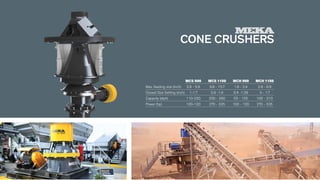

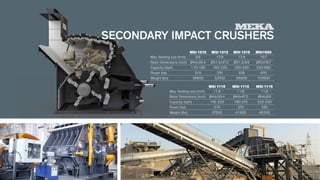

The document details a company's 30-year history in the manufacturing of concrete plants and crushing & screening equipment, highlighting its comprehensive services, engineering expertise, and global customer base across over 65 countries. It describes their extensive product range, including various types of crushers, screens, and batching plants, alongside manufacturing capabilities and a strong dealer network. The company emphasizes its commitment to quality and customer service through experienced personnel and robust after-sales support.