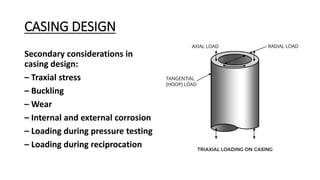

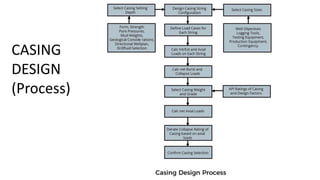

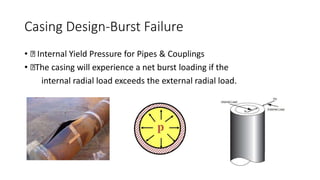

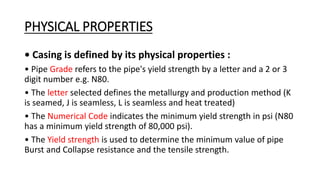

Casing is a crucial tubular component run in wellbores after drilling, serving various purposes such as preventing hole collapse, protecting water zones, and isolating pressure zones. The design and selection of casing must account for strength under different loading conditions, including burst, collapse, tension, and compression. Key factors in casing selection include its physical properties, grades, weights, and connectivity for optimal performance throughout drilling and production phases.

![Casing Designations

• When ordering casing, we should specify the following:

• Grade: refers to the yield strength and metallurgy of the tubular [N80,

K55, H40]

• Weight: refers to weight per unit length of tubular [47.0 lb/ft, 29.0 lb/ft]

• Size: refers to the outside diameter of tubular [13 3/8”, 9 5/8”]

• Connection: the coupling used to connect the tubulars [Buttress, VAM,

LT&C]

• Range: refers to average length of tubular joint [API: R1 = 16 to 25 ft,

R2 = 25 –34 ft and R3=35 – 45 ft]](https://image.slidesharecdn.com/casingdesignppt-240710130812-a4b65136/85/Casing-Physical-Properties-casing-Grades-and-design-ppt-10-320.jpg)