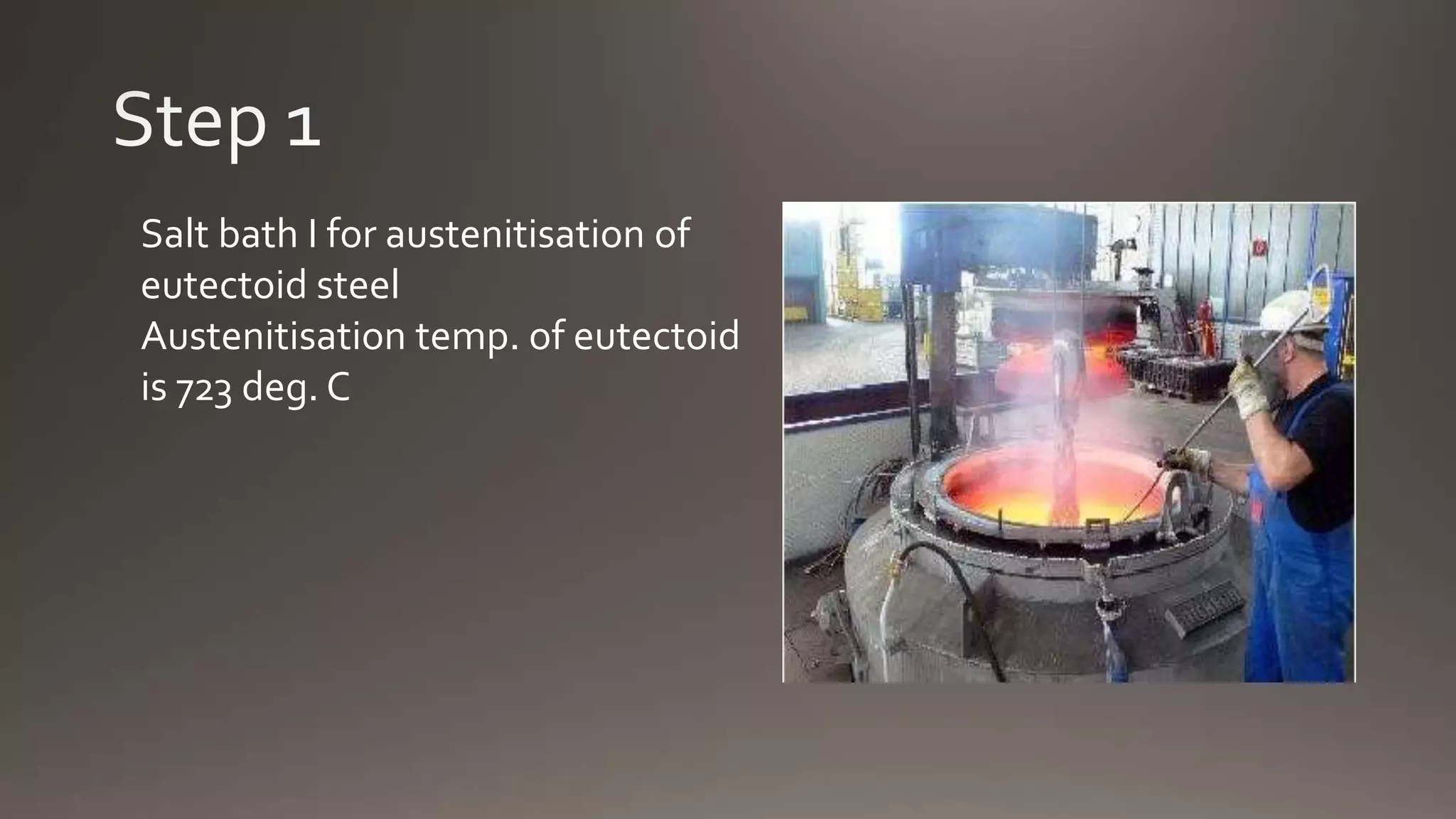

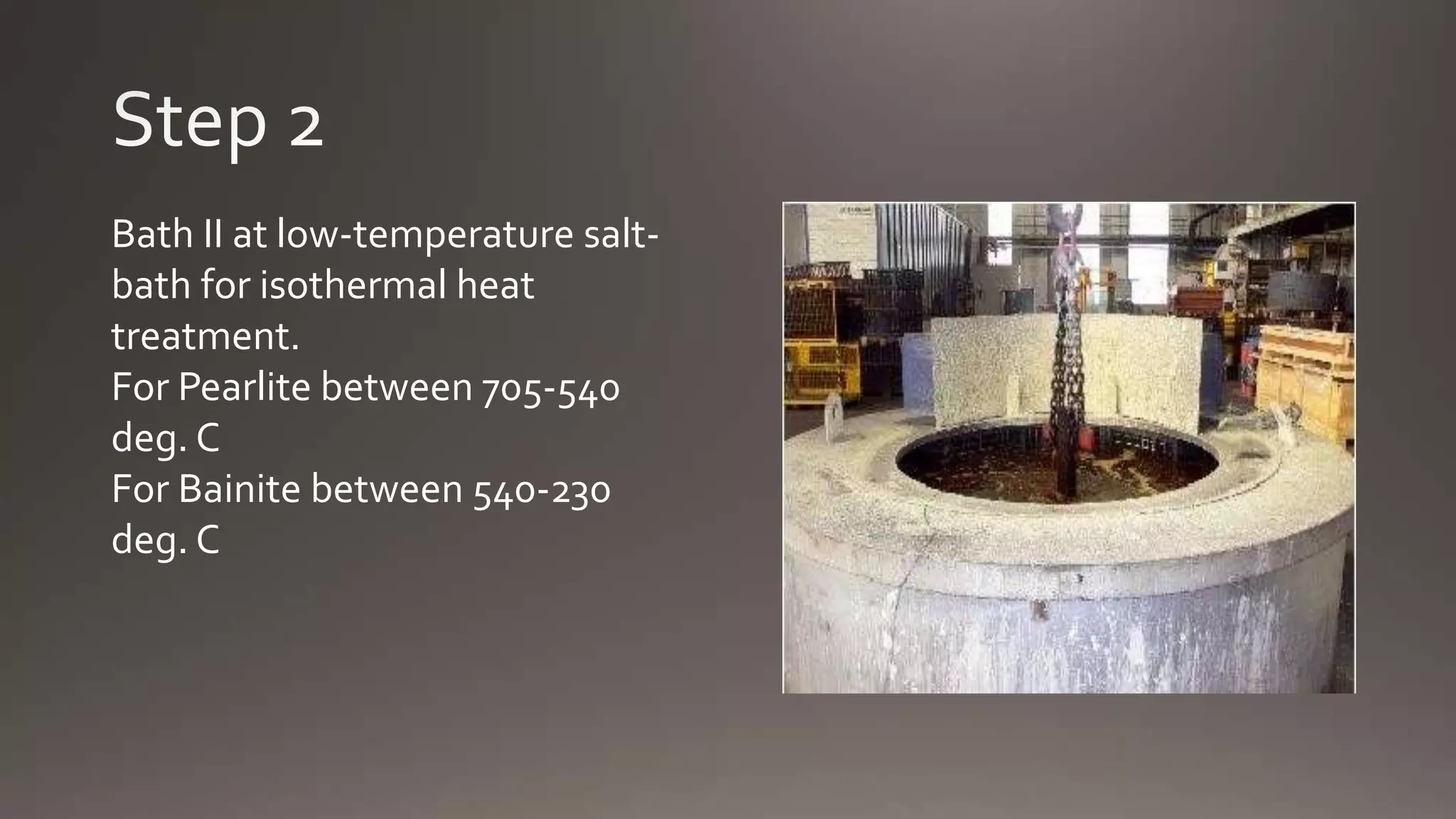

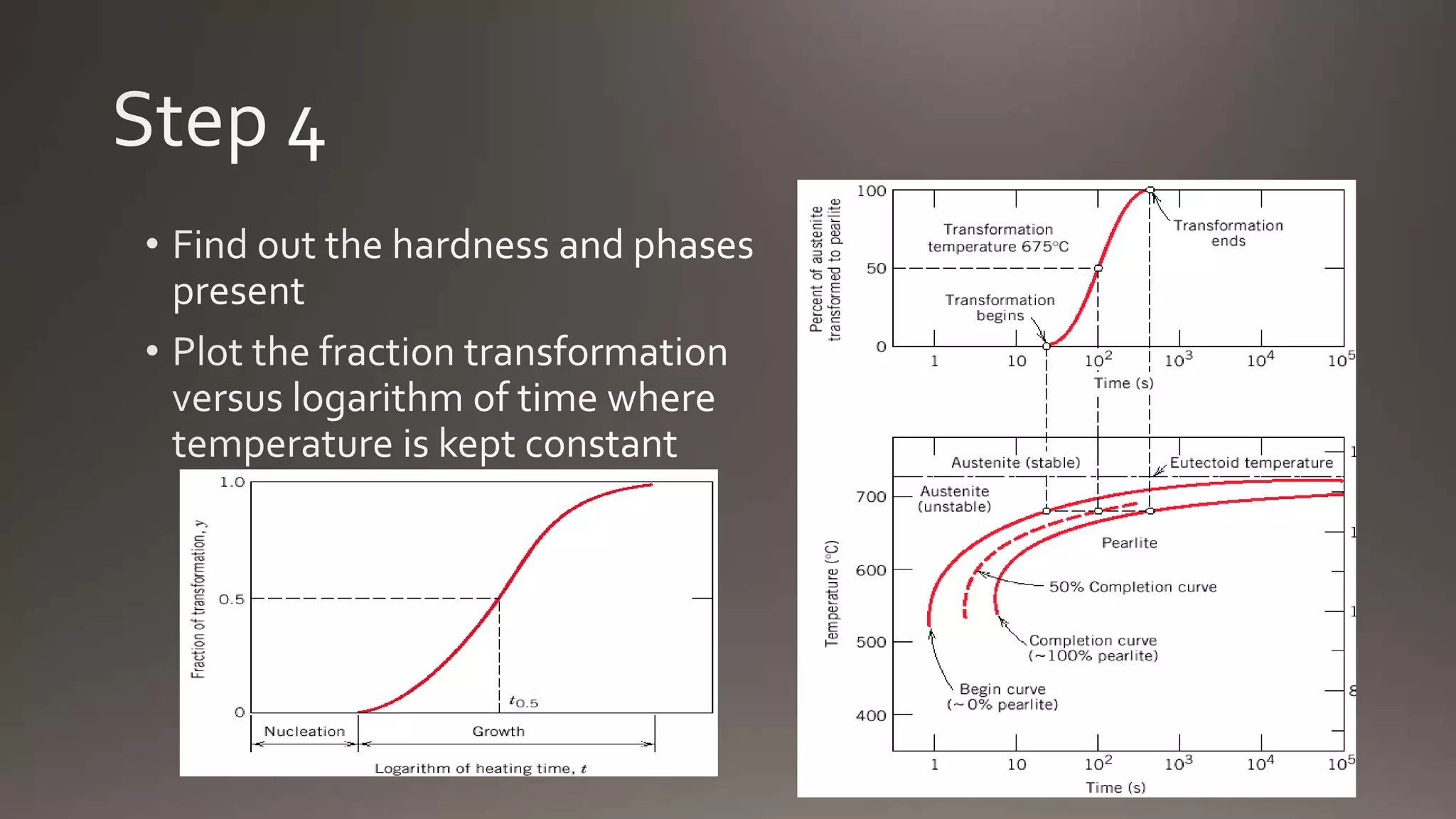

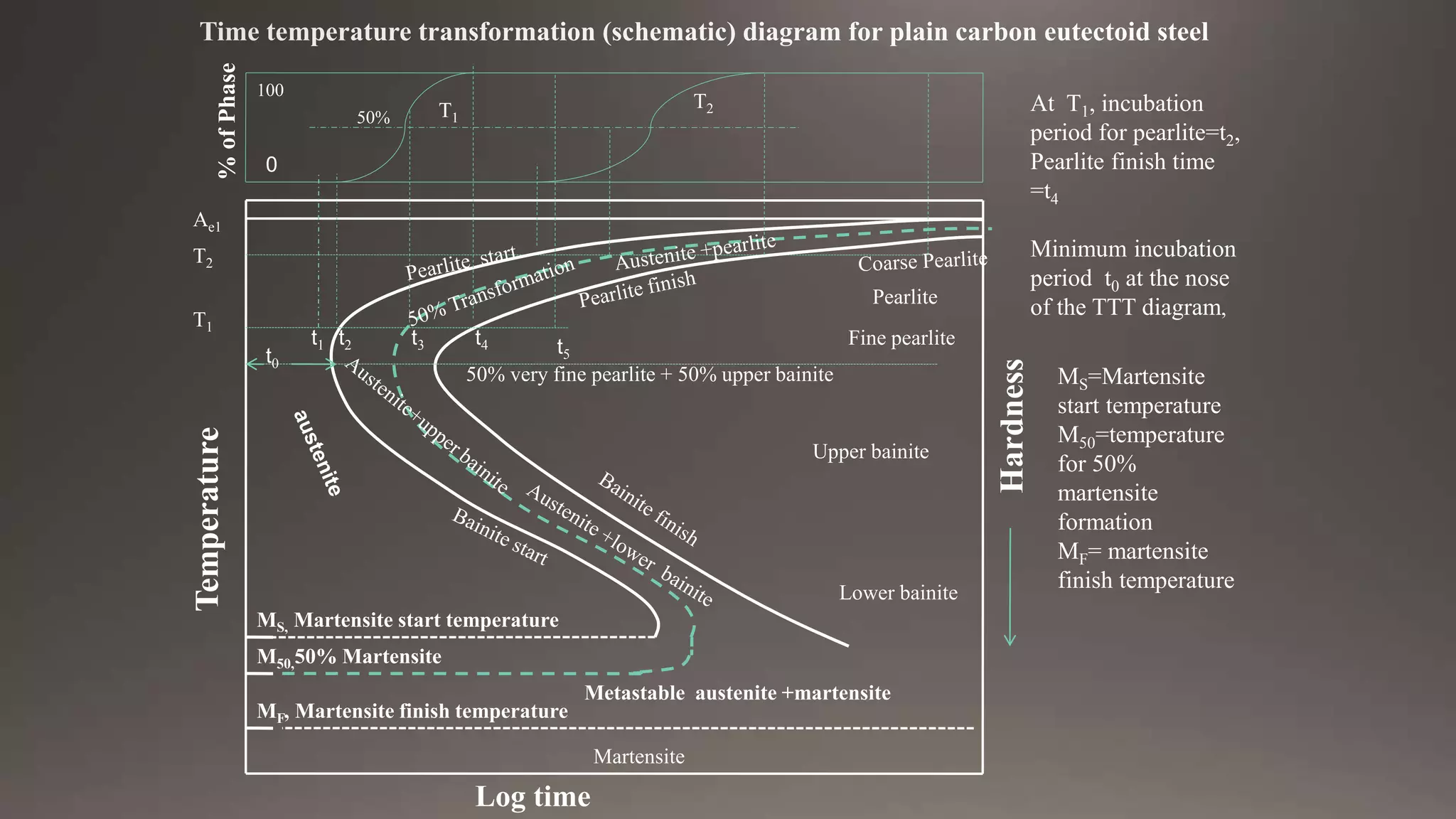

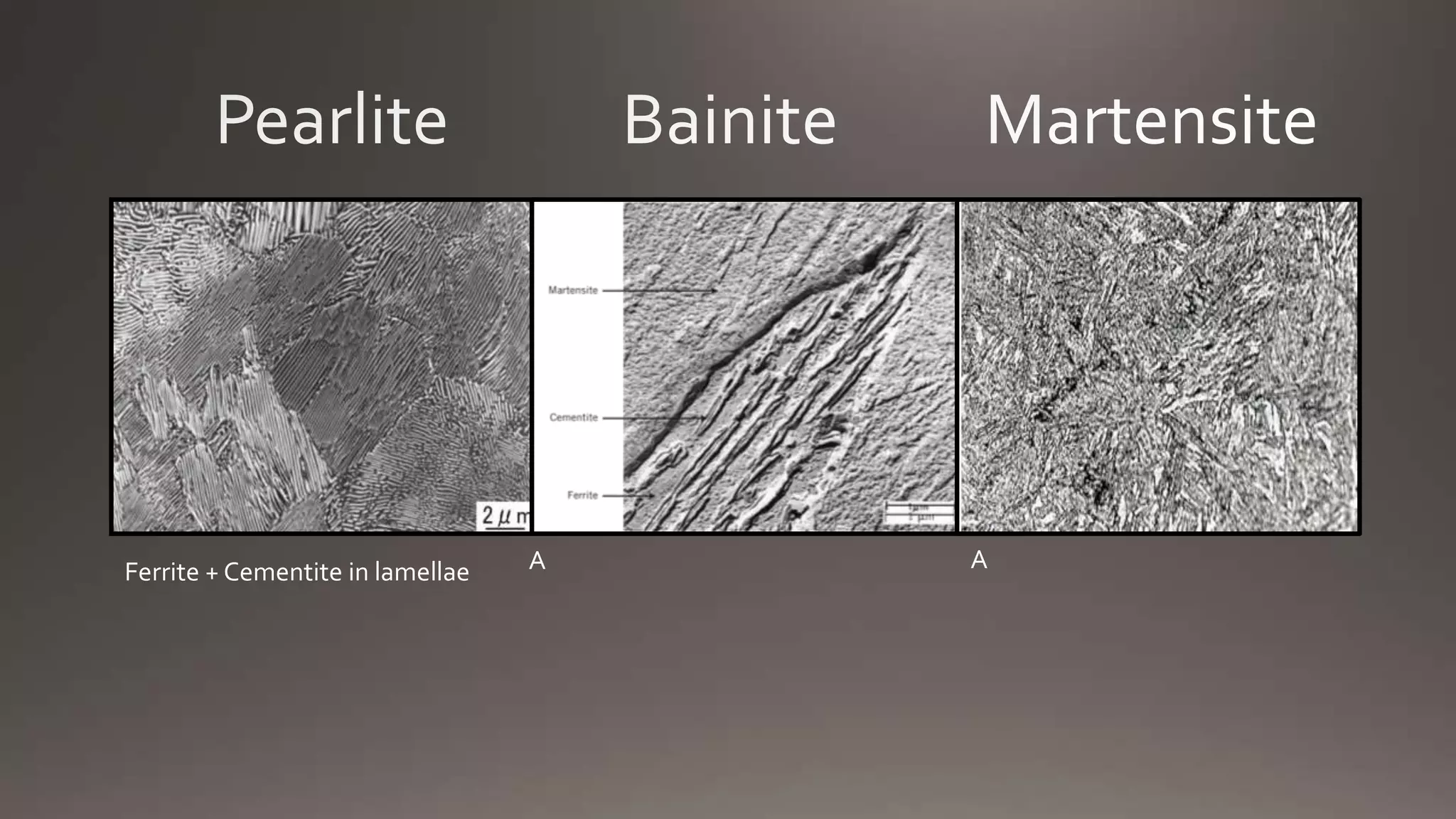

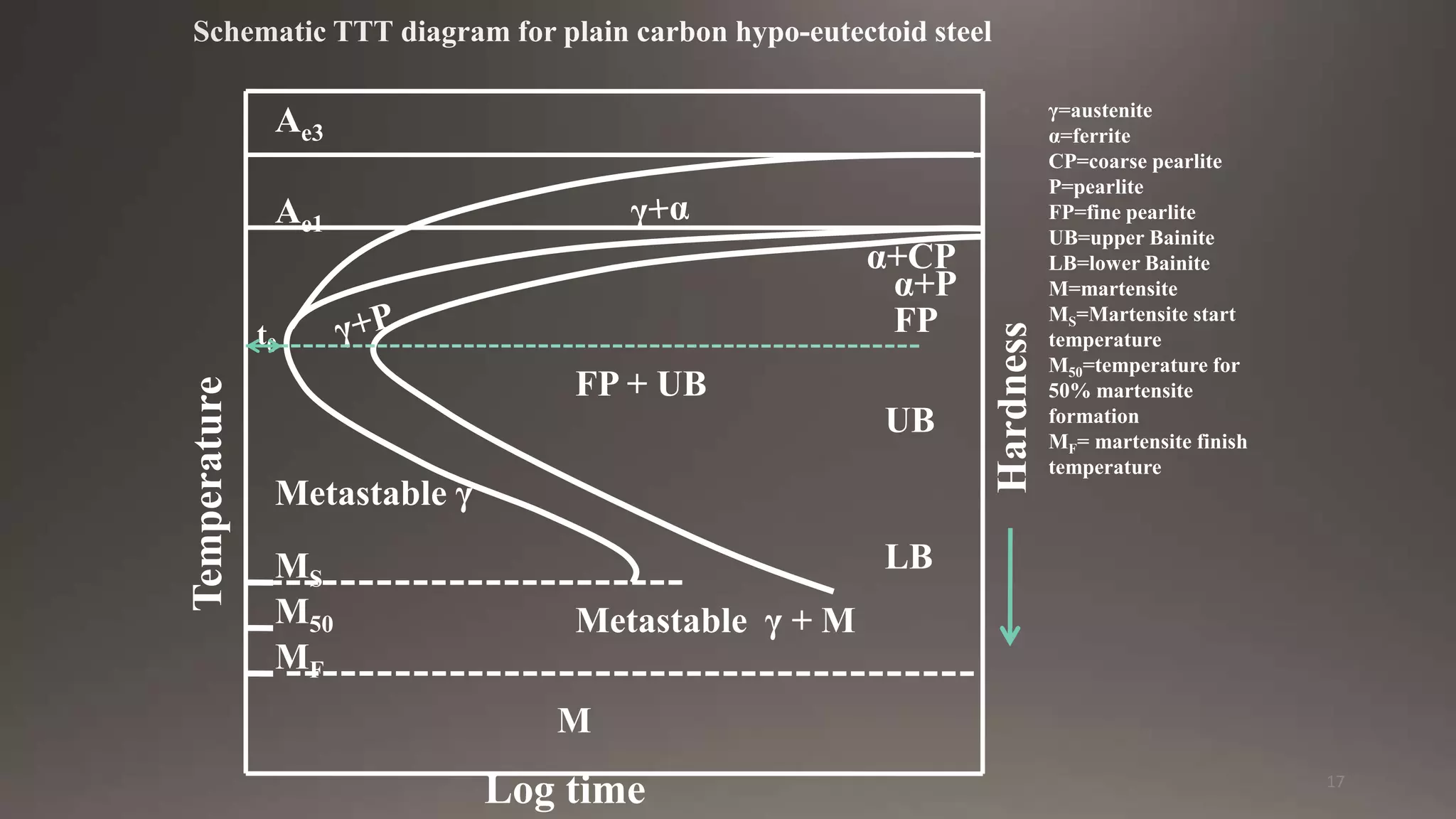

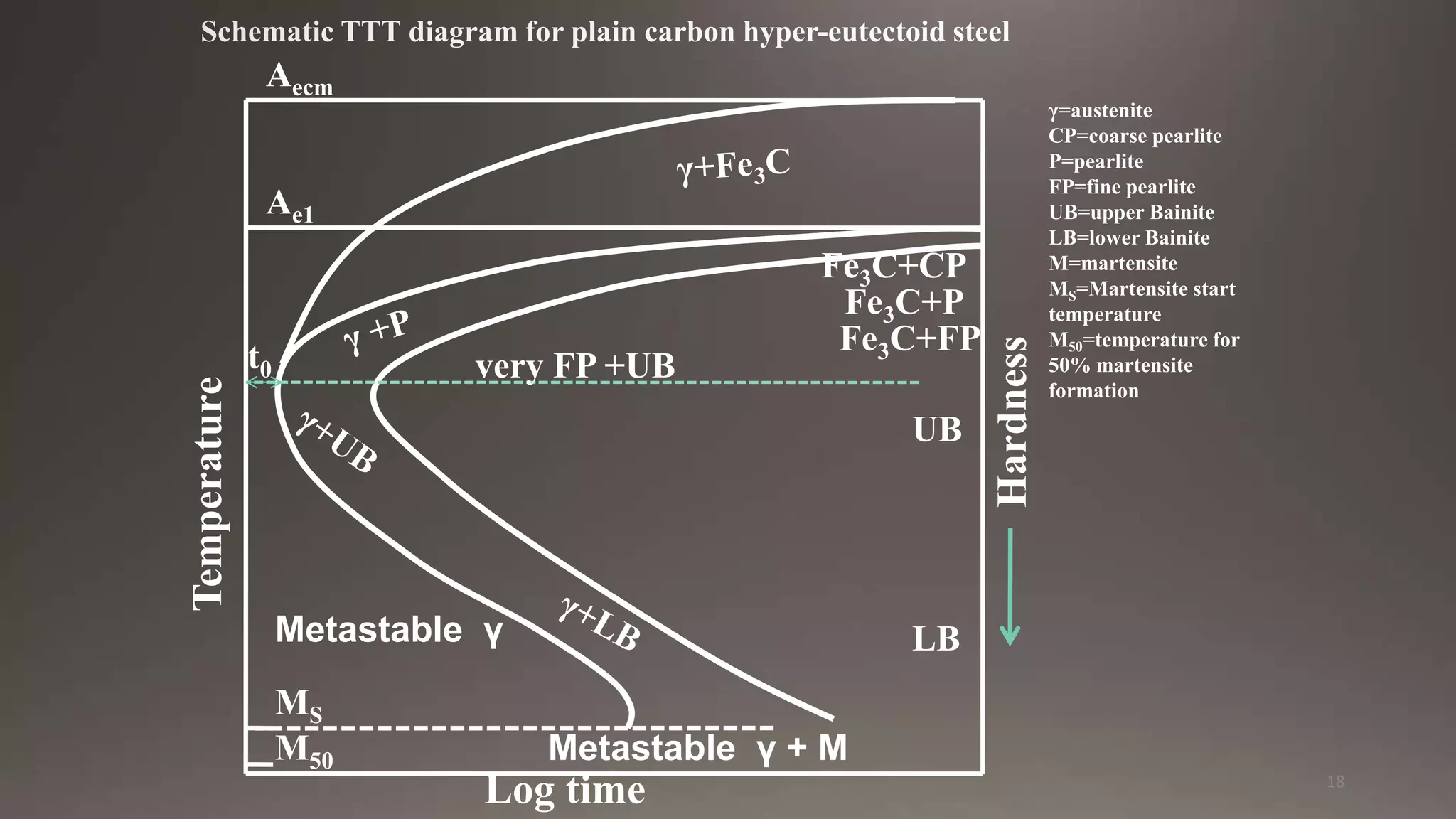

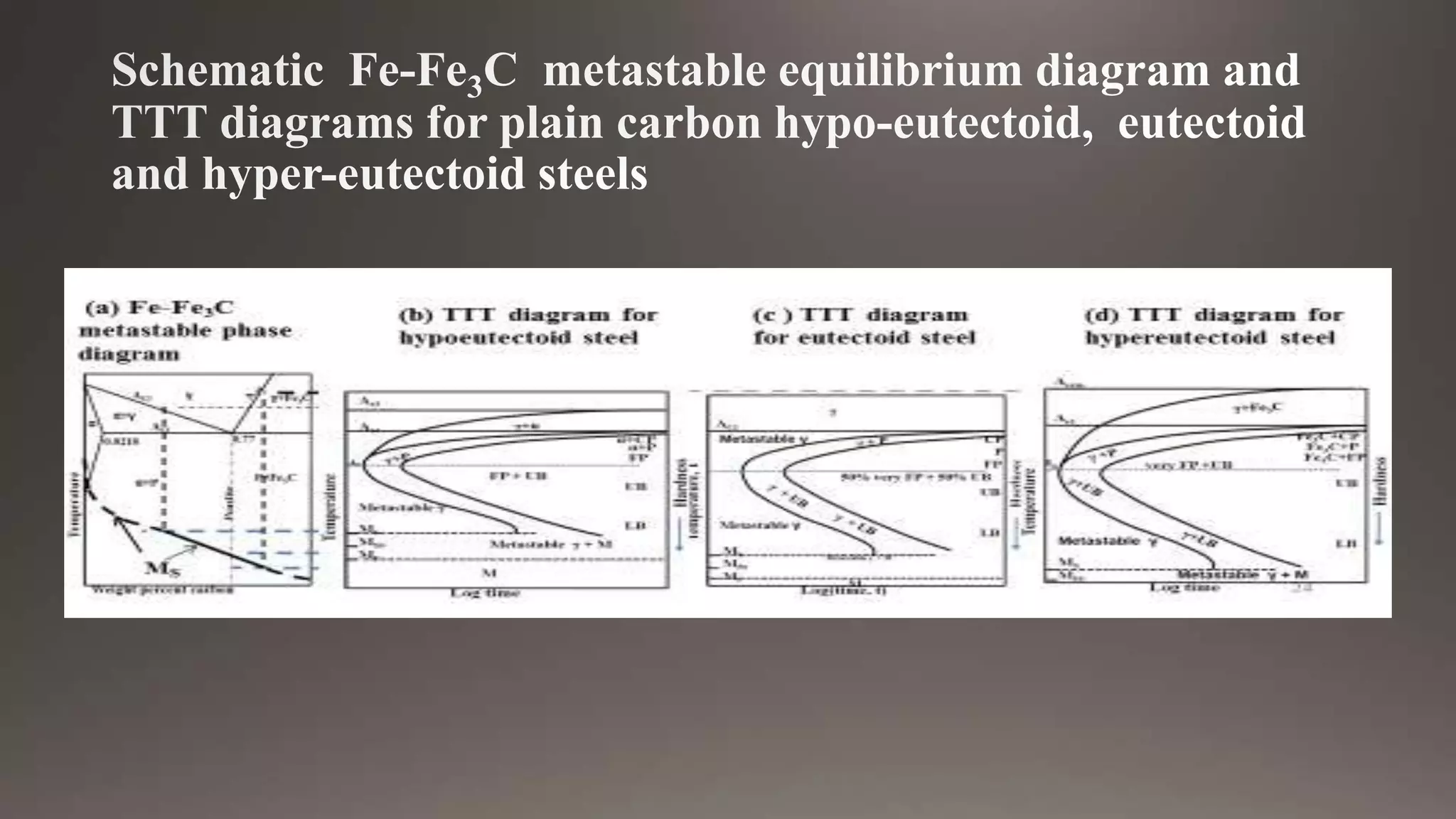

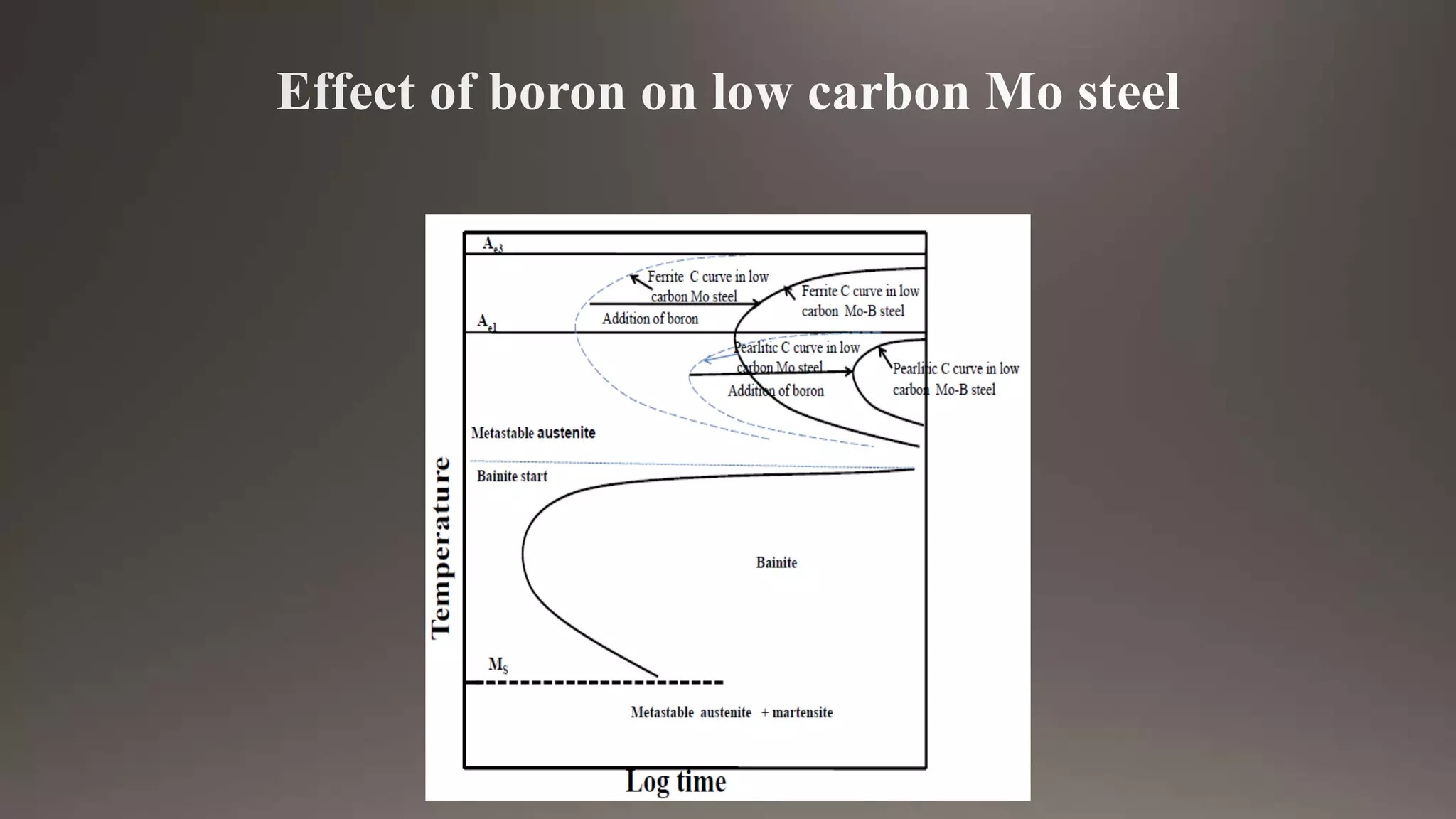

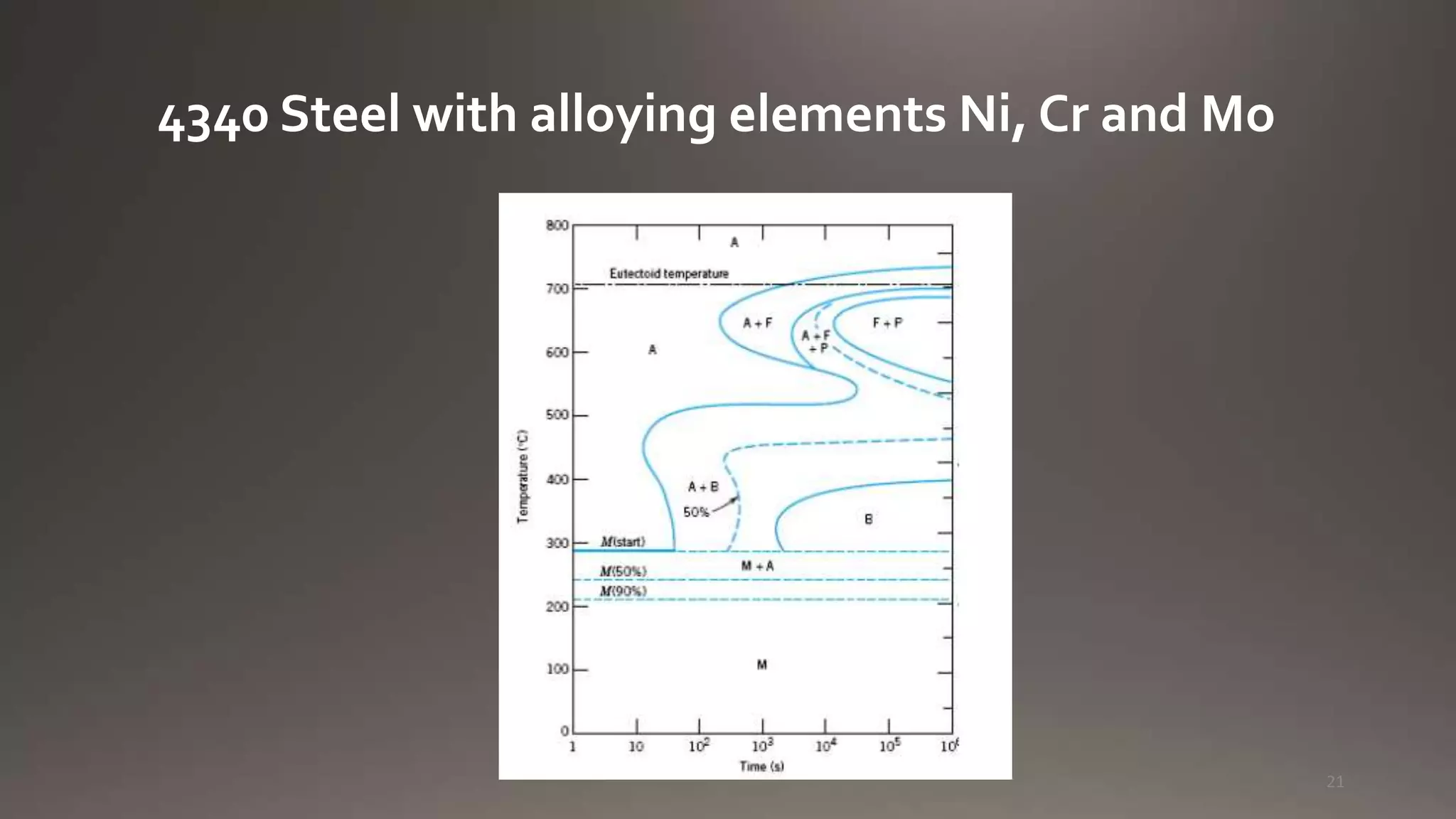

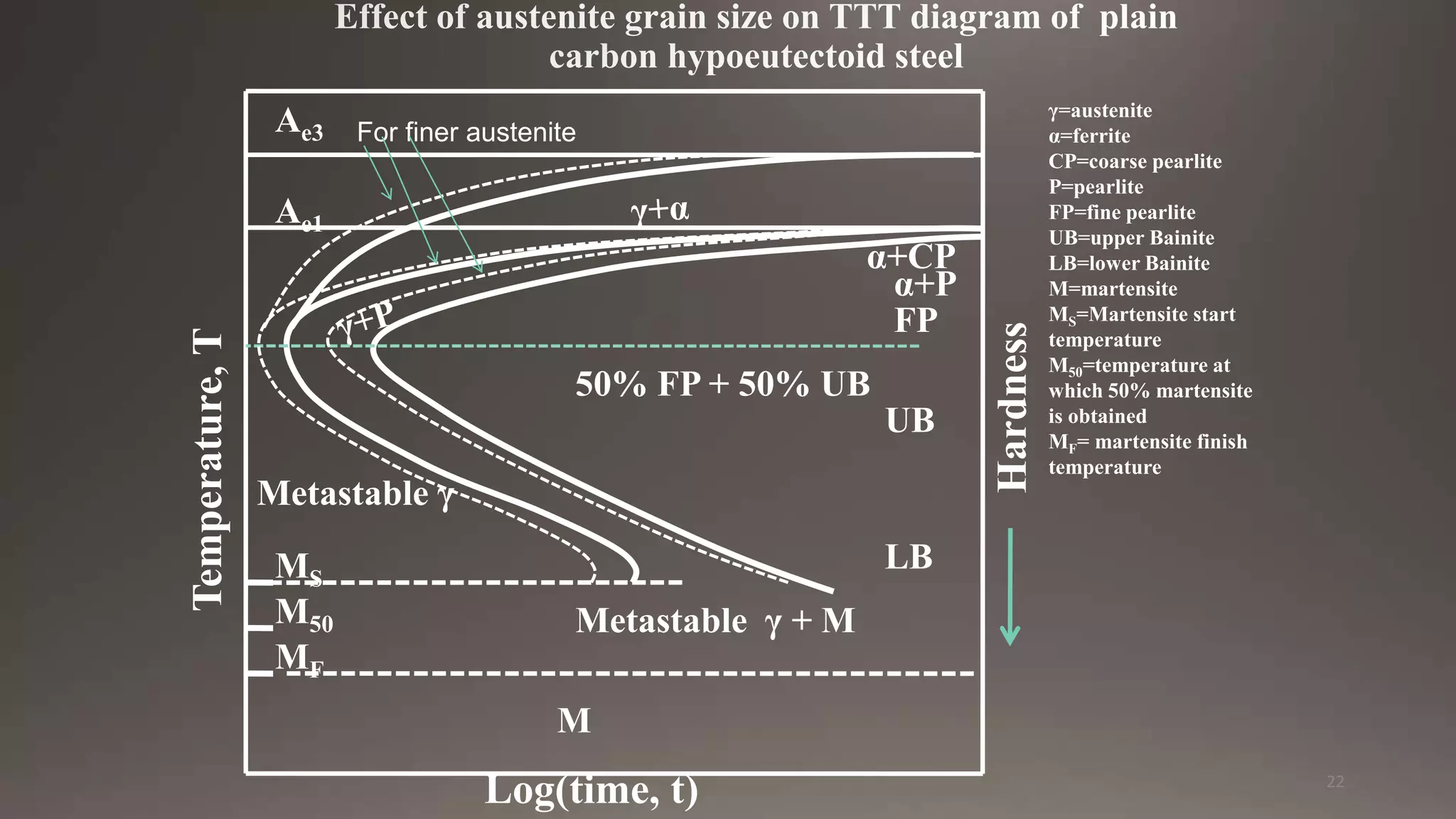

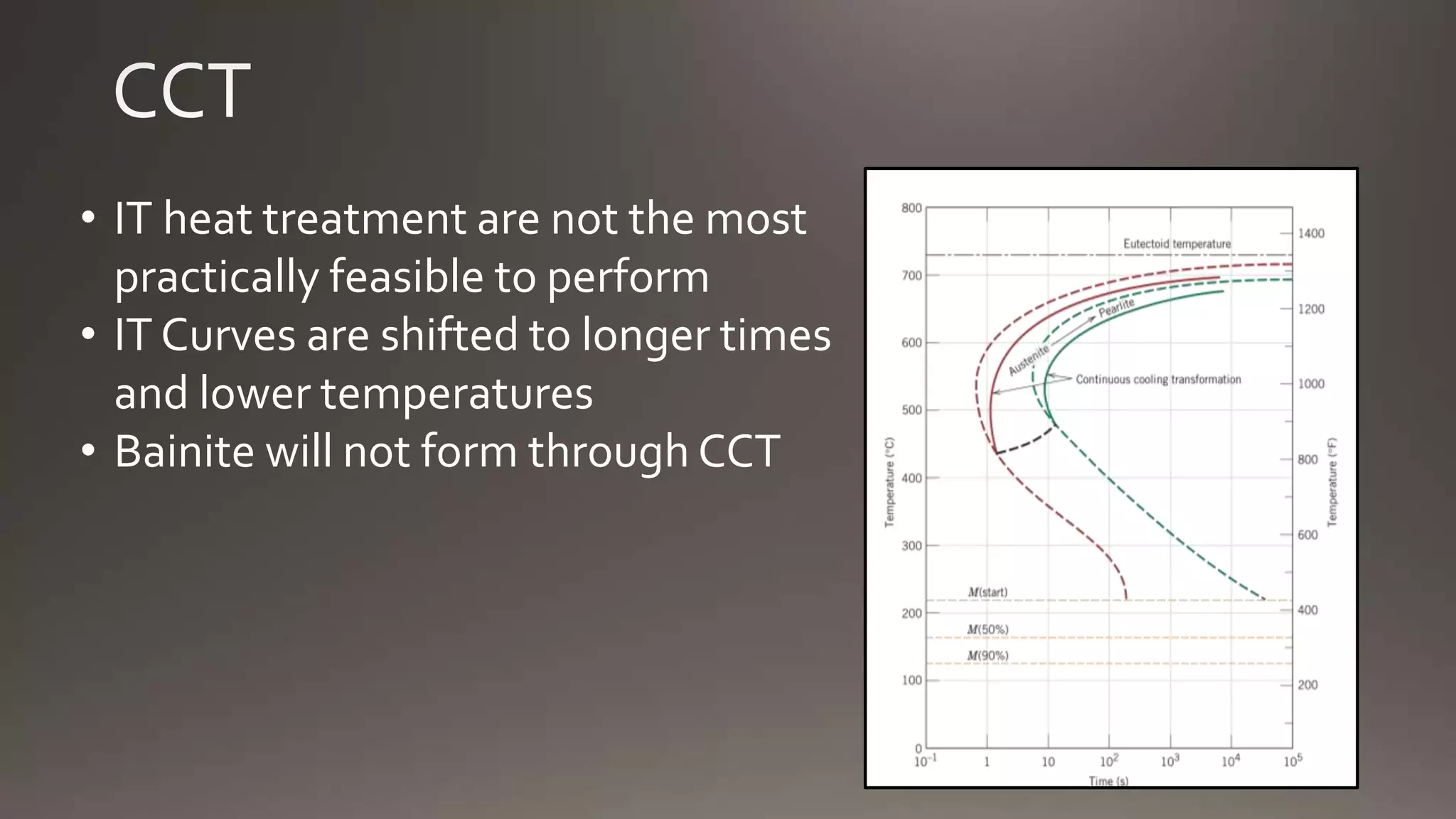

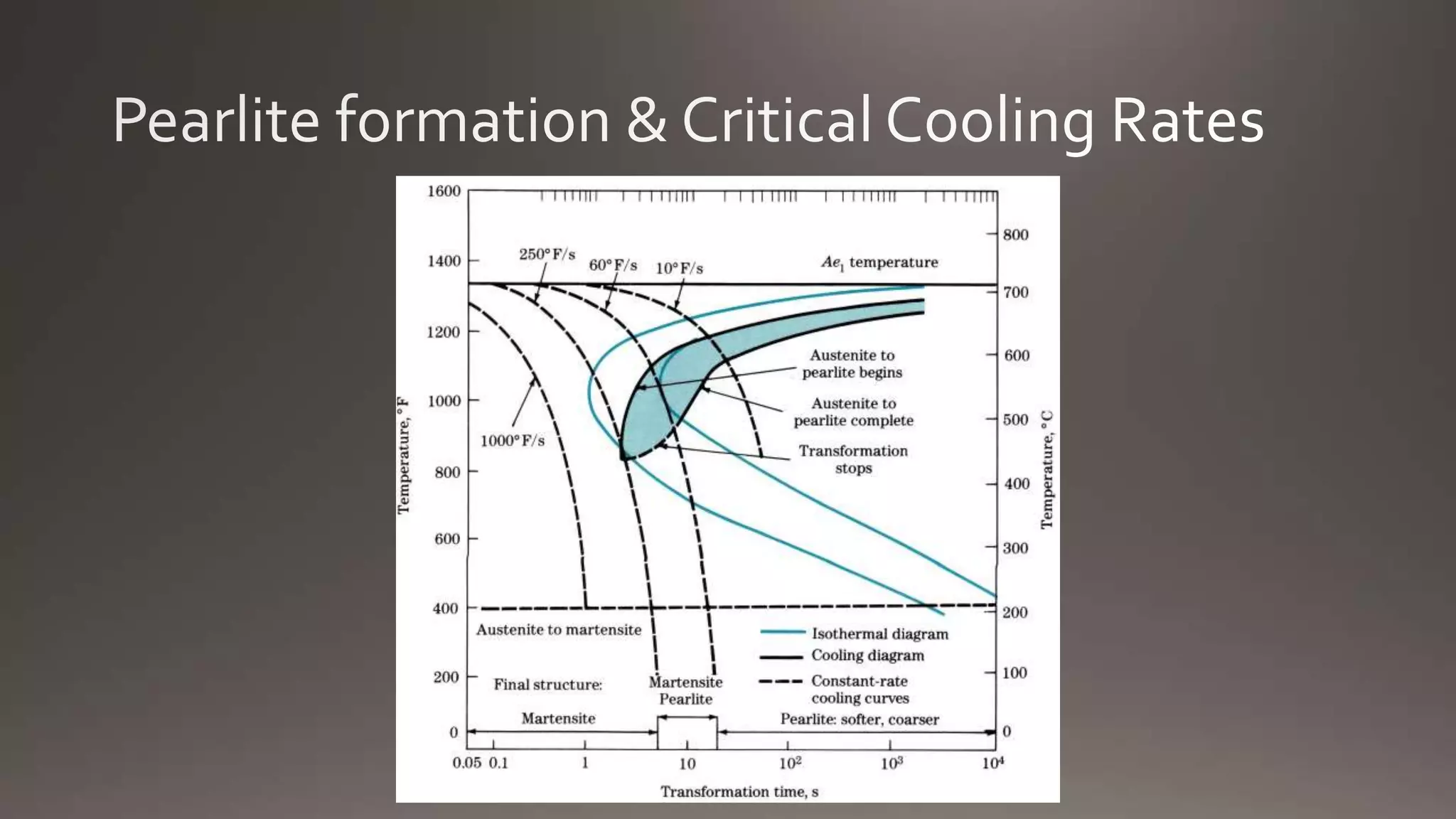

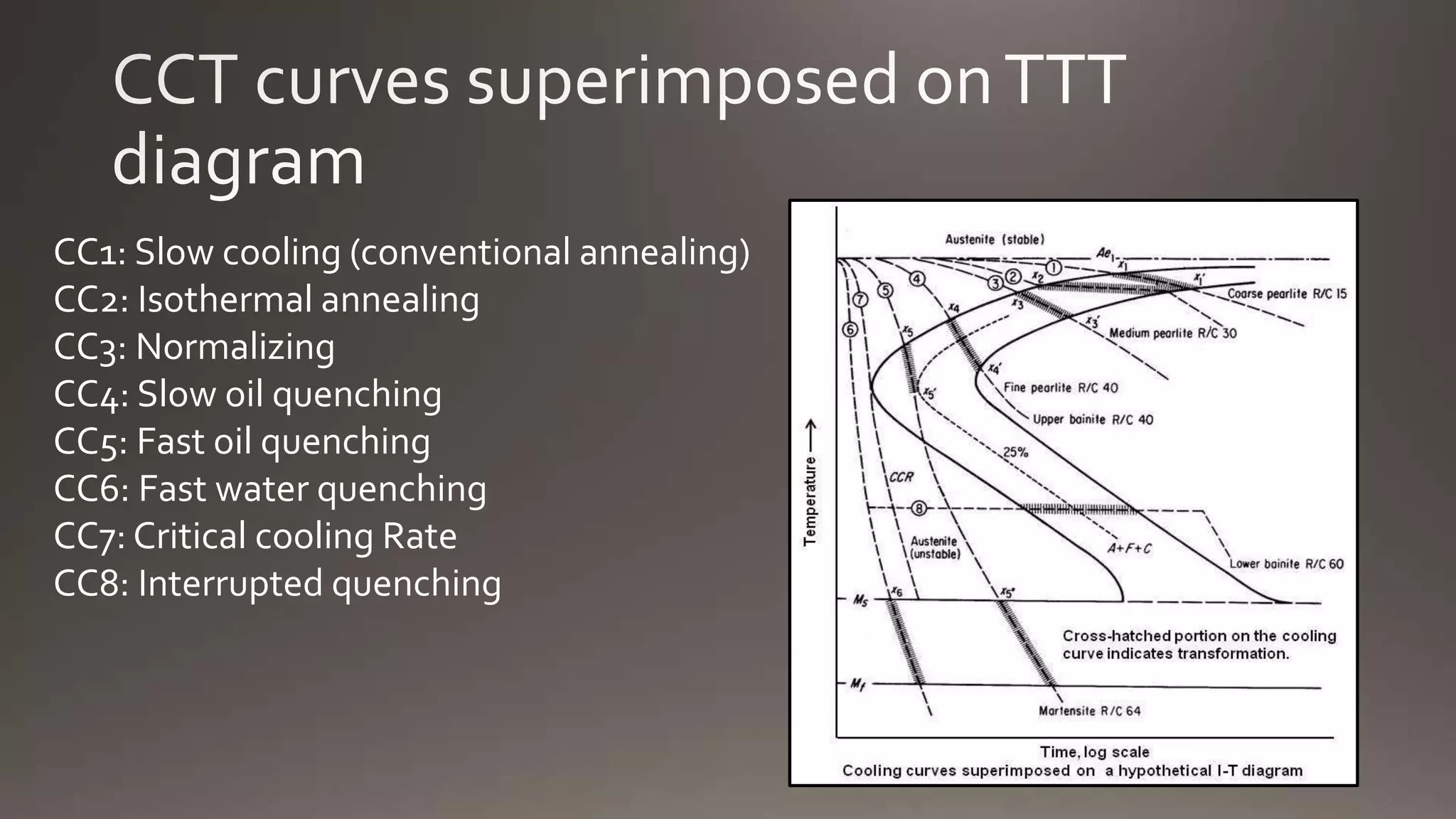

The document discusses heat treatment processes for eutectoid steel, detailing the temperatures and phases involved in austenitization and the formation of microstructures such as pearlite and bainite. It includes information on various treatments, incubation periods, and martensite formation temperatures, as well as limitations regarding practical feasibility. Additionally, the document outlines cooling curves and different quenching methods related to these processes.