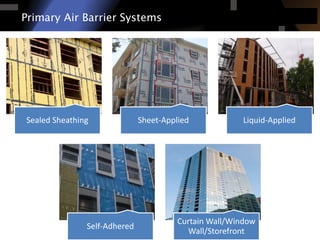

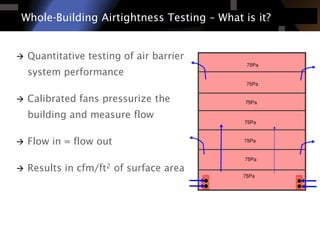

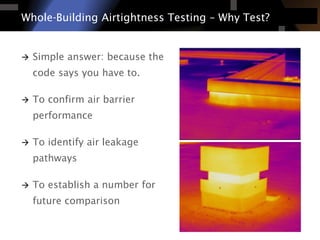

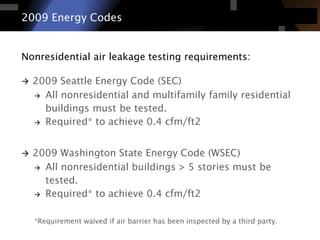

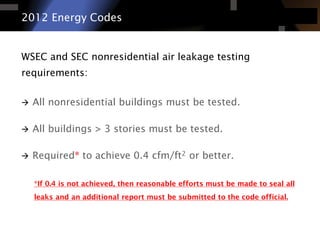

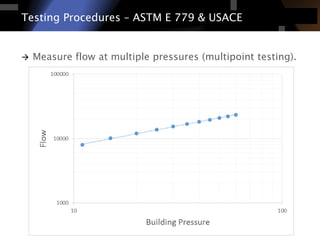

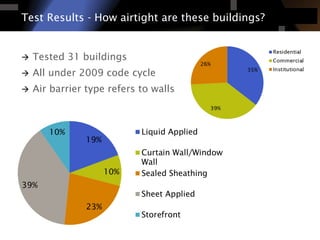

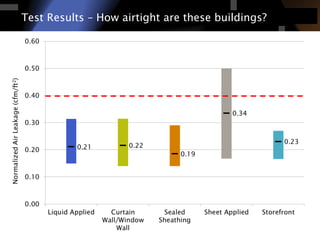

This document discusses building airtightness testing that was conducted in Washington State on 31 buildings. It provides an overview of airtightness testing procedures and requirements under the 2009 and 2012 energy codes. Test results showed that while an airtightness of 0.4 cfm/ft2 is attainable, achieving it requires repetitive simple details, experienced teams, and coordination between designers, contractors and trades to minimize air leakage.