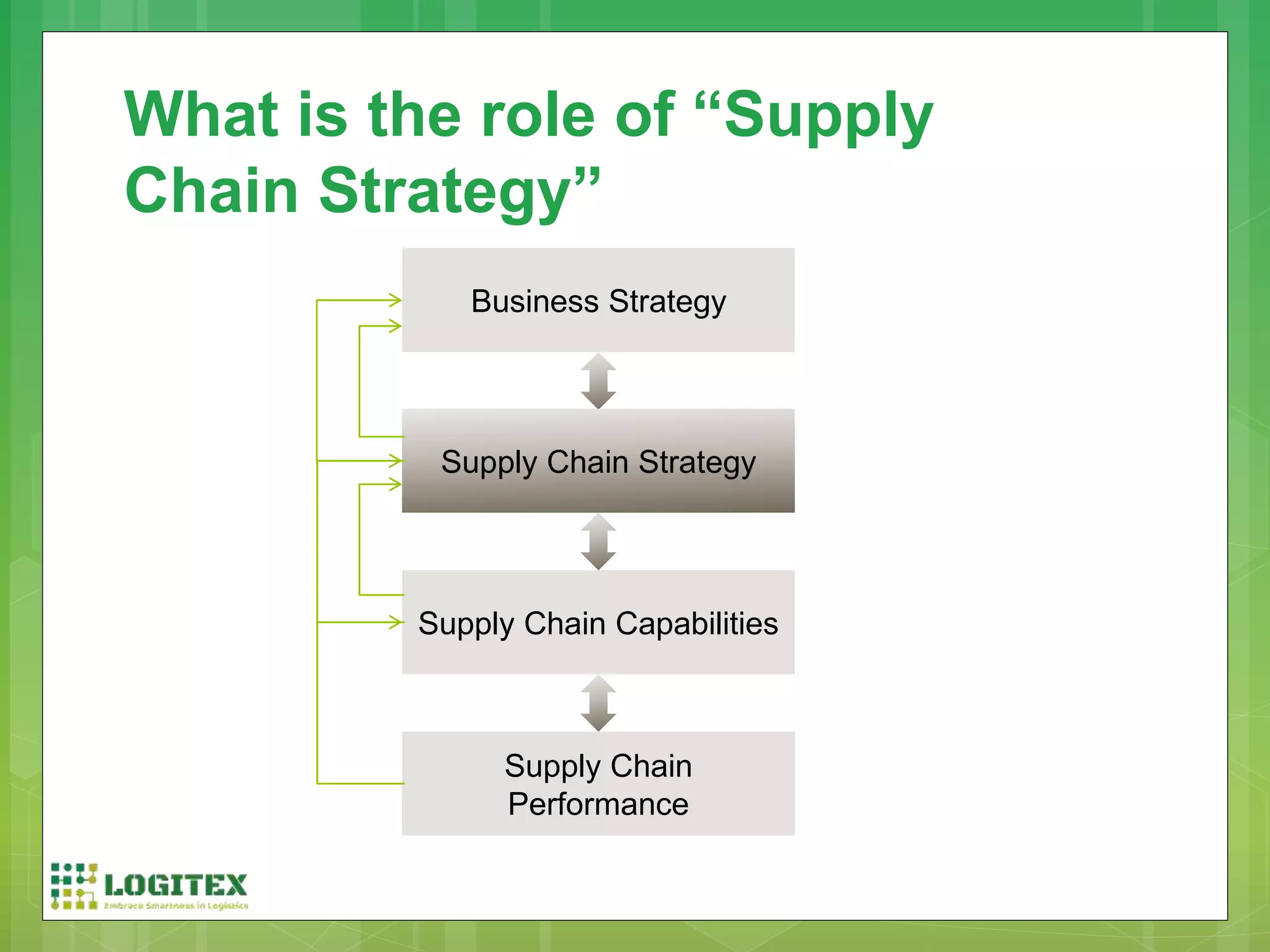

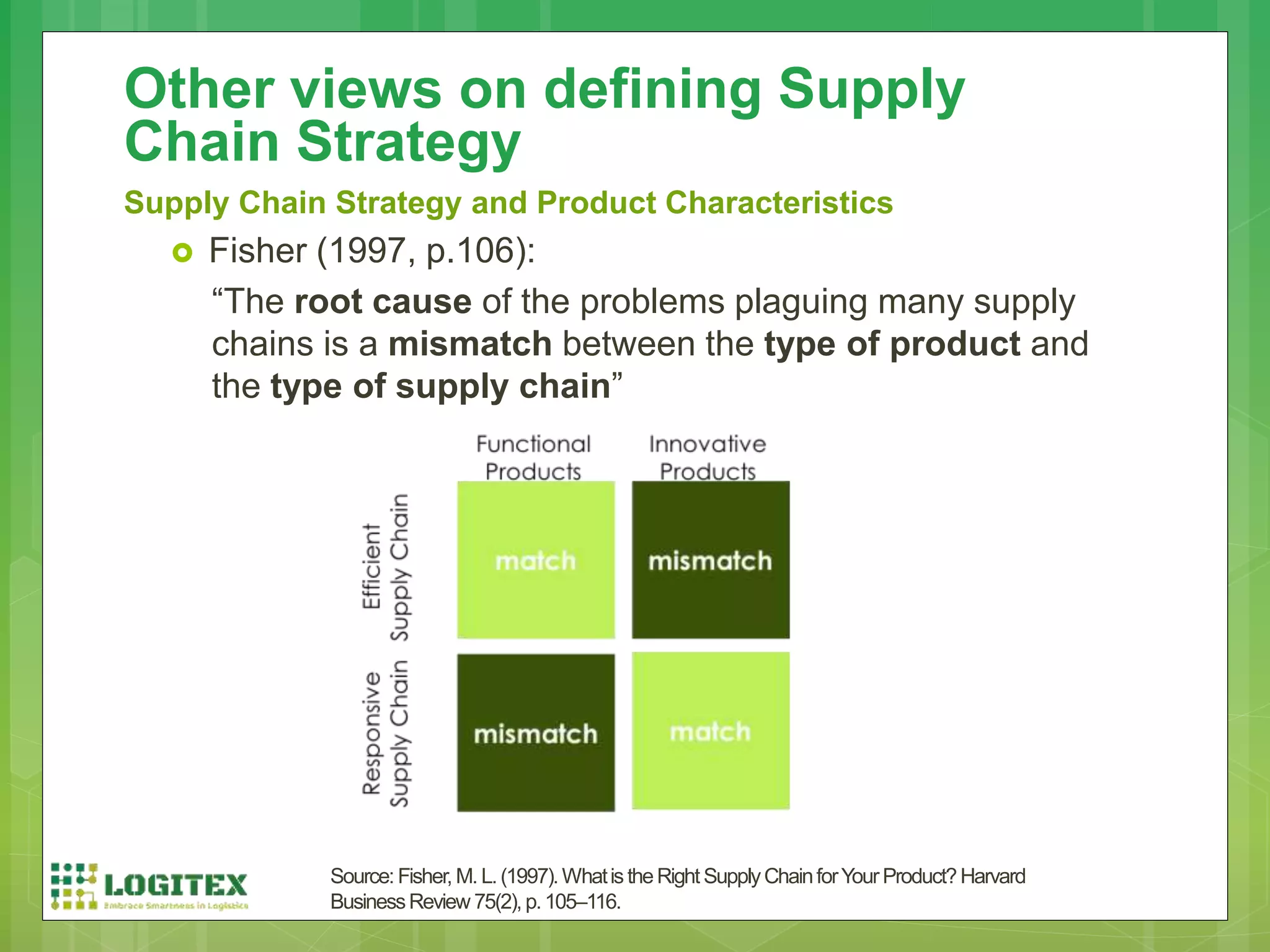

The document outlines the importance of defining a supply chain strategy for various stakeholders, including supply chain managers and logistics service providers. It discusses how a clear strategy aligns organizational goals with supply chain capabilities and performance, emphasizing the balance between efficiency and responsiveness based on product characteristics and market dynamics. Additionally, it introduces five principles of supply chain management that focus on strategy alignment, customer value, performance measurement, capability development, and the role of integration and collaboration.