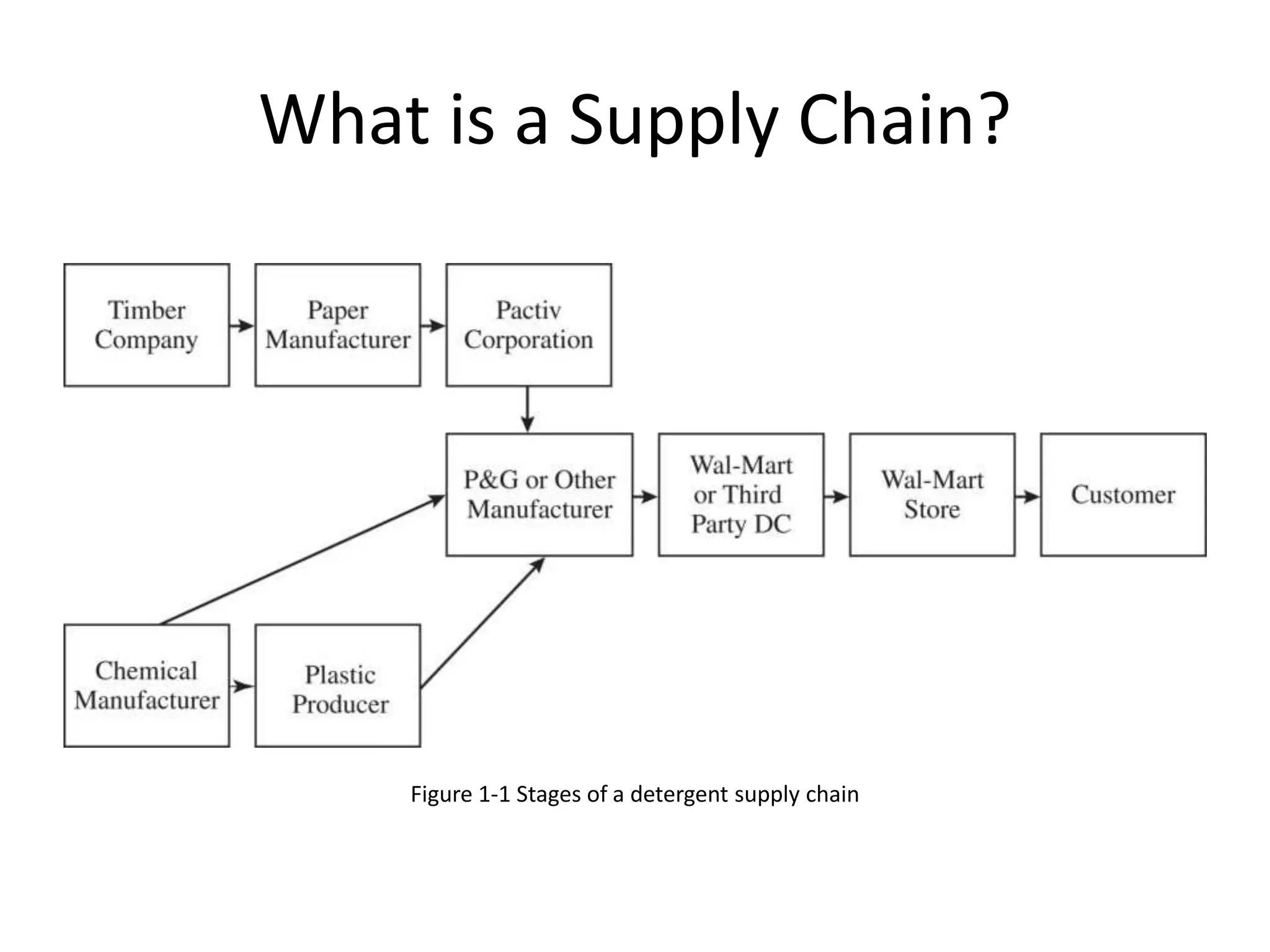

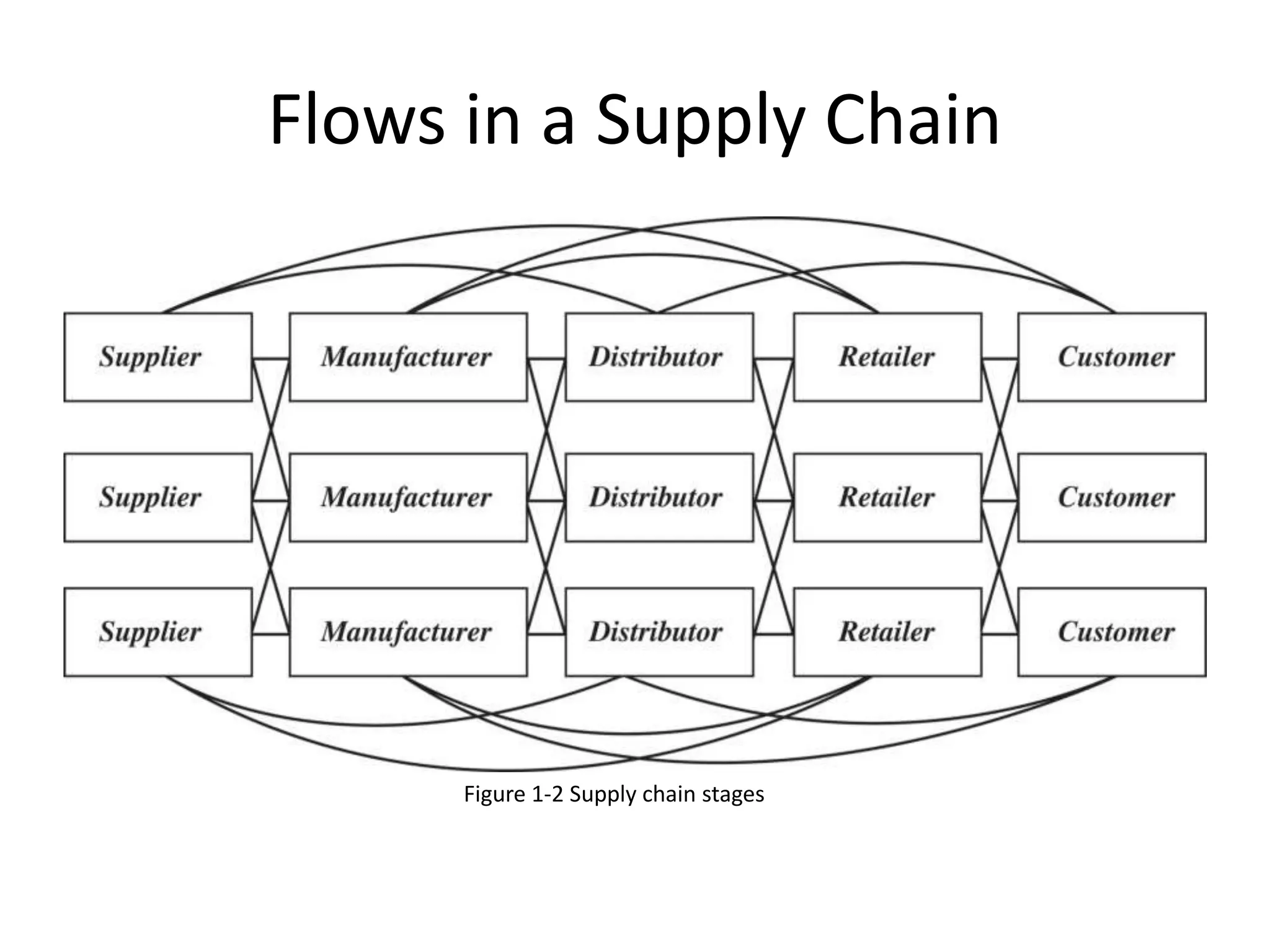

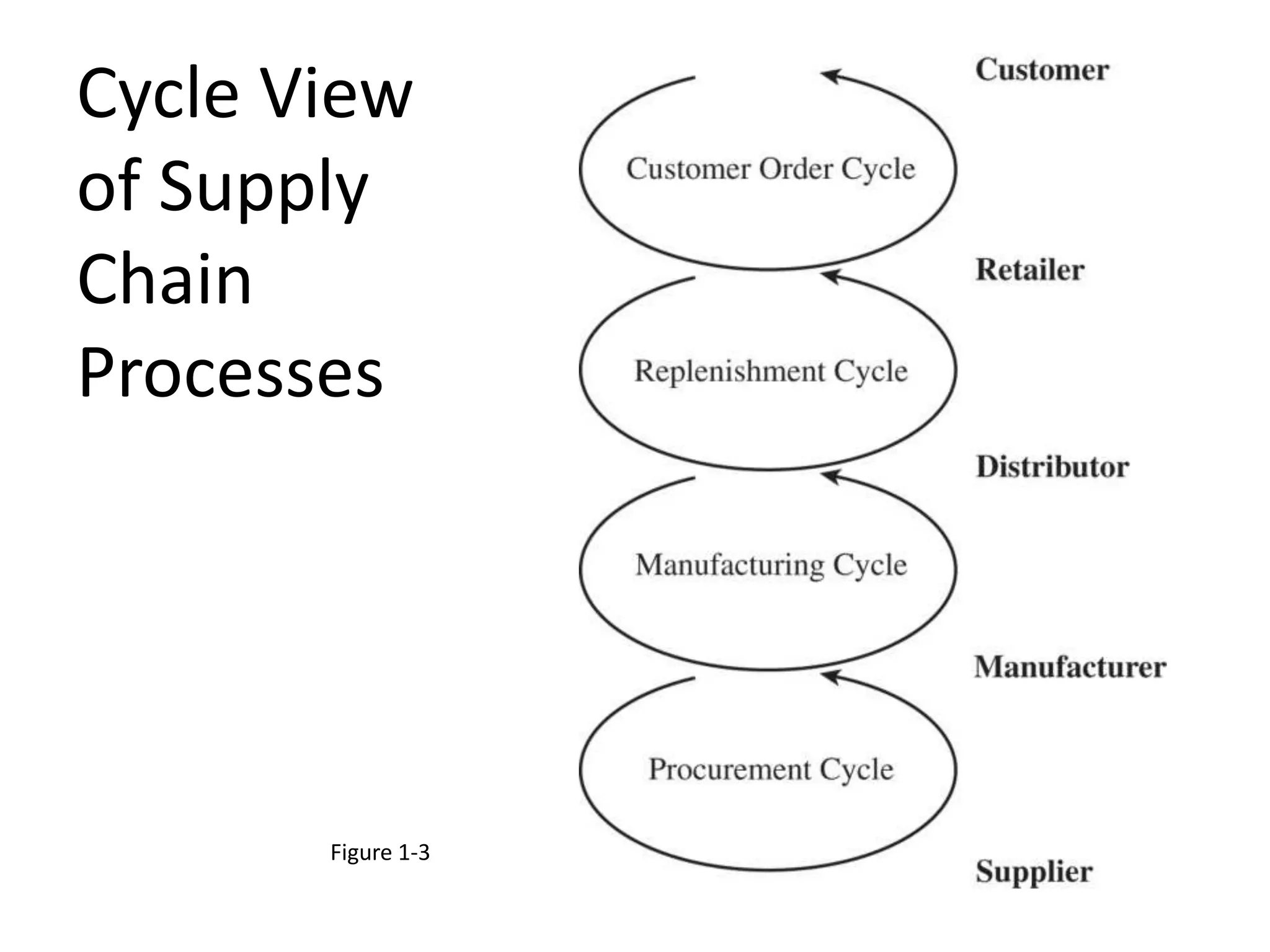

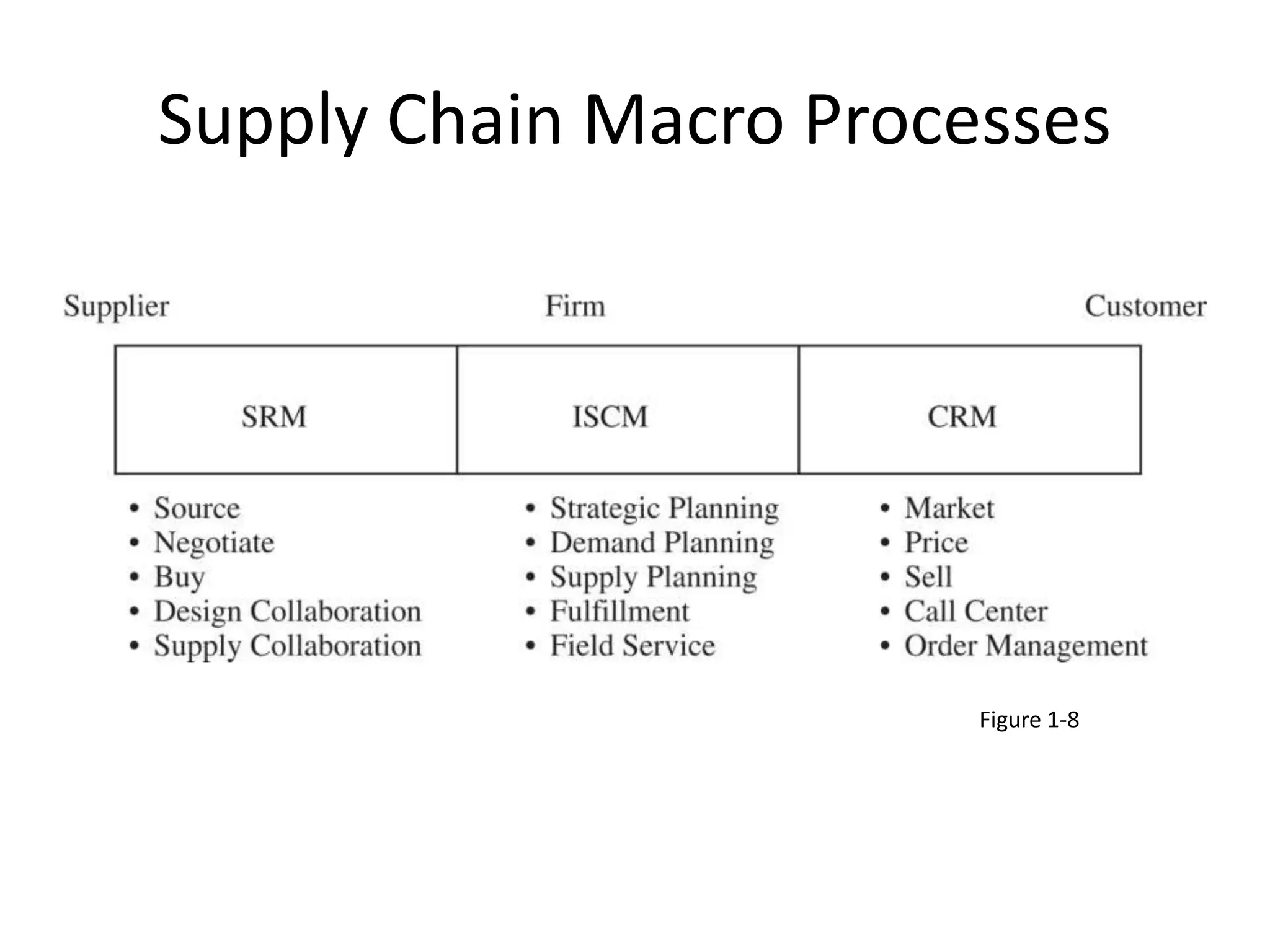

This document provides an overview of key concepts in supply chain management. It defines a supply chain as consisting of all stages involved in fulfilling a customer request, from suppliers to manufacturers to distributors. The objective of a supply chain is to maximize overall value by balancing customer value and supply chain costs. Supply chain decisions are classified into three phases - strategy, planning, and operations. Effective supply chain management requires integrating processes for customer relationship management, internal supply chain management, and supplier relationship management.