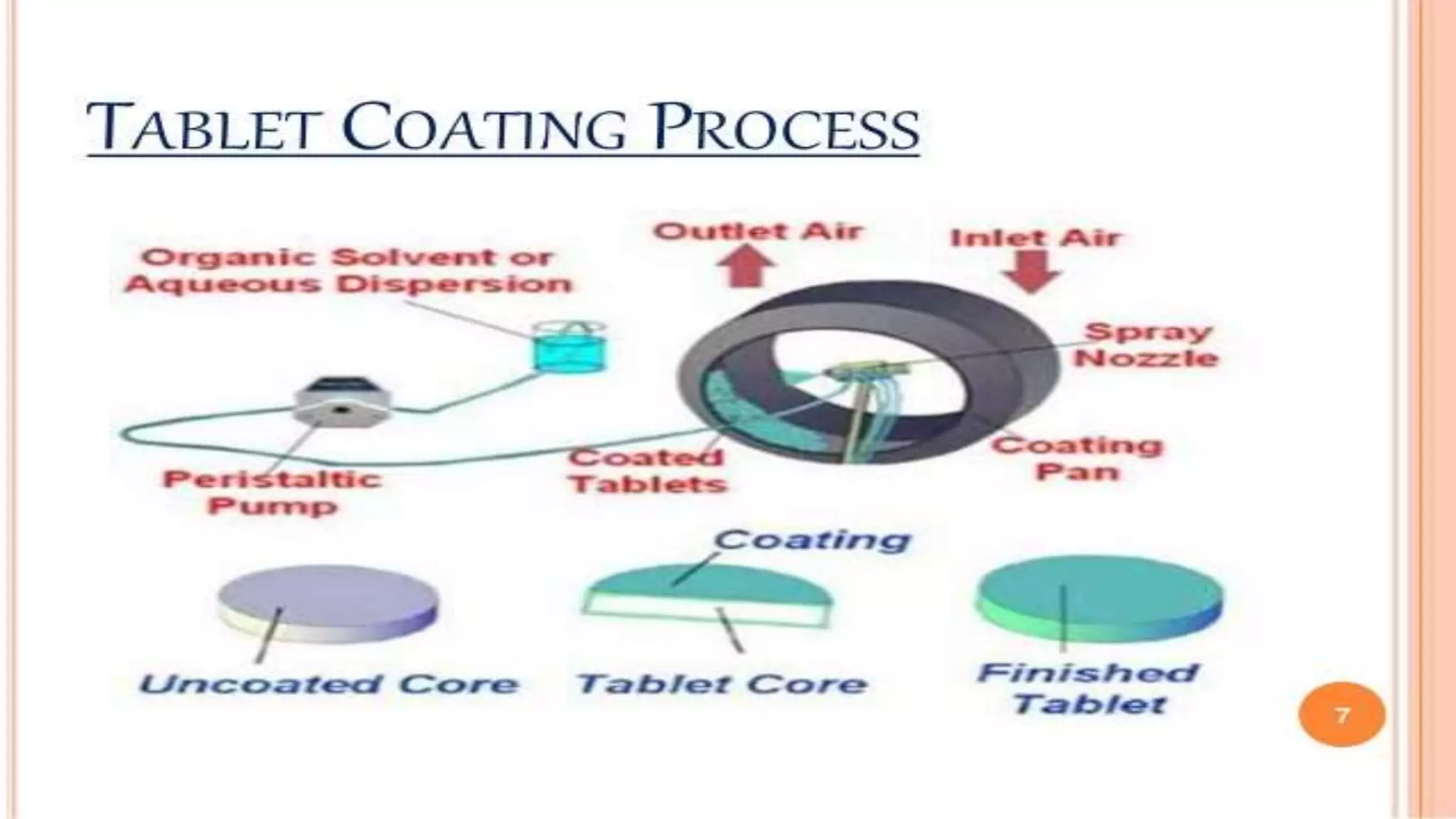

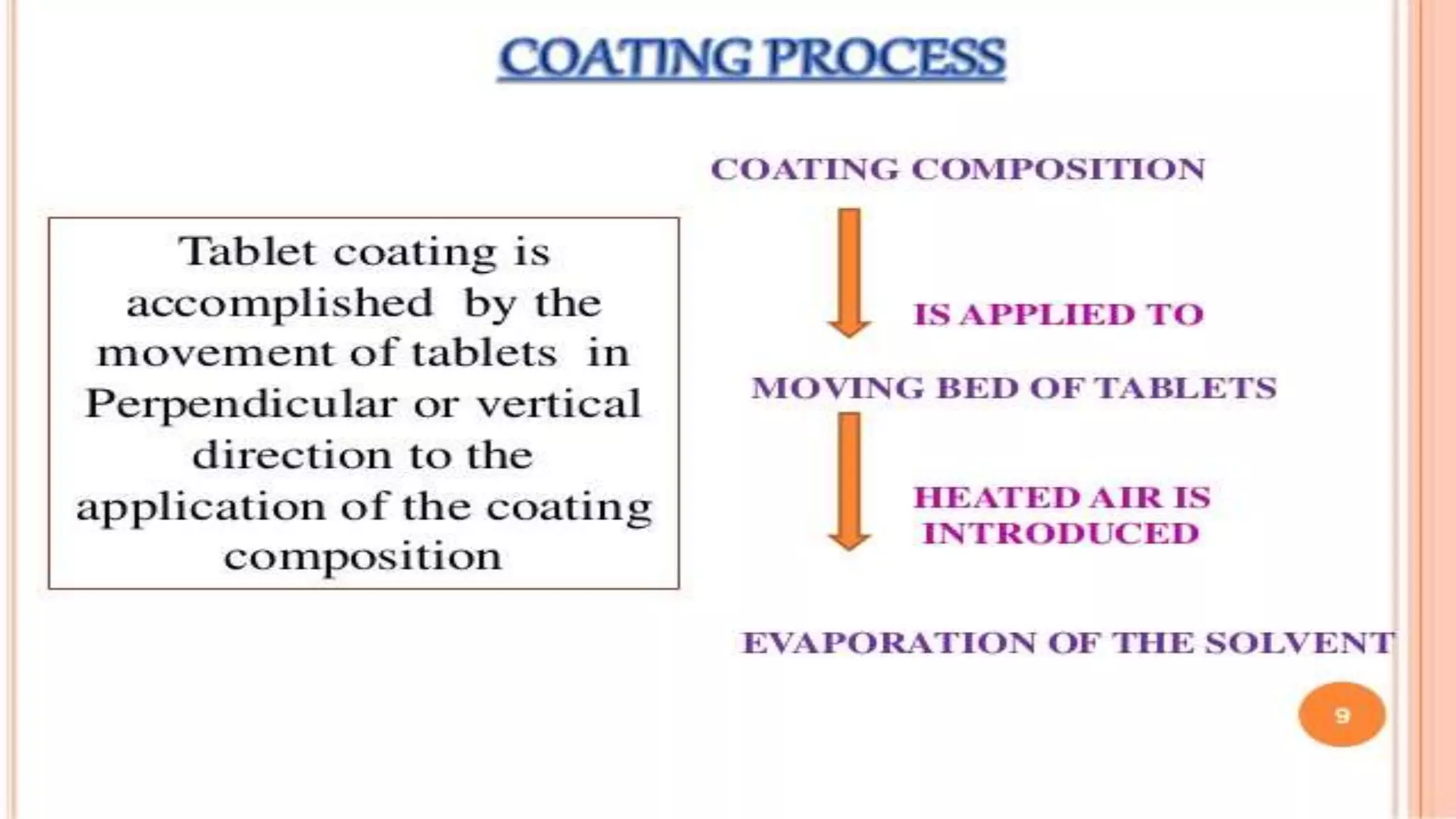

Tablet coating is the final step in tablet production used to mask tastes, protect drugs, and control drug release. The objectives of coating include masking odors and tastes, providing physical and chemical protection, and controlling or protecting drug release. Coating considerations include tablet properties like shape and surface area, the coating process and equipment, and the coating composition of polymers, colors, plasticizers, and solvents. There are three main types of coatings: sugar coating which provides taste masking and elegance; film coating which provides a thin uniform film; and enteric coating which protects acid-labile drugs and provides site-specific delivery to the intestines.