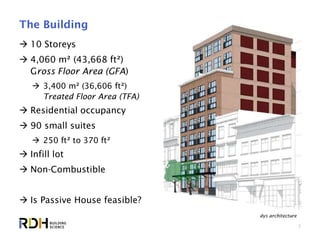

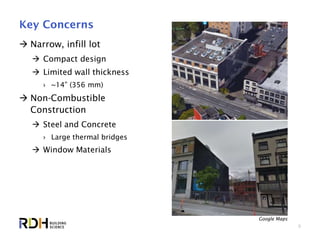

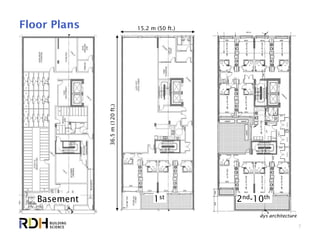

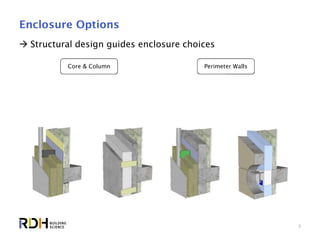

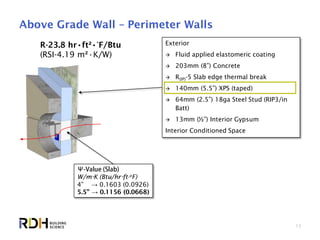

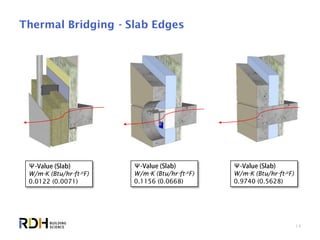

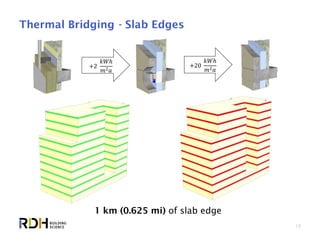

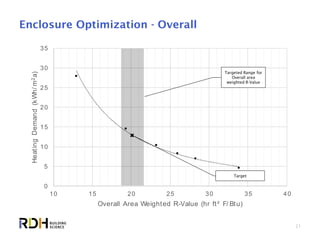

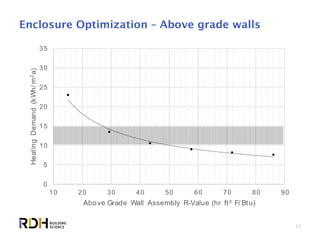

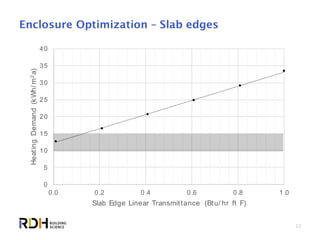

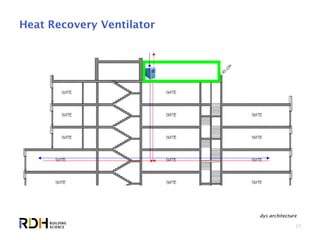

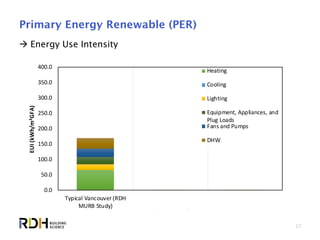

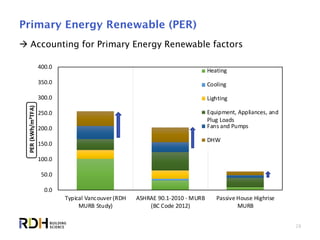

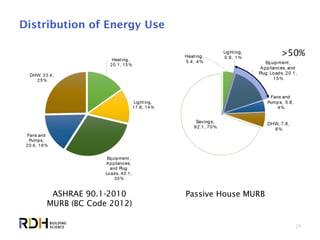

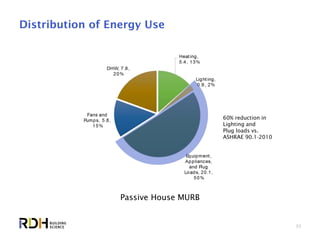

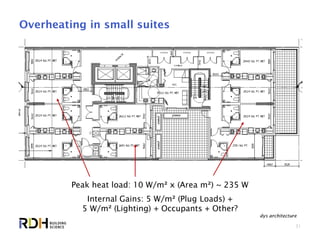

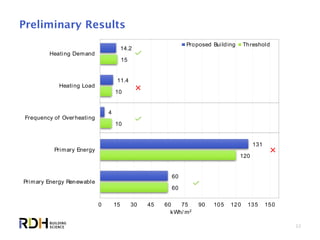

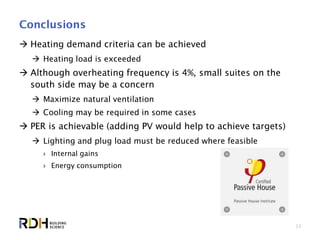

The document presents a feasibility study for achieving passive house standards in a high-rise concrete building in Vancouver. It discusses the building's design, construction challenges, energy performance metrics, and strategies for optimizing natural ventilation and minimizing heat loss. Key concerns include the building's compact design, limited wall thickness, and the need to address overheating in small suites.