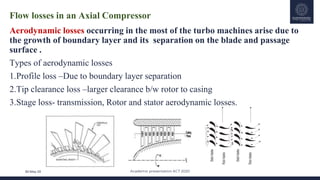

1. Aerodynamic losses occur in axial compressors due to boundary layer growth and separation on blades and passage surfaces, including profile, tip clearance, and stage losses.

2. Off-design operation of a compressor occurs when it deviates from its design point, which can result in unstable flow due to surge or stall.

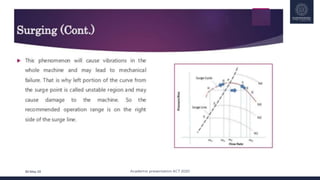

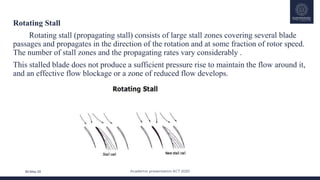

3. Surge is a complete breakdown of steady flow through the compressor that involves reversing flow direction and can damage the compressor blades, while stall occurs when blade surfaces separate from the flow in individual blades, rotating zones, or flutter.