Embed presentation

Download to read offline

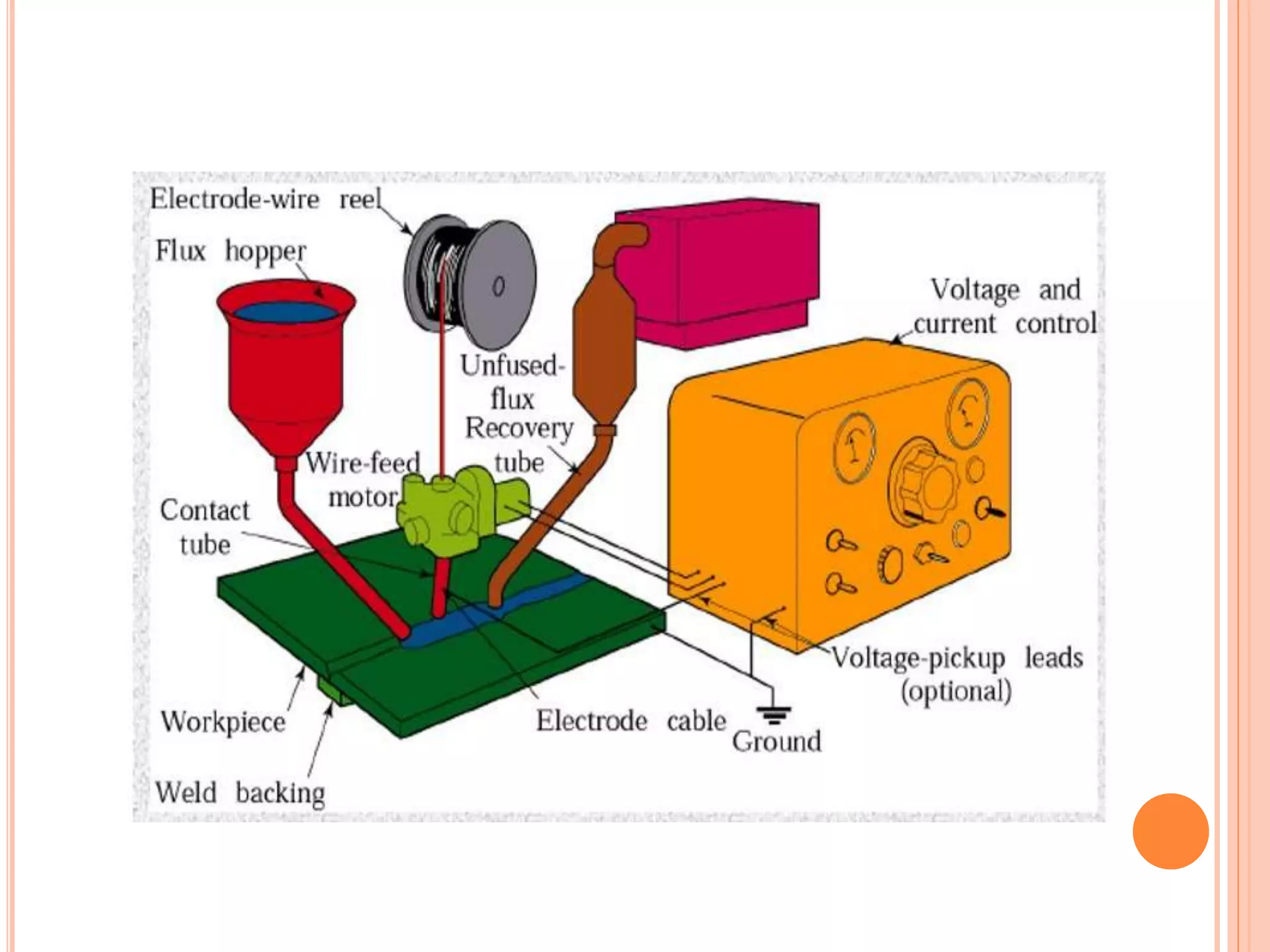

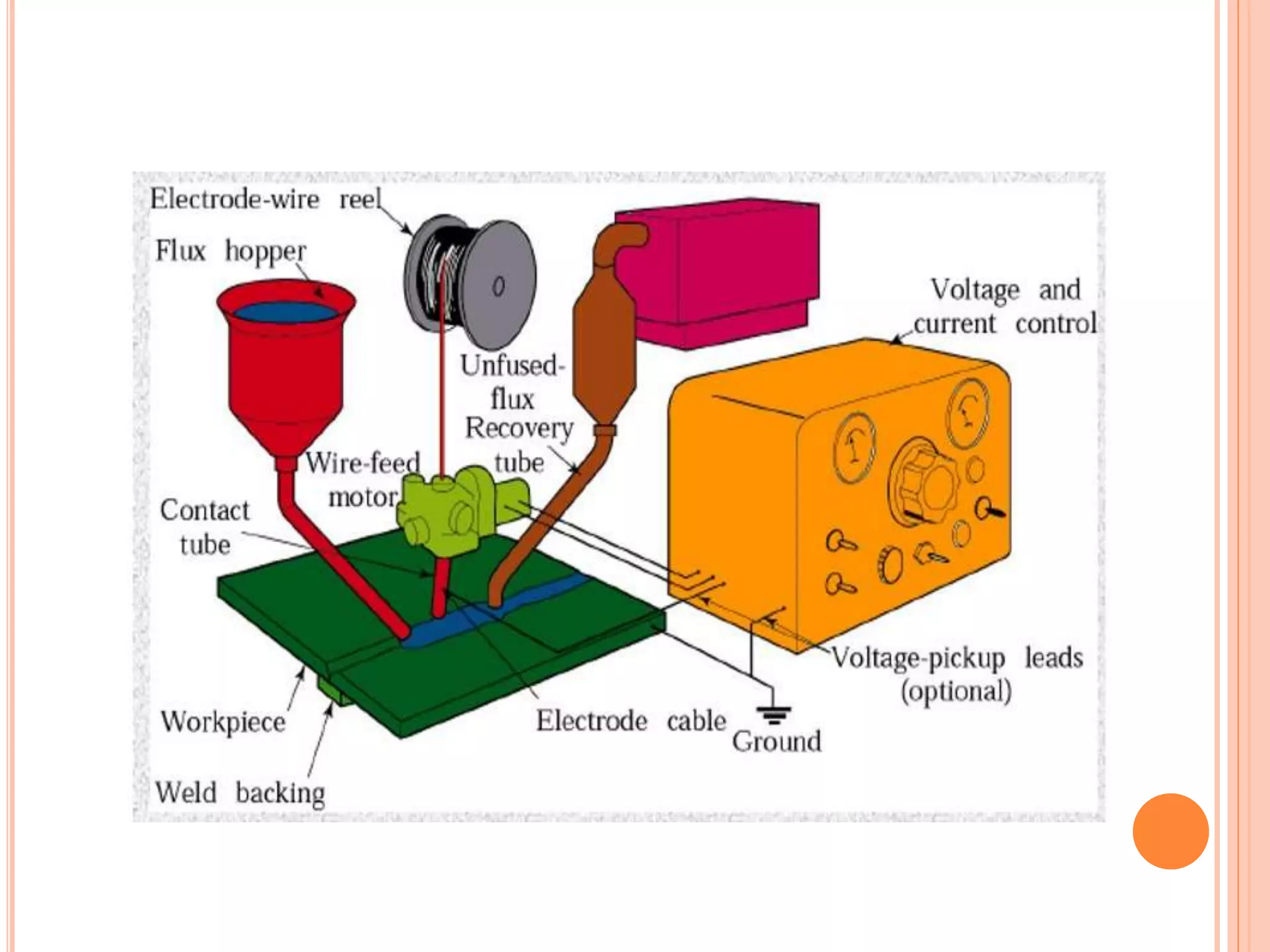

Submerged arc welding involves an electric arc between a consumable electrode and workpiece that is covered by granulated flux. The flux melts during welding to form a slag that covers and protects the weld area from contamination while allowing for deep penetration and high welding speeds of up to 3.8 meters per minute on 3mm thick steel plates or welding of plates up to 75mm thick in a single pass.