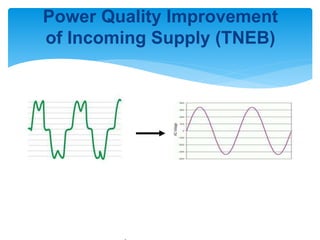

The document discusses steps taken to improve power quality from the incoming electricity supply. It includes:

1) Installing an HT AVR to regulate the voltage variation within ±1%.

2) Installing UPS systems to reduce losses during power outages.

3) Upgrading the voltage from 11kV to 33kV to improve stability.

Problems before these changes included machine failures and breaker tripping due to low and fluctuating voltage. The AVR installation stabilized the voltage and avoided these issues. Upgrading the voltage capacity and UPS systems further improved power reliability.