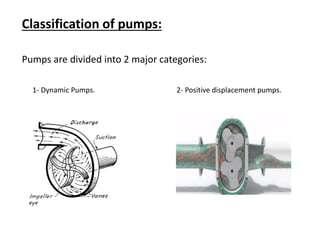

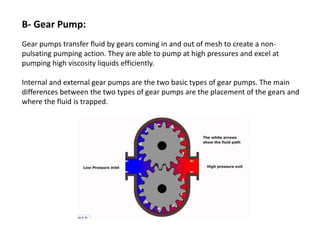

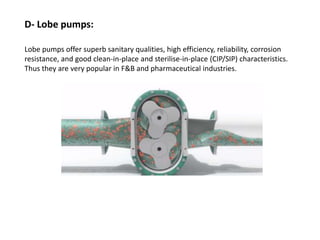

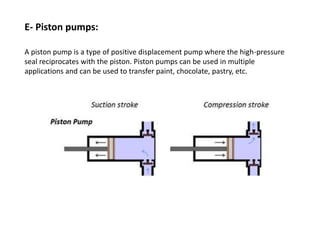

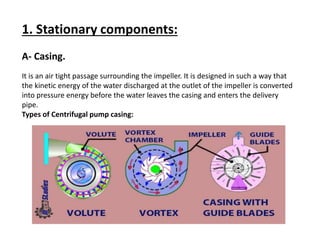

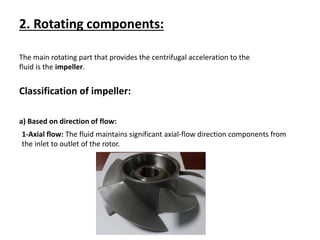

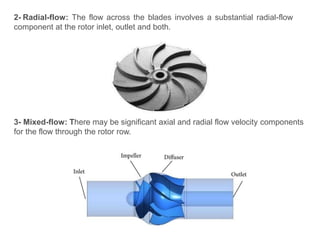

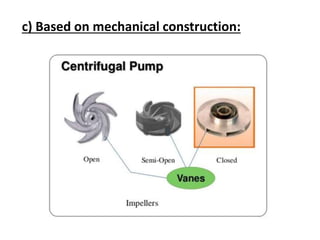

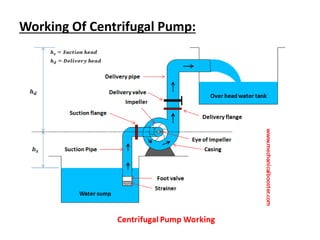

Pumps are devices that move fluids, categorized mainly into dynamic and positive displacement types. Dynamic pumps include centrifugal and submersible pumps, while positive displacement pumps comprise diaphragm, gear, peristaltic, lobe, and piston pumps, each with specialized uses. The document also discusses the construction and working mechanisms of centrifugal pumps, detailing their stationary and rotating components.