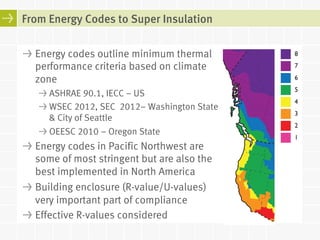

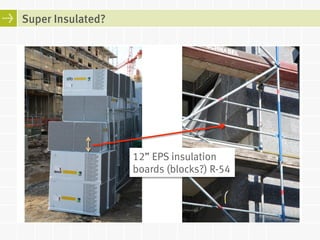

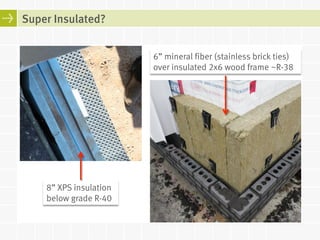

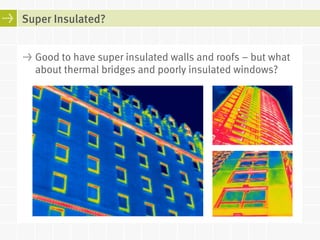

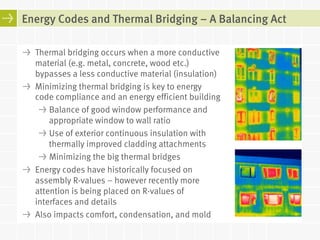

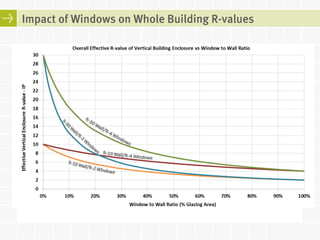

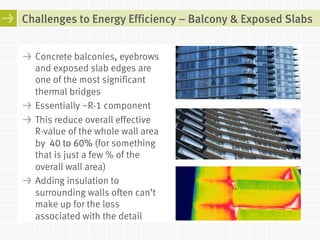

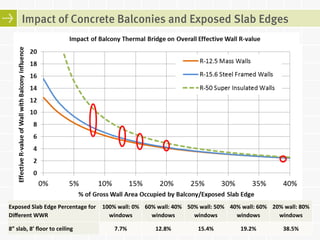

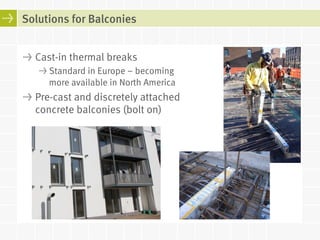

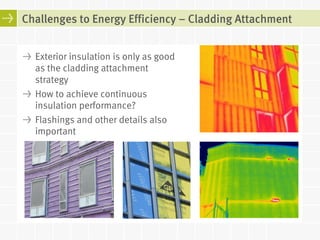

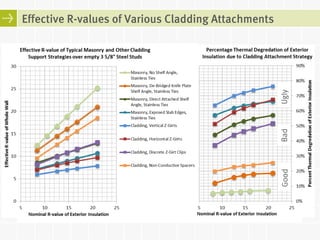

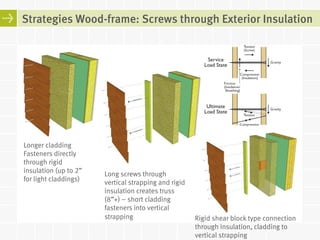

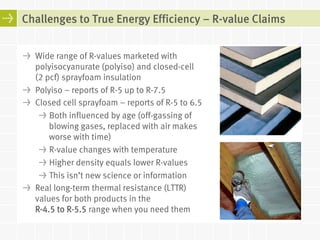

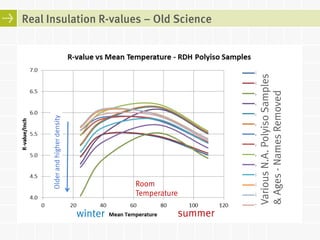

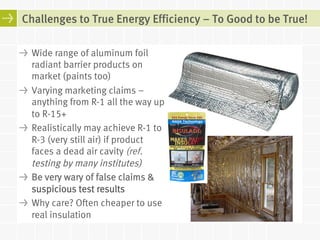

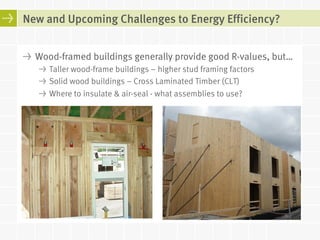

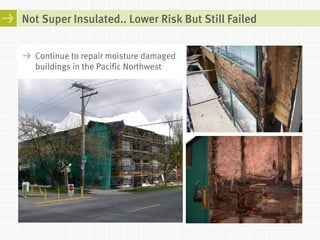

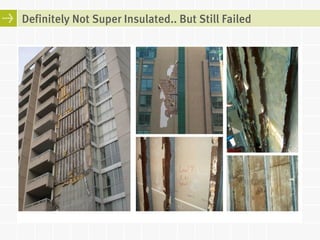

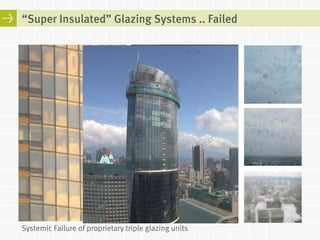

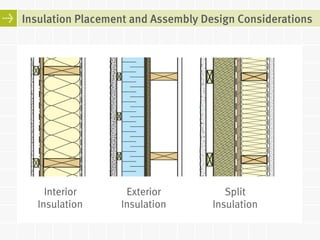

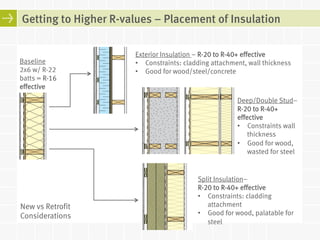

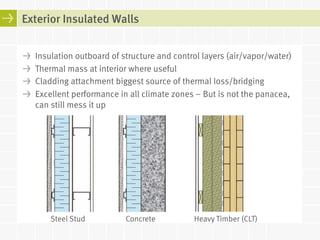

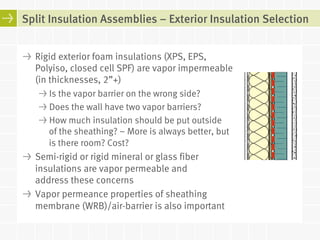

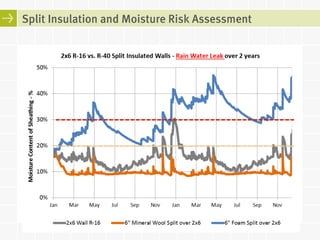

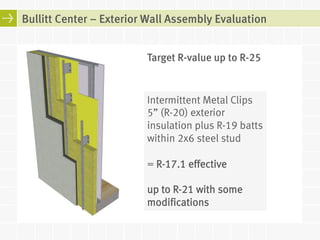

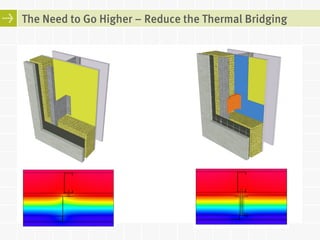

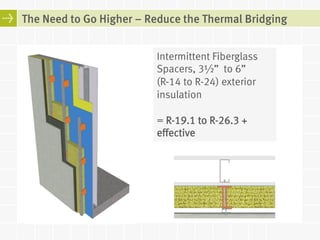

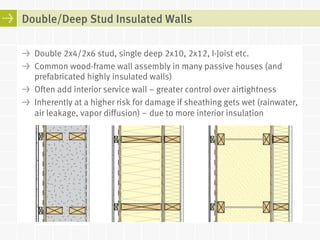

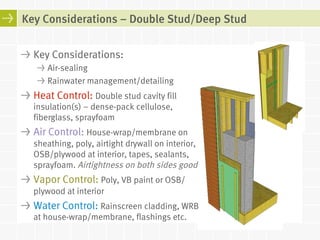

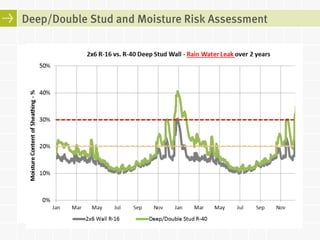

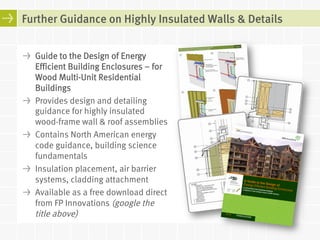

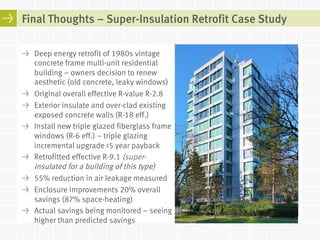

The document discusses the design and considerations for super-insulated building enclosures in the Pacific Northwest, focusing on energy efficiency, durability, and compliance with stringent energy codes. It highlights various aspects such as thermal bridging, insulation placement, and the importance of airtightness in achieving effective R-values. The presentation also emphasizes the need for careful design and detailing to balance energy performance with building durability.