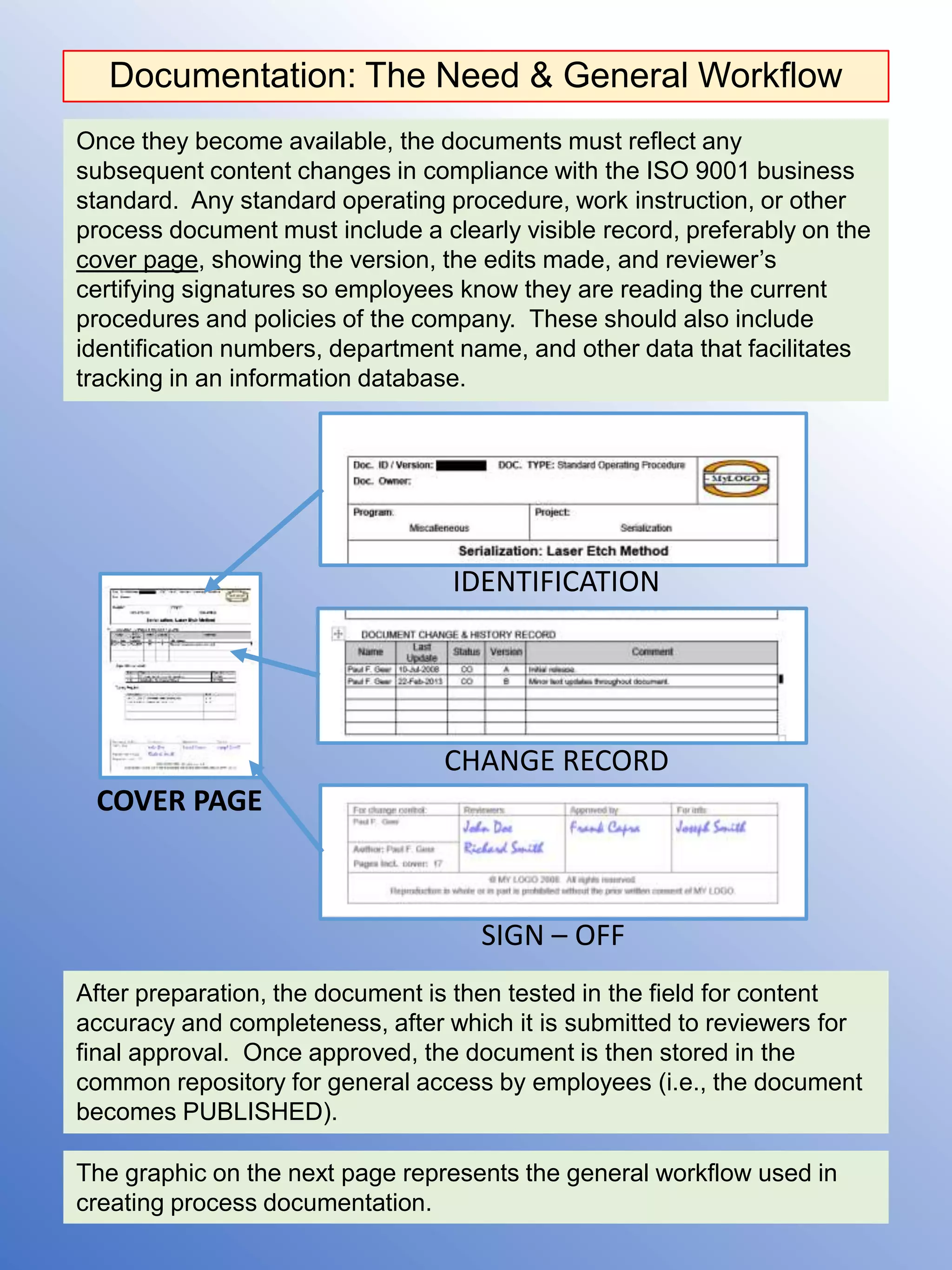

The document provides an overview of the need for technical documentation in manufacturing companies. It discusses how as products become more complex, documentation is needed to ensure consistent quality and training of employees. The document outlines the general workflow for writing technical documentation, including identifying gaps, gathering information, developing content, testing, and publishing documents. It provides examples of documentation content including procedures, standards, and specifications for manufacturing processes.