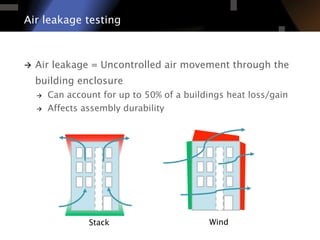

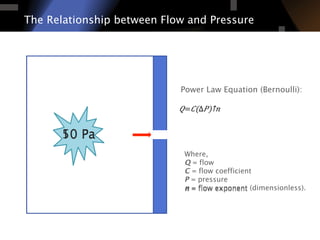

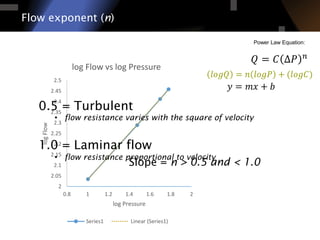

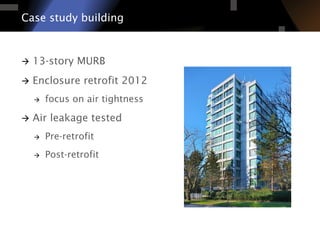

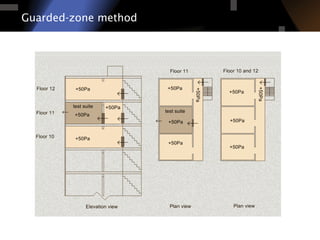

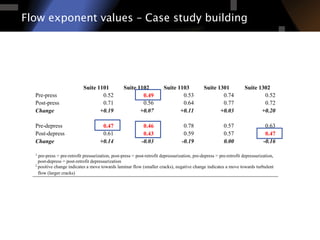

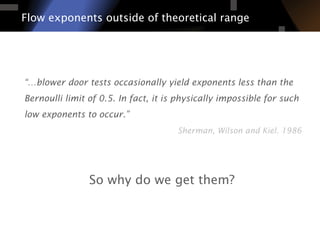

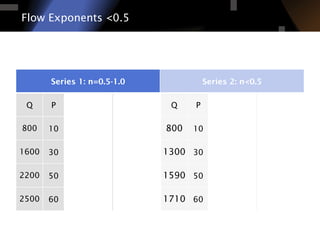

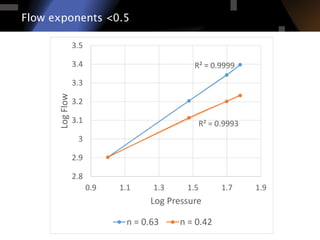

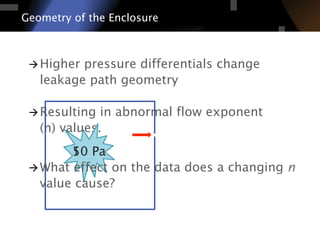

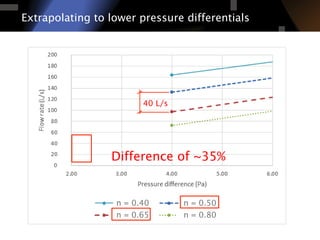

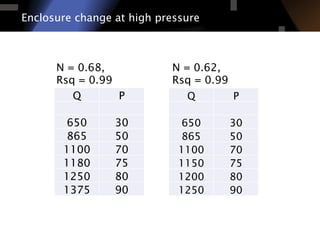

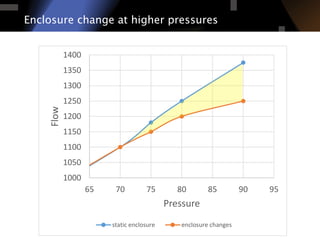

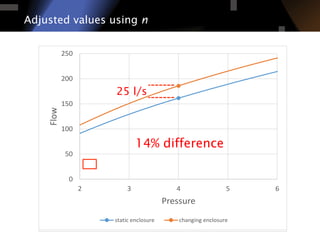

The document discusses air leakage testing and its impact on building energy efficiency, detailing the relationship between flow and pressure through flow exponent values. A case study is presented that showcases the effects of retrofitting on air leakage rates and the significance of flow exponent interpretations in evaluating building performance. It concludes that flow exponent values are critical for accurate energy modeling and compliance, while emphasizing the need for further research in this area.