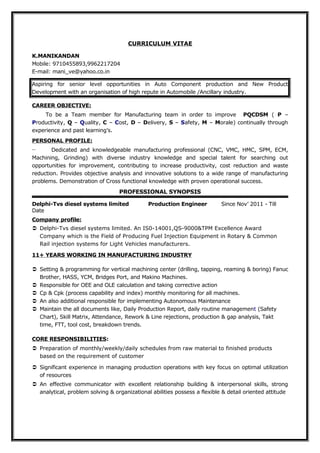

K. Manikandan is seeking a senior level position in automotive production or new product development. He has over 11 years of experience in manufacturing, including setting and programming CNC machines. His responsibilities have included improving productivity, quality, cost, delivery, safety and morale. He is skilled in lean manufacturing techniques and has reduced scrap rates and machine downtime through continuous improvement efforts.