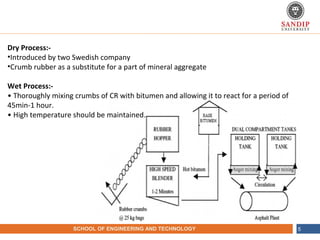

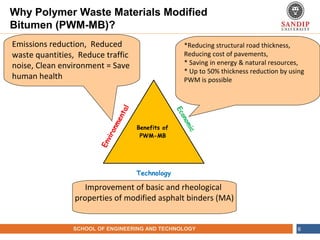

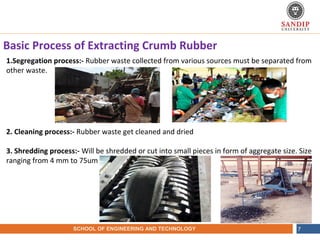

The document presents a study on crumb rubber modified bitumen (CRMB) as a sustainable alternative in highway materials, addressing the growing environmental issue of polymer waste, particularly scrap tires. It details the processes for extracting crumb rubber, the benefits and challenges of using it in bitumen, and concludes that CRMB significantly enhances the properties of conventional bitumen while also promoting recycling and reducing environmental pollution. Key findings suggest that using specific sizes of crumb rubber optimizes performance and stability, making it a viable option for construction.