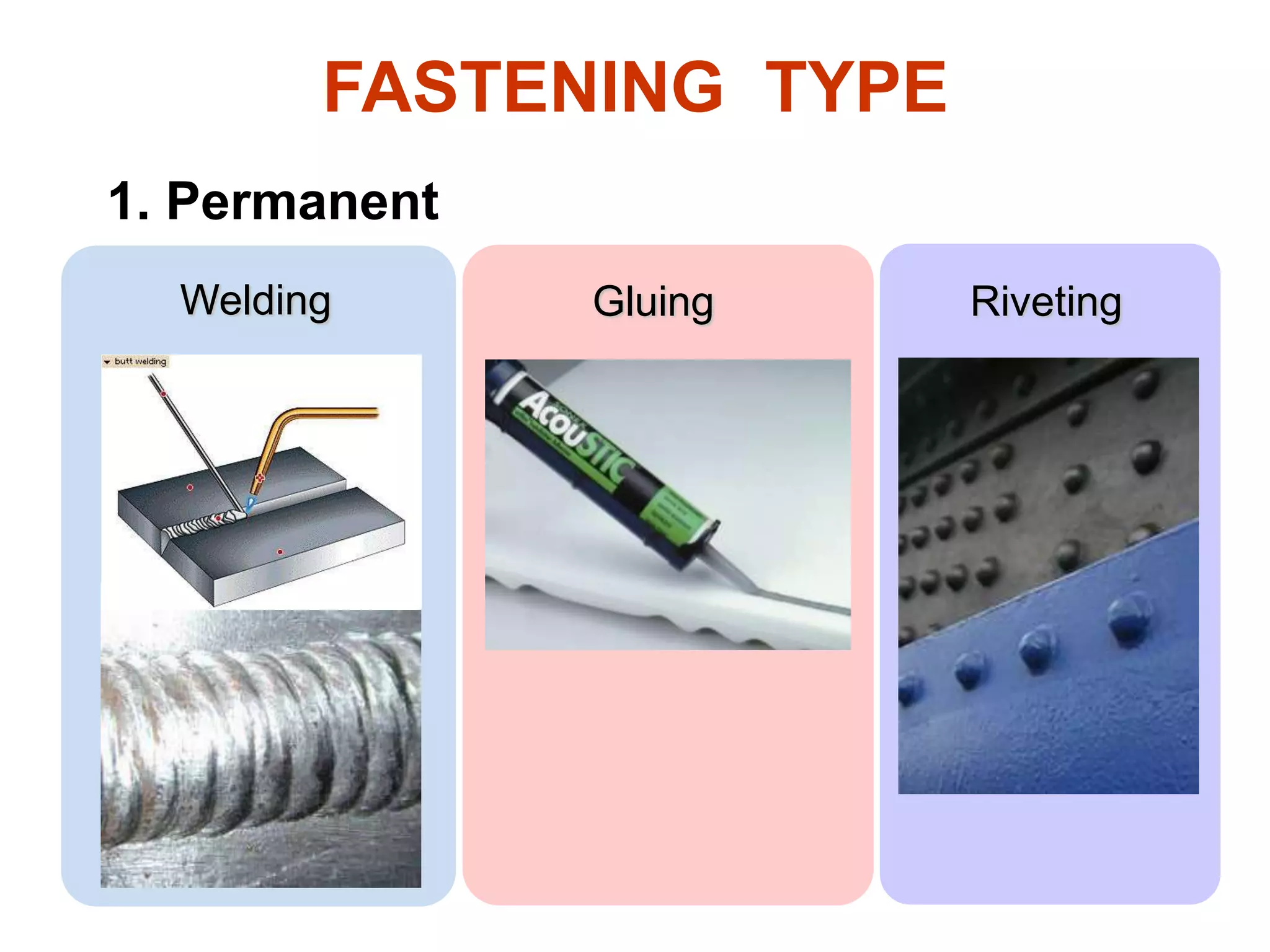

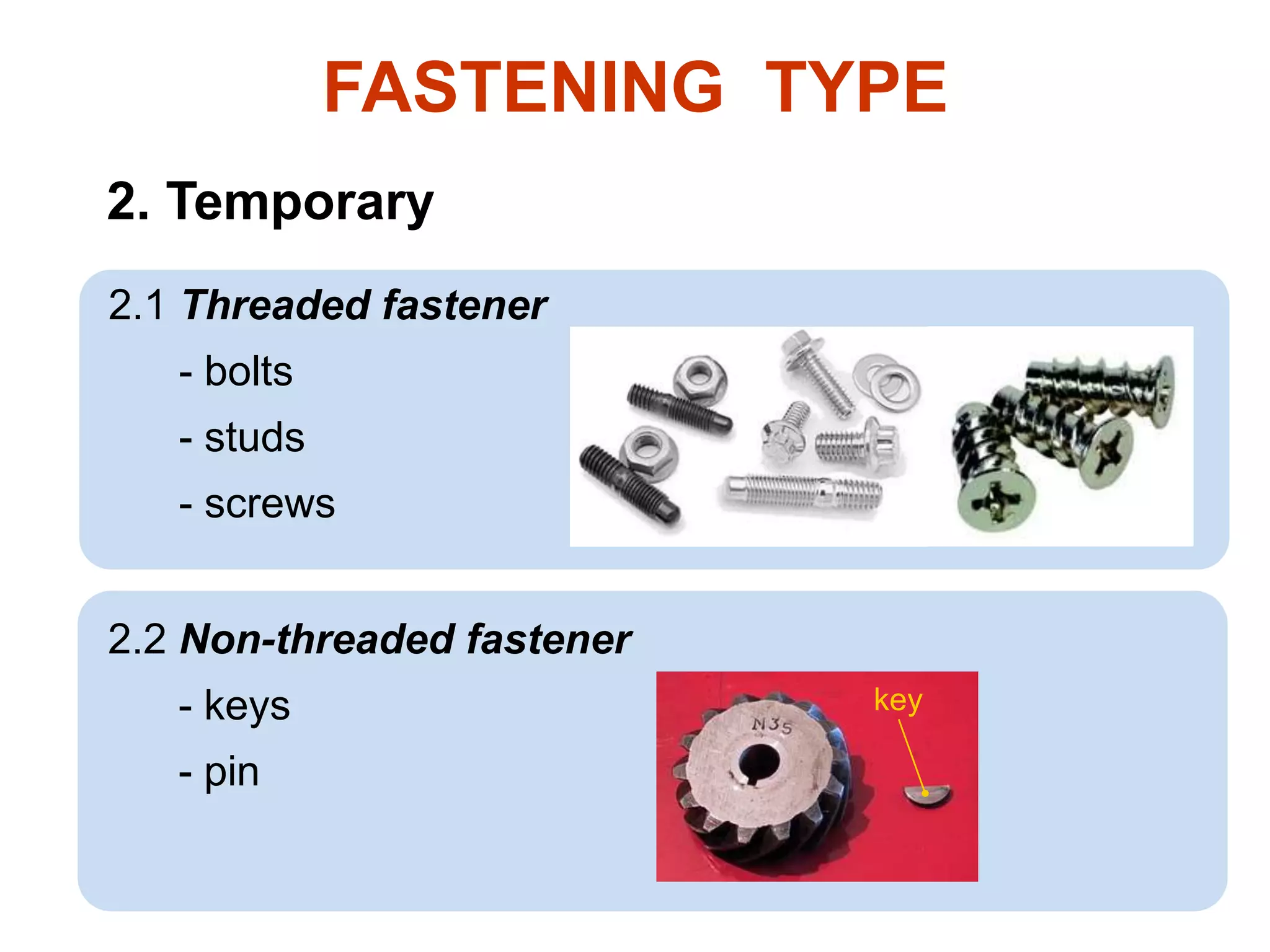

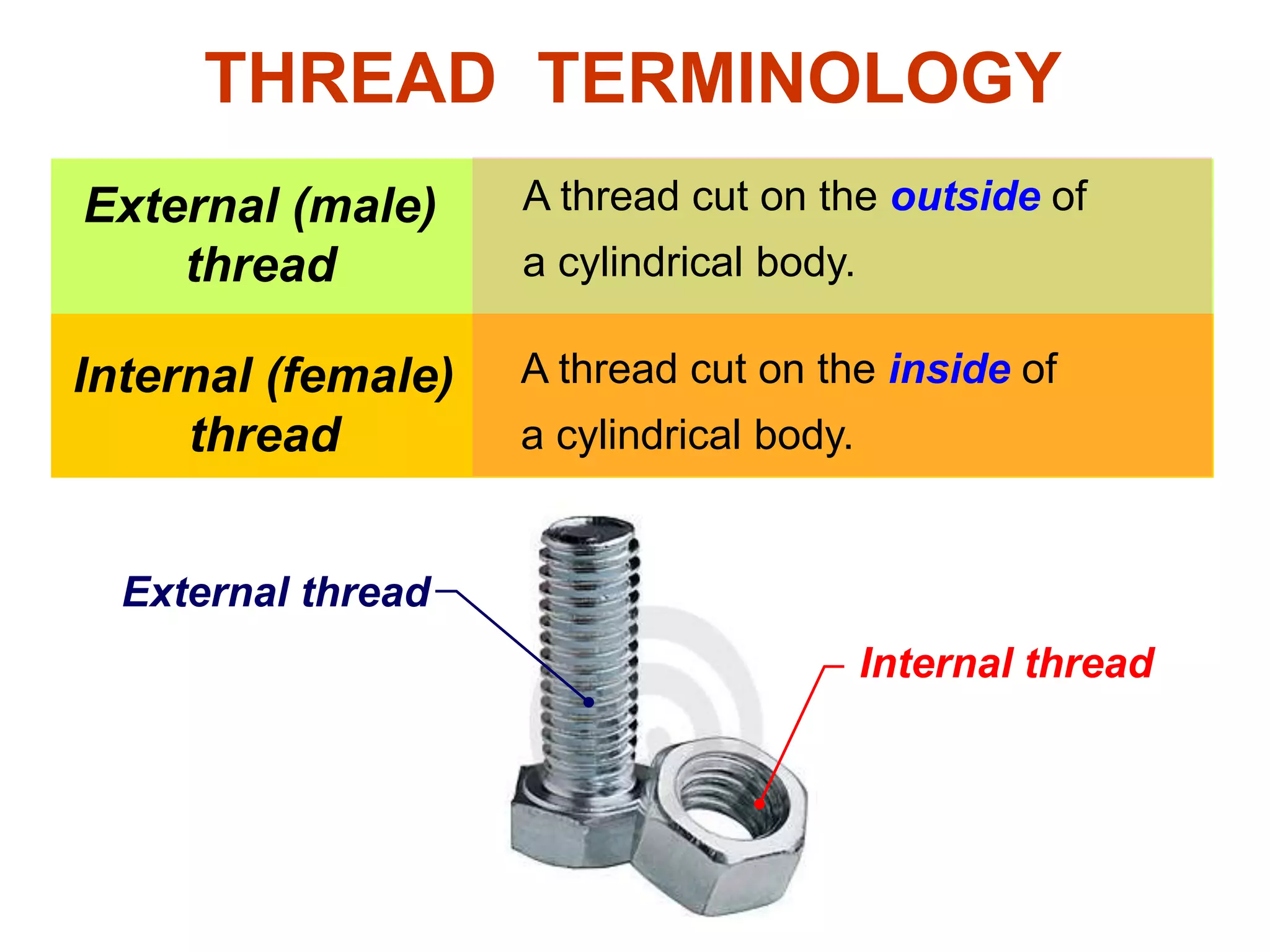

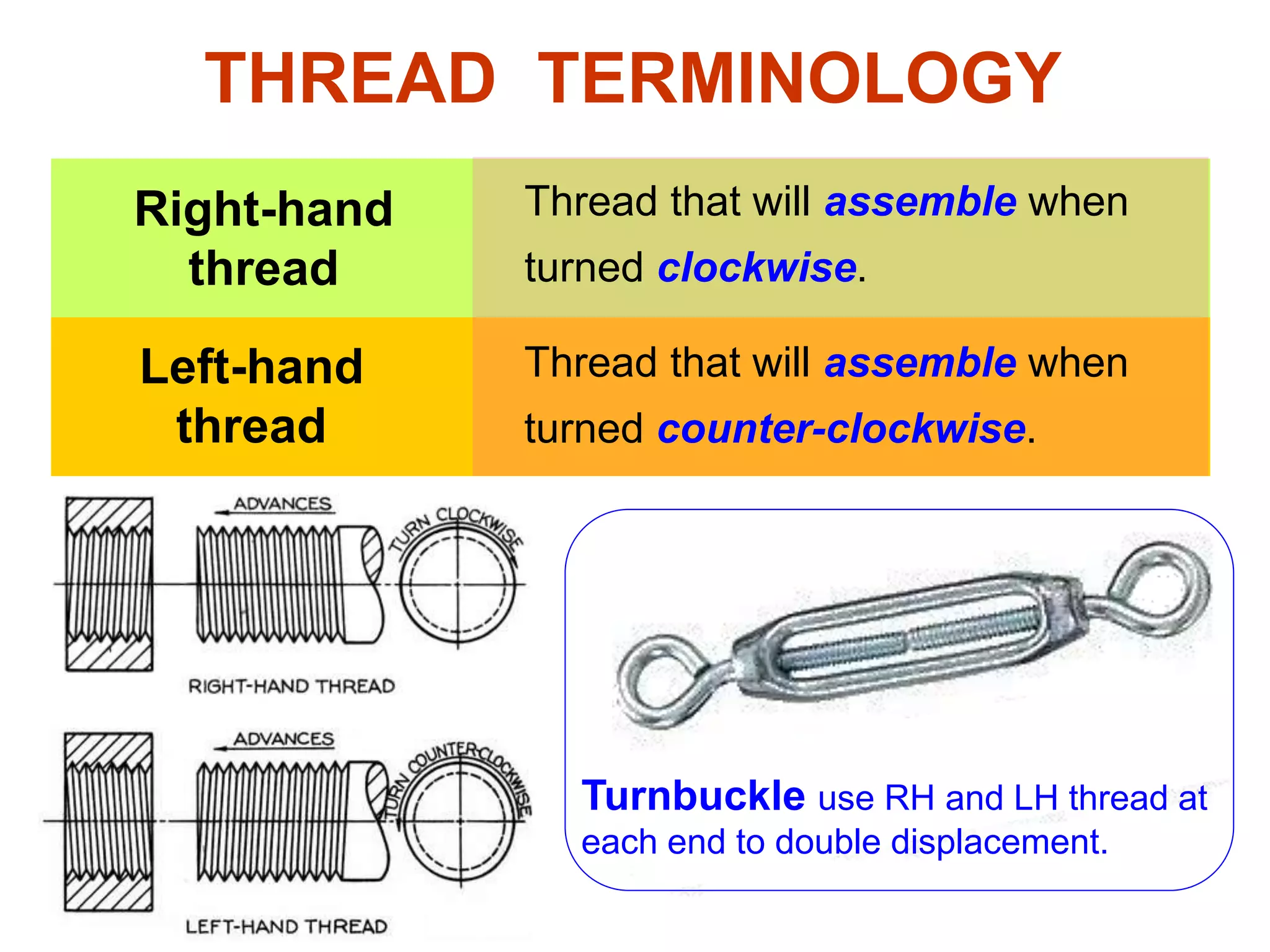

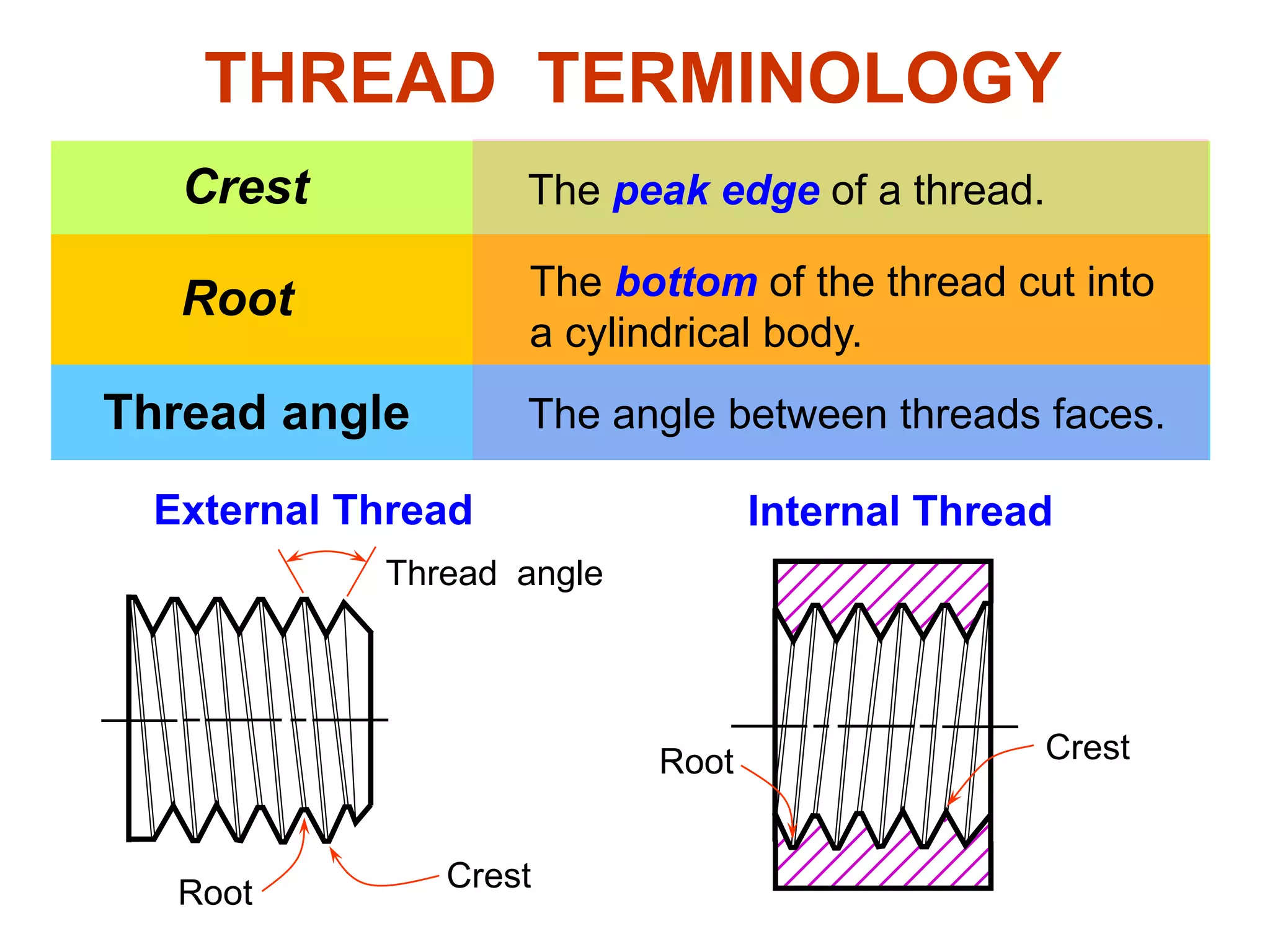

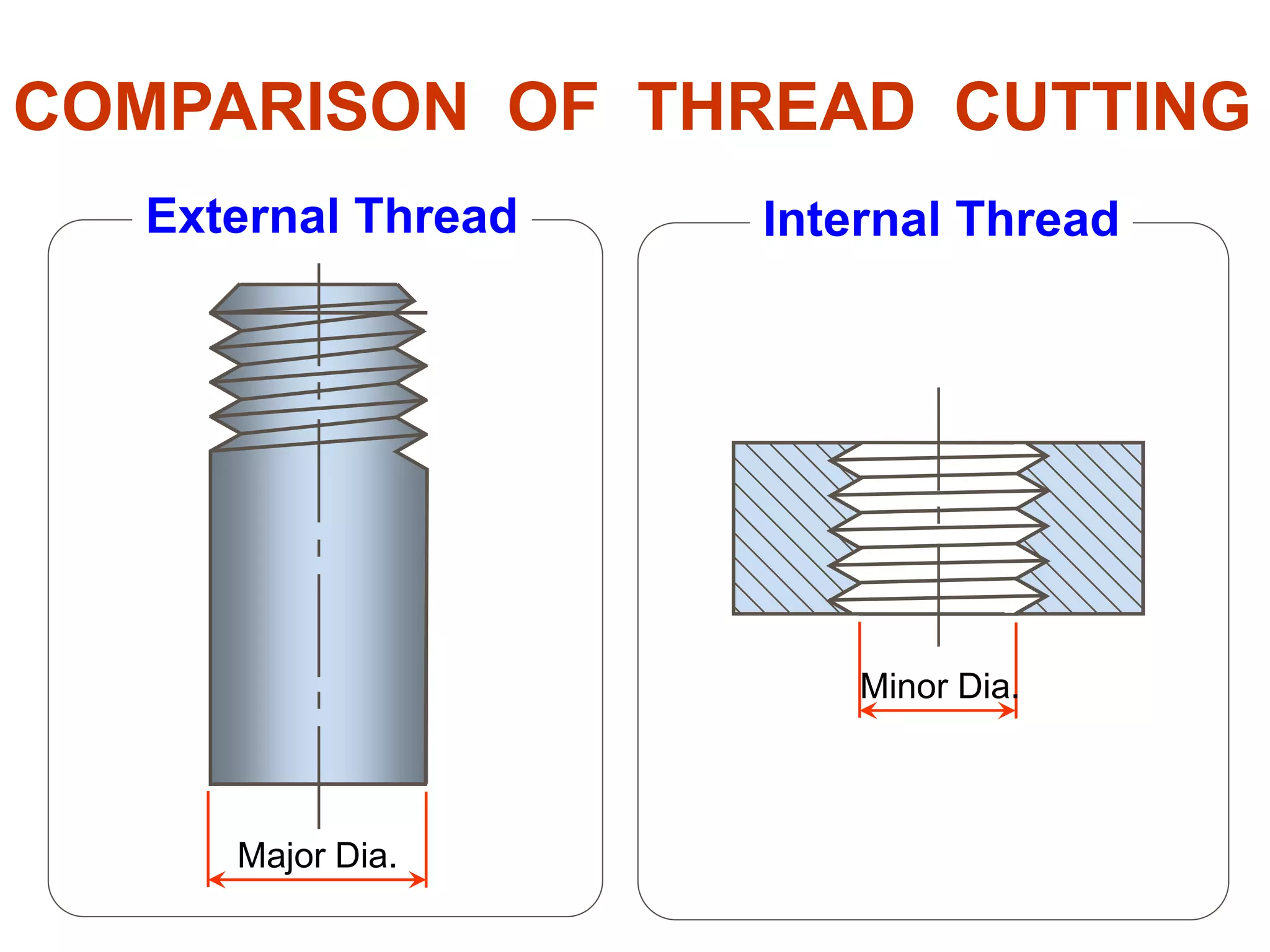

1. The document discusses different types of threaded fasteners including bolts, studs, screws, and set screws. It describes thread terminology and provides details on external and internal thread cutting tools.

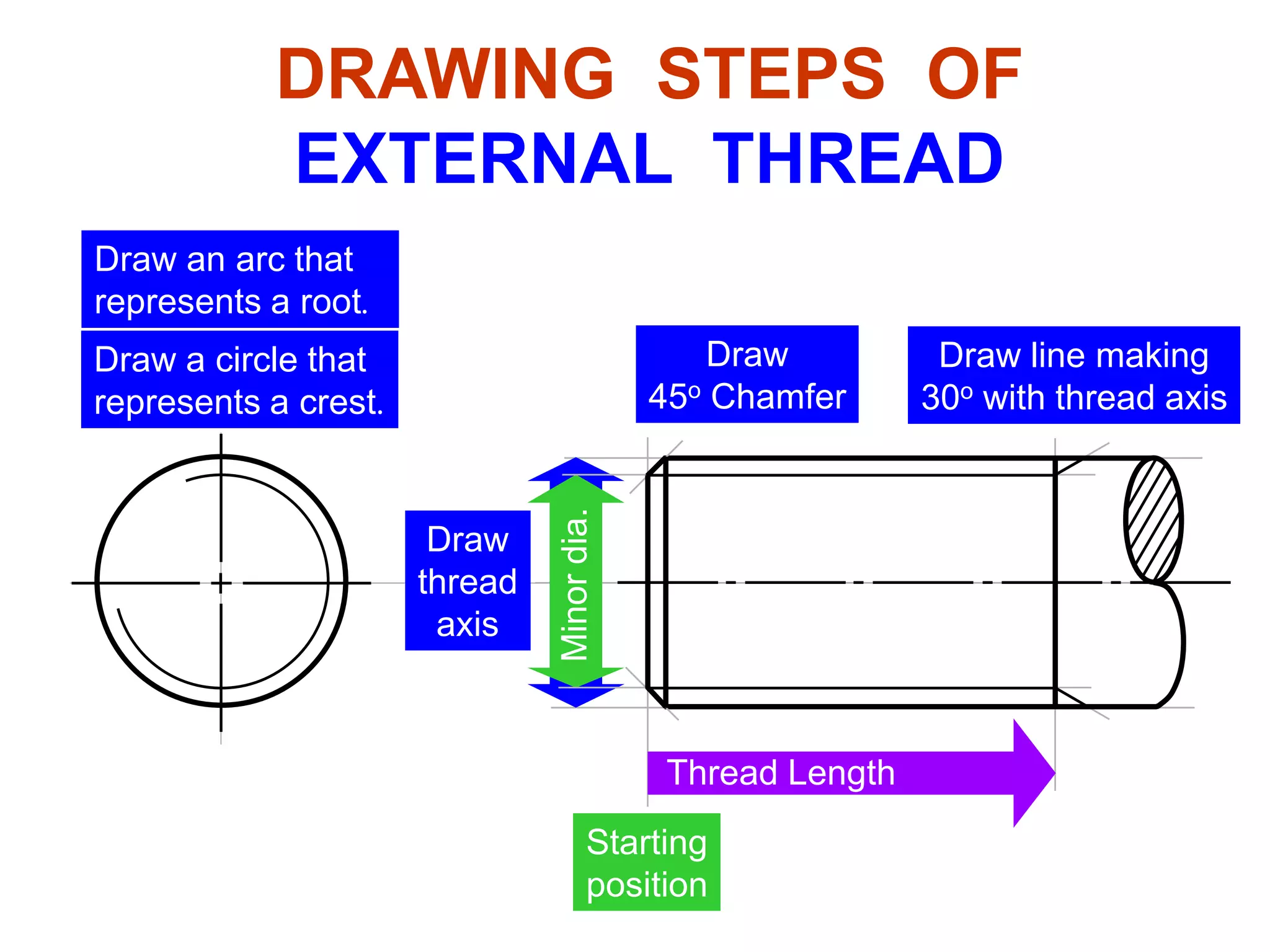

2. Thread drawings are explained through detailed, schematic, and simplified representations. Dimensioning of external and internal threads as well as threaded holes is also covered.

3. Drawing procedures are provided for bolts, nuts, studs, and cap screws. Their applications in assembly are illustrated along with counterbore and countersink hole features.

![Nominal

size

Major

diameter

Pitch Minor

diameter

Tap drill size

M6 6.00 1.00 4.92 5.00

M8 8.00 1.25 6.65 6.75

M10 10.00 1.50 8.38 8.50

M12 12.00 1.75 10.11 10.00

METRIC COARSE THREAD

Minor diameter = Major diameter – Pitch

Minor diameter ≈ Tap drill size

[Table 9.1]

Metric thread

In thread drawing, the following relationship is used.](https://image.slidesharecdn.com/chapter11threadfastener-230804135726-cb7d1b0a/75/Chapter-11-Thread-Fastener-ppt-25-2048.jpg)

![Nominal

size

Major

diameter

Pitch Minor

diameter

Tap drill size

M8 8.00

0.75 7.188 7.25

1.00 6.917 7.00

M10 10.00

0.75 9.188 9.25

1.00 8.917 9.00

1.25 8.647 8.75

METRIC FINE THREAD

[Table 9.2]

Minor diameter = Major diameter – Pitch

Minor diameter ≈ Tap drill size

In thread drawing, the following relationship is used.](https://image.slidesharecdn.com/chapter11threadfastener-230804135726-cb7d1b0a/75/Chapter-11-Thread-Fastener-ppt-26-2048.jpg)