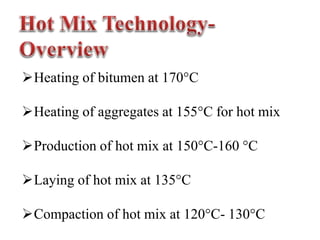

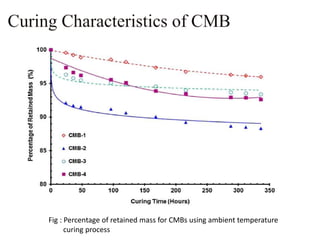

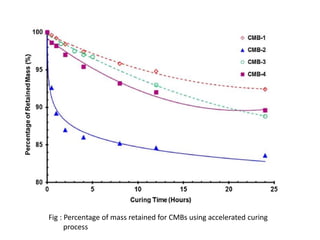

The document discusses the properties and testing of cold-mix asphalt (CMA) and its binders, highlighting that CMA offers advantages such as no heating requirements, reduced pollution, and faster project completion compared to hot-mix asphalt (HMA). It outlines various cold-mix binders, their testing methods, and their relationship with engineering properties, emphasizing the need for effective evaluation procedures. The research concludes with recommendations for using dense-graded CMA with specific binders for pothole repairs in suitable weather conditions.