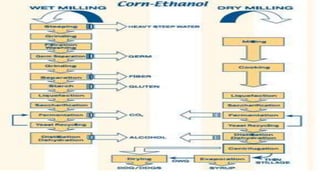

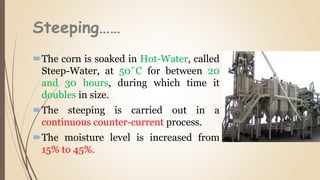

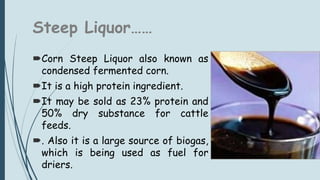

Corn starch is produced through either a dry milling or wet milling process. The wet milling process is more complex but extracts more products. It involves soaking corn kernels, separating the germ to extract oil, grinding to separate starch from fiber and gluten, and refining the starch through centrifugation and washing. Final starch can be dried or modified. Corn starch has many industrial uses including in food products, paper, and as a base for high fructose corn syrup. Byproducts like steep liquor and corn gluten are also valuable feed ingredients.