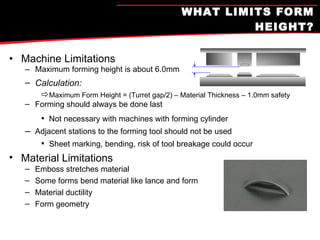

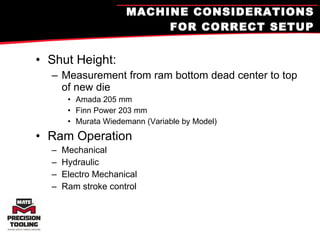

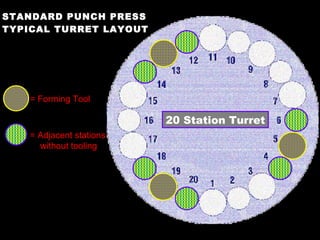

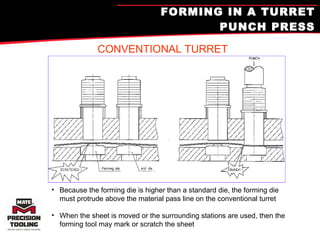

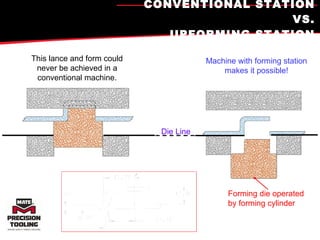

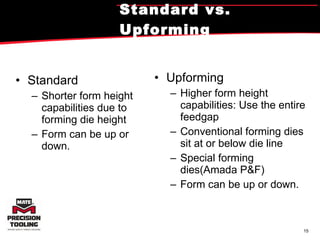

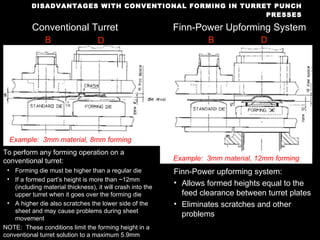

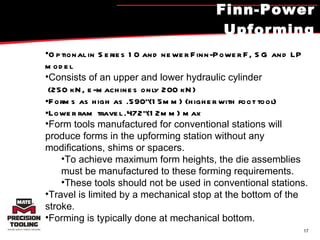

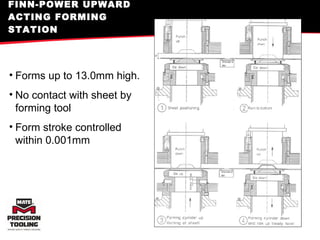

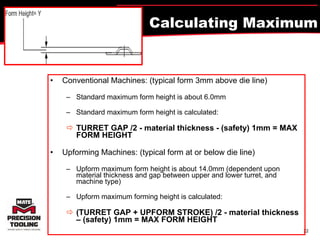

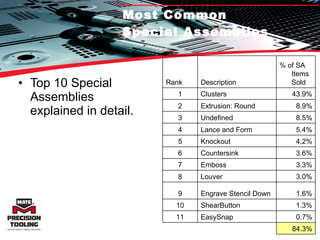

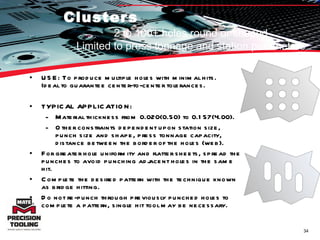

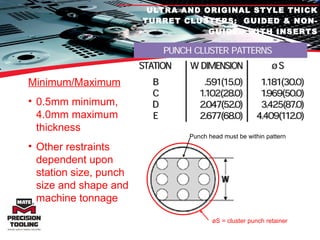

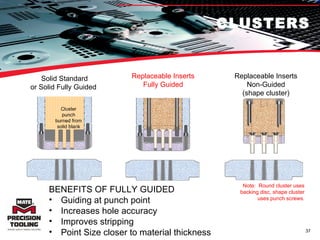

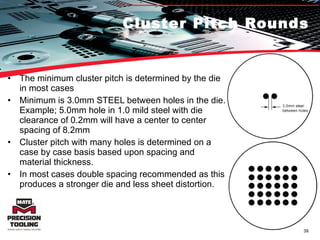

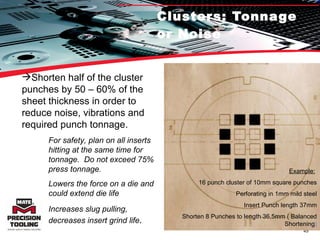

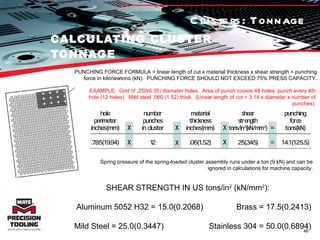

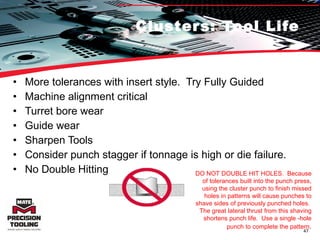

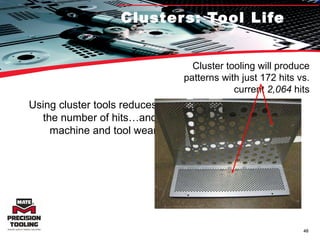

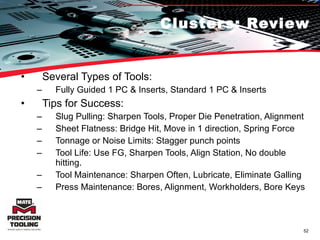

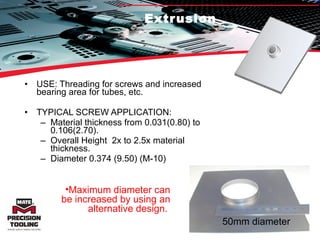

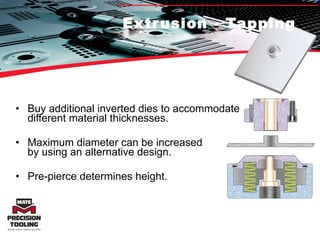

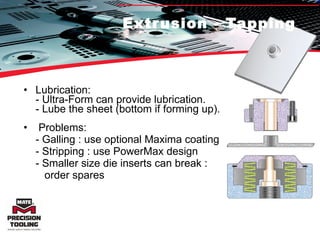

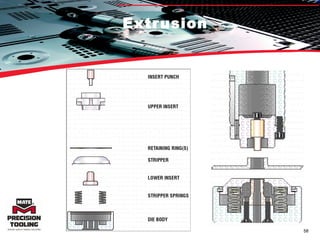

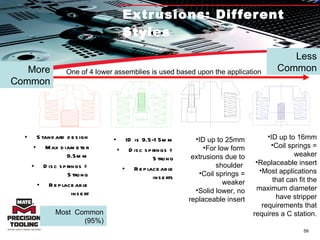

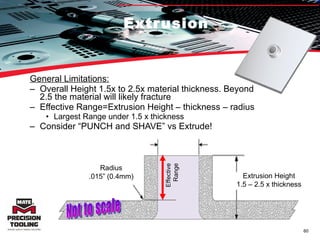

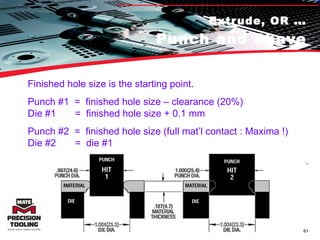

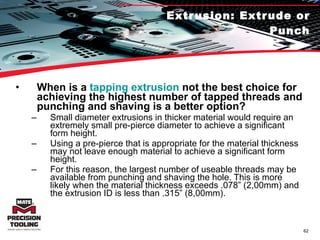

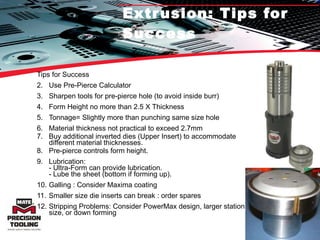

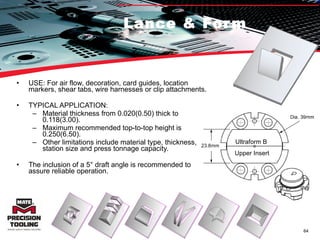

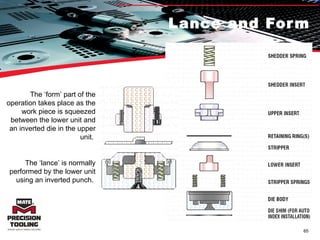

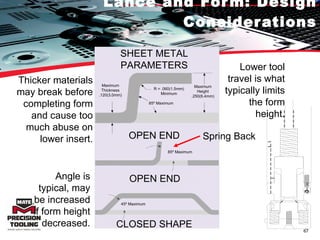

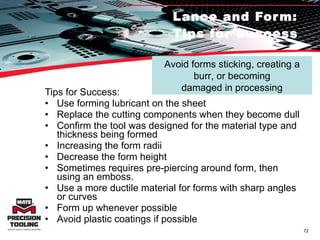

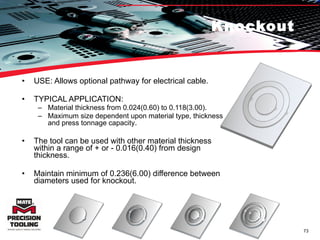

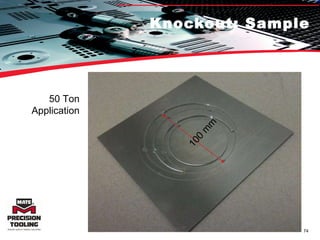

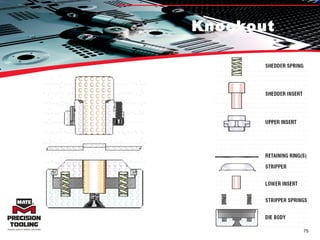

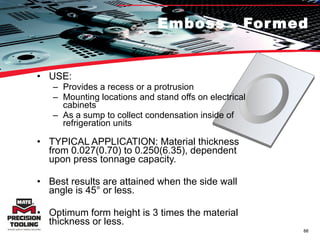

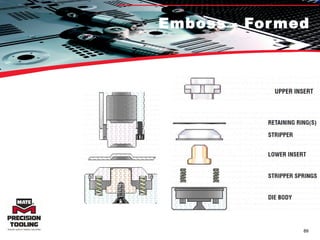

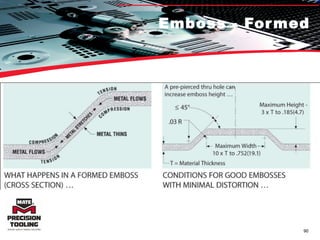

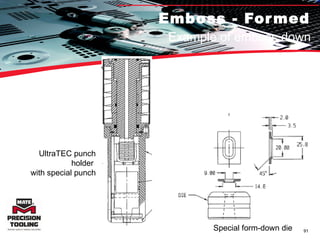

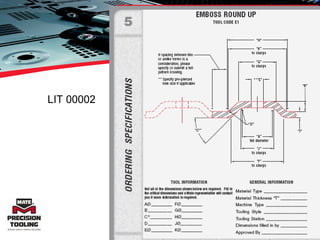

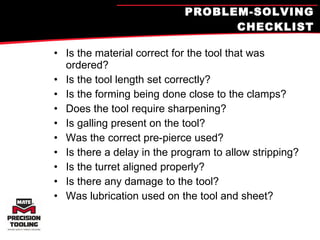

The document provides an overview of forming solutions and techniques for increasing efficiency in manufacturing operations. It discusses why forming is useful for eliminating secondary operations and reducing tool wear. Various forming methods and considerations for setup are covered, including maximum forming heights, material properties, machine capabilities, and tool recommendations. Common forming tools like clusters and extrusions are explained in detail.