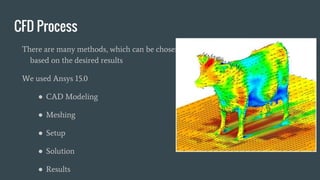

The document summarizes an Ansys CFD simulation of film cooling effectiveness comparing different shaped cooling holes. It discusses that CFD uses numerical methods to solve complex fluid flows and is used in aerospace, sanitation, medicine, and more. The simulation process in Ansys 15.0 includes CAD modeling, meshing, setup of variables like momentum and boundaries, solution of the mesh, and results analysis including velocity, vorticity, and temperature contour comparisons to experimental data. The simulation aimed to match results from a dissertation on film cooling effectiveness of different hole shapes.