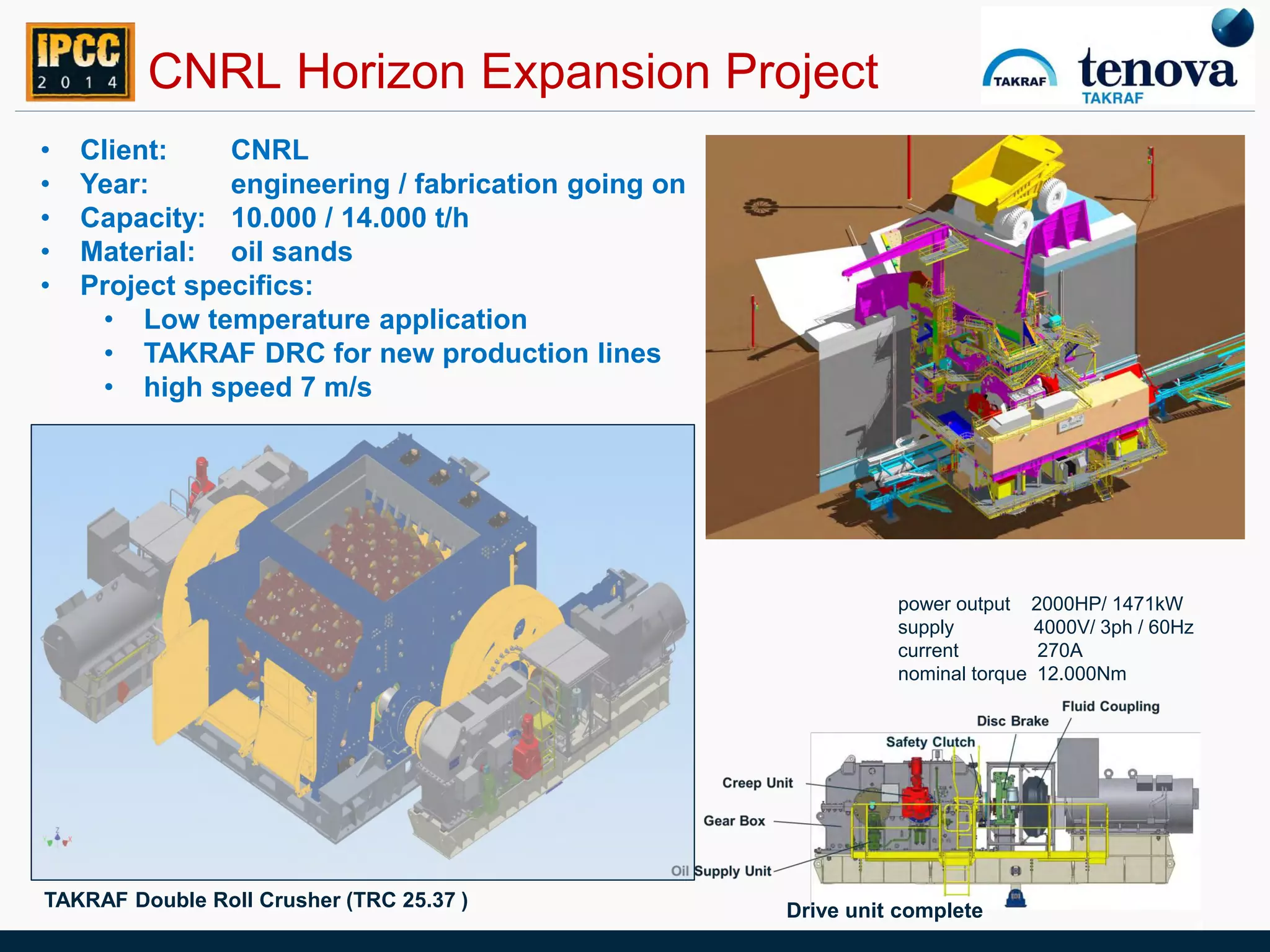

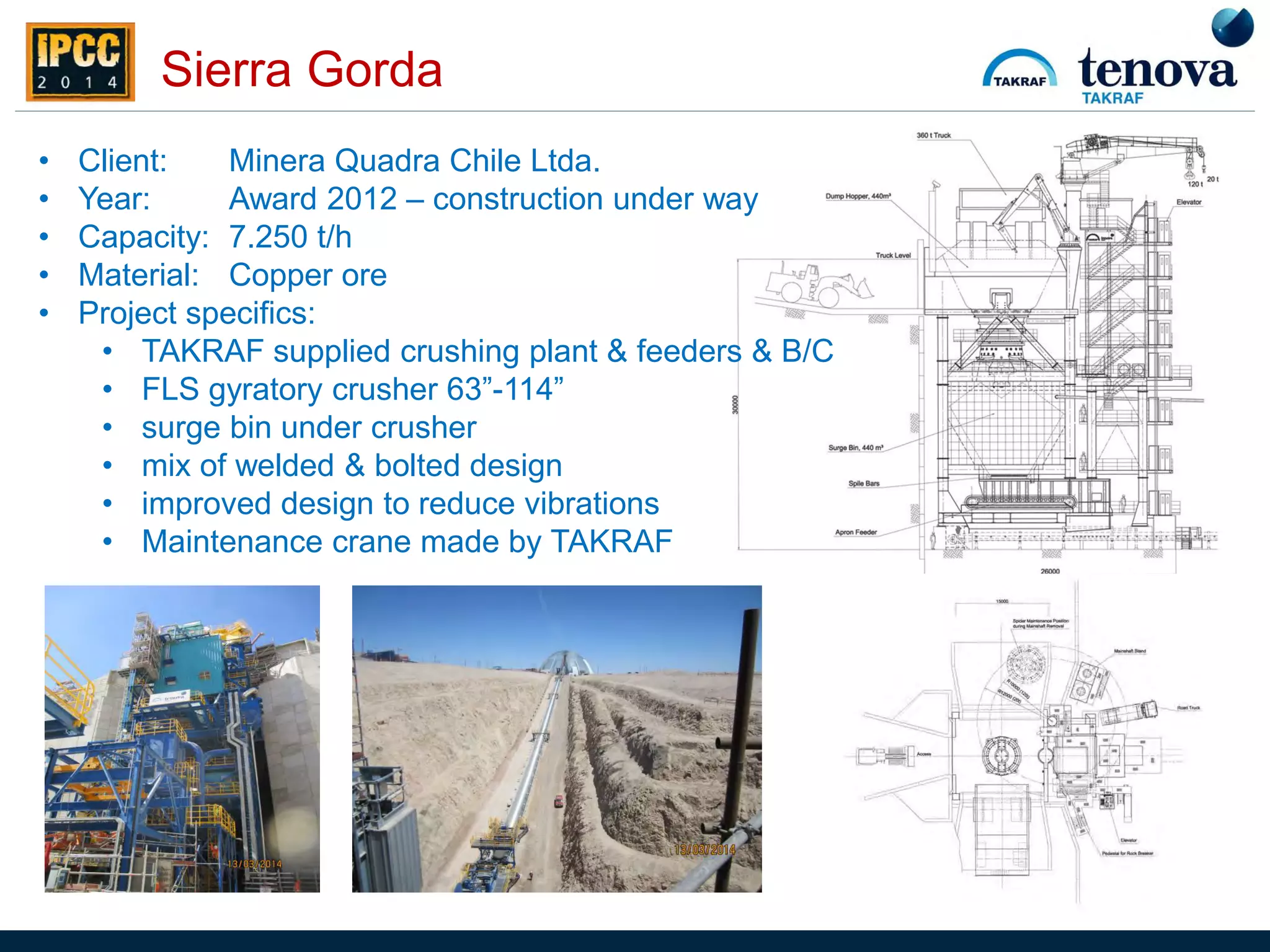

This document summarizes configurations for various TAKRAF IPCC systems and current installations. It describes several semi-mobile and fully mobile crushing plants supplied by TAKRAF to clients in Australia, Canada, Chile, Senegal and Kazakhstan. Specifics of the plants include crushers, conveyors, transfer points and material capacities. It also provides an overview of TAKRAF's history and portfolio of mining equipment and conveying solutions.