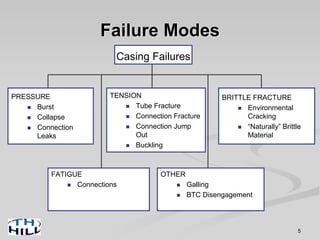

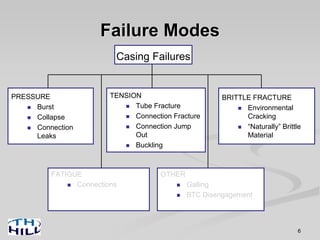

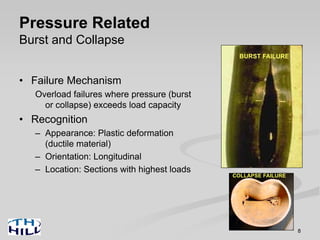

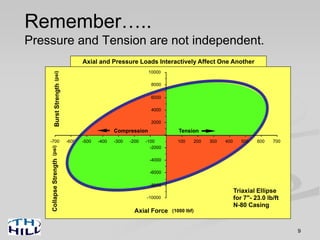

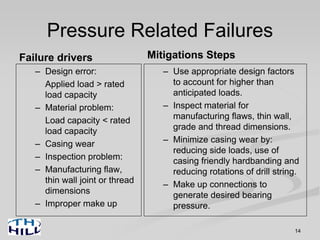

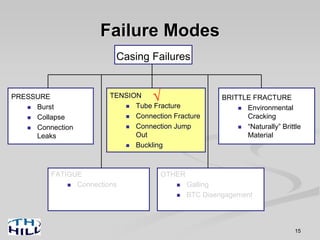

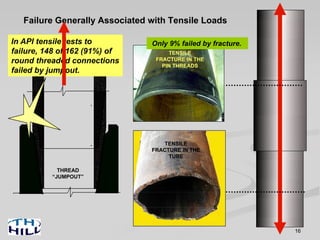

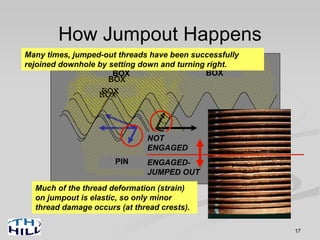

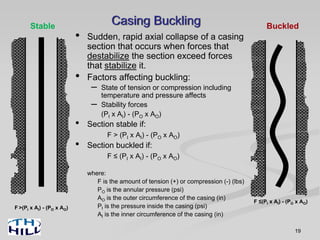

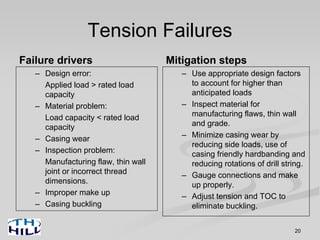

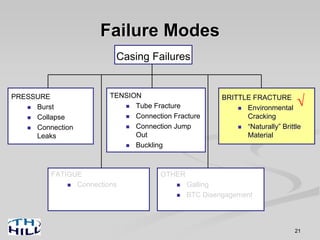

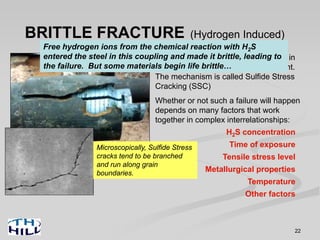

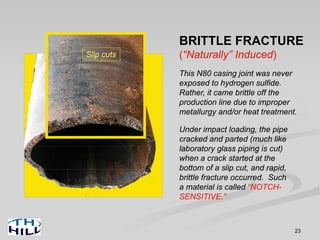

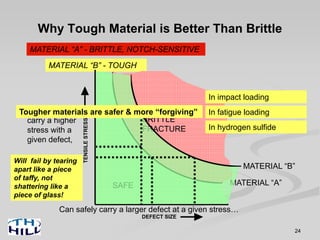

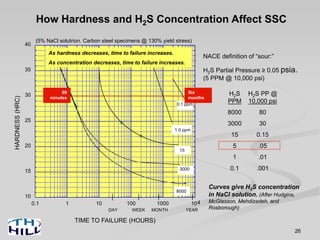

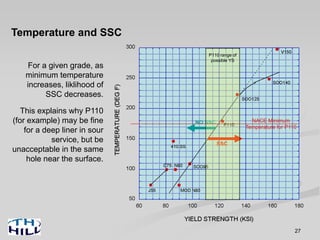

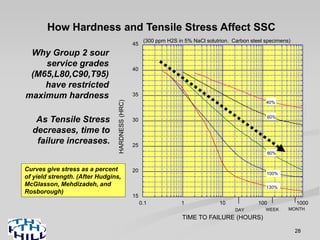

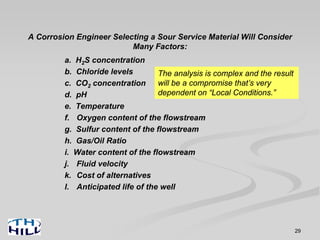

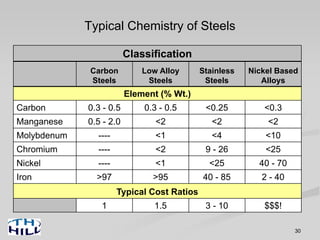

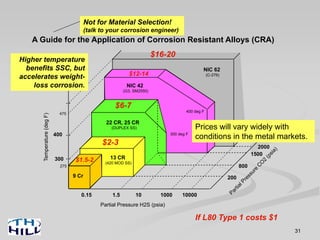

The document discusses common failure modes in casing such as pressure-related failures from burst or collapse, tension-related failures from tube fracture or buckling, and brittle fractures from environmental cracking or naturally brittle materials. It provides details on the causes and mechanisms of different failure types and recommends mitigation steps such as using proper design factors, inspecting materials thoroughly, minimizing casing wear, and ensuring proper connection makeup. The discussion focuses on preventing failures by selecting appropriate casing grades and properties based on factors like hardness, hydrogen sulfide concentration, tensile stress levels, and temperature.