282 • 111eory and PTClctice of Foundation Design

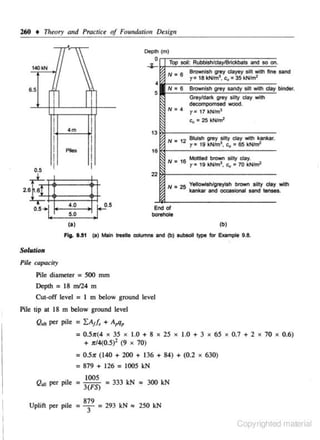

Case 1: Pier well (Fig. 10.9)

0

ic__rD_N ~

, .,

l

ul

Fig. 10.9 Active and passive pressure diagram for pier weJI in cohesive soil.

Depth or tension crack, d, =

where

D

= depth

2c[ii"; <: D

r

below scour line,

c = cohesion

r=

unit weight of soil

2

Permissible moment.

M, =

=

~ ( 2c.JN, ~

+ yDN,

~ ~) 8

~(~ rN,D'+ c.jN,D') s

( 10.32)

For d,<D

M=

,

(

~ [!rD'( N,- *)+cD2F.+ J~, )]s

(10.33)

Case 2: Abutment well (Fig. 10.10)

Tension crack extends down ro a depth dr where net Pa = 0

D

1

(a)

(b)

(e)

Fig. 10.10 Active and pa$$1"' pre..ures on abutment well In 'e'L~Y."~~~Iiled

material](https://image.slidesharecdn.com/theoryandpracticeoffoundationdesignreadable-131111103422-phpapp01/85/Theory-and-practice_of_foundation_design_readable-306-320.jpg)

![Well Foundations • 283

That is, (b) + (c) = (a)

or,

or,

( 10.34 )

For d, <:. D

then P. = 0, that is,

same as

in

case

I of pier well.

For d, < D. that is, (a) > (b) but < (b) + (c)

P• exists below dl"

At base,

M, = ![!rD'(N.- ;.) cH'(JN, ;;)]B- ~ B

2

+

+

Po

(10.35)

For (a) < (b)

Then net P. is trapezoidal.

At base,

(10.36)

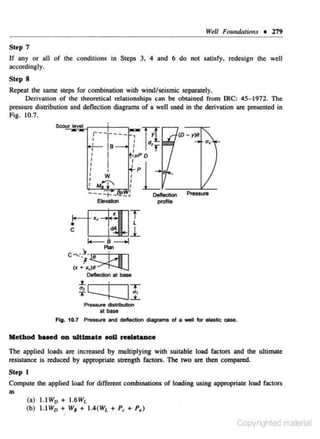

10. 10 WELL SINKING

The sinking or a well foundation is done by excavating the soil within the dredged hole. This

can be done manually or by mechanical dredger. A mechanical dredger consistS or prongs

with hard steel teeth which are pushed into the soil. When the dredger is pulled up, the

prongs c lose to form a bucket full of excavated soil. The mechanical dredger should be

adapced to suit the soil condition.

With increasing depth of well during well sinking, the friction on the sides of the well

increases. If the weight of the steining is not adequate to overcome the friction, suitable

kentledge may be placed on a platform 10 i!ICffiiSO the load on the steining. Air and water

jets are also used to minimize friction. Compressed air is used when well sinking is done

below water level to counter the water pressure inside the well.

Example 10.1

A bridge 120 m long. is to be constructed over a river having Q..... = 2418 mlts,

HFL = 81.17 m; LWL = 73.00 m and existing bed level = 72.00 m. The subsoil consists of

Copyrighted material](https://image.slidesharecdn.com/theoryandpracticeoffoundationdesignreadable-131111103422-phpapp01/85/Theory-and-practice_of_foundation_design_readable-307-320.jpg)

![308 +

111~ory

and Practice of Foundation Design

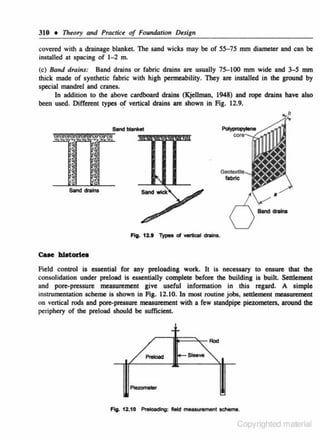

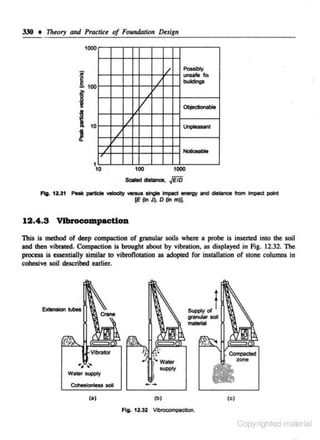

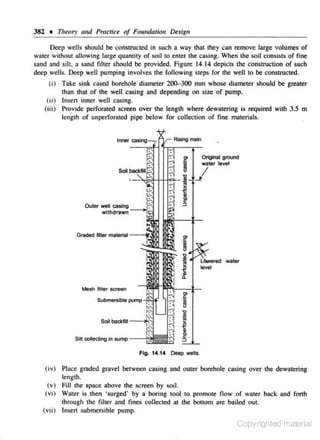

In the earlier days, sand drains, 300-500 mm diamerer, were insralled by filling with

sand the vertical holes made into the soil at predetermined spacing. Nowadays sand wicks and

prefabricned venical drains (PVD), e.g., band drains are mostly used ro have more efficienr

consolidarion under the preload. When a soil is preloaded by dead weighr, the horizonral

drainage path is reduced and the soil undergoes radial drainage. Each drain well has an

axisymmetric Zone of influence with a radius approximately l/2 times the well spacing. 1be

flow "!ithin the zone is a combination of radjaJ flow towards lhe sand drain and vertical flow

towards the free-draining boundary. The average degree of consolidation is rhen given by,

U=

where

I - (I - U•)(l -

UiJ

(12. 1)

u.

= average degree of consolidation due to radial drainage and

Uz = average degree of consolidation due to vertical drainage.

Assuming unifonn vertical strain ar the surface, Barron (1948) gave the expression for degree

of consolidation due to radial drainage as,

u. =

2

where F.= (

n

"

2

n -I

)log.n -

I - exp(-

T, =

c,:

d,

dra1 n d tameter

. '

= radial

(12.2)

(3n'~ 1).

4n

= !!.J_ _ equivalent drain spacing

d ,.. -

s;:)

d

• an

time factOr.

The drains may be insralled in either square or triangular grid. Considering the influence area

of each drain to be circular. we have

d~ = 1.13s for square pattern

}

(12.3)

• LOSs for triangular pattern

where

s = actual drain spacing (refer Fig. 12.7).

SQuare grid Triangular grid

s

ct. •1.13s

n • d.Jd.,

Fig, 12.1

s

ct. • t.05s

T, =c,tld]

Spadng of vertical drains.

Copyrighted material](https://image.slidesharecdn.com/theoryandpracticeoffoundationdesignreadable-131111103422-phpapp01/85/Theory-and-practice_of_foundation_design_readable-332-320.jpg)

![Ground lmprovemenr Tech11;ques • 321

•

s

0

•

0'

.•

'- Stone COlumn

•

0

•. [~r(1

•

(diamolord)

0

•

0-------0

1

fl

seone CXlfUmn

(dlamolet d)

•'>]""

< , - 1 .oe[Jl'(il + f)

ei)J"'

+

(fl - f)

.•

•

d

O>l R. . rtqular ..._,.,..,,

(a) Square · - •

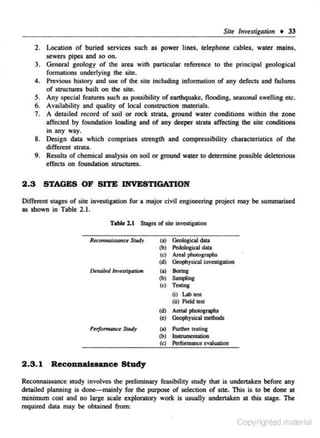

Fig. 12.21 Spac:ing ol atone cok.wnno.

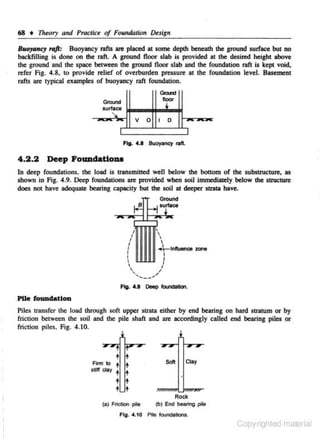

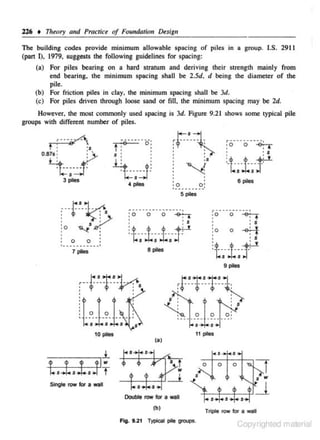

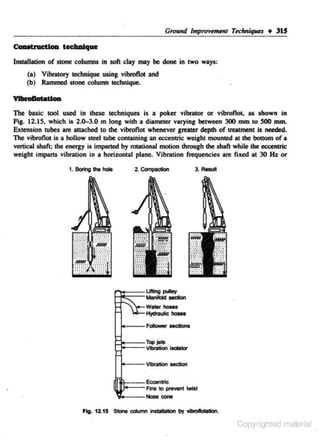

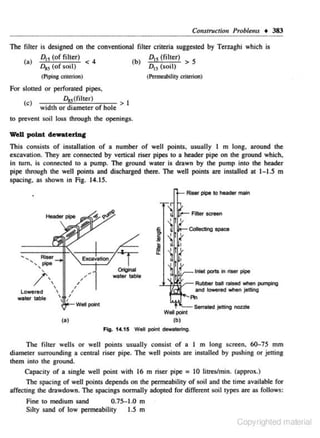

Analysis of granular pile foundations for triangular grid of piles show that s ignificant

reduction in settlement occutS only if the spacing of stone column is close (sld S 4) and the

piles are insulled to fuU depth of consolidating layer. However, too close a spacing (sld s 2)

is not feasible from construction point of view. Thus. a stone column spaci'ng {s/d) of 2.~

is adopted for mQSt practical problems. Also it has been recognized that closer sp:~Cing is

preferred under isolated footing than beneath large rafts (Greenwood. 1970).

LoU CU'f7IDC capacity of I.Dd1Yldu.l etoae columna

A stone column is subjected to a sttess condition much alike that imposed in the standard

triaxial '"t as shown in fig. 12.22. A vertical stress, <J, is applied by surface loading, aod a

radial effective suess. <J, results ftom the horizonllll reaction of the ground. Therefore, the

factors which govern the soik:olumn behaviour are (Hughes et at.. 197S):

-- ••

--{

- - :•

•

•

-~

--·

--·••

•

••

.--

•

•

•

~-

•

•

•

,- •

~-

...

"'

,:..,Y.!!!JI

• ~

•

Ag. 12.22 Slresses acting on stone column.

Copyrighted material](https://image.slidesharecdn.com/theoryandpracticeoffoundationdesignreadable-131111103422-phpapp01/85/Theory-and-practice_of_foundation_design_readable-345-320.jpg)

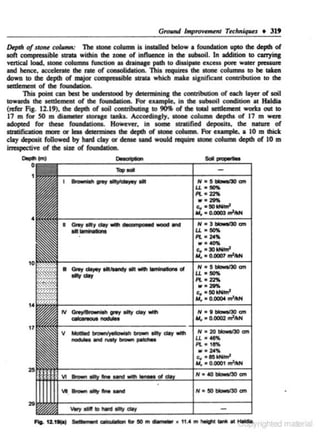

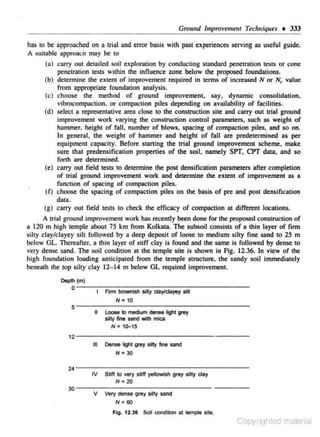

![Grou11d Improvement Tech11iques • 339

Layer

H(m)

I

2

s

10

s

II

Ill

IV

v

IS

Pu (kN/m2) t.p (kN/m2)

48

56

82

127

171

250

46

31

15

14

c,

1 + e0

0.06

0.16

0.08

0.08

0.05

6 (m)

0.031

0.152

0.183

0.076

O.oJ5

0.109

O.oJ8

l: 0.292 m

(* 290 mm)

Effective overburden pressure p. alter stag~ 1 pre~ has been detumined for full coosolldation under

the preload. ln reality. for s.lnlta Ill, IV and V. p. values would be less due to lower degree of consolidation.]

[Nou:

Consider residual settelement of stage l preload occuning in stage II and settlement for

s~age ll preload as

I 0%

30%

I 0%

Stage II : 90%

30%

I 0%

Stage I :

of stratum I and ll

of stratum Ill

of str.uum Ill and IV

of stratum I and II

of Stratum ll

of stratum Ul and IV

Settlement at centre = (0.1 x 0.390) + (0.3 x 0.096) + (0.1 x 0.034)

+ (0.9

X

0.183) + .(0.3

X

0.76) + (0.1

X

0.033)

= 0.262 m - 260 mm

Total settlement during stage I and slage II preload at centre is

383 + 260 = 643 mm

(e) Settlement of tank eentre during hydrotest: Ap = 38 kN/m2

6 =

Layer

H(m)

I

II

Ill

IV

2

5

10

v

15

s

L

C,

I + ~o

H log Pe + Ap

Po

Po (kNtm') Ap (kN/m2)

104

128

158

186

266

37

35

20

17

II

c,

I + 'o

0.10

0.16

0.08

0.08

0.05

6 (m)

0.026

0.084

0.04

0.110

O.oJ

0.095

O.Q25

l: 0.205 m

(.,. 205 mm)

(Nole give-n i n (d) abo..·e is valid for this case also.J

Copyrighted material](https://image.slidesharecdn.com/theoryandpracticeoffoundationdesignreadable-131111103422-phpapp01/85/Theory-and-practice_of_foundation_design_readable-363-320.jpg)

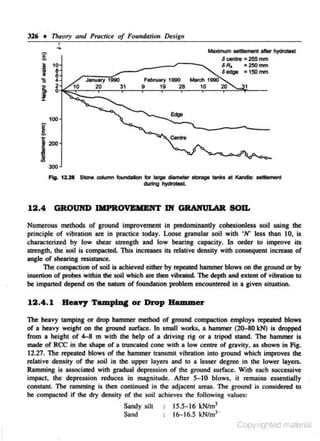

![342 • 17teory and Pracrke of FoundarU:m Design

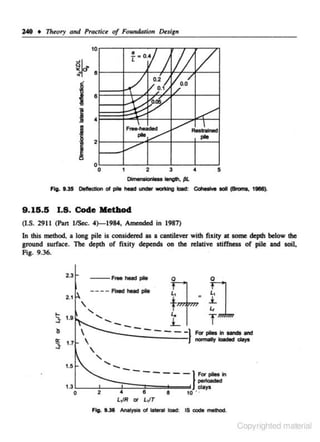

(e) Be•ring capacity of tank foundation

Tank loading

E

Sand pad

Sand fill

E

"'

2

.

For 18 m h1gh tank, q,

= 180 X224

30

+ 2.0

= 135 kN/m2 ("'nd pad)

(f) Diameter of stone column = 500 rom

Spacing: 1.0 m c/c triangular grid

Area= 0.2 m2

Influence area = 0.866 ( 1)2 = 0.866 m2

02

.

Area rallo = _· x 100 = 23%

0 866

.

Olpacity of stone column

q,. =25c, =25 x 40 = 1000 kN/m 2

Using Eq. ( 12.8)

1 +sin;'

. .,, (a,.- u + K c,)

I - SID 'f"

= 4.26[(18

X

2 - 10) X 1.5 - 10 + 4

(GWT I m BGL. K = 4;

X

40) = 805 kN/m2

9' = 38°, and depth of bulging 2

m)

Q,1, per stone column = 0.2 x 805 = 161 kN

rJ

~11

Q.,, • -161 = 80.5 kN Say 80 kN

FS

2

per stone column = -

(g) Be3ring c•pacity of treated ground,

q~l

= [80 + (0.866 - 0.2)(6

X

50)/2.5]/0.866

= 188 kN/m2 > 135 kN/m2

Copyrighted material](https://image.slidesharecdn.com/theoryandpracticeoffoundationdesignreadable-131111103422-phpapp01/85/Theory-and-practice_of_foundation_design_readable-366-320.jpg)

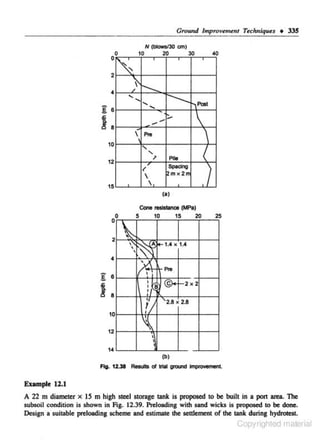

![Earthquake Response of Soils (lltd Fou,dotions • 357

Fig. 13.11 Time history of shear stress during earthquake (Seed and ldriss. 1962).

where.

(...!...) ~.a=

g =

0' =

0

a~ =

=

r,

average cyclic shear stress developed during eanhquake,

maximum ground acceleration.

acceleration due to gravity,

total overburden pressure in the sand layer under consideration,

initial effective overburden pressure at depth under consideration, and

stress reduction factor ( 1.0 at ground surface to 0.8 at S m depth)

(refer Fig. 13.12).

·

r=~

04

.

05

(r

_

06

.

),

07

.

.

08

3

8

g

1

/

9

6

~ 12

15

18

v

/

/

v

/'

1.0

09

I

/

21

Fig. 13.12 Stre:s.s reduction factor

tot

liQuefaction analysis (Prakash. 1980).

For exampl e~ let us consider a site where the ground water table is at the ground surface and

a= 0.2 g. At a depth or S m, the average cyclic stress ratio during earthquake works out as

0 .29 (refer Eq. (13.3)].

Copyrighted material](https://image.slidesharecdn.com/theoryandpracticeoffoundationdesignreadable-131111103422-phpapp01/85/Theory-and-practice_of_foundation_design_readable-381-320.jpg)

![Construction Problems

0

t

379

P.mpW0 or test wetl

p round surface

~I G<Ound surface

2rCU<VO

Orawdown

curve

-

Initial water

{_~~

H

1m-

Impermeable Pata

, ••• J•••l ••JpJ.l ••••••• t,

snta

R

----.1

(a)

Unconfined

aquifer

(b)

Fla. 14.1 o Olsd>lrge trom well$.

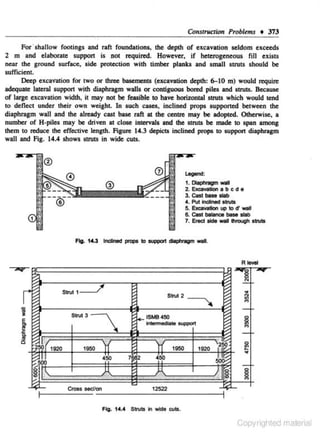

(a) Fully penetrating well [refer Fig. 14.10 (a)]

trK(H 1 - h 1 )

Q = log,(R/r)

( 14.3)

(b) Partially penetrating well [refer Fig. 14.10 (b))

(14.4)

where,

discharge from a fully penetrating well in an unconfined aquifer (m3/s),

discharge from a partially penetration well in an unconfined aquifer (m3/s),

coeffictent of permeability of soil (mls),

height of ground water above the top of aquifer before drawdown (m),

height of water in the well above the top of aquifer after d"'wdown (m), that

is, drawdown = H - h(m),

r = radius of well or equivalent well (m),

R = radius of influence (m), and

h, = penetrating of well below water Ulble (m).

Q=

Q, =

K=

H =

It =

Copyrighted material](https://image.slidesharecdn.com/theoryandpracticeoffoundationdesignreadable-131111103422-phpapp01/85/Theory-and-practice_of_foundation_design_readable-403-320.jpg)

![Co!lstructio" Problems • 387

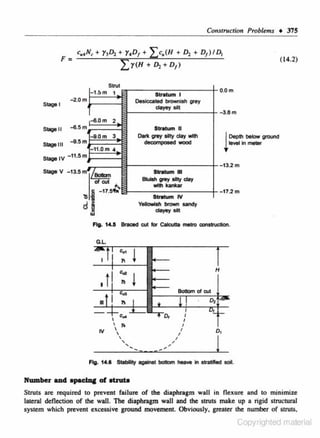

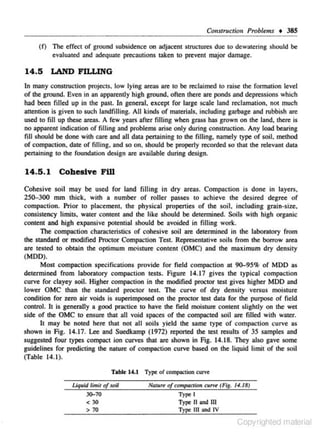

h may however be understood that irrespective of the type of compaction curve. the

highest value of MOD as marked by point A should be taken for specifying the field

compaction parameters in cohesive soil.

14.5 . 2

Granular Fill

Granular soil, predominantly sand, happens to be the mos1 suitable material for land filling.

Well graded sand (D001D 10 > 4) gives good compaction when saturated and vibrated. These

give high bearing capacity and low settlement potential and sand appears to be best suited for

under water filling.

The compaction of granular soil is determined by the relative density, defined as

R =

0

t:mal( -

tmak

e

x

100%

(14.6)

emi"

where.

= maximum

void ratio under loose condition,

t'mi• = minimum void ratio under dense condition, and

t: =: void ratio achieved at site.

emak

•

In terms of dry density, the relative density can be expressed as

Ro

~(

Yot- <rt>mi• )((]'")""")

<r,>.,.. <r.>"". r,

(14.7}

where.

Y.t = dry density achieved in the field,

(y ).,., = maximum dry density as determined in the laboratory, and

4

(rJ)11Wa = minimum dry density as detennined in the laboratory.

For field compaction. a relative density of at least 80% should be specified. This can be

easily achieved by placing lhe loose sand in 300 mm layers, nooding it with water and then

compacting it with vi bro:~tory rollers to 250 mm thick.

Numerous buildings have suffered damages due to inadequate attention given to the

ground filli ng in the construction area. Som and Sahu (1993} report the collapse of a

4·storey building soon after construction near Calcutta. The building was supported on a

c,entral raft with two-.way interconnected strip placed 5.3 m below the ground which had

indicated a bowl·shaped profile sloping across the building. A diffc,rential excavation was

made 10 locate the foundation below the lowest point Subsequent filling on the foundation

put an overburden pressure of varying magnitude across tile building area. This caused a non·

unifonn foundation pressure varying from 16 tlm1 on western side to 11 t/m2 on the eastern

side of the foundation, as shown in Fig. 14.19. The factor of safety against bearing capacity

failure was only 1.5. This is believed to have led to significant yielding of the soil and the

building tilted towards the western race due 10 heavier stress concentnnion. Subsequent

consolidation settlement (the building collapsed almost 3 years after St.."lrl of construction)

appears to have led to further tilting of the building and an estimated angular distortion of

1186 occurred towards the western side as against a permissible angular distortion of ll300 for

Copyrighted material](https://image.slidesharecdn.com/theoryandpracticeoffoundationdesignreadable-131111103422-phpapp01/85/Theory-and-practice_of_foundation_design_readable-411-320.jpg)