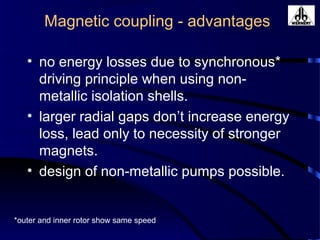

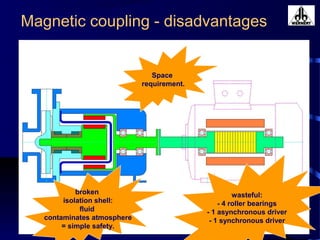

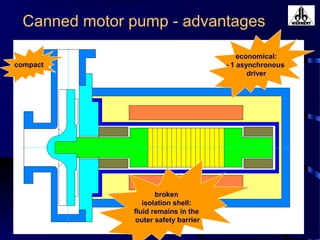

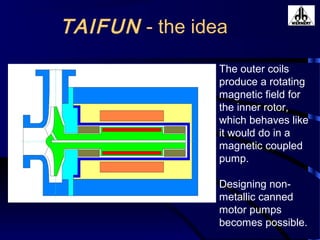

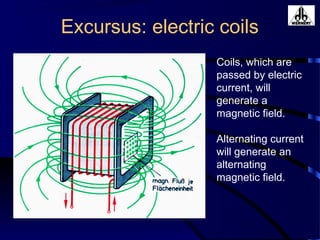

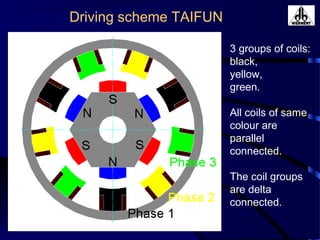

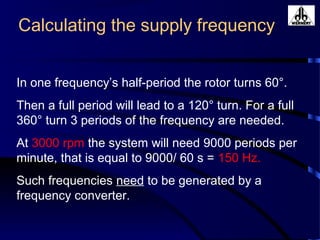

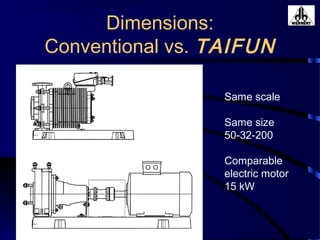

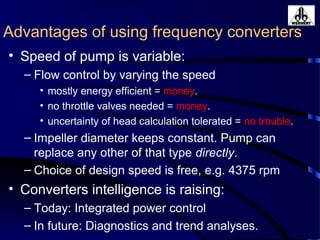

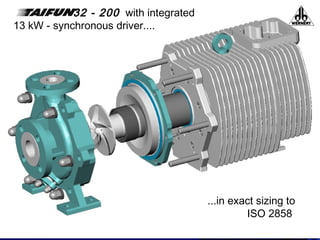

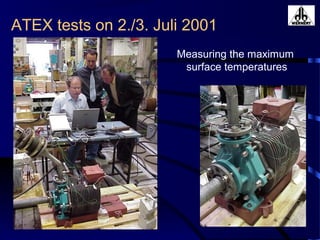

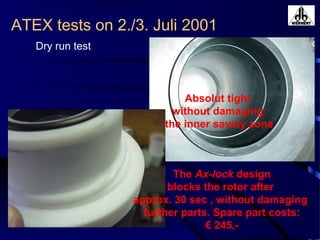

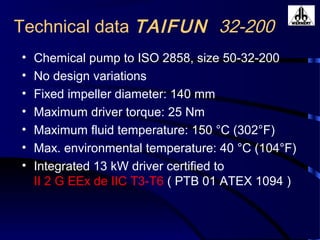

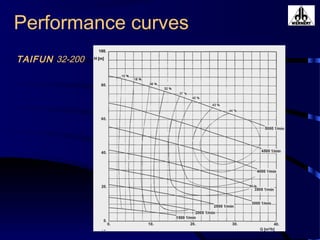

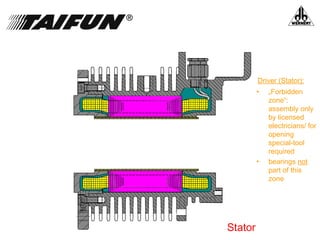

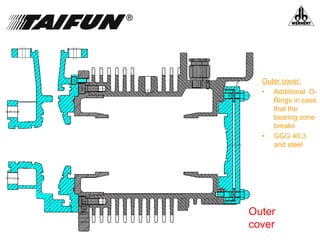

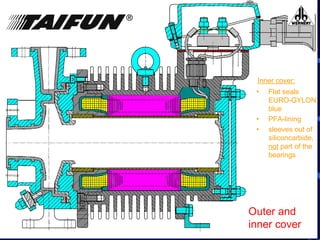

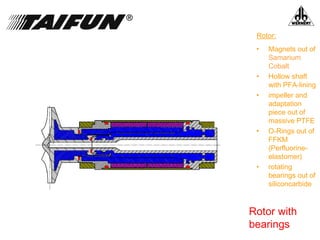

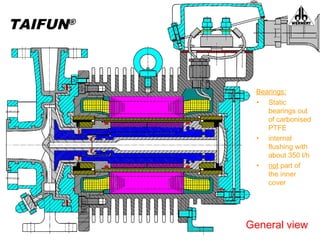

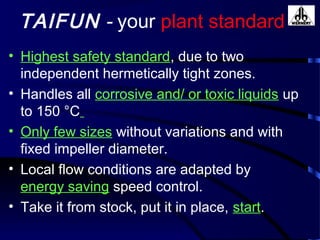

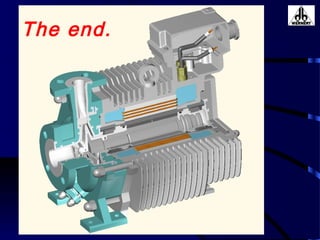

The document summarizes the TAIFUN centrifugal pump concept, which uses a rotating magnetic field to drive the pump impeller synchronously like a magnetic coupling, but with the motor integrated in a canned design for safety. Key advantages are high efficiency due to synchronous operation, compact design, double safety barriers, and ability to customize flow with variable speed control. Initial prototypes were tested successfully in 2001 and the pump design has advantages over conventional canned motor pumps for chemical applications requiring temperatures up to 150°C.