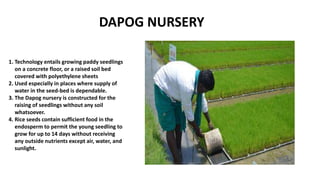

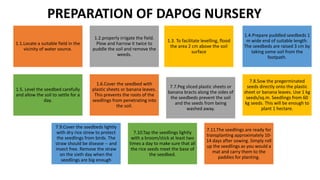

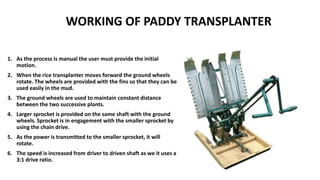

The document discusses several farming methods including dapog nursery farming and hydroponics. Dapog nursery farming involves growing seedlings on plastic sheets or banana leaves placed over raised seedbeds, without soil. This saves time and space compared to traditional nursery methods. Hydroponics is described as growing plants without soil by using nutrient solutions, allowing for less water and space usage. Other topics covered include advantages of poly mulching, uses of hydrogels to retain water for plants, and a brief overview of paddy transplanters used in rice farming.