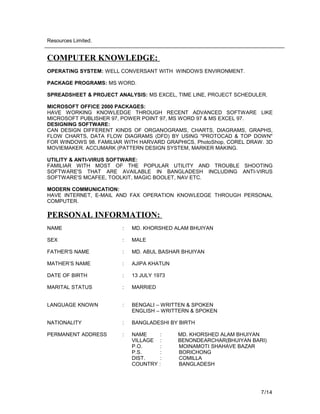

This document is a curriculum vitae for Md. Khorshed Alam Bhuyan, a garment technician. It summarizes his objective of creating and managing a state-of-the-art manufacturing plant. It then lists his professional characteristics such as analytical skills, experience in liaising with different functions of the value chain, and strong technical skills. Finally, it details his employment history and roles in sample coordination, CAD/cutting, and as a senior technical manager for various garment companies.