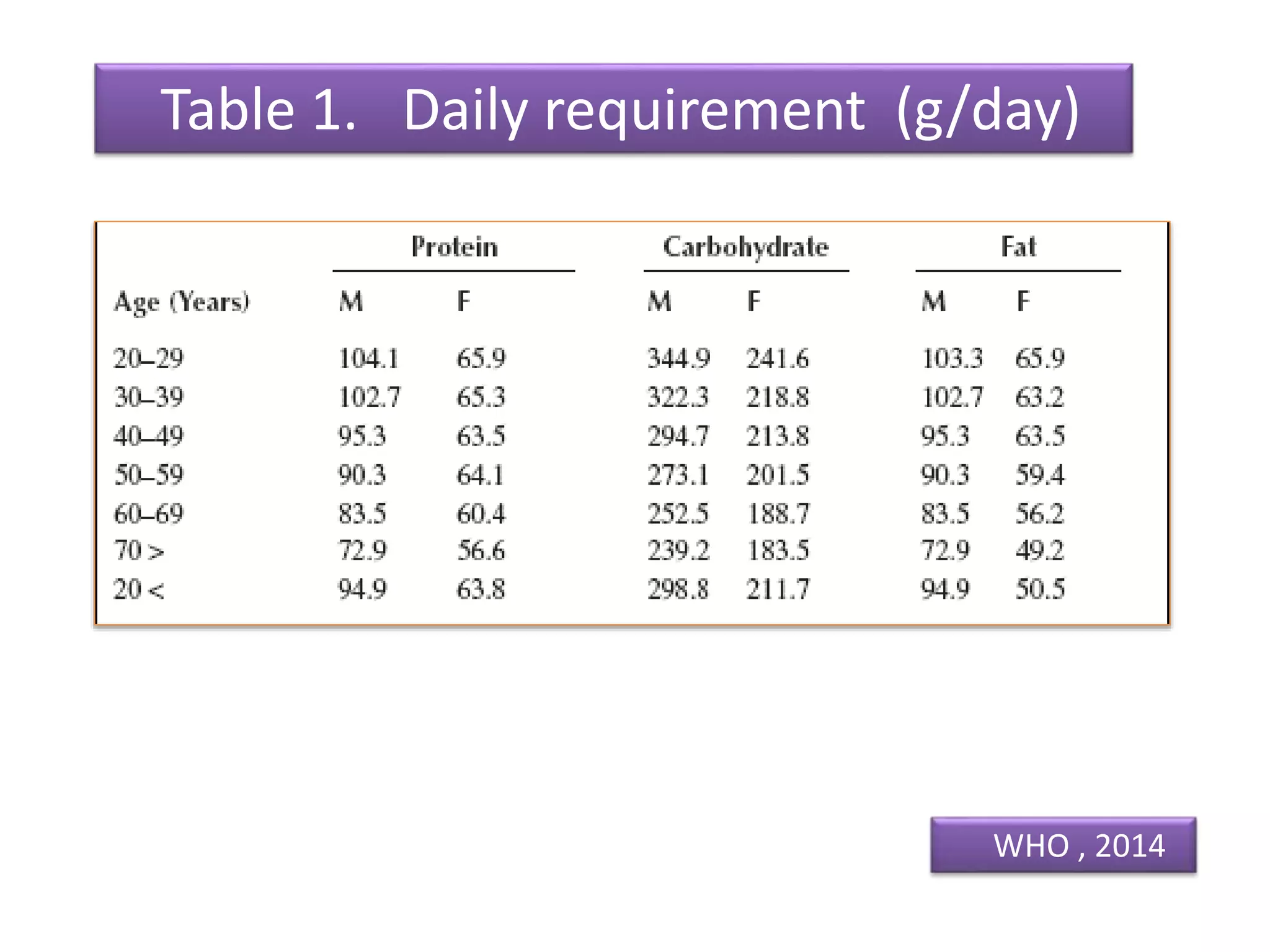

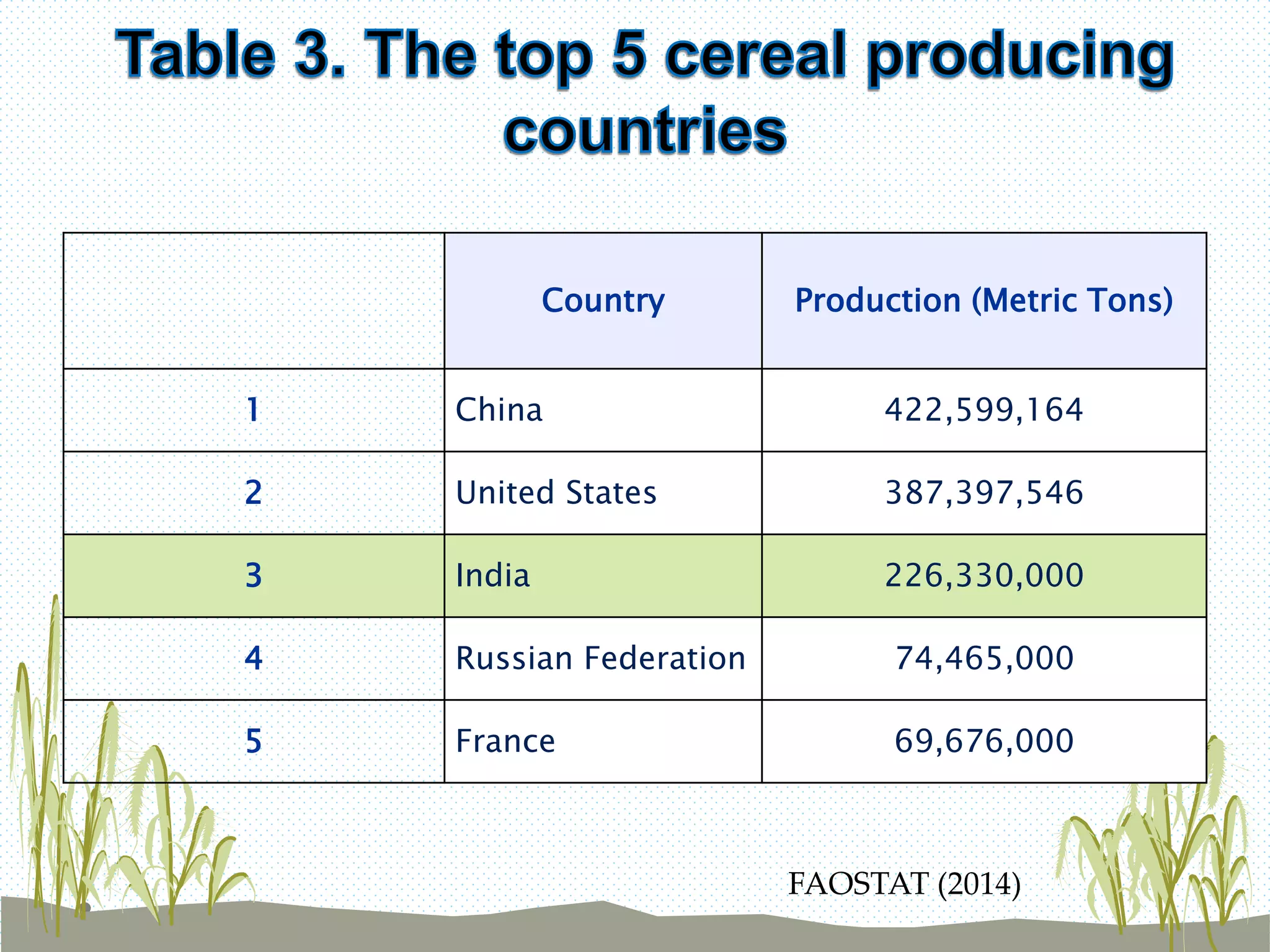

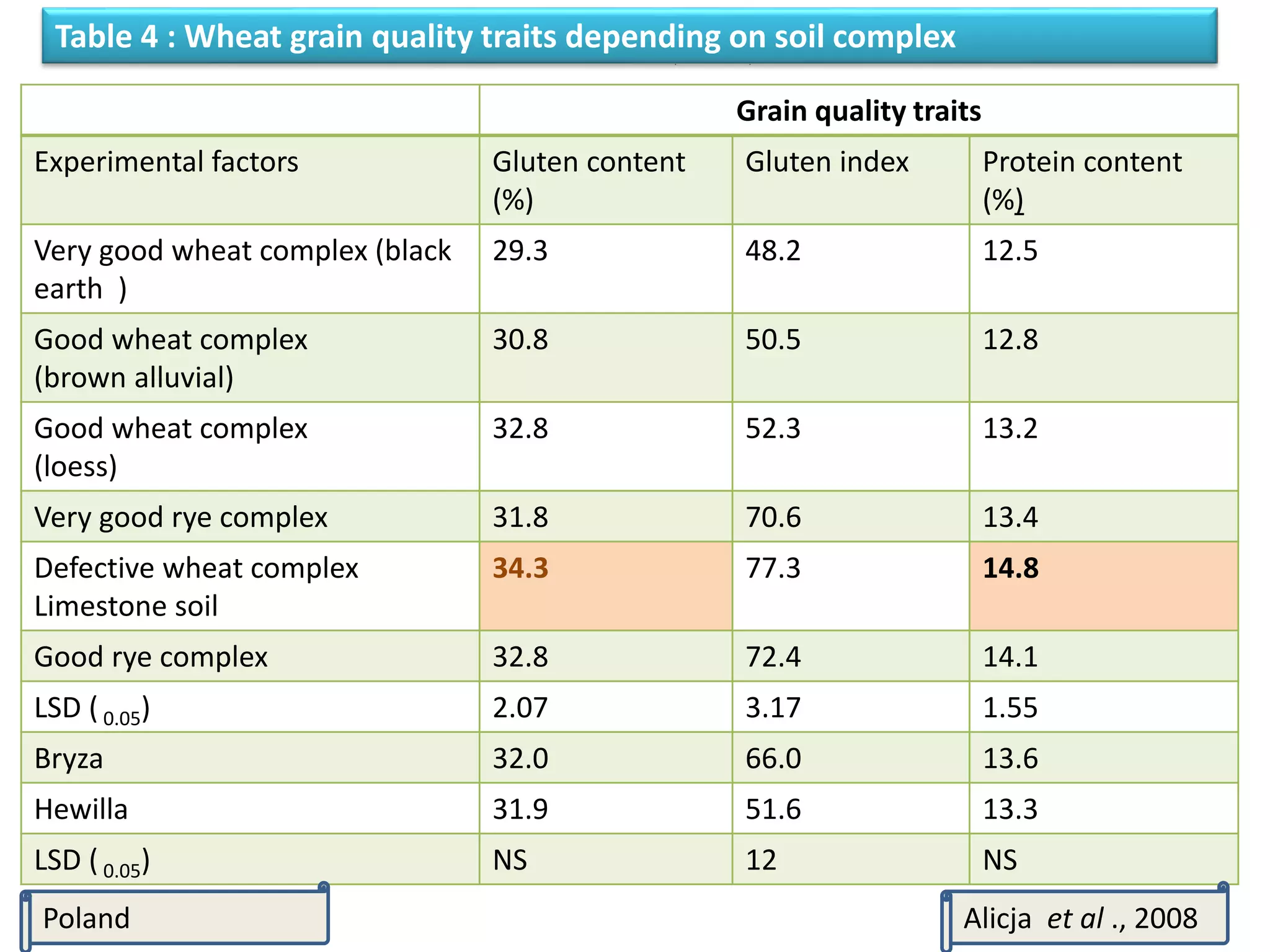

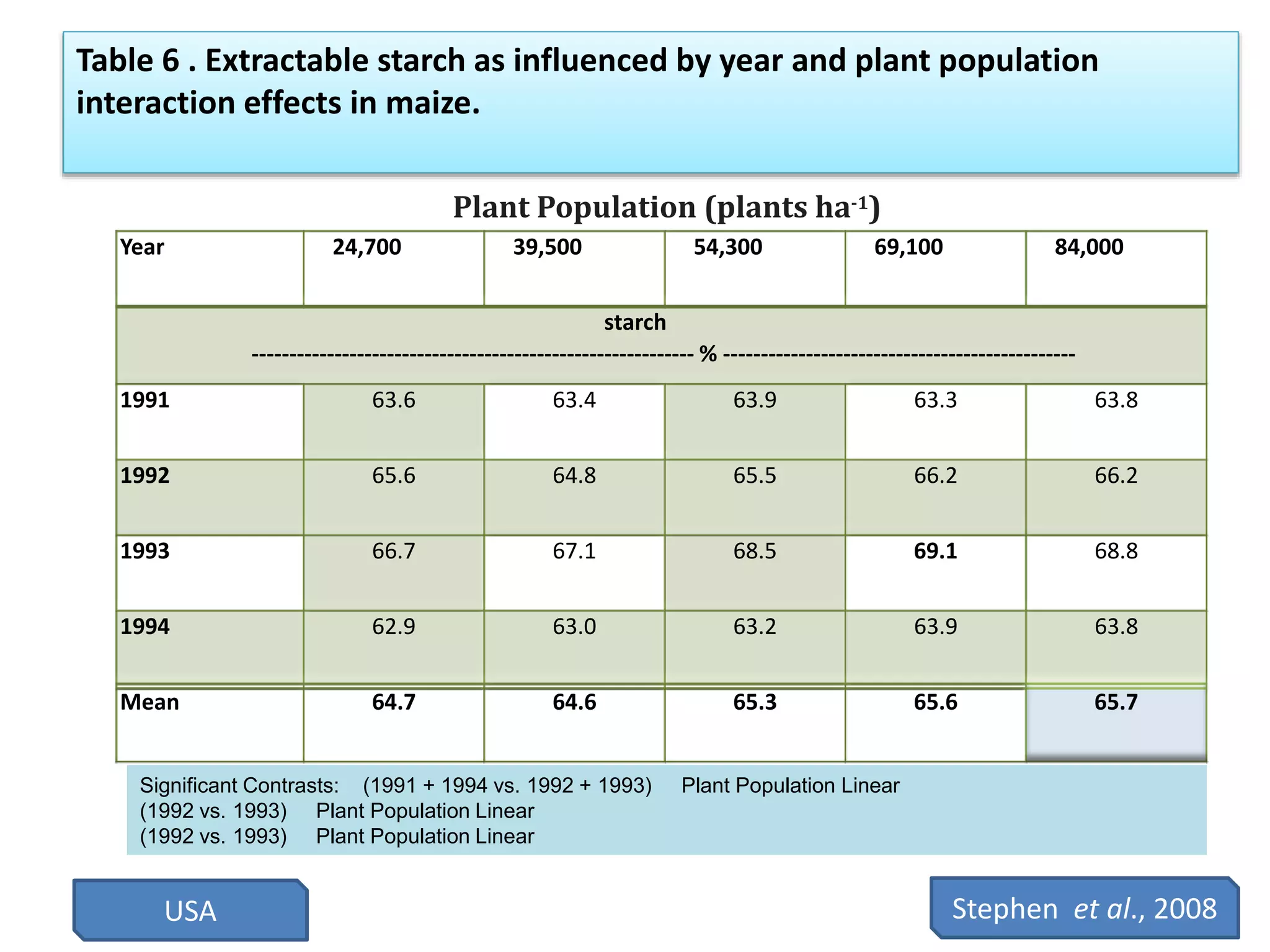

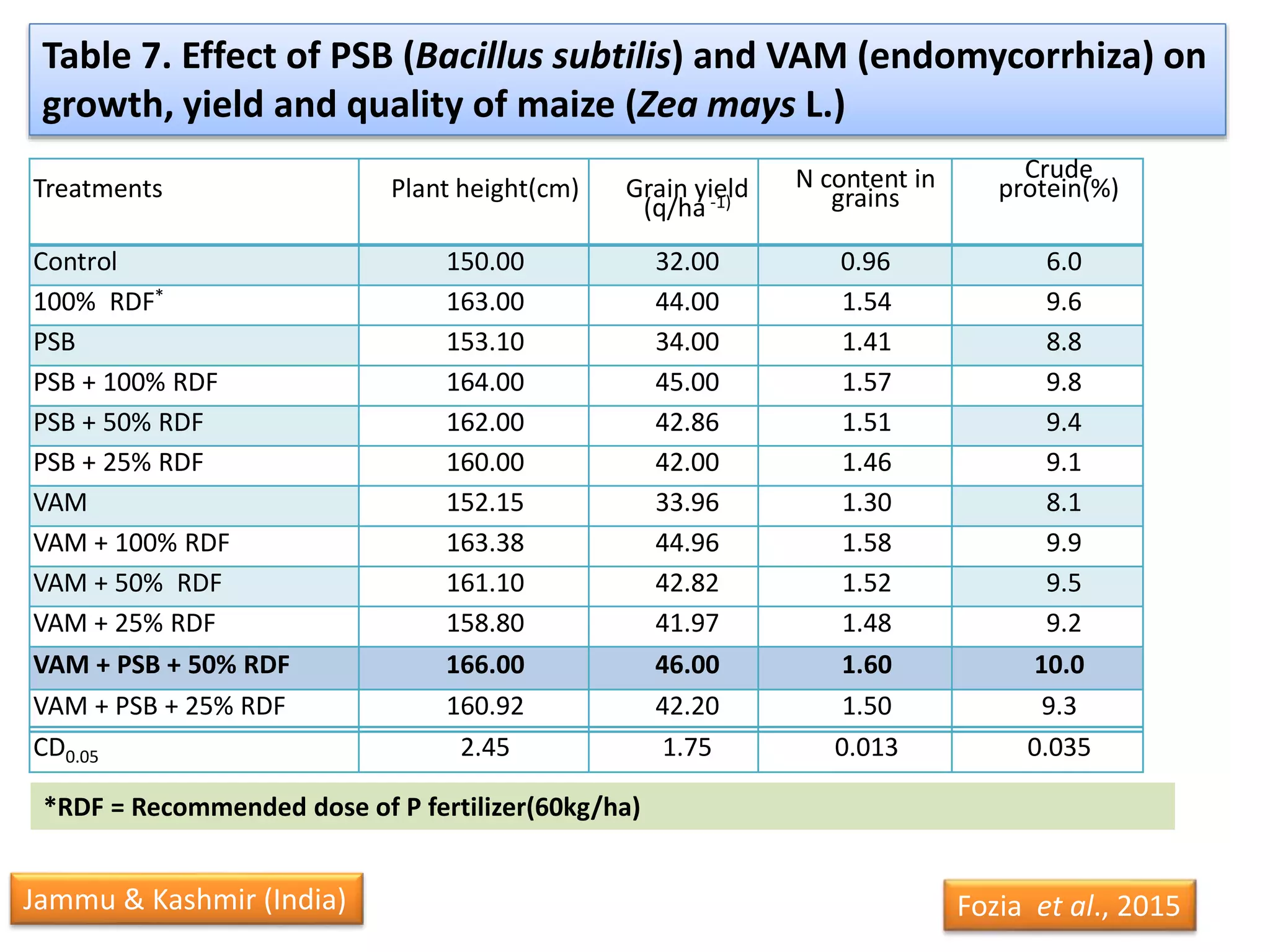

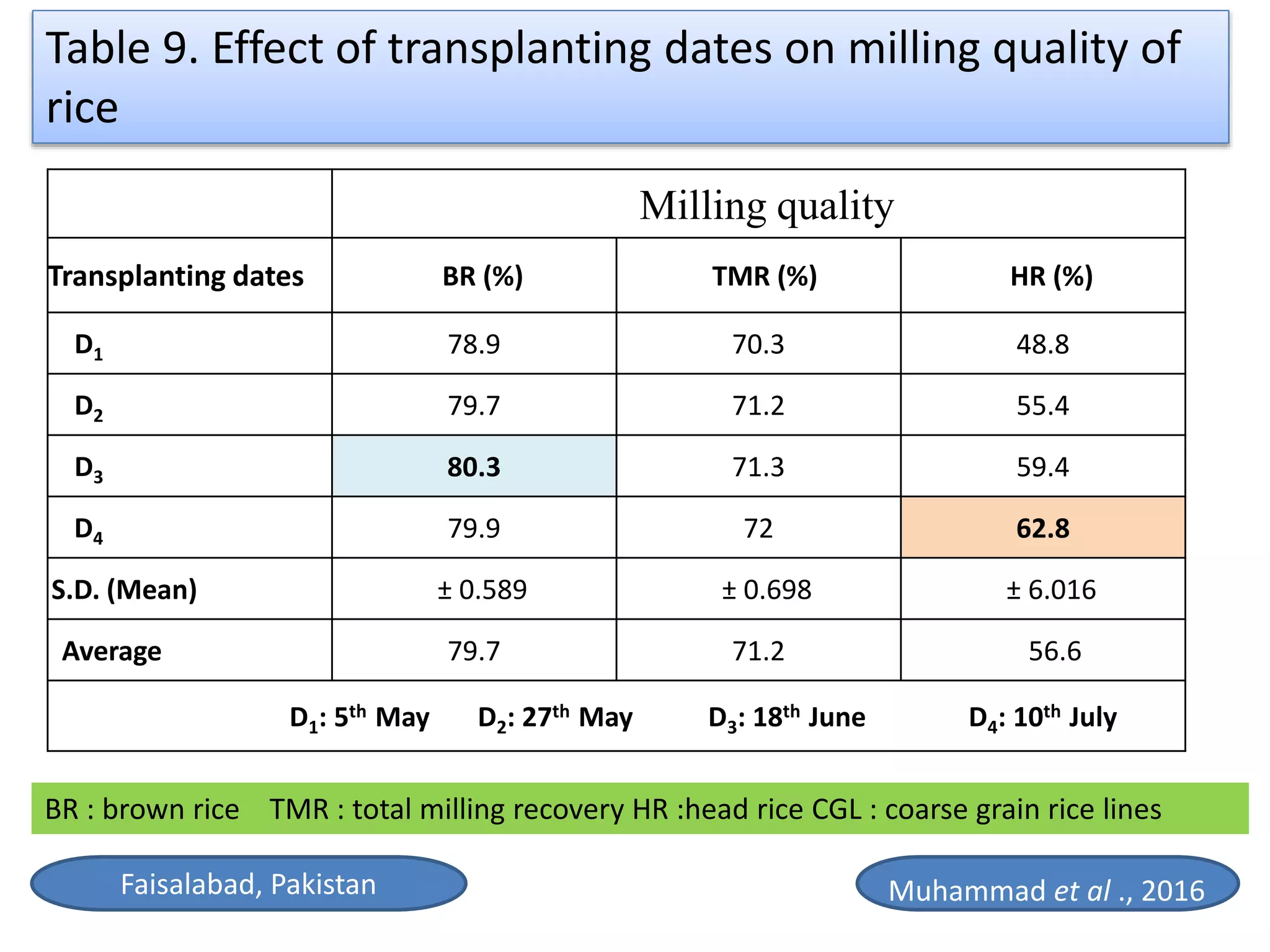

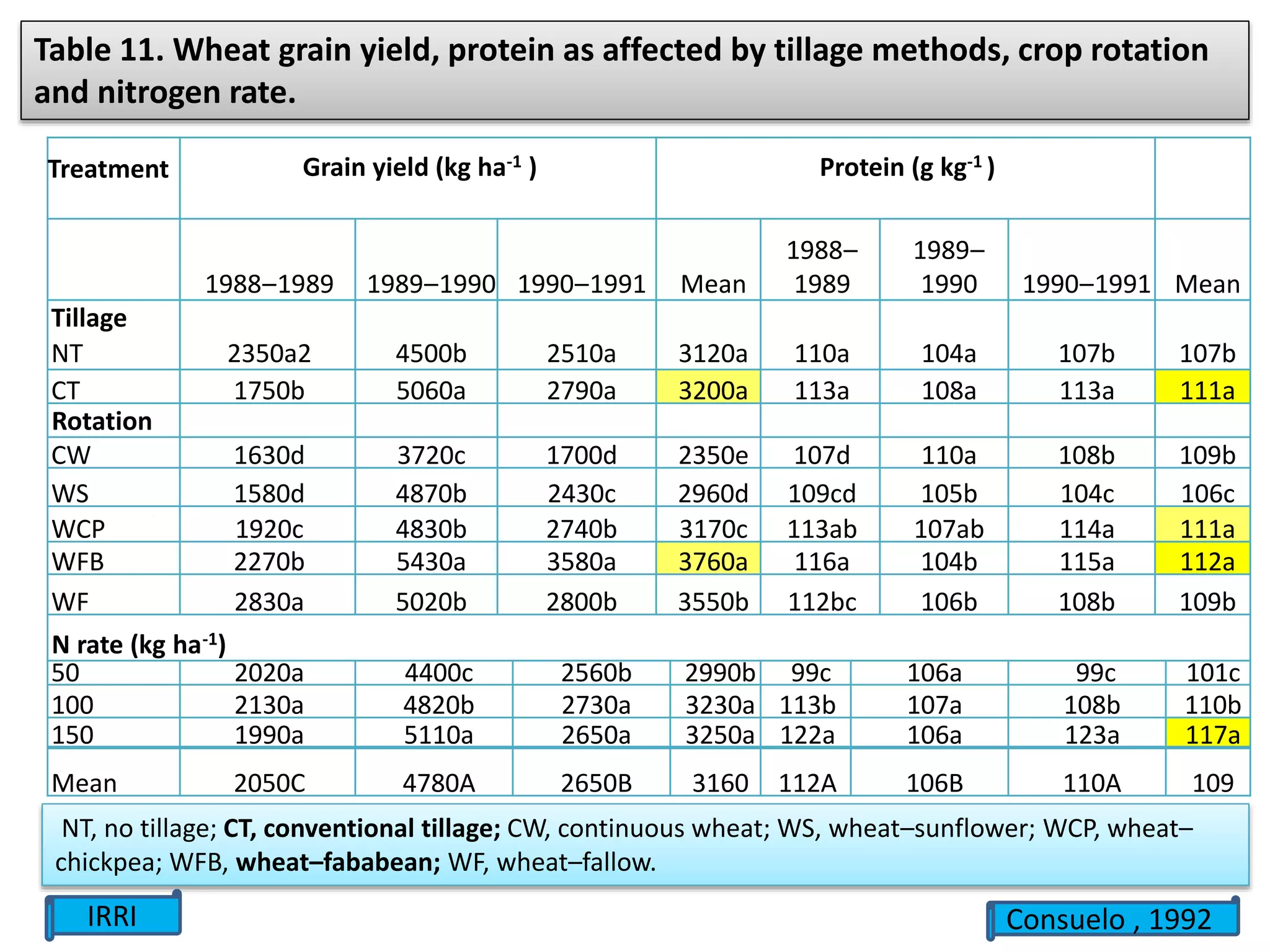

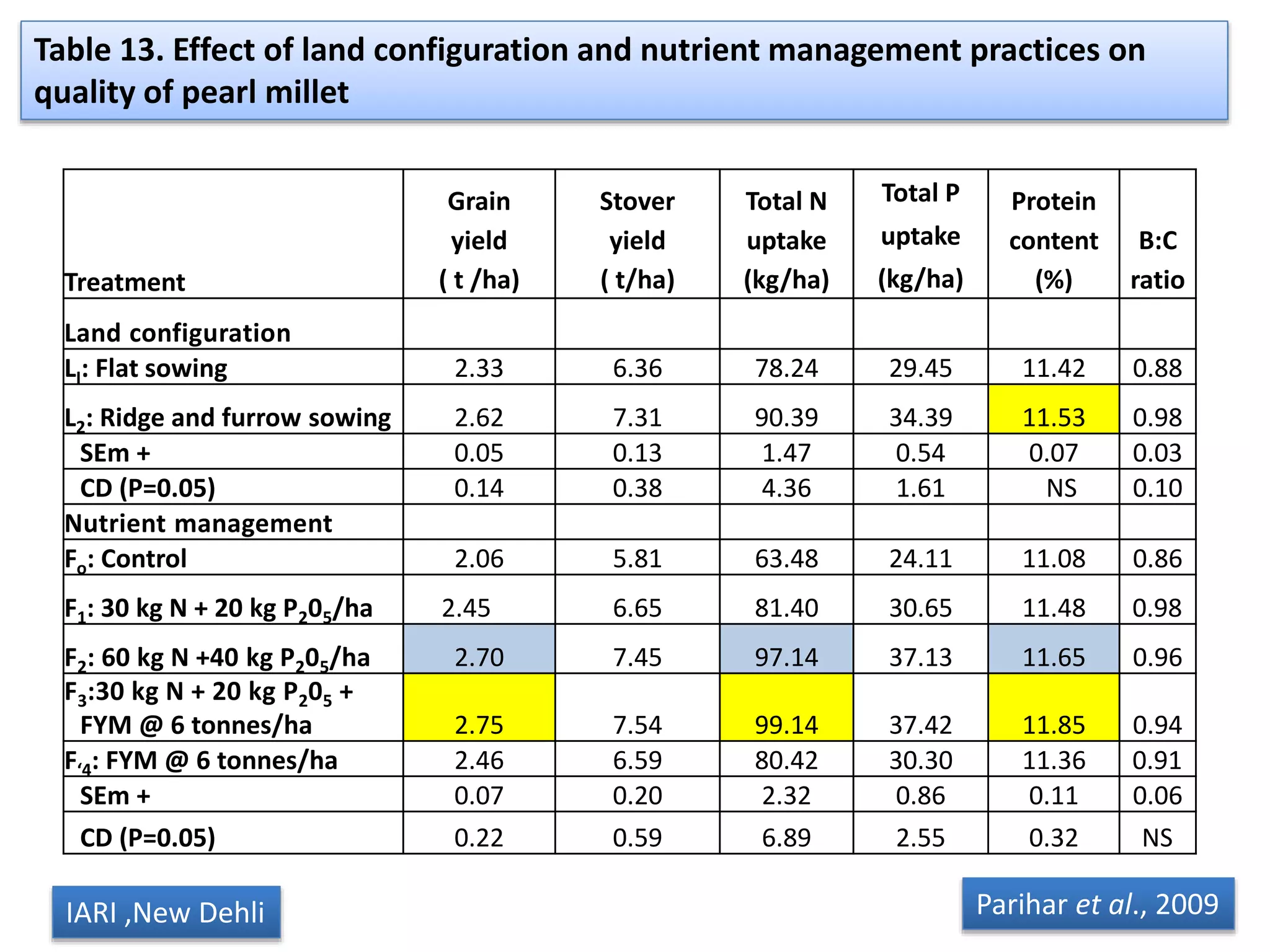

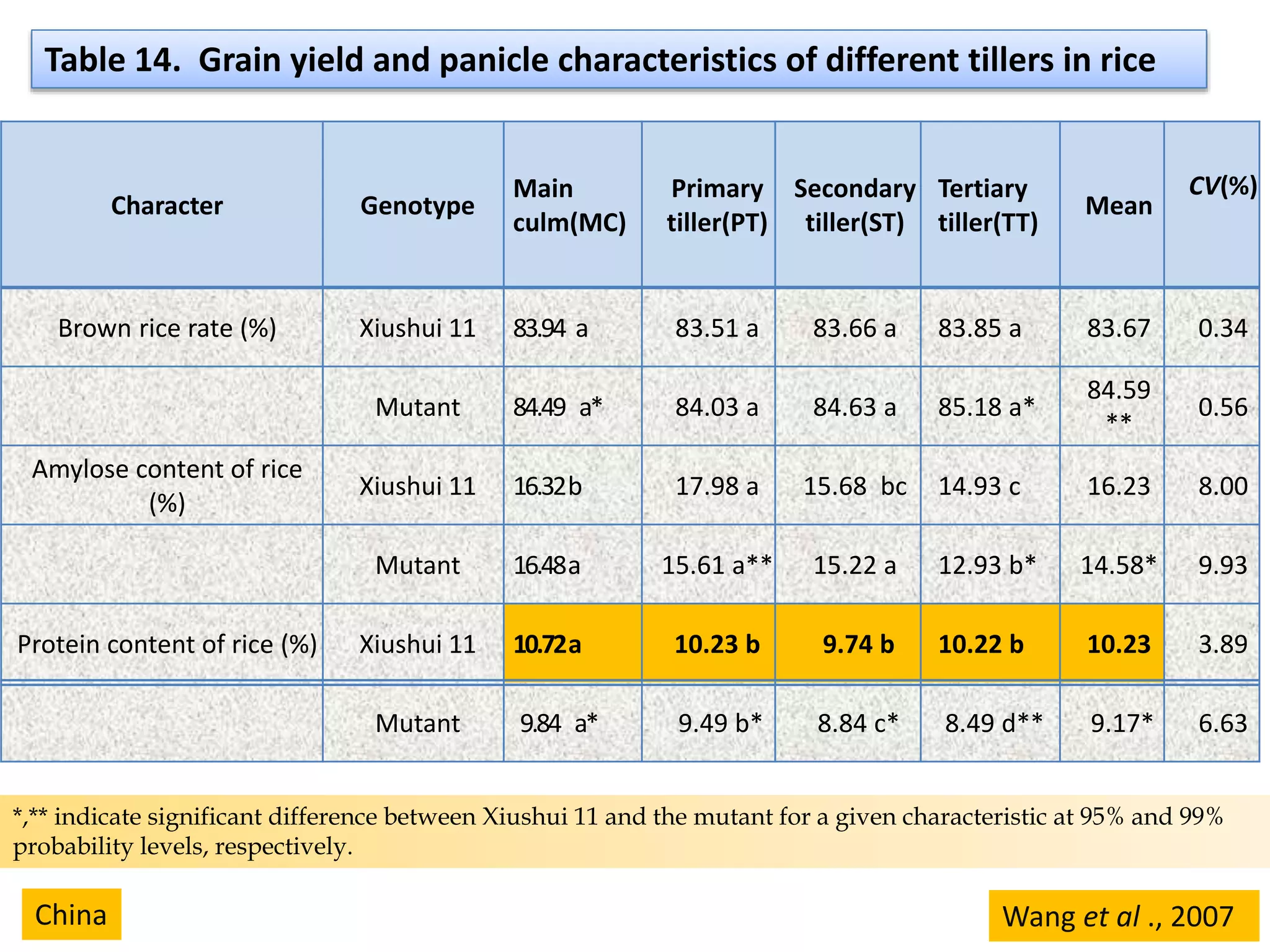

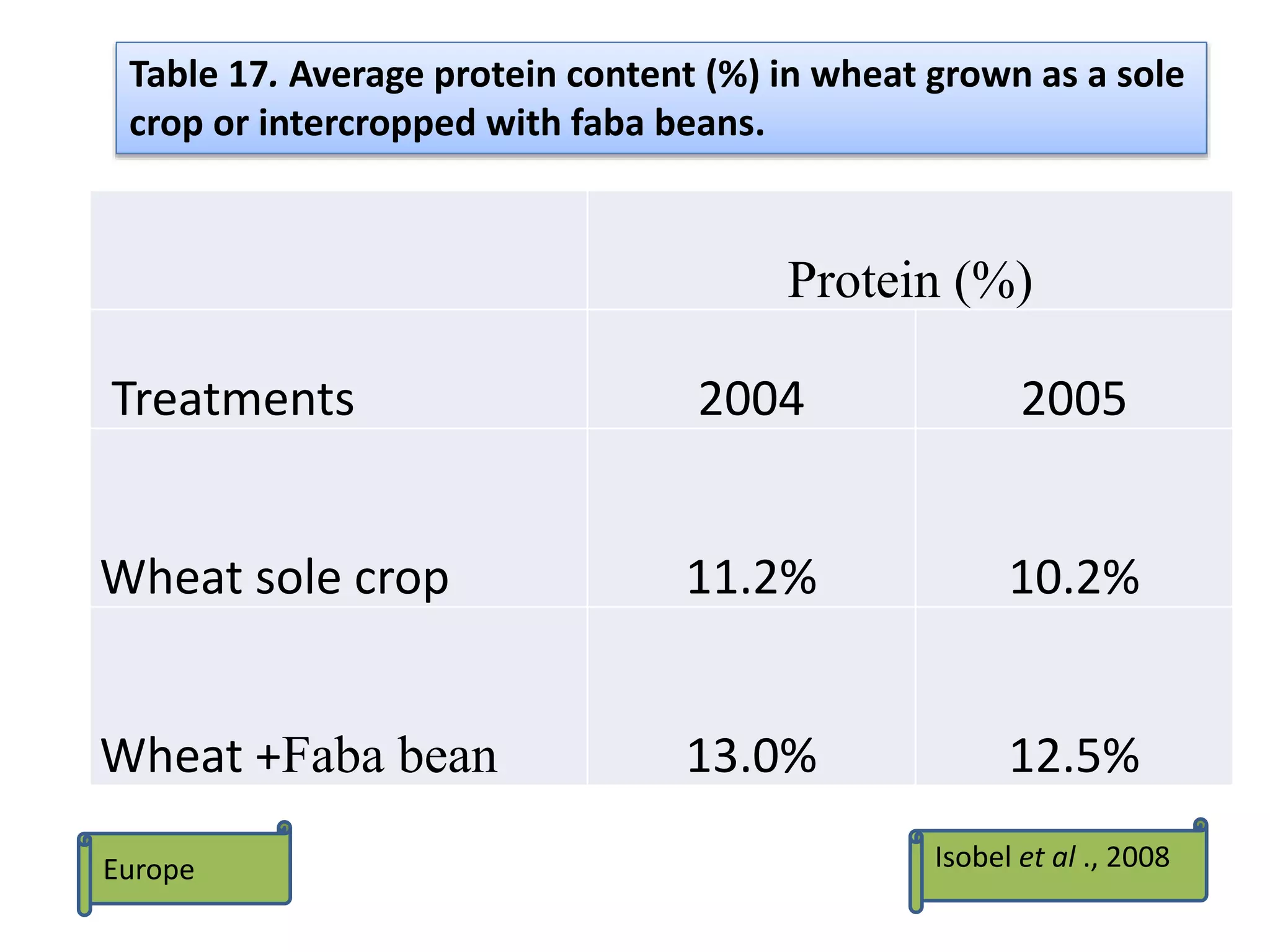

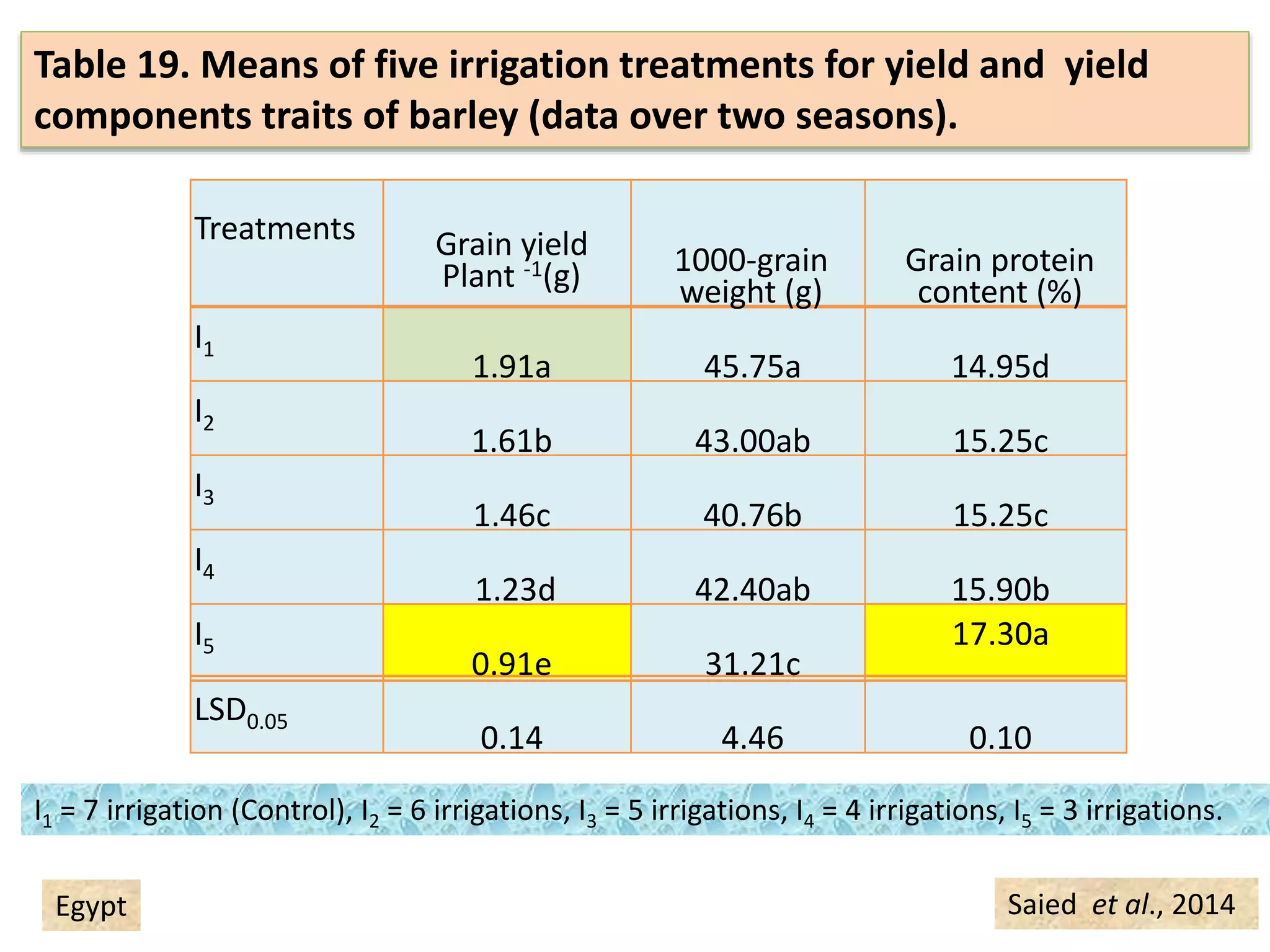

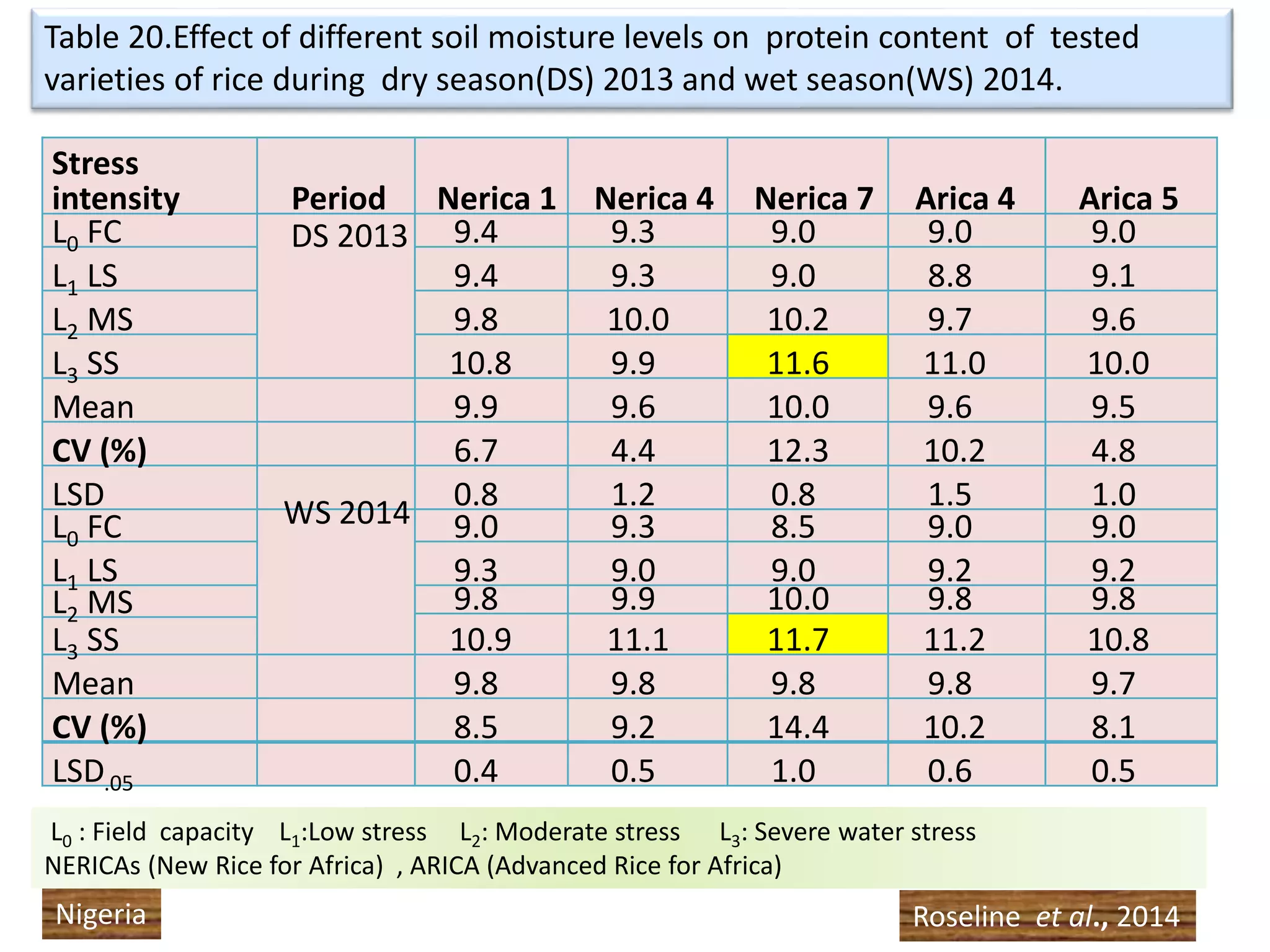

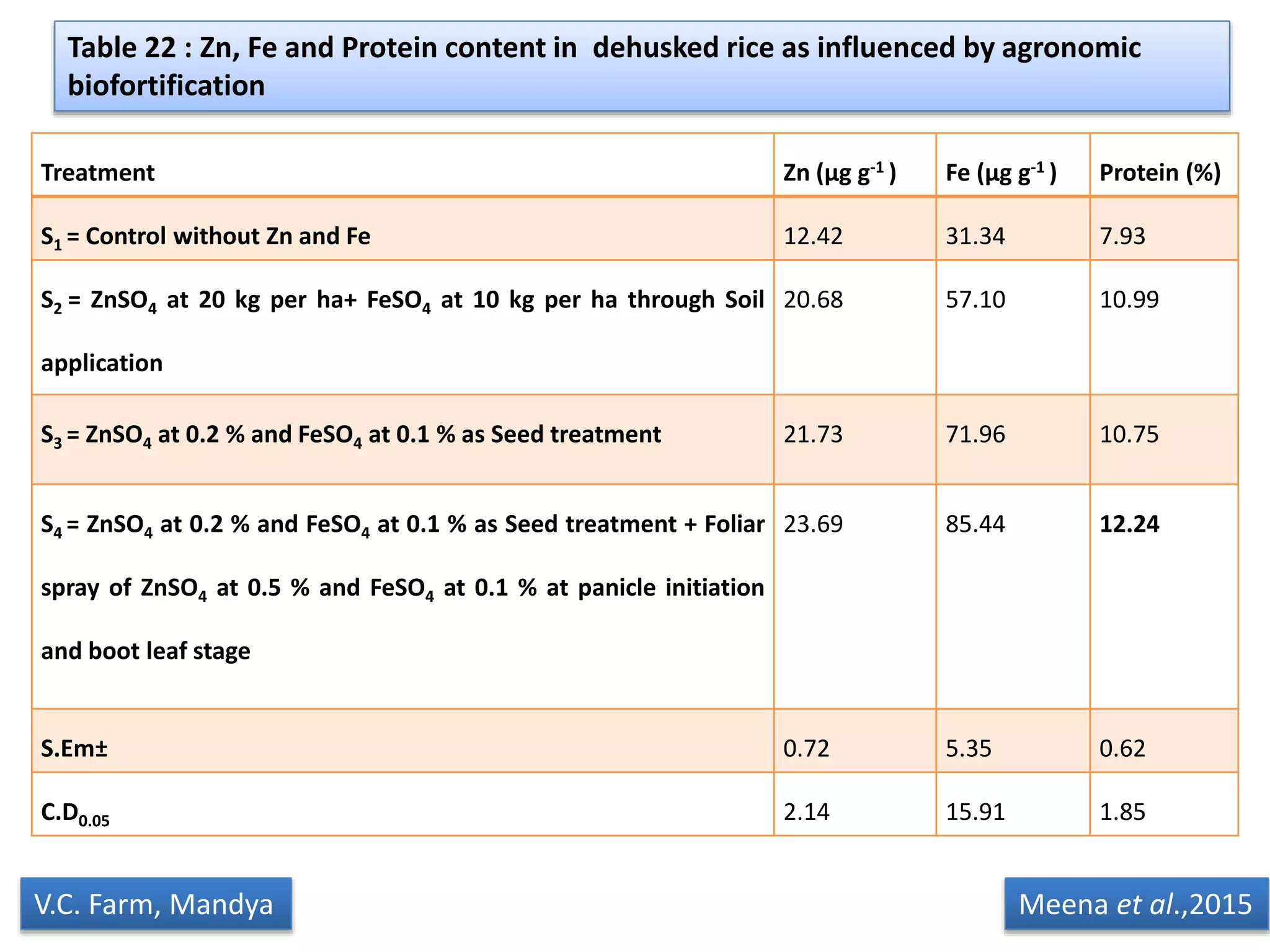

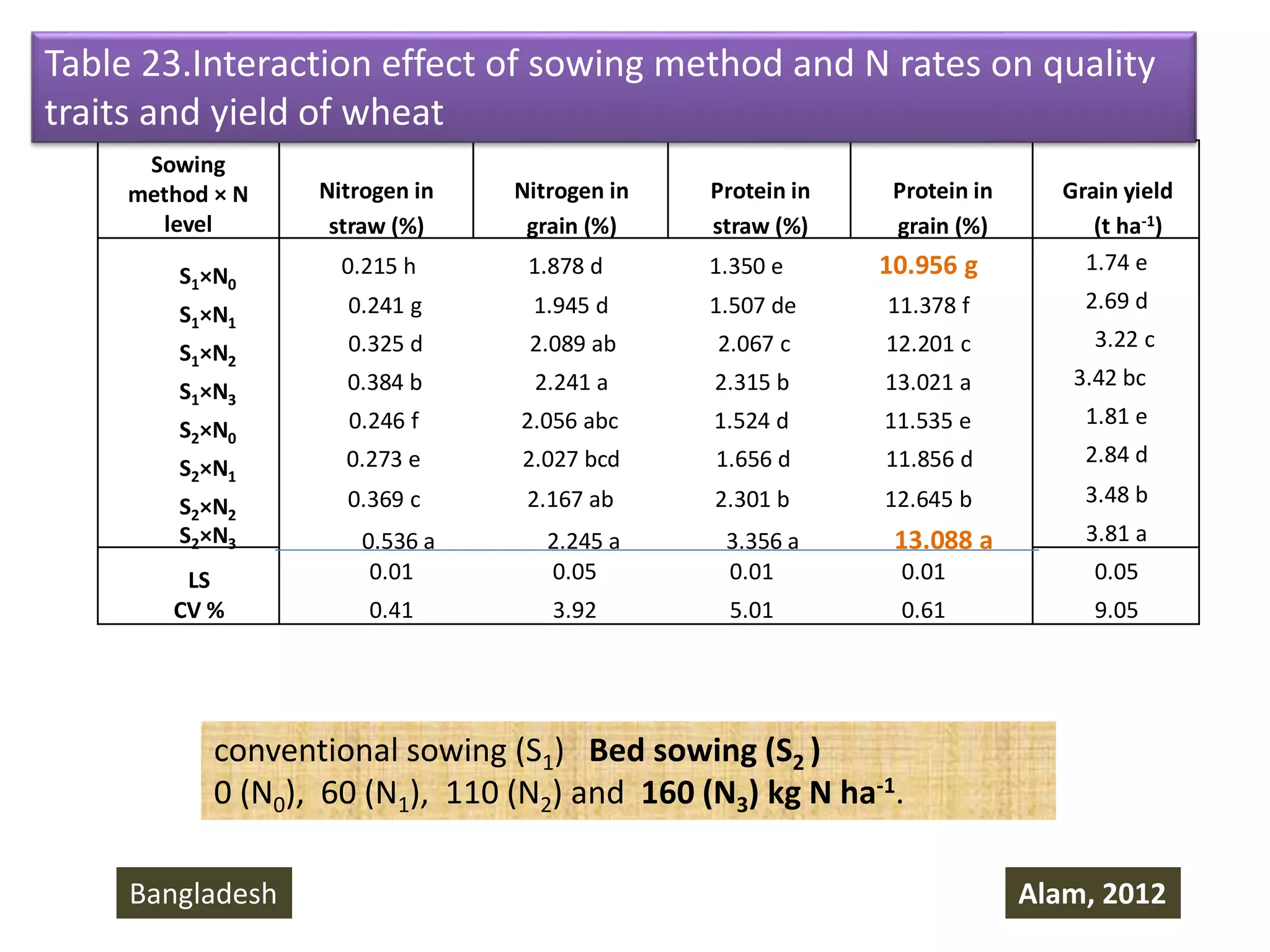

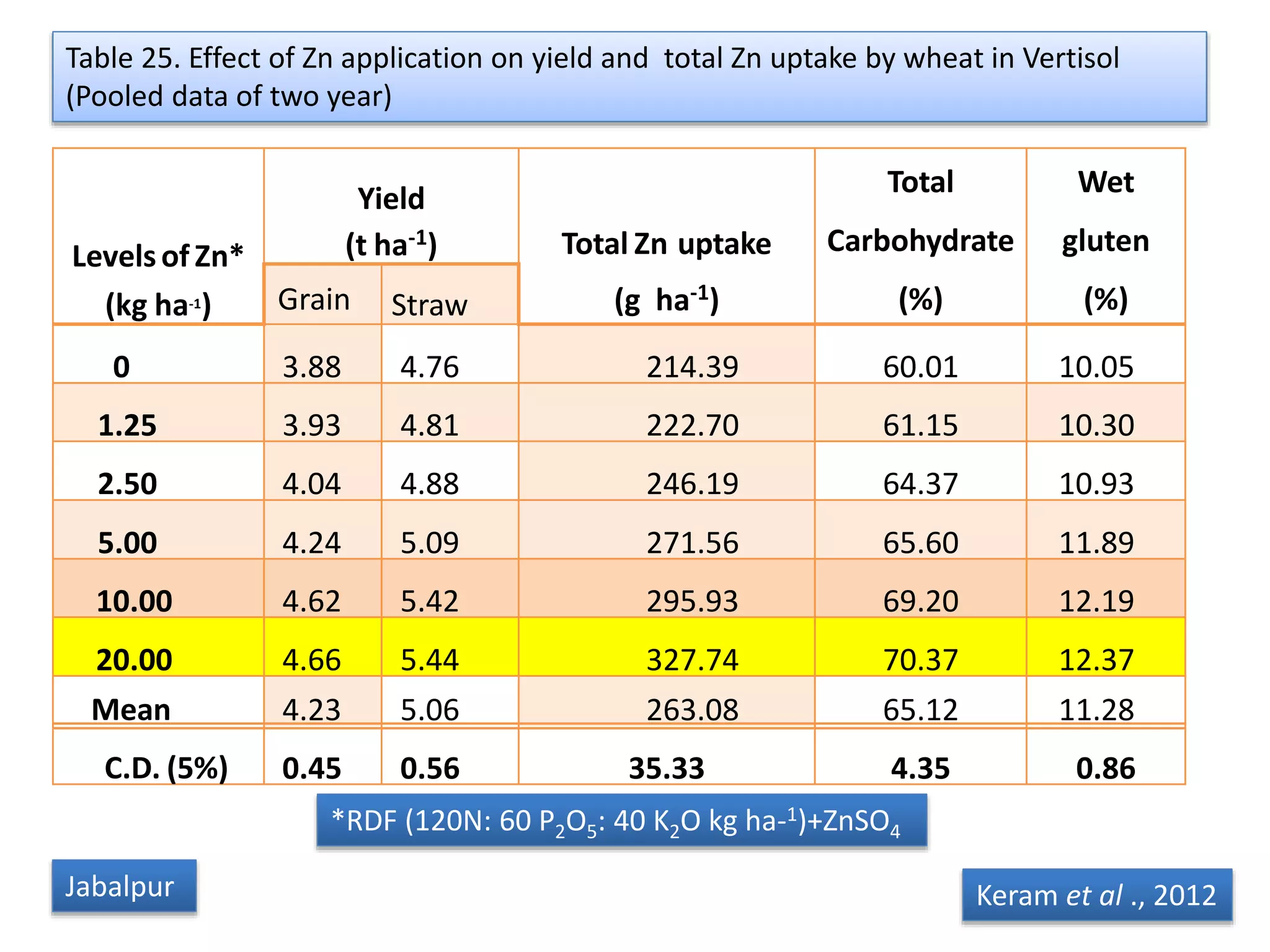

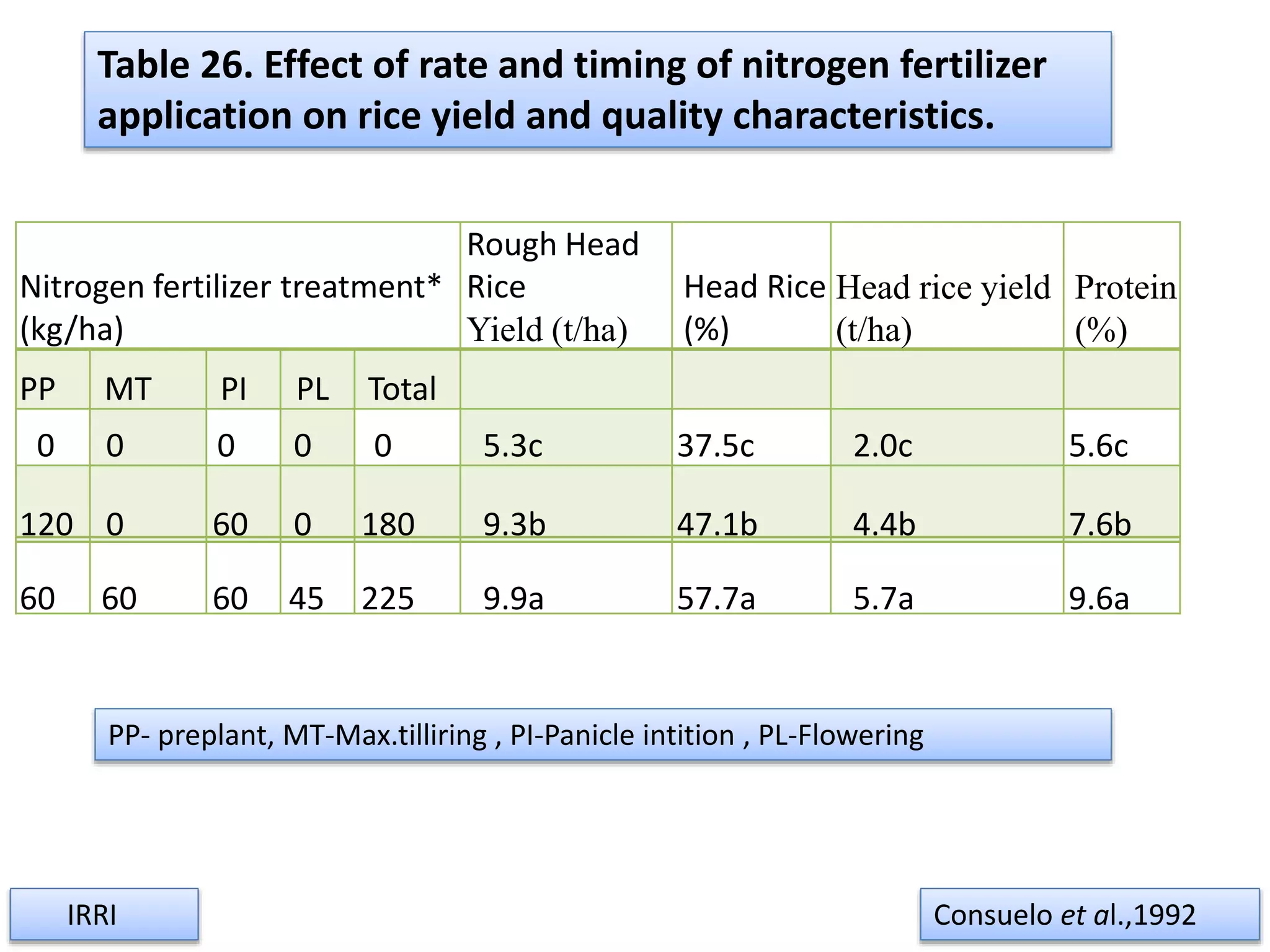

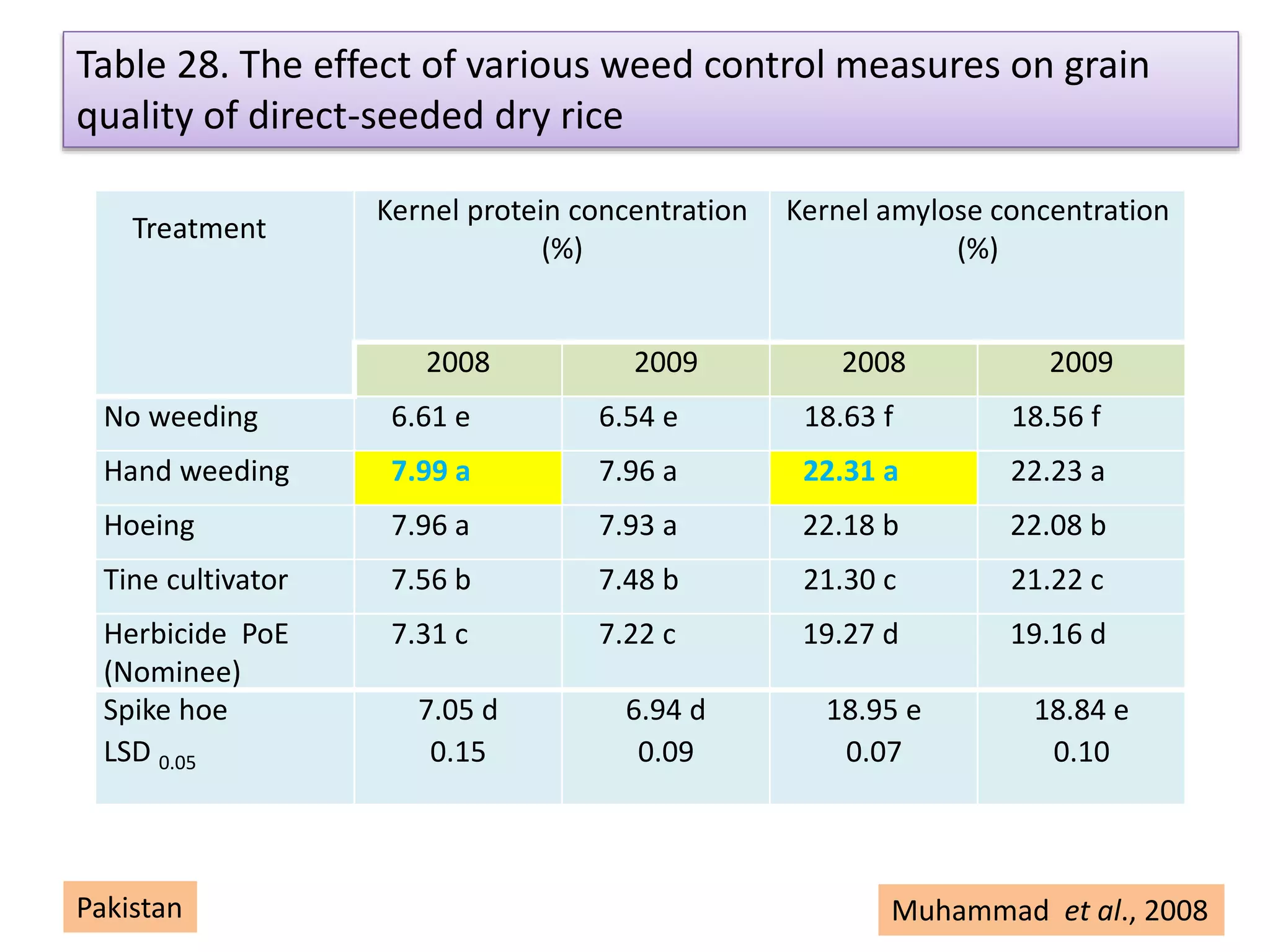

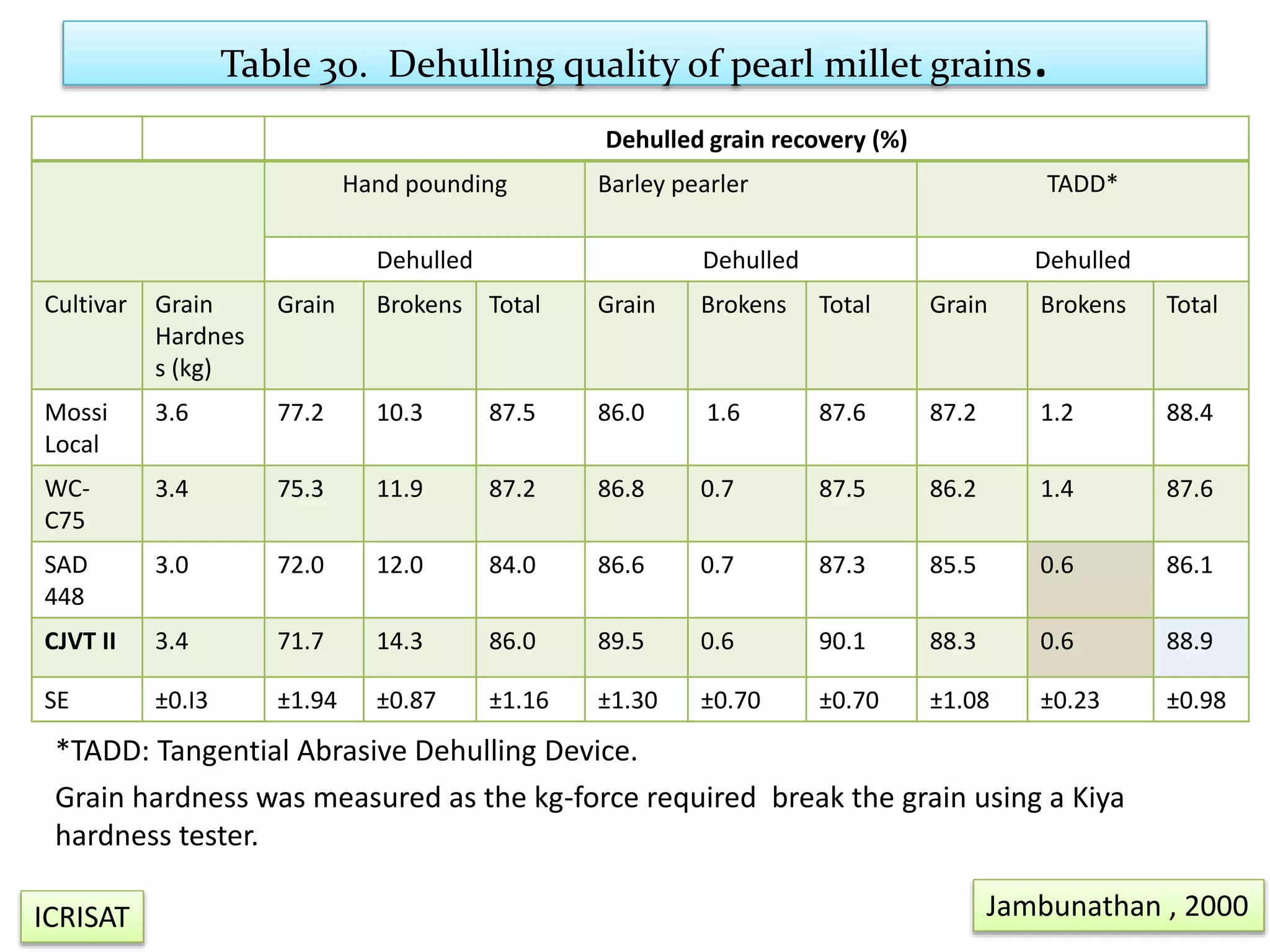

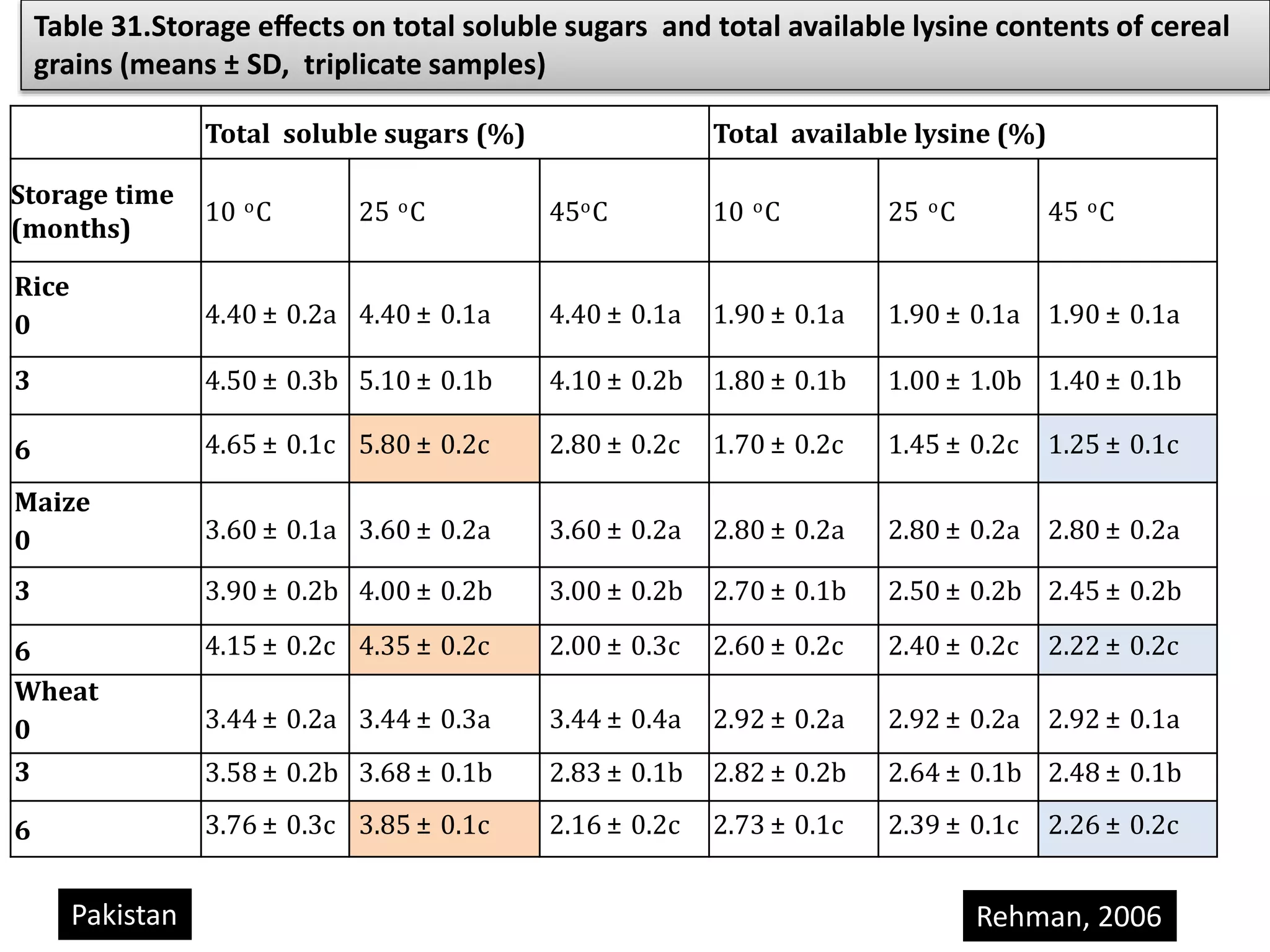

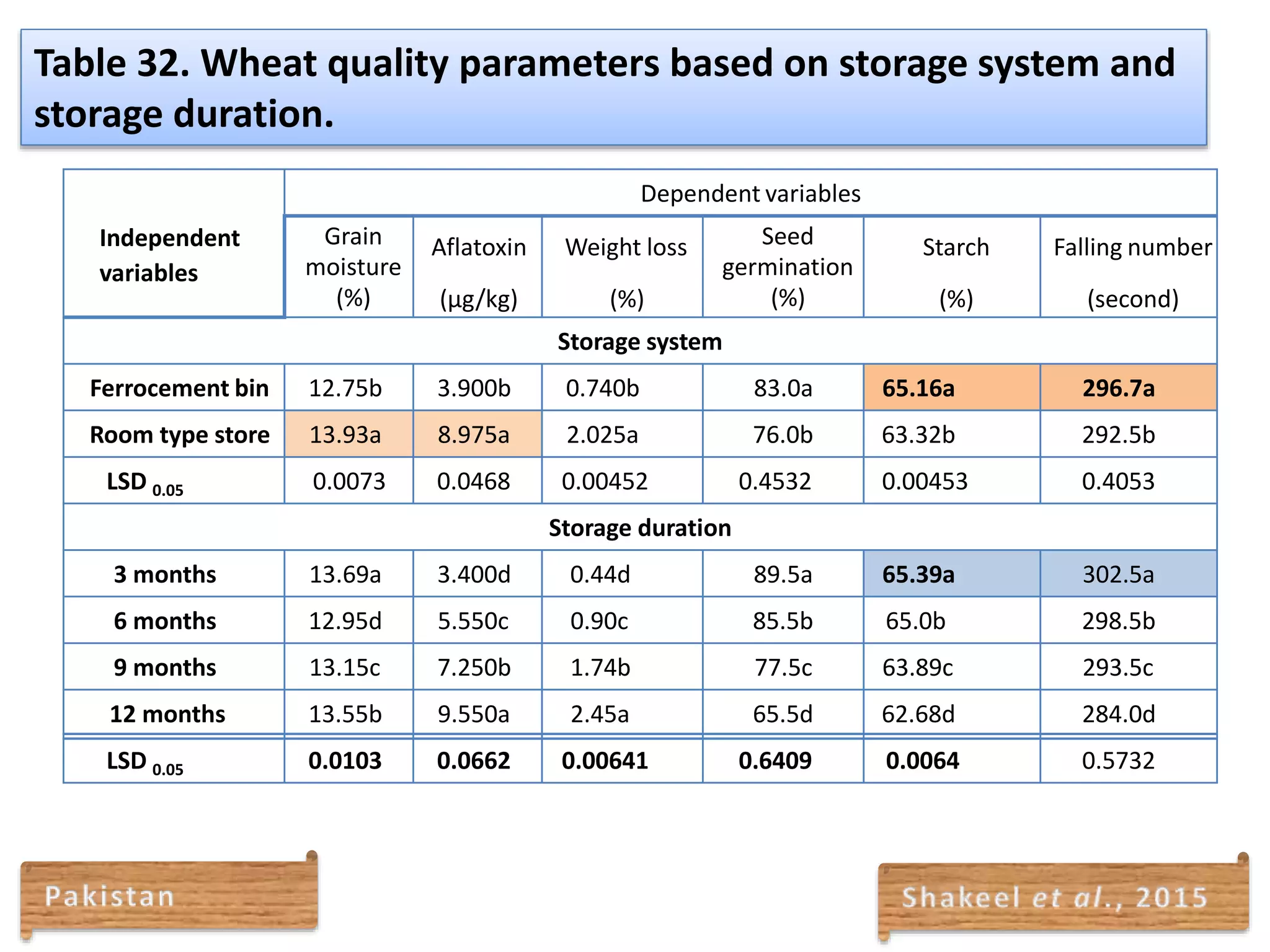

This document summarizes research on improving the quality of various cereal grains through agronomic practices. It includes tables showing the effects of factors like planting methods, nutrient levels, tillage systems and crop rotations on the protein, starch, and oil content as well as yields of crops like maize, wheat and rice. The results demonstrate how agronomic biofortification through optimized fertilization and cultivation techniques can enhance the nutritional quality of staple grains.